Medium isolation reciprocating plunger pump and delivery system with same

A medium isolation and plunger pump technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc., can solve the problems of poor cooling effect, pollution of conveying medium, and large heat generation. , to achieve reliable operation, avoid wear, and enhance applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

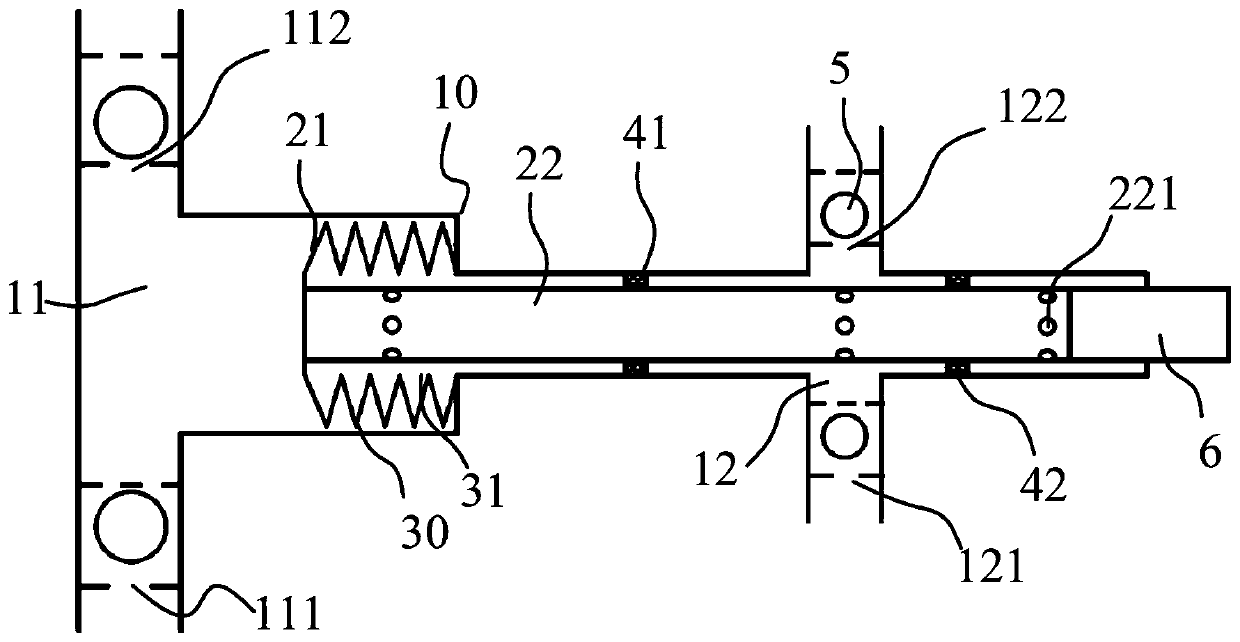

[0031] figure 1 is a schematic cross-sectional view of a medium-isolated reciprocating plunger pump according to an embodiment of the present invention. like figure 1 As shown, the embodiment of the present invention provides a medium-isolated reciprocating plunger pump, which includes a pump body 10 and a plunger assembly. The plunger assembly has a plunger 21 and a plunger rod 22 connected to the plunger 21 . The pump body 10 defines a conveying medium chamber 11 and a cooling medium chamber 12 arranged at the rear end of the conveying medium chamber 11 . The conveying medium chamber 11 has a conveying medium inlet 111 and a conveying medium outlet 112 . The coolant chamber 12 has a coolant port 121 and a coolant port 122 . The plunger 21 is arranged in the conveying medium cavity 11 , and the plunger rod 22 is installed in the cooling medium cavity 12 .

[0032] The plunger assembly also includes a deformable spacer 30 coaxially arranged with the plunger 21, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com