Filter tank

A technology of filters and filter components, which is applied in the field of water treatment, can solve problems such as the inability to solve the needs of medium and small water treatment equipment, the large area of the filter, and the large amount of water used for backwashing, so as to reduce the amount of water used for flushing and the water head. Less loss and increased flushing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

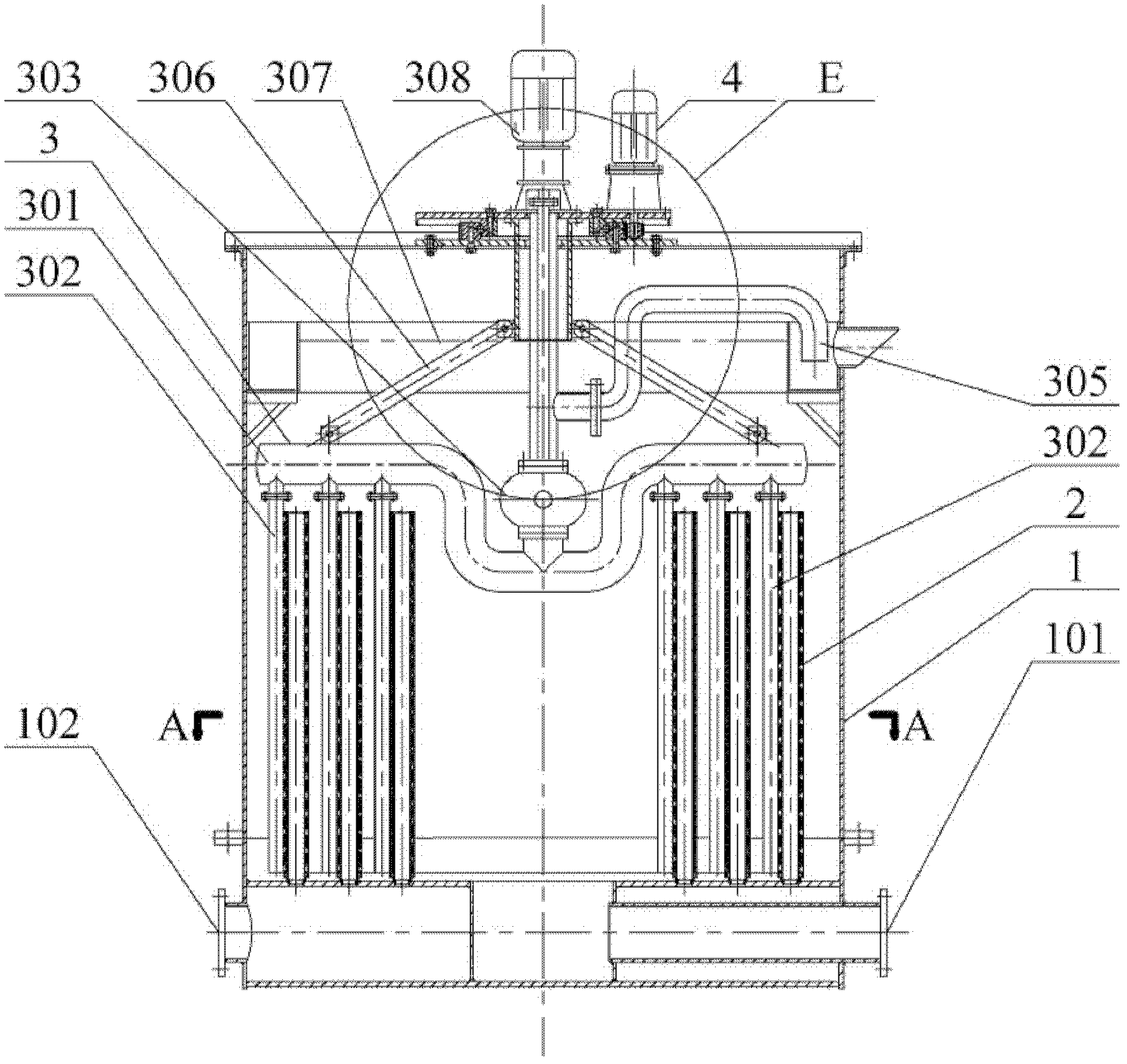

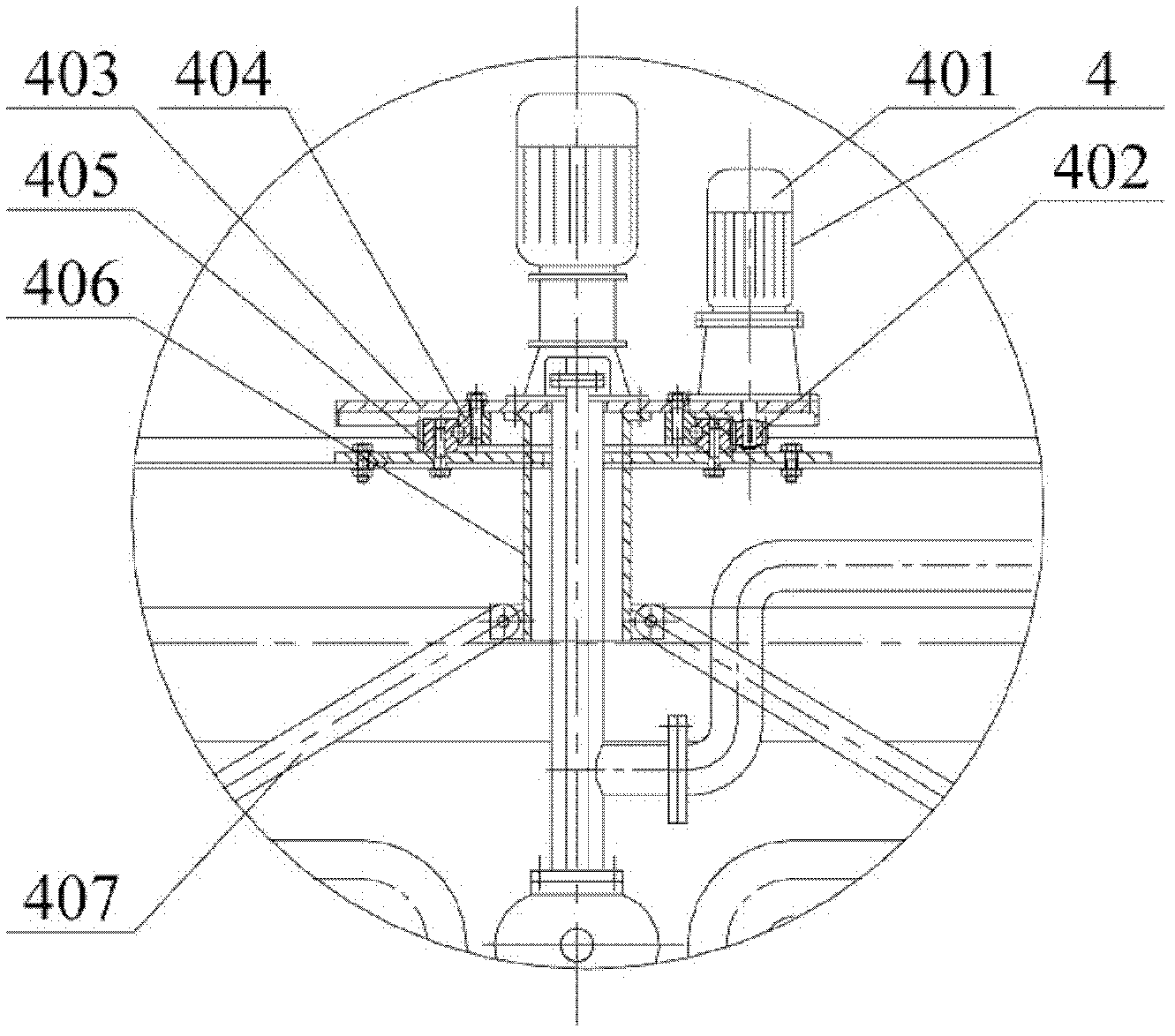

[0046] The technical content and features of the present invention will be described in detail below by referring to the illustrated embodiments in conjunction with the accompanying drawings. For the convenience of description, the "left" and "right" described below are consistent with the left and right directions in the drawings, but this should not be a limitation of the technical solution of the present invention.

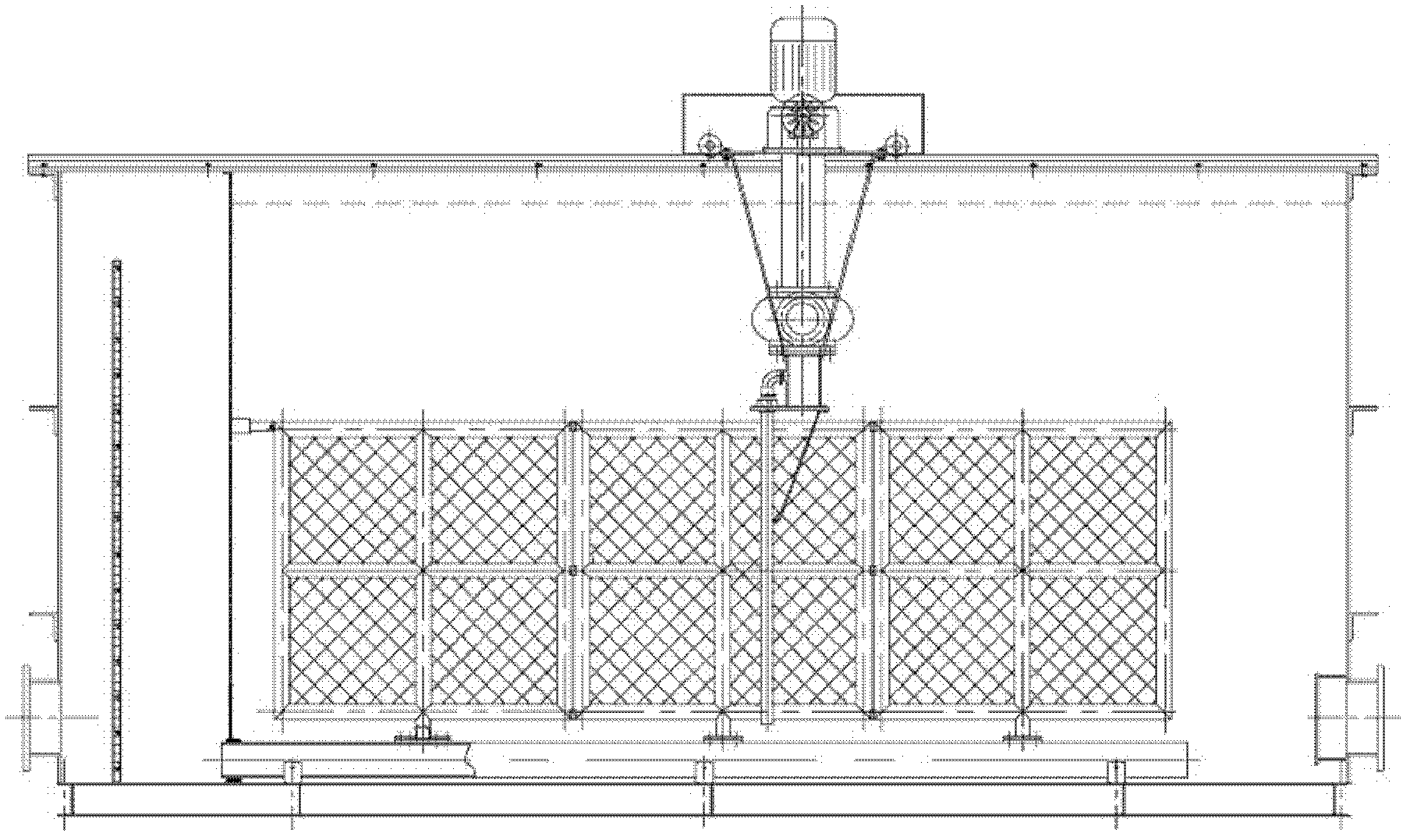

[0047] combine Figure 2 to Figure 4 Illustrate the filter tank of the present invention, which includes a steel cylindrical housing 1 with a raw water inlet pipe 101 and a purified water outlet pipe 102 at the bottom, an annular filter assembly installed in the housing 1 and communicated with the purified water outlet pipe 102 2. The backwash assembly 3 matched with the annular filter assembly 2 and the rotary mechanism 4 that drives the backwash assembly 3 to rotate. The casing 1 is made of stainless steel, which facilitates the construction and transportati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com