No-clean hypa for vacuum cleaner

A no-cleaning, vacuum cleaner technology, applied in chemical instruments and methods, filtration separation, layered products, etc., can solve problems affecting motor life, secondary pollution of indoor environment, fine dust drilling, etc., to improve airflow stability. , Improve the anti-dust ability, improve the effect of filtering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

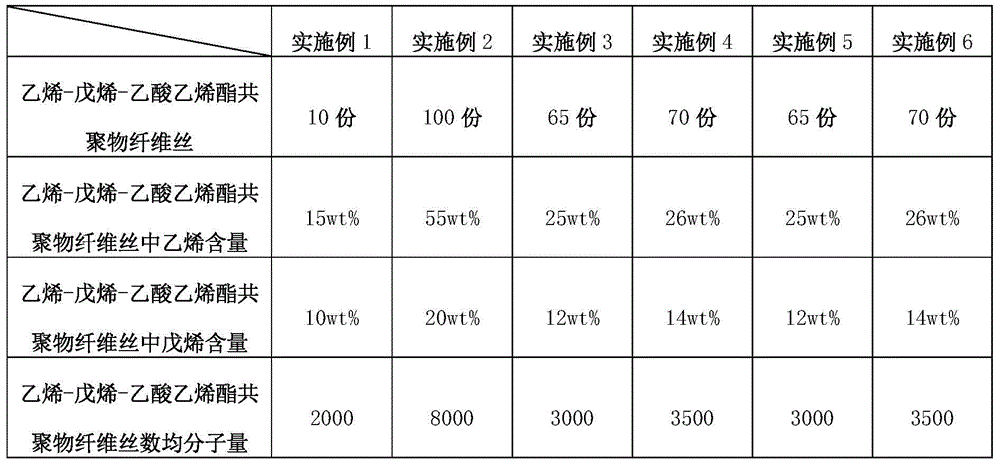

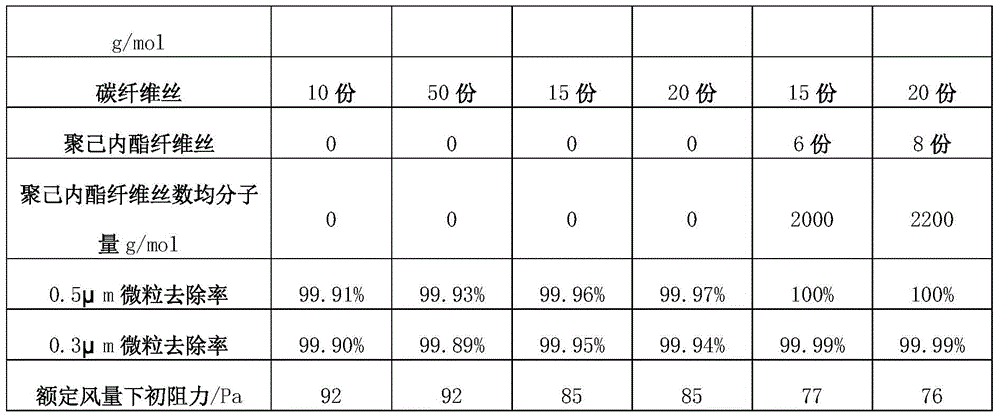

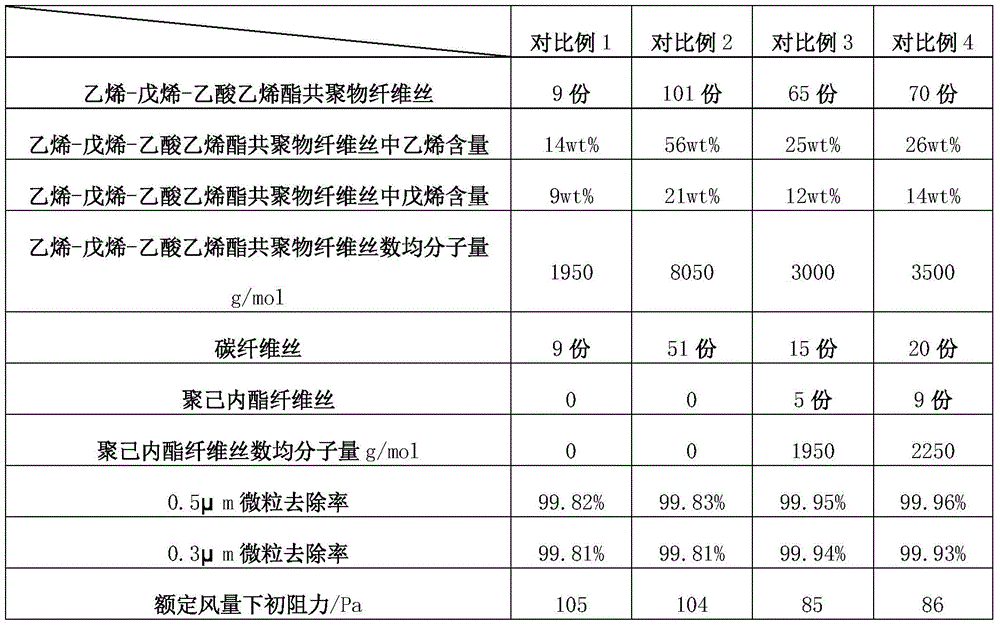

[0019] This case proposes an embodiment of a no-clean hypa for vacuum cleaners, comprising two layers of glass fiber layers and a modified fiber layer located between the two layers of glass fiber layers, wherein the modified fiber layer includes the following materials in parts by weight:

[0020] 10-100 parts by weight of ethylene-pentene-vinyl acetate copolymer filaments;

[0021] 10-50 parts by weight of carbon fiber filaments.

[0022] The study found that when a modified fiber layer is inserted in the traditional glass fiber layer, the characteristics of the modified fiber layer can be used to optimize and upgrade Hypa. Ethylene-pentene-vinyl acetate copolymer is a random copolymer. Its synthesis method is the same as that of polyvinyl acetate. It only needs to mix the three mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com