Technology for blocking mine water bursting through backflow grouting

A technology of mine water inrush and grouting, which is used in sealing/isolation, wellbore/well components, earth-moving drilling, etc., and can solve problems such as incomplete water inrush in sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

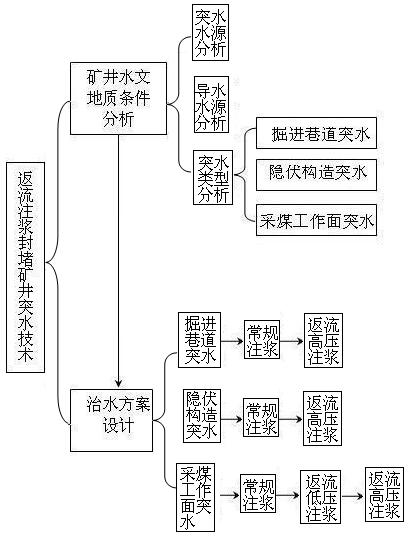

[0032] Refer to attached figure 1 , backflow grouting plugging mine water inrush technology, specifically includes the following steps:

[0033] 1. Analysis of mine hydrogeological conditions

[0034]Because the backflow grouting water plugging technology has its specific application conditions, it is necessary to analyze the hydrogeological conditions of the mine before deciding to use the grouting technology. It mainly includes the causes of water damage, the amount of water inrush, the source of water inrush, the nature and distribution range of mine water filling and replenishment channels, and hydrostatic pressure. Only by clarifying these problems can we formulate a feasible grouting water blocking technology and engineering plan.

[0035] mainly includes:

[0036] (1) Analysis of water inrush source;

[0037] (2) Analysis of water guide channels;

[0038] (3) Analysis of water inrush types.

[0039] The types of water inrush include water inrush in excavation road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com