Cellulose acylate film, polarizing plate, and liquid crystal display device

A technology of cellulose acylate and acylate film, which can be used in polarizing elements, instruments, optical elements, etc., can solve the problems of not being able to achieve damp-heat durability and humidity dependence improvement at the same time, achieve low humidity dependence, and inhibit exudation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0226] [Preparation of Cellulose Acylate Film]

[0227] (film formation process)

[0228] The method for producing the cellulose acylate film in the present invention can widely employ any known method for producing a cellulose acylate film, and the film is preferably produced by a solvent casting method. In the solvent casting method, a film can be produced by casting a solution (dope) of cellulose acylate dissolved in an organic solvent.

[0229] The organic solvent preferably includes solvents selected from the group consisting of ethers with 3-12 carbon atoms, ketones with 3-12 carbon atoms, esters with 3-12 carbon atoms and 1-6 carbon atoms. Halogenated hydrocarbons. The ethers, ketones and esters may have a cyclic structure. Compounds having two or more of ether, ketone and ester (ie -O-, -CO- and COO-) functional groups can also be used as the organic solvent. The organic solvent may have other functional groups such as alcoholic hydroxyl groups. In the case of the...

Embodiment 1-18、 comparative example 1-22

[0342] [Formation of cellulose acylate film]

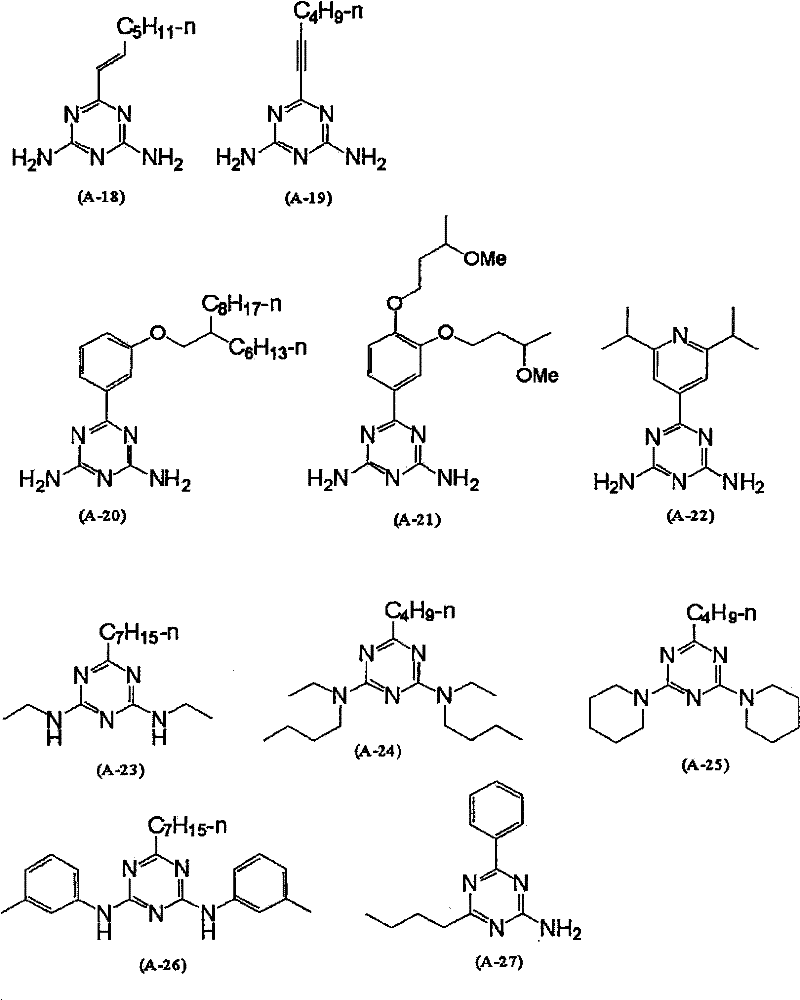

[0343] Cellulose acetate (A) and cellulose acylate (B) were prepared using the raw materials (pulp or cotton linters) described in Table 1. Cellulose acetate (A), cellulose acylate (B), plasticizer 1 and plasticizer 2 were added to the mixing tank in the amounts shown in Table 1, and then a solvent (containing 86.5 parts by mass of A mixed solvent of dichloromethane and 13.5 parts by mass of methanol), the mixture was stirred to dissolve the components, and then filtered through a filter paper with an average pore diameter of 34 μm and a sintered metal filter with an average pore diameter of 10 μm to prepare a cellulose acylate concentrate liquid. Films were formed by solution casting and then used in Examples 1-18 and Comparative Examples 1-22.

[0344]At the same time, the concentration of cellulose acylate in the dope was controlled to 22% by mass. The dope was filtered through filter paper (manufactured by Toyo Roshi Kaisha...

Embodiment 19-28

[0388] Films were produced in the same manner as in Example 15 except that [Plasticizer 1] was changed from P-1 to P-2 to P-11, respectively, and evaluated. As in Example 15, all the haze and damp heat durability results were A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap