Beverage dispensing machine and operating method

a technology of a beverage dispenser and a dispensing machine, which is applied in the direction of machine control, process control, instruments, etc., can solve the problems of inability to quickly, or instantly, control the operation of the known valve, and the inability to quickly adjust the backpressure, etc., to achieve simple and effective valve maintenance and simple cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Coffee 1

[0057]An amount of 8 g of coffee powder is loaded in the brewing chamber and pressed by a moveable piston at 10 kg / cm2. The piston is blocked in its final position, i.e. above the coffee powder, by means of mechanical or electrical restraining devices. The coffee powder is provided by a grinder through a chute extending toward the brewing chamber.

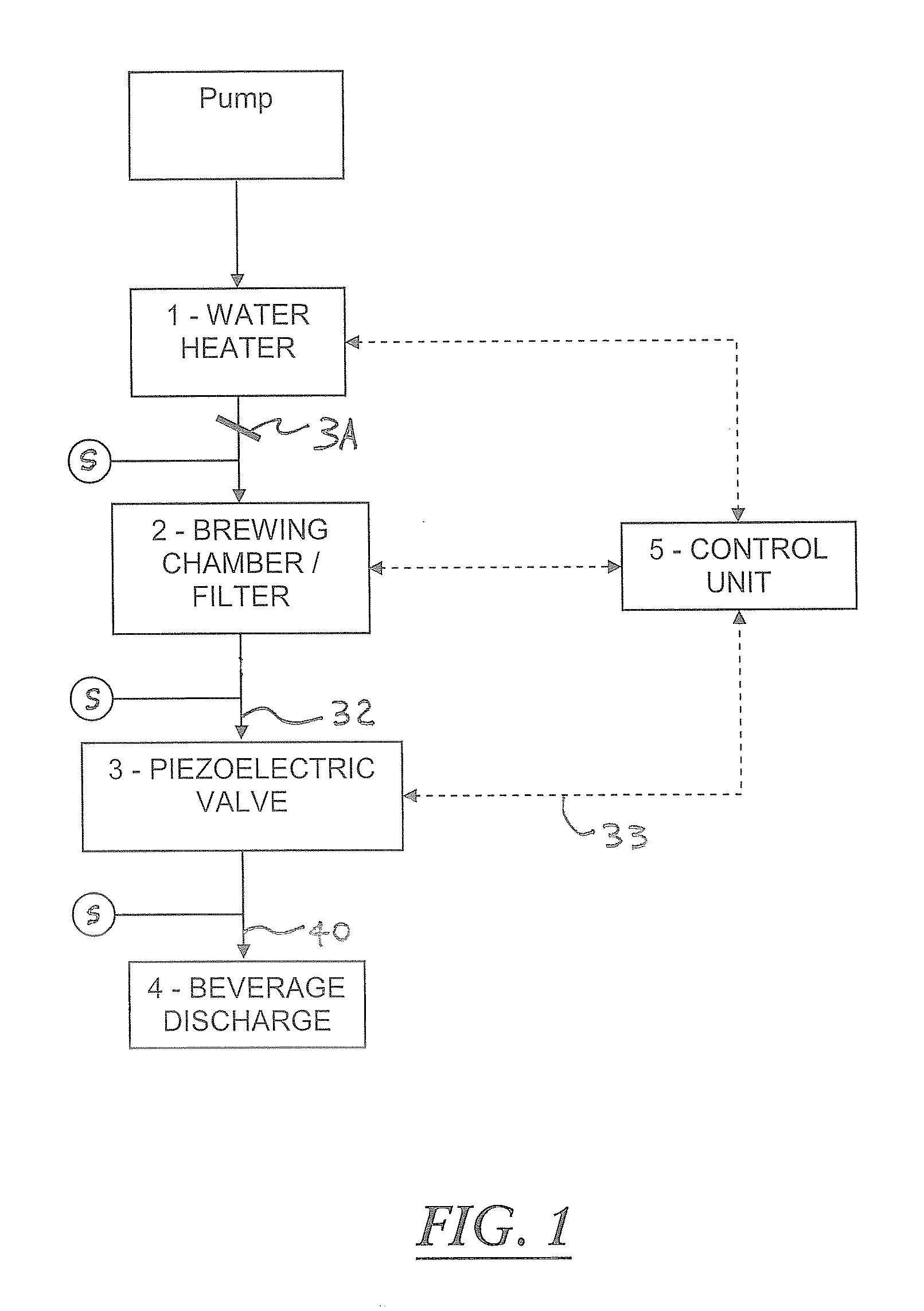

[0058]Water is heated by powering the water heater 1 until the temperature sensor measures 90° C. Circulation of the water across the water heater 1 and toward the brewing chamber 2 is provided by a pump (not shown) positioned upstream of the heater 1 (for instance a rotative pump).

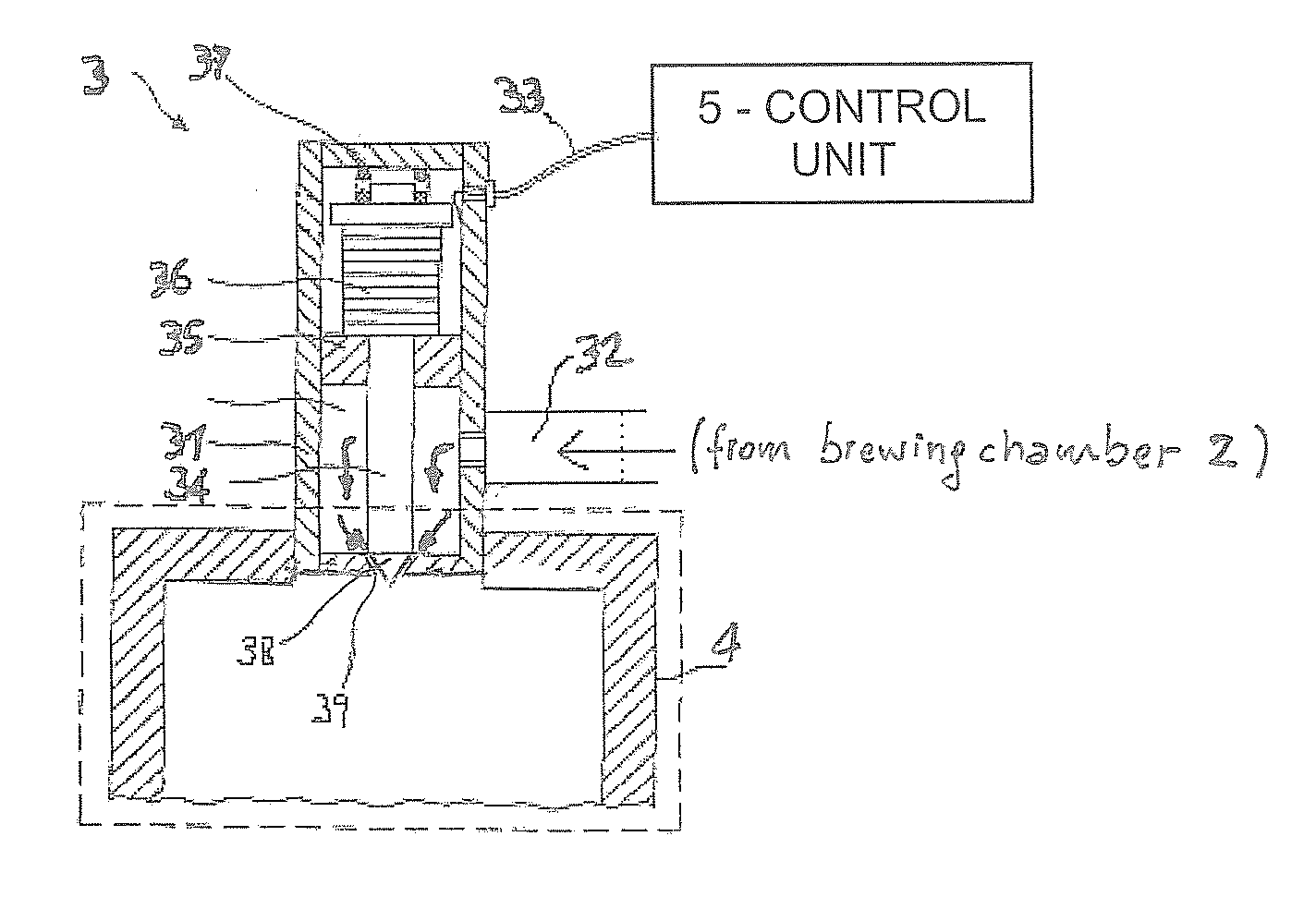

[0059]An on / off valve, positioned upstream of the brewing chamber 2 is commanded by the control unit 5 to open, thereby allowing the hot water to enter the chamber 2. At this time the piezoelectric valve 3 remains closed and the pressure within the brewing chamber increases.

[0060]After a preset time lapse, for instance 5 seconds, the control unit 5 comman...

example 2

Coffee 2

[0063]An amount of 10 g of coffee powder is loaded in the brewing chamber 2 and pressed by a moveable piston at 4 kg / cm2. The piston is then blocked above the coffee powder, within the brewing chamber.

[0064]Water is heated by powering the water heater 1 until the temperature sensor measures 80° C.

[0065]An on / off valve, positioned upstream of the brewing chamber 2 is commanded by the control unit 5 to open, thereby allowing the hot water to enter the chamber 2. At this time the piezoelectric valve 3 remains closed and the pressure within the brewing chamber increases up to 10 bar.

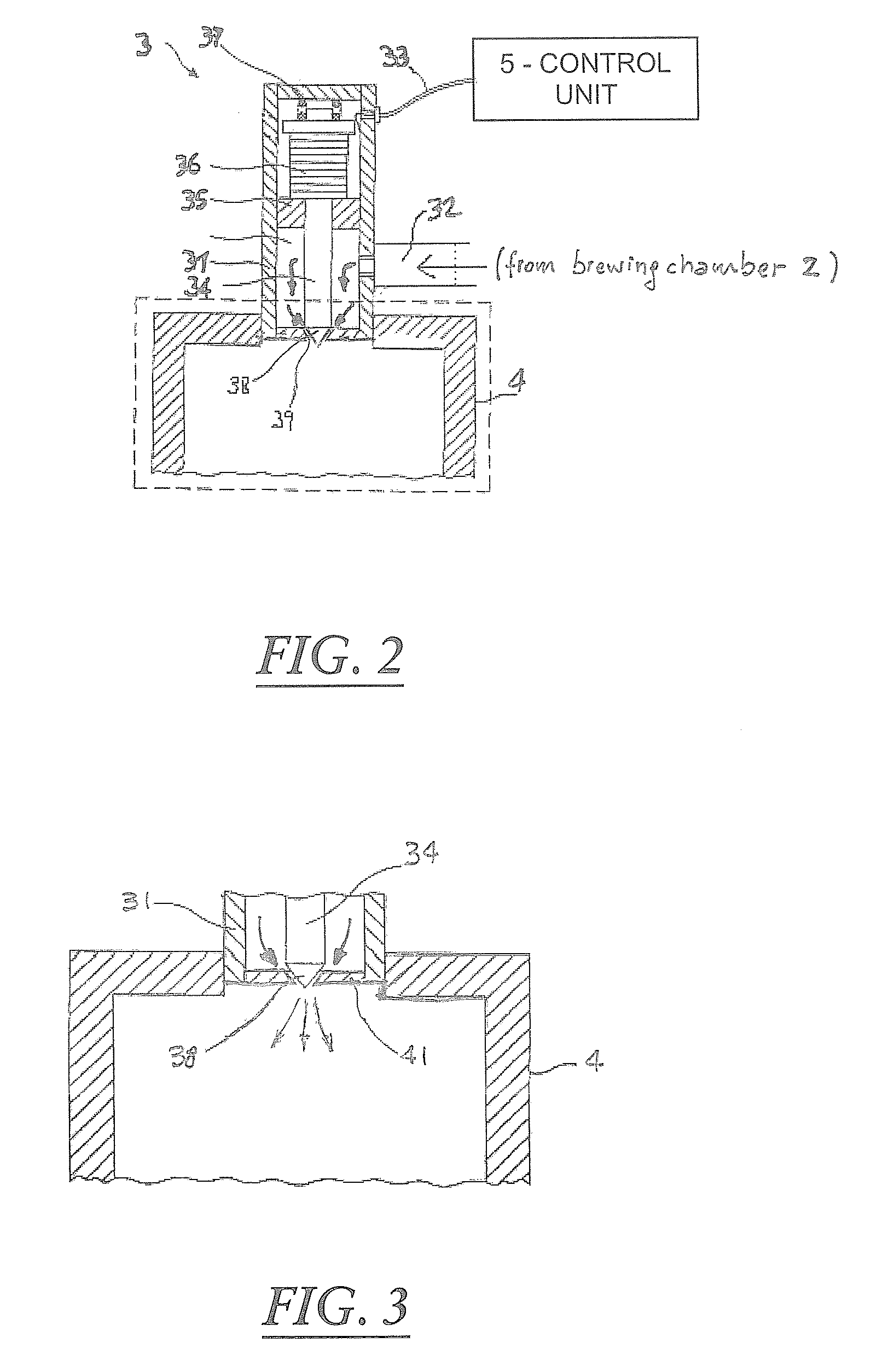

[0066]When the pressure of 10 bar within the brewing chamber is met, or after 2 seconds, the control unit 5 commands the valve 3 to open. The piezoelectric valve 3 is promptly responsive and the shutter 34 is rapidly raised a given extent above the seat 39, this causing the beverage to exit the chamber 2.

[0067]Upon completion of the delivering of the beverage to the user, the control unit 5 activates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com