Limiting structure of vehicle body welding fixture

A technology of welding fixture and limit structure, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex structure design, high manufacturing cost, and high processing precision requirements, and achieve simplified structure design and processing Manufacturing, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

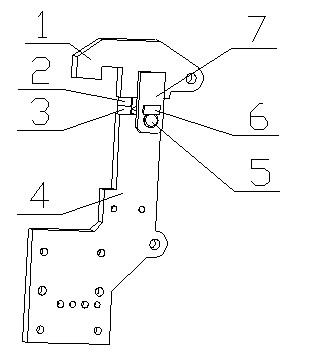

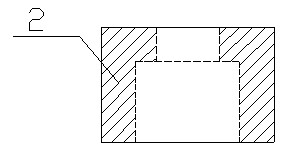

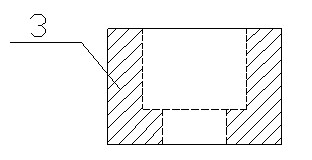

[0014] Such as figure 1 As shown, a body welding jig limit structure, including the compression arm 1, upper limit block 2, lower limit block 3, connecting plate 4, rotating shaft 5, rotating shaft anti-rotation block 6 and hinge plate 7 and other components. The connecting plate 4 is used as a bridge connecting the fixture support and the positioning and pressing unit, its lower end is connected with the fixture support through bolts, and its upper end is connected with the hinge plate 6 and the compression arm 7 through the rotating shaft 5 (the hinge plate 6 and the compression arm 7 Usually carbon dioxide shielded welding is used to connect); in order to prevent the rotation shaft 5 from being severely worn during the movement and resulting in poor connection accuracy and strength, a square rotation shaft anti-rotation block 6 is welded on the hinge plate 7 to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com