Anti-electrostatic shell fabric in calvary twill weave

A technology of anti-static fabrics and weaves, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of loose texture, affecting anti-static function, and low overall tightness of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

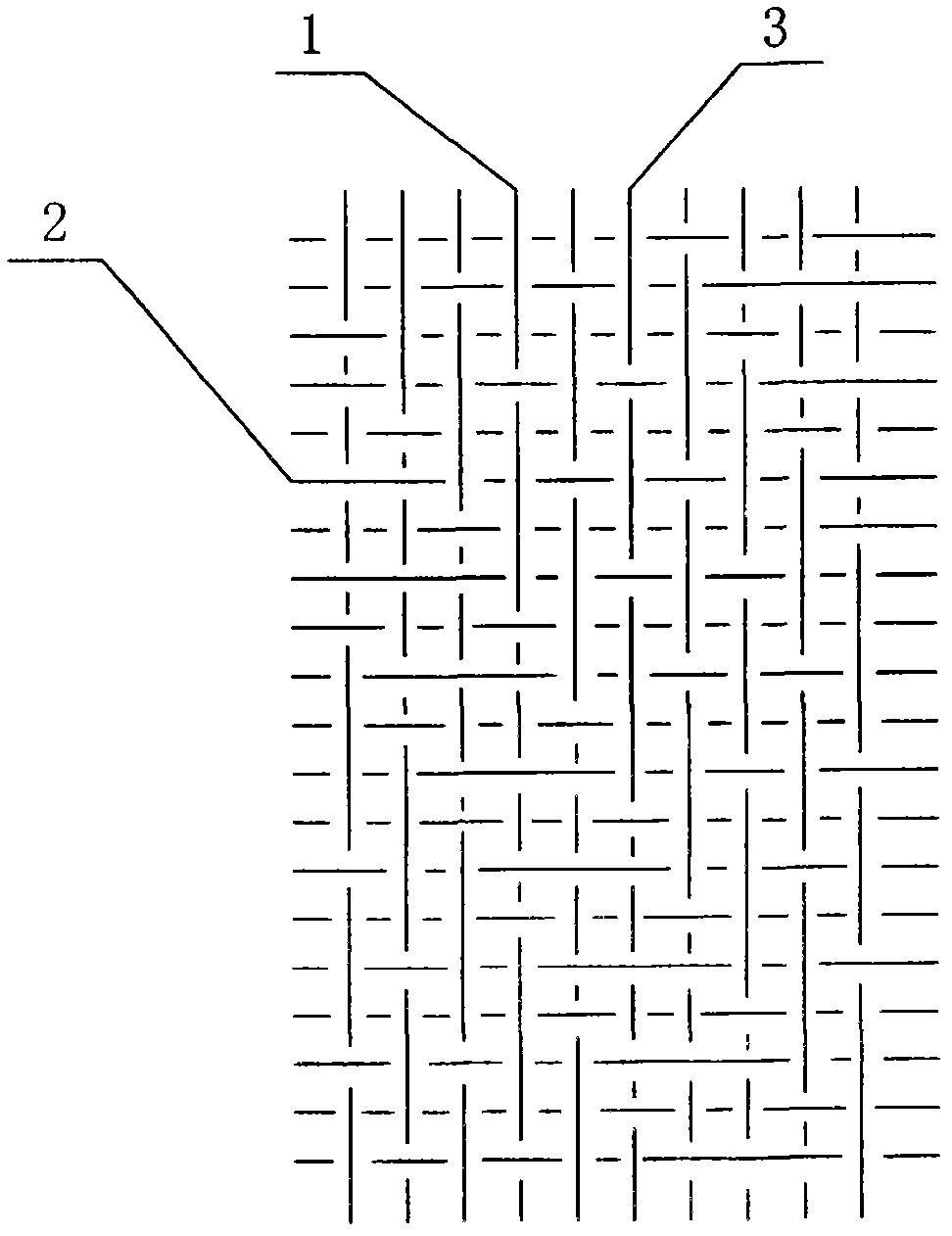

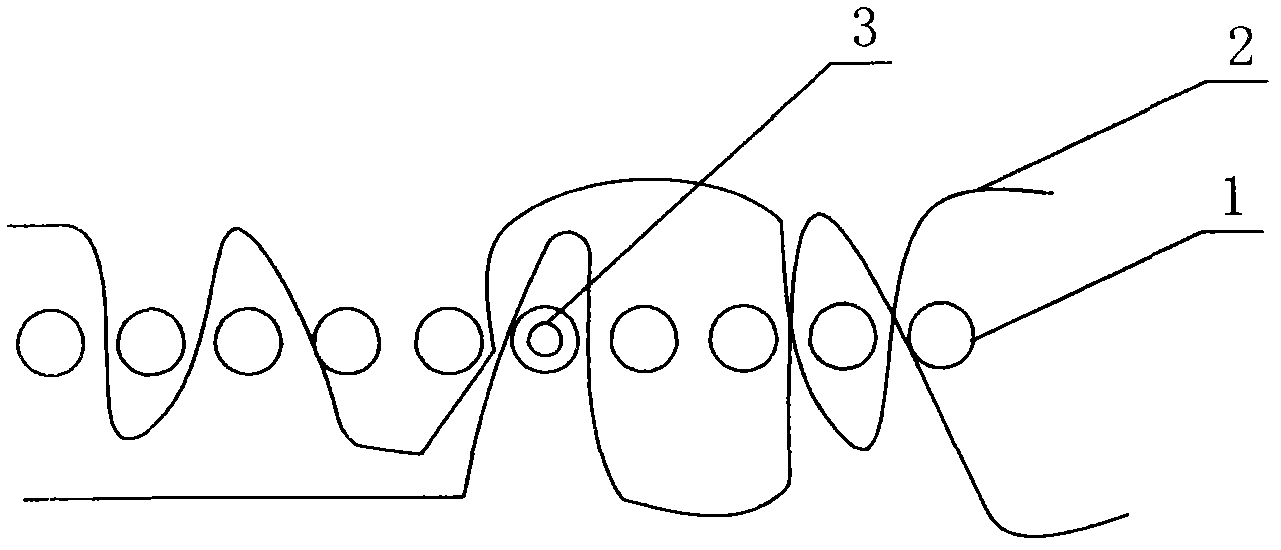

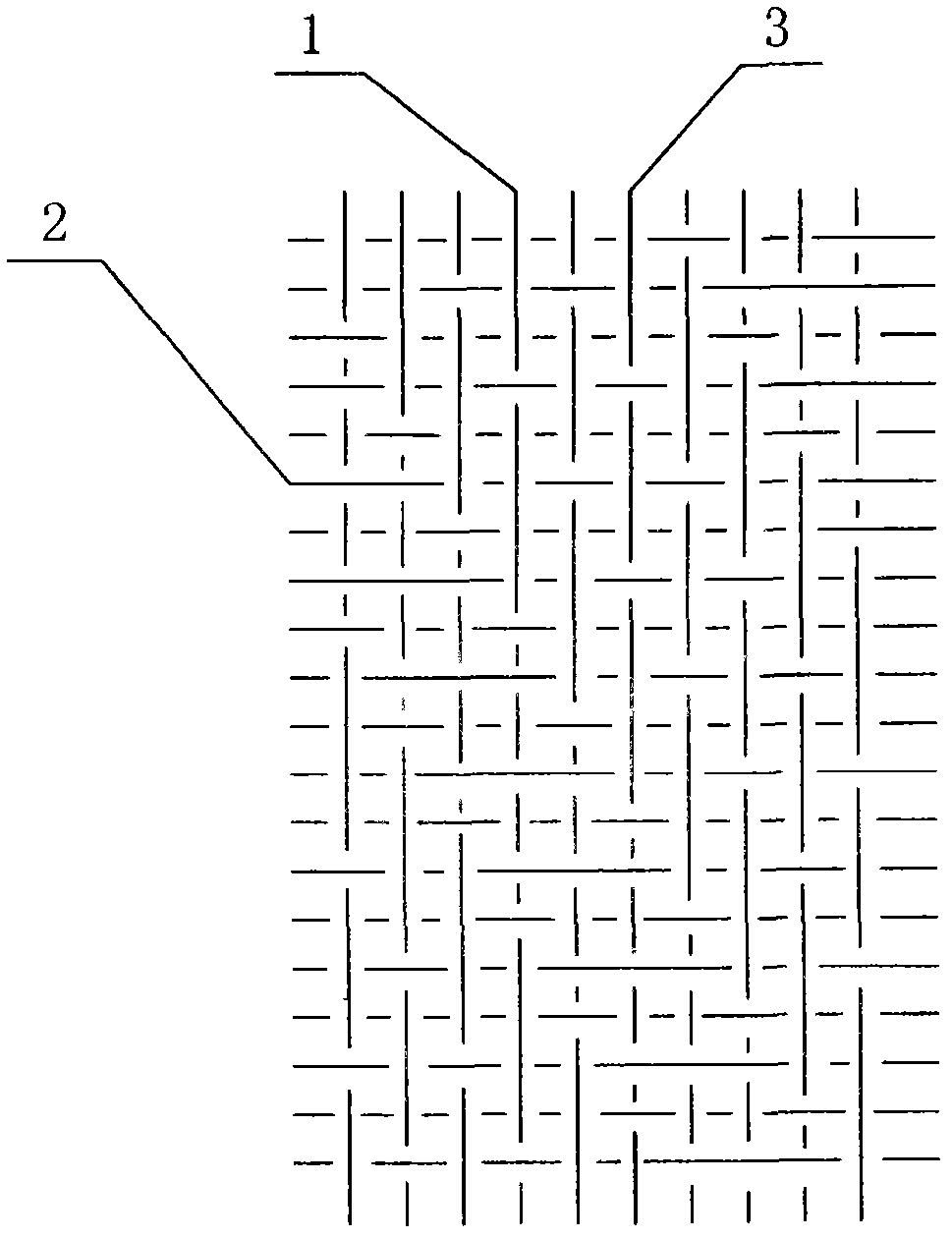

[0009] Combine figure 1 , figure 2 It can be seen that the antistatic fabric of the cavalry oblique weave of the present invention includes warp yarn 1, weft yarn 2, and antistatic yarn 3. The specification of the fabric is: [T / JCF 45+(T / C45+E20D))*16240*9863″Anti-static cavalry oblique. Specifically, warp 1 uses T / JCF 45 warp, weft 2 uses 16-inch weft yarn, antistatic yarn 3 is wrapped by 20D conductive yarn and 45 polyester cotton yarn to increase the antistatic effect of the fabric. The density of warp yarn 1 is 240 yarns / inch, and the density of weft yarn 2 is 98 yarns / inch The width of the door is 63 inches. The warp yarn 1 and the weft yarn 2 are interwoven to form a fabric matrix. The fabric matrix adopts a composite twill weave structure with four up and down, three up and down, four up and two down, one up and down, one up and two down. The total tightness of the fabric matrix is 103.77%, of which the warp tightness is 126.2%, and the weft tightness is 85.6%. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com