Lining-built tunnel piping sheet

A tunnel segment and lining technology, which is applied in the field of tunnels, can solve the problems of low stability of tunnel construction quality, high requirements for the accuracy of cladding positions, and poor contact flatness of block surfaces, etc., so as to reduce unstable factors and improve The effect of improving the construction ring quality and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

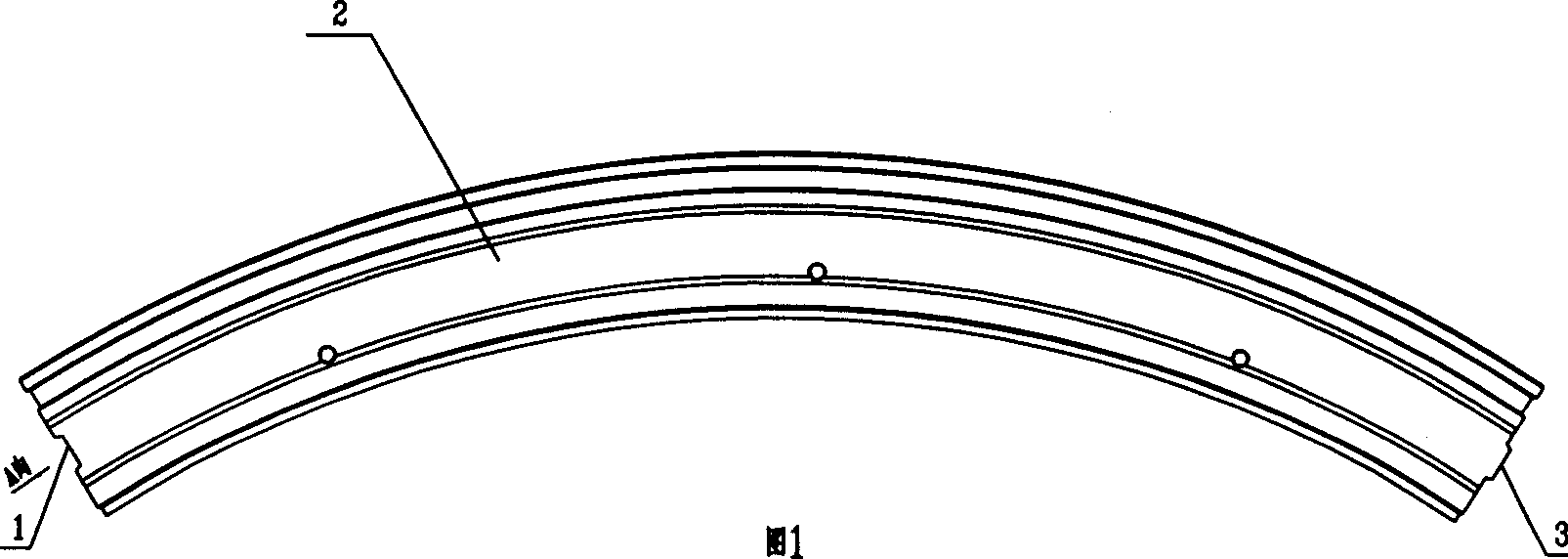

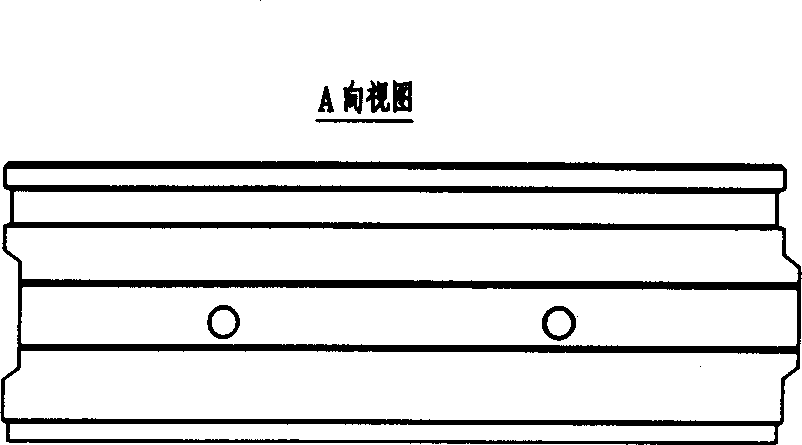

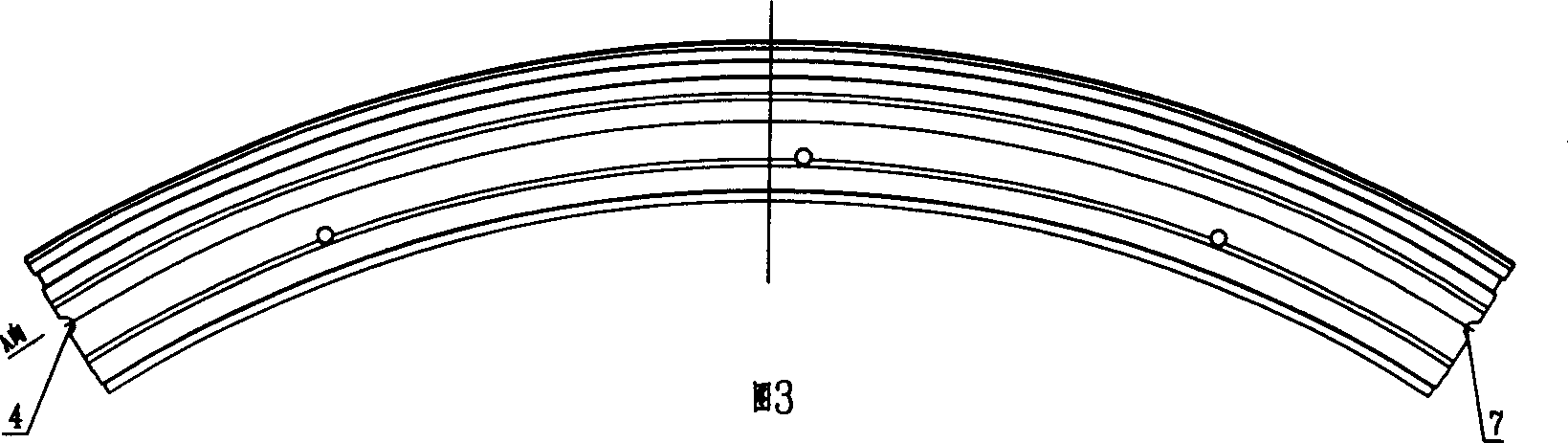

[0018] Embodiment: A lining tunnel segment involved in this embodiment includes a segment 2 and a segment 6, and a raised plane 8 of 1-5 mm is set at the middle of the segmental surface of the segment 2 and segment 6, even if the segment The concrete in the middle of the block surface of pieces 2 and 6 is slightly higher than the concrete at the surrounding corners by 1-5mm, so that when the pieces 2 and 6 are assembled, the surrounding concrete surfaces do not directly contact, which can effectively prevent the stress concentration at the corners of the pieces 2 and 6 Fragmentation occurs, replacing the practice of pasting cork cushions on the block surface in the prior art.

[0019] Strip-shaped grooves 4 and 7 are arranged on the block surfaces at both ends of the segments 2 and 6 respectively, and the end faces of the grooves 4 and 7 are in the shape of a semicircle. The grooves 4 and 7 respectively provided on the surface of each block have the same shape and size, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com