Ground-effect train

A train and ground effect technology, applied in the field of ground effect trains, can solve the problems of increasing the floor space, restricting the development and application of technology, increasing the width of the body, and achieving the effect of small floor space, compact structure and reduced body width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

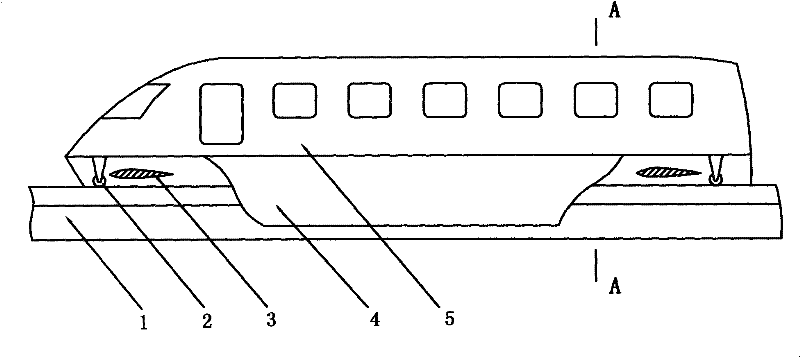

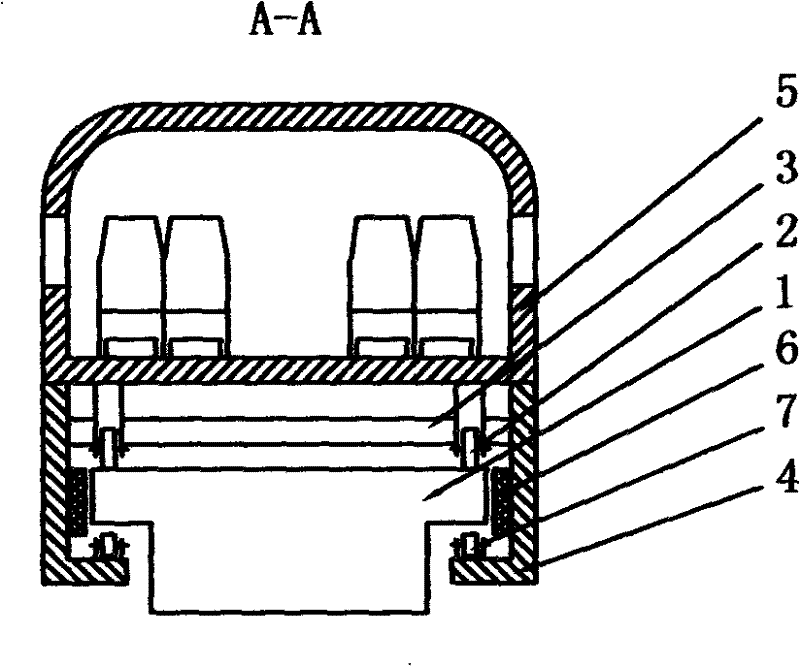

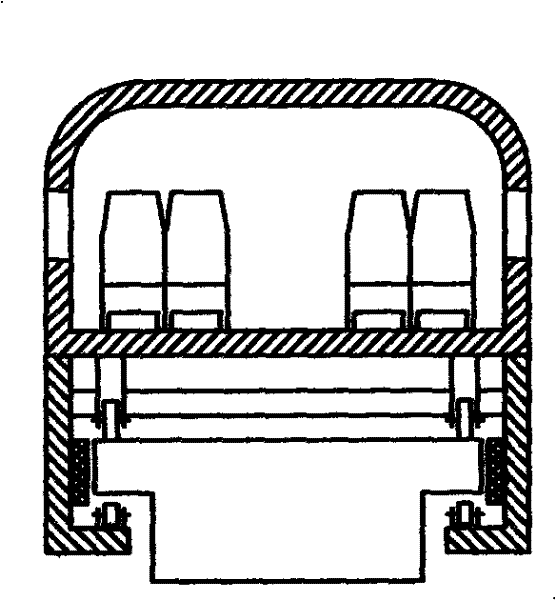

[0014] exist figure 1 , figure 2 In the shown structural diagram of the present invention, the baffle plate 4 is installed on both sides of the vehicle body 5, the lifting wing 3 is installed on the lower part of the vehicle body 5, and is connected with the baffle plate 4, and the propeller 6 and the spacer wheel 7 are installed on the baffle plate 4 respectively. .

[0015] When the ground-effect train runs under the impetus of the propeller 6, the vehicle body 5 slides on the track 1 through the wheels 2 at first. 1 contact, thereby reducing frictional resistance during operation. After the vehicle body 5 rises to a certain degree, the spacer wheel 7 contacts with the track 1 to prevent the train from breaking away from the track 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com