Welding twist drill

A technology of twist drills and twist drills, which is applied in the direction of twist drills, etc., can solve problems such as the impossibility of drill bits, and achieve the effect of low price, good use effect and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

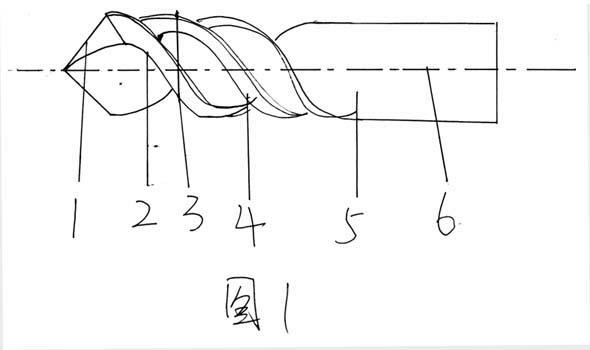

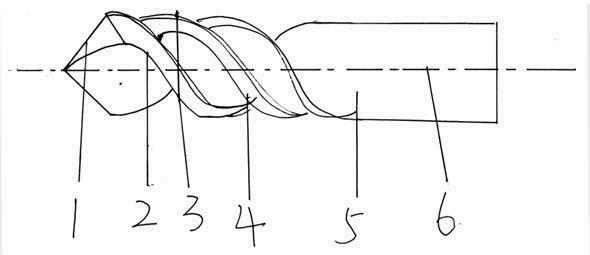

[0010] figure 1 Middle: Take a piece of high-quality high-speed steel for the cutting part (1) and the front twist part (2) of the drill head, and another piece of ordinary round steel for the shank part (5) and the back twist part (4) of the drill bit ), by welding one end of the high-speed steel and one end of the ordinary round steel as a whole, and then process the weld scar part, and make the blank of the twist drill through centerless grinding, in order to make the deep hole drilling loose, the head of the twist drill The outer diameter of the cutting part (1) and the front twist part (2) is slightly larger than that of the rear twist part (4) and the drill shank part (5), and is finally ground into a welded twist drill (6) by a drill bit grinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com