Board edge sawing machine

An edge sawing machine and plate technology, which is applied to sawing components, sawing equipment, wood processing appliances, etc., can solve the problems of large plate straightness and diagonal errors, low work efficiency, and small geometric tolerances. Improves straightness and accuracy, improves work efficiency, and increases stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

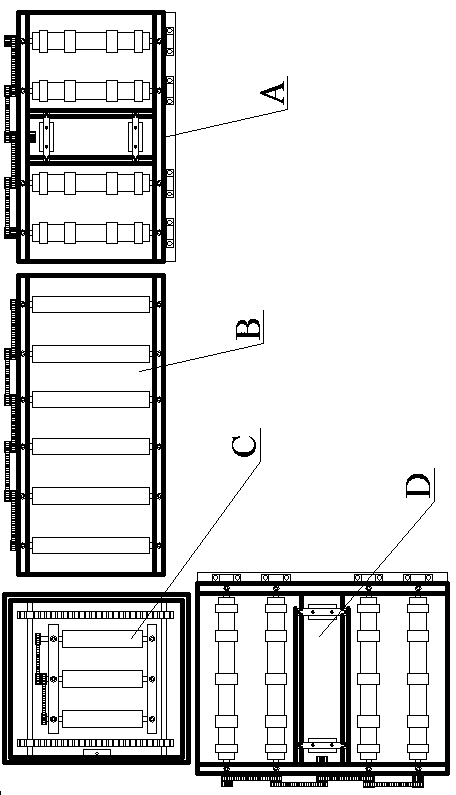

[0023] Such as figure 1 As shown, a board sawing machine is composed of a first sawing machine A, a conveyor B, a transfer machine C, and a second sawing machine D, and the structure of the second sawing machine D is the same as that of the first sawing machine A is the same, but it forms an angle of 90° with the first edge sawing machine A in the horizontal plane, the first edge sawing machine A, the conveyor B, and the transfer machine C are sequentially connected end to end, and the second edge sawing machine D and Conveyor B is respectively connected to two adjacent right-angle sides of transfer machine C.

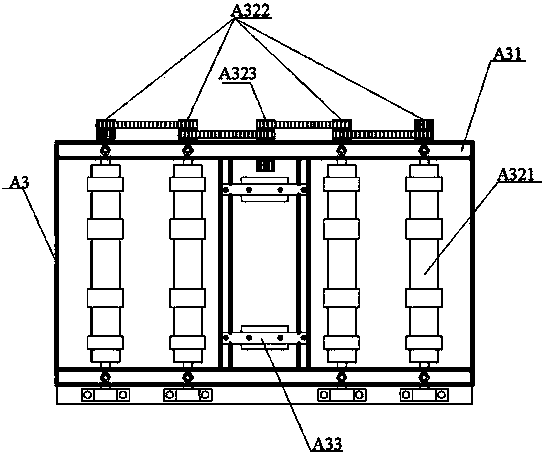

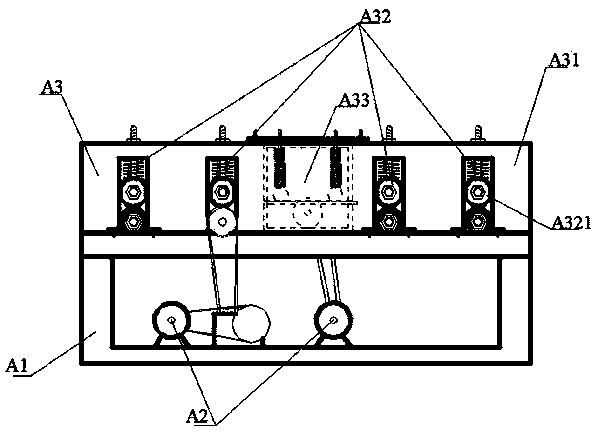

[0024] Such as Figure 2 to Figure 4 As shown, the first edge sawing machine A is composed of a frame A1, a power mechanism A2, and an edge sawing mechanism A3, wherein the edge sawing mechanism A3 is fixedly connected to the frame A1, and the power mechanism A2 is installed on the frame, and is connected with The edge sawing mechanism A3 is connected; the edge sawin...

Embodiment 2

[0030] The present invention comprises two conveyors B connected end to end. Two push plates C31 are installed on the transfer chain C3 of the transfer machine C, and the distance between the two push plates C31 on the circumference of the transfer chain C3 is half the circumference of the transfer chain C3. Other structures are the same as in Embodiment 1.

Embodiment 3

[0032] The present invention comprises two conveyors B connected end to end. The transfer chain C3 of the transfer machine C is equipped with three push plates C31, and the distance between the two push plates C31 on the circumference of the transfer chain C3 is one third of the circumference of the transfer chain C3. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com