Elevator shaft wall assembled by combined shaft frames

An elevator shaft and combined technology, applied in the field of elevators, achieves the effects of reducing production costs, shortening the construction period, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

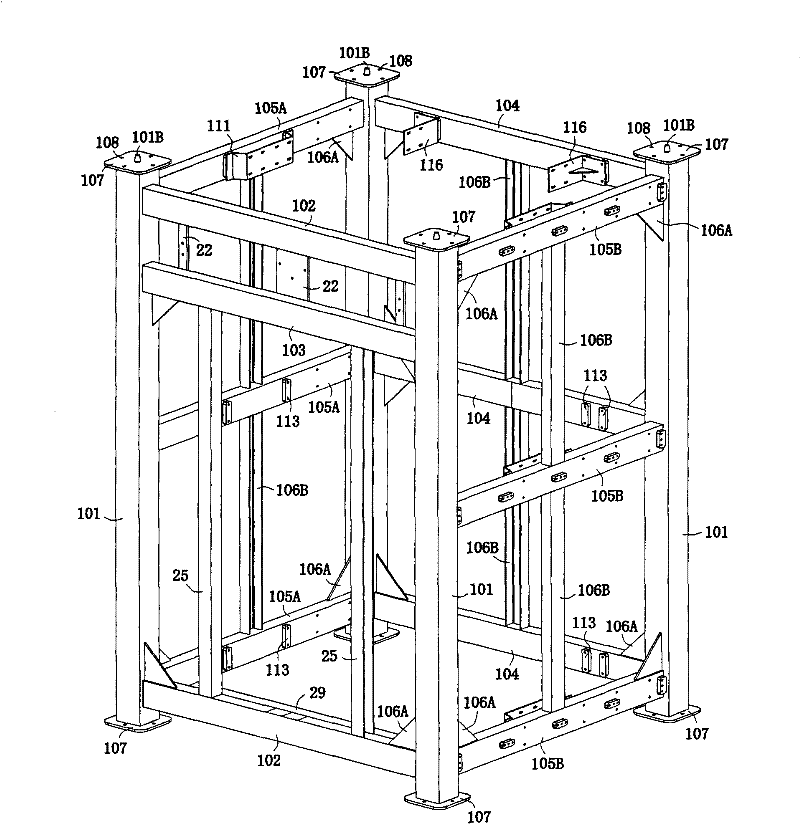

[0055] Embodiment one: if figure 1 , Figure 21 As shown, an elevator shaft wall assembled by a combined derrick includes a steel structure well tower and a pit body 13. The steel structure well tower is composed of more than two derricks 1 according to the number of elevator installation floors. The bottom of the steel structure well tower is horizontally fixed on the anchor bolts 134 on the upper surface of the pit body 13 through high-strength bolts 108A.

[0056] Such as figure 1 As shown, each of the derrick 1 includes four uprights 101, the uprights 101 are distributed at the four corners of the derrick 1, the top and bottom of the uprights 101 are horizontally fixed with a connection seat 107, and the connection seat 107 is provided with 4 connecting holes 108, each of the derricks 1 is connected with high-strength bolts 108A through the connecting holes 108.

[0057] Each said derrick 1 comprises 3 rear beams 104, 3 left side beams 105A and 3 right side beams 105B. ...

Embodiment 2

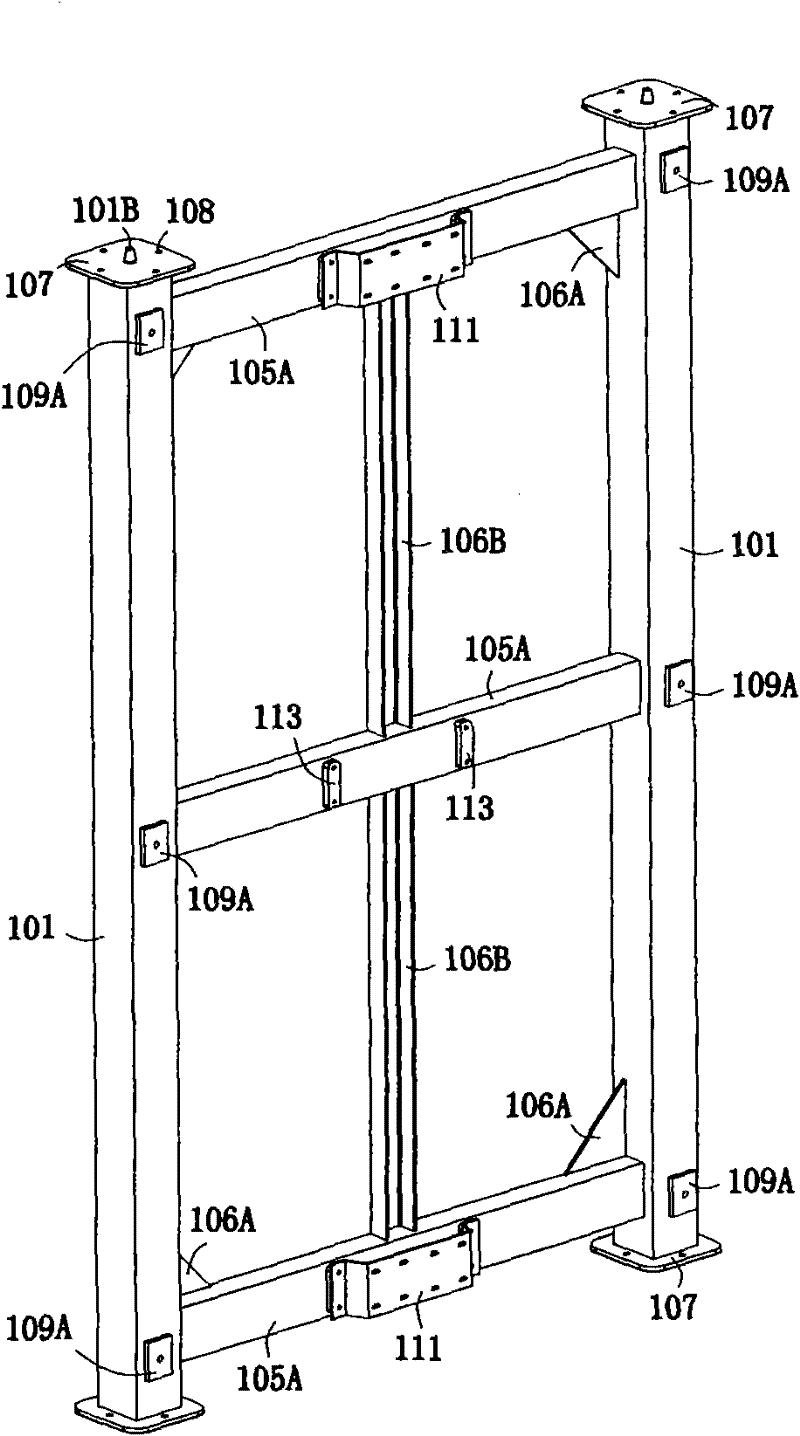

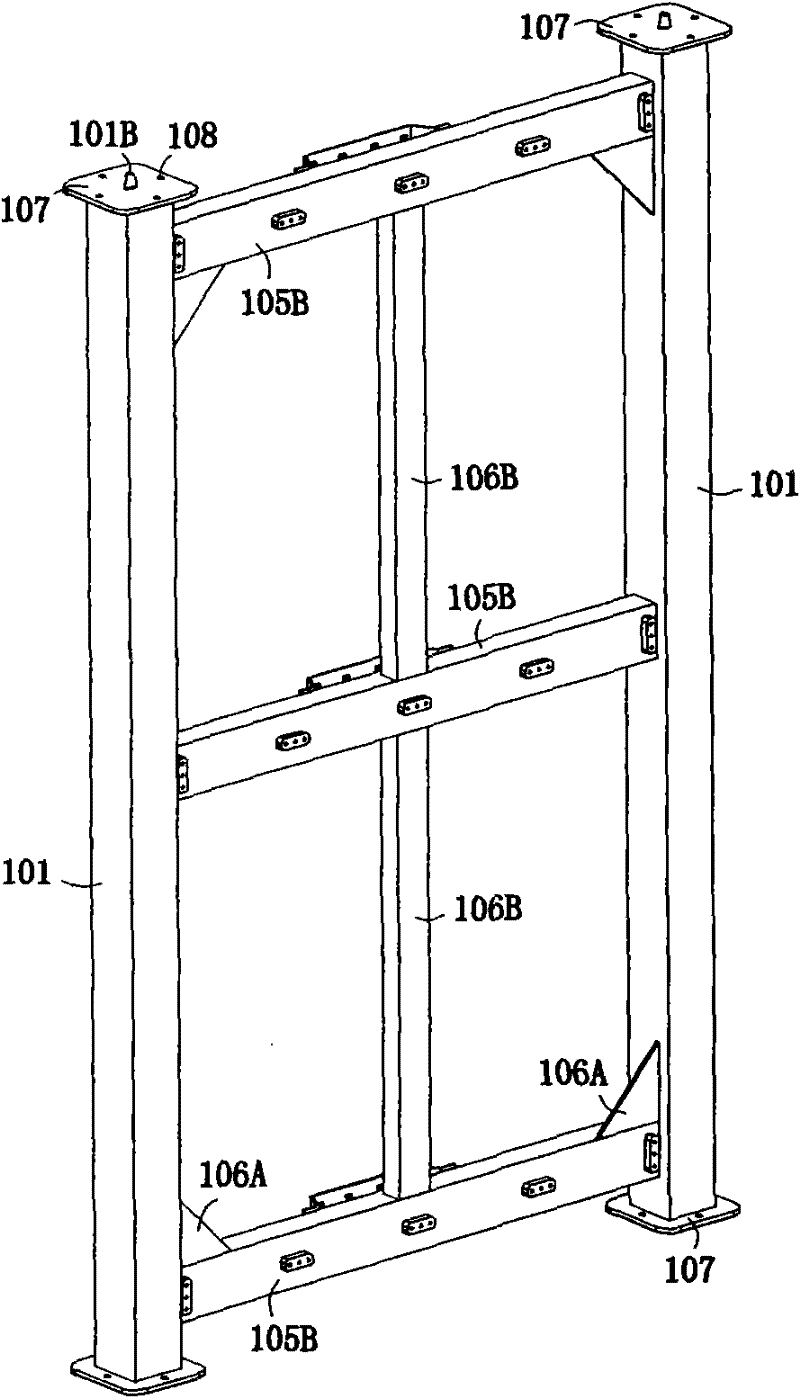

[0079] Embodiment 2: This embodiment is basically the same as the previous example, the difference is that the described derrick adopts the sub-frame processing method. The sub-frame processing method is to decompose the combined derrick 1 into a left frame, a right frame, a front frame and a rear frame, then process them separately, and then assemble it into an integral derrick on the spot.

[0080] figure 2 Left frame right view shown. Described left frame comprises 2 columns 101 on the left side and 3 left side beams 105A, and the two ends of described left side beam 105A are connected laterally with described 2 columns 101 respectively; For increasing intensity, described left A reinforcement plate 106A is provided between the side beam 105A and the column 101, and a reinforcement frame 106B is provided between the left beam 105A; the left frame also includes a car guide rail 110 and three car guide rail frames 111. The car guide rail frame 111 is arranged on the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com