Magnetic control chemical chain combustion reaction device and method

A chemical chain combustion and reaction device technology, applied in the direction of exothermic chemical reaction heat generation, using non-combustion exothermic chemical reaction to generate heat, heating devices, etc., can solve the problem of reducing gas fuel combustion efficiency and reducing non-magnetic porous oxygen Problems such as effective conversion of solid and magnetic porous oxygen carriers, uneven distribution of porous oxygen carrier particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

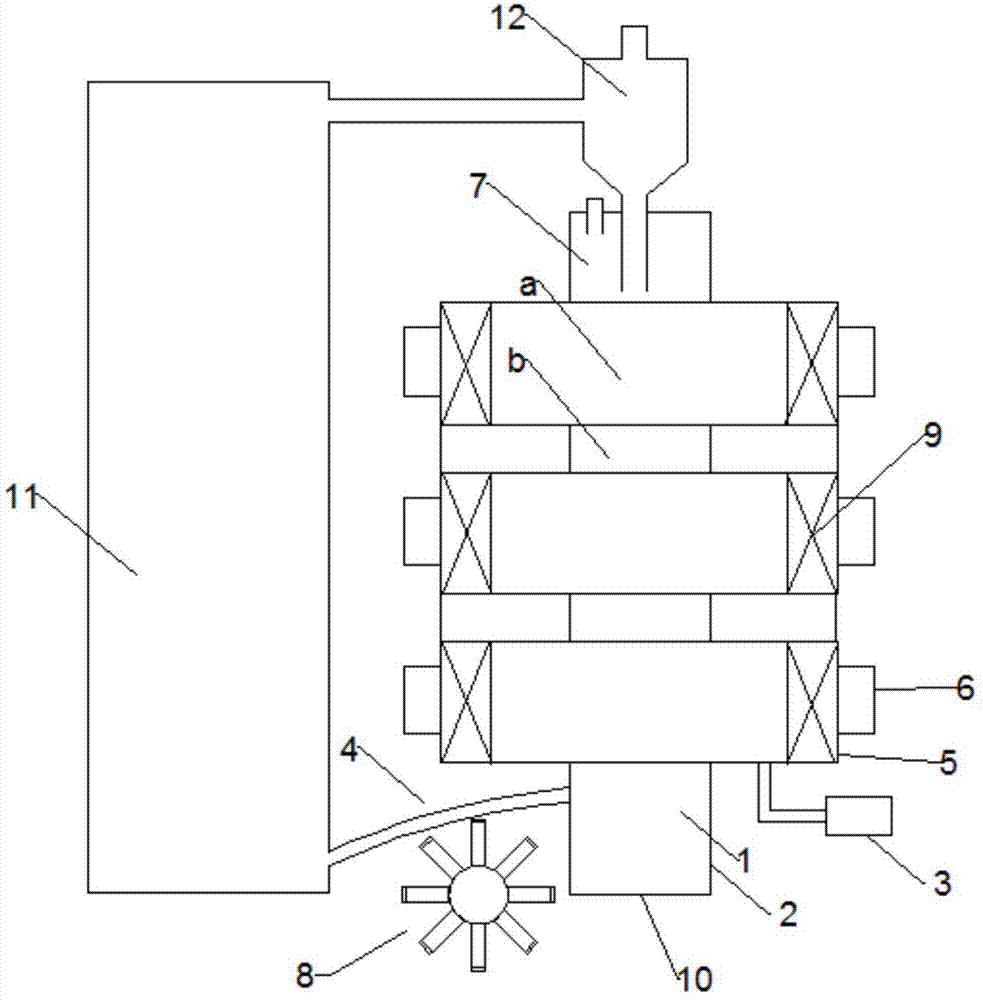

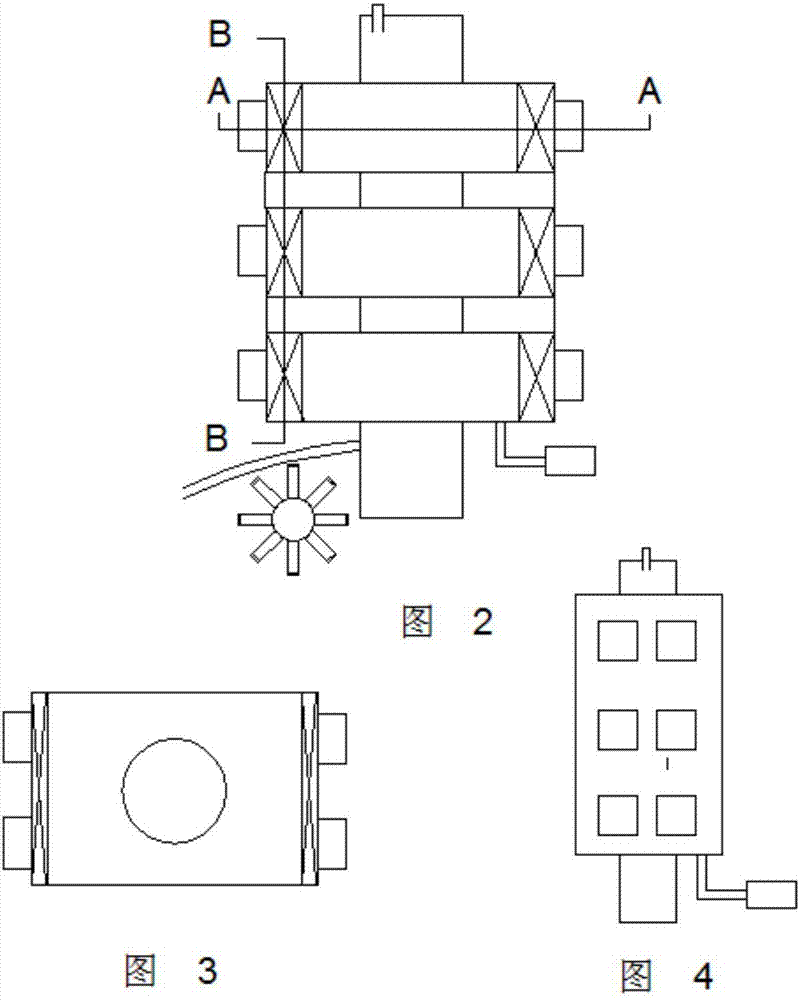

[0043] The embodiment of the present invention is illustrated by taking a pulsed magnetic field coupled rotating magnetic field with three magnetic field generators as an example to control the chemical chain reduction reaction. Its structure is as follows Figure 1~4 As shown, the device includes a fuel reaction channel 2, an air distribution plate 10 is arranged at the bottom of the fuel reaction channel 2, a discharge pipe 4 is provided on the left, and a rotating magnetic field separation device 8 is provided at the lower end of the discharge pipe 4 . Three magnetic field generating devices 5 are arranged between the front end and the end of the fuel reaction channel 2, each of the magnetic field generators 5 includes a cavity, the fuel reactor pipeline 2 passes through the middle of the cavity, and the fuel reaction channel 2 is The magnetic field generator 5 is divided into a section with a magnetic field and section b without a magnetic field. Exciting coils 9 are wound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com