Anti-counterfeiting packing can for wine bottle

A technology for packaging cans and wine bottles, which is applied in the field of new metal wine bottle anti-counterfeiting packaging cans, which can solve the problems of destroying the can body and raising the production threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

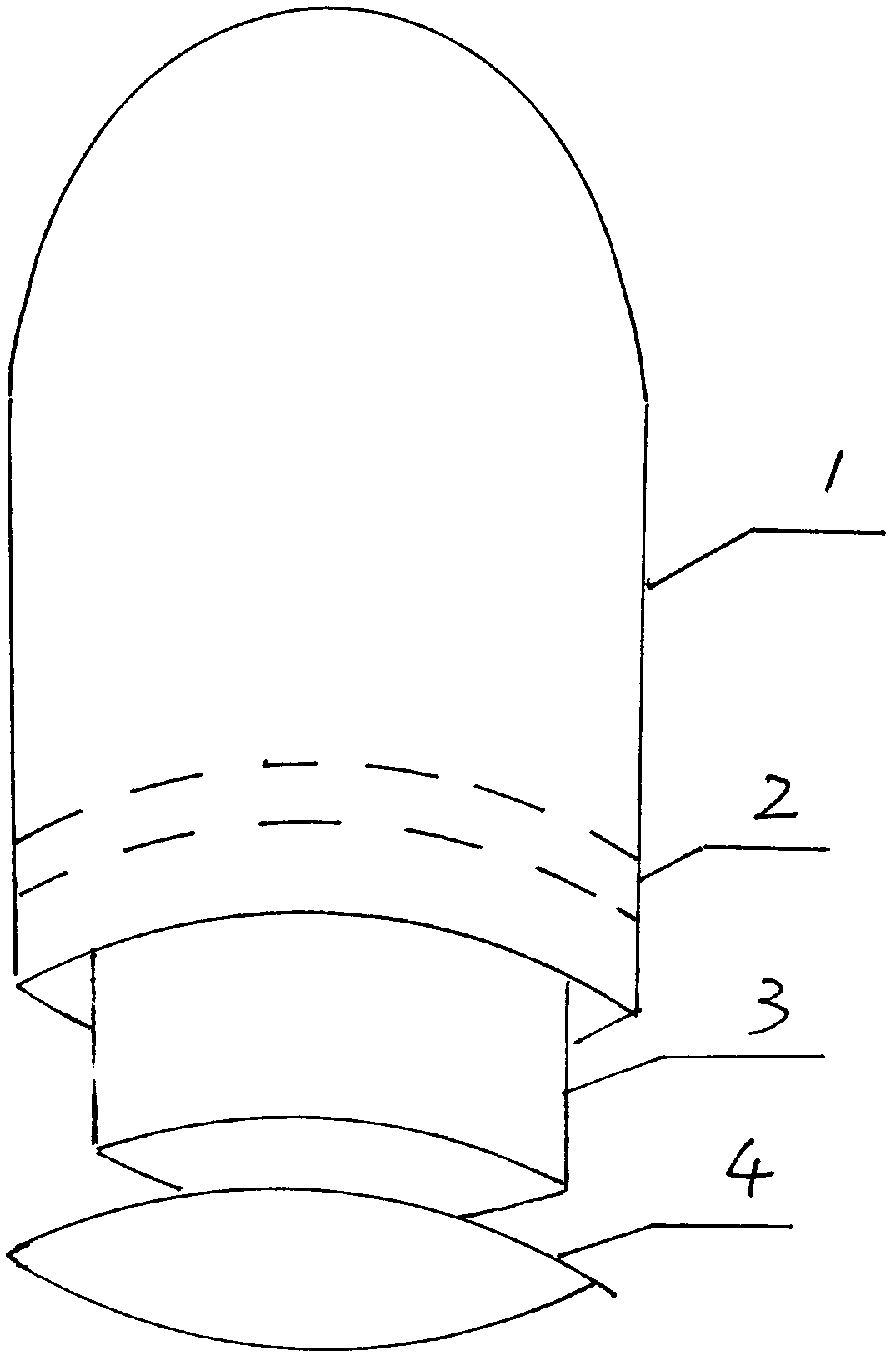

[0007] Implementation Option 1; if figure 1 As shown; the wine bottle anti-counterfeit packaging can is composed of the can body (1) and the bottom cover (4). The can body including the top and the waist is integrally formed by multiple stretching and pressure processing techniques, and the can body is provided with a tear strip (2). , the wine bottle (3) is loaded from the bottom and then pressed against the body and the bottom cover. When in use, the tear strip is opened, the tank body is disconnected, and the wine bottle can be taken out.

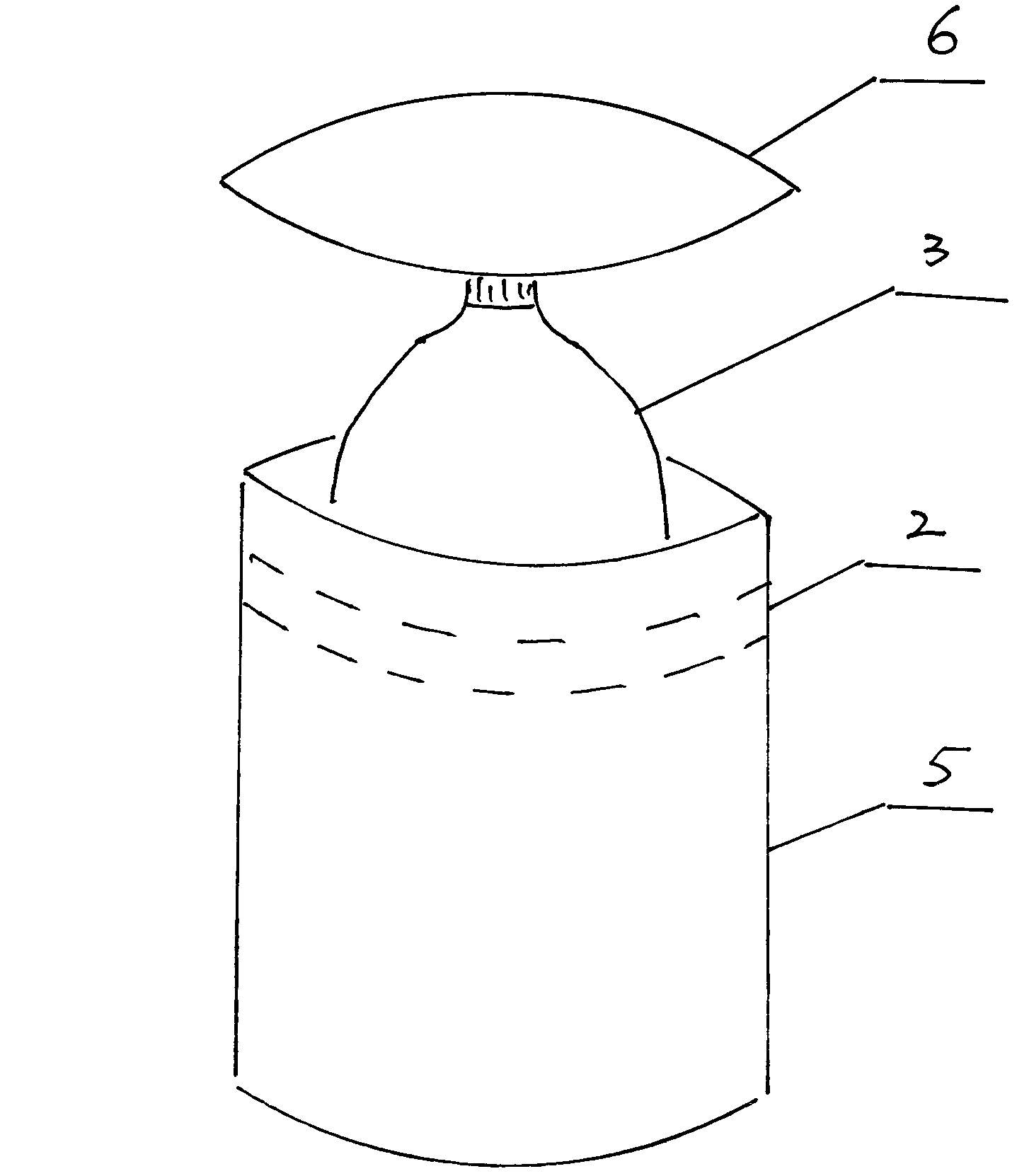

[0008] Implementation Option 2; if figure 2 As shown; the wine bottle anti-counterfeit packaging can is composed of a can body (5) and a top cover (6). , the wine bottle (3) is loaded from the top and then pressed against the tank body and the top cover. When in use, the tear strip is opened, the tank body is disconnected, and the wine bottle can be taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com