Structure of damping disc for automobile clutch driven disc assembly

A clutch and assembly technology, applied in the field of automobile clutch driven plate assembly, can solve the problems of losing the limiting effect of the damping spring, poor fluidity, easy to produce tearing, etc., to strengthen the limit and improve the fluidity , avoid dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

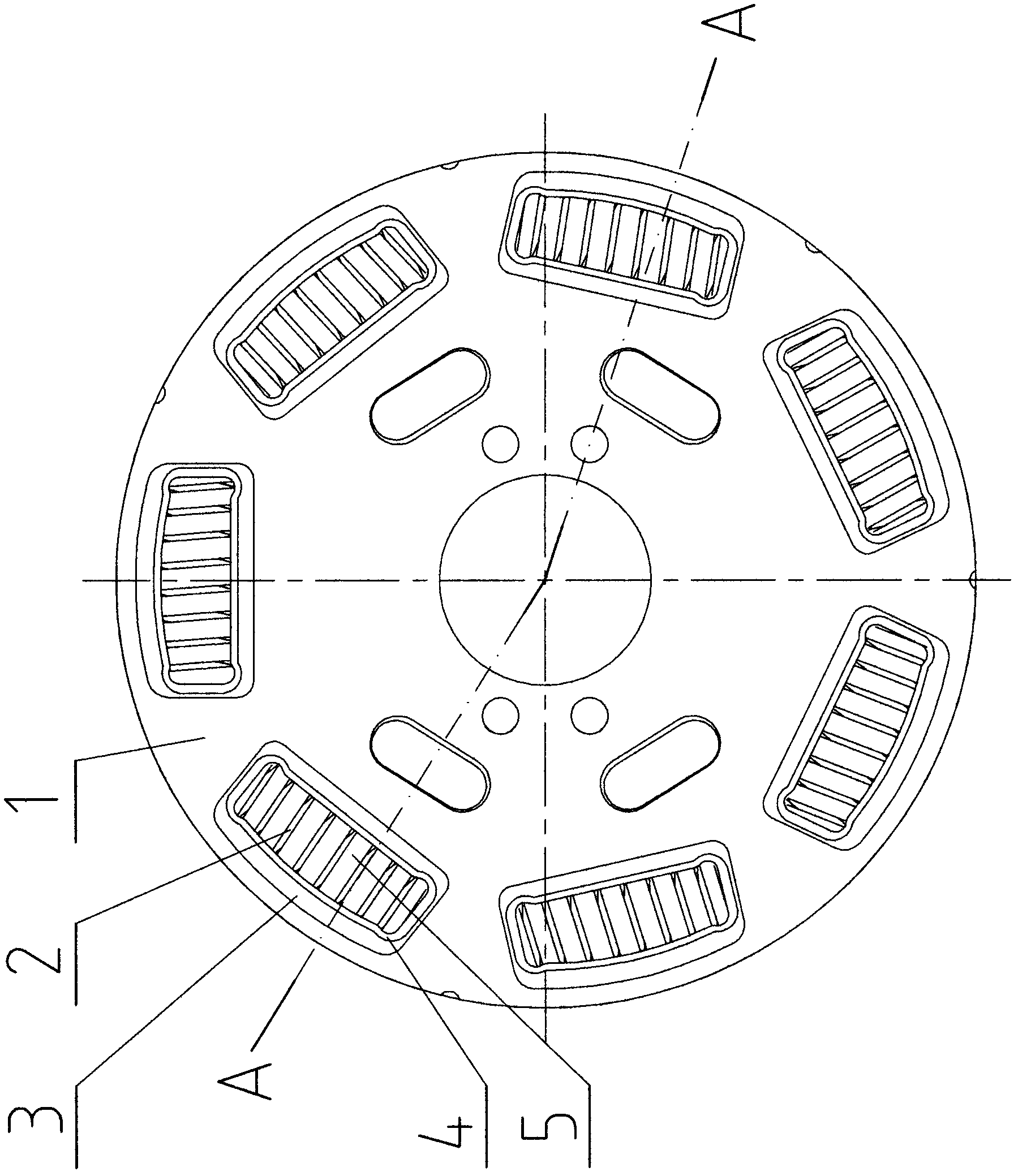

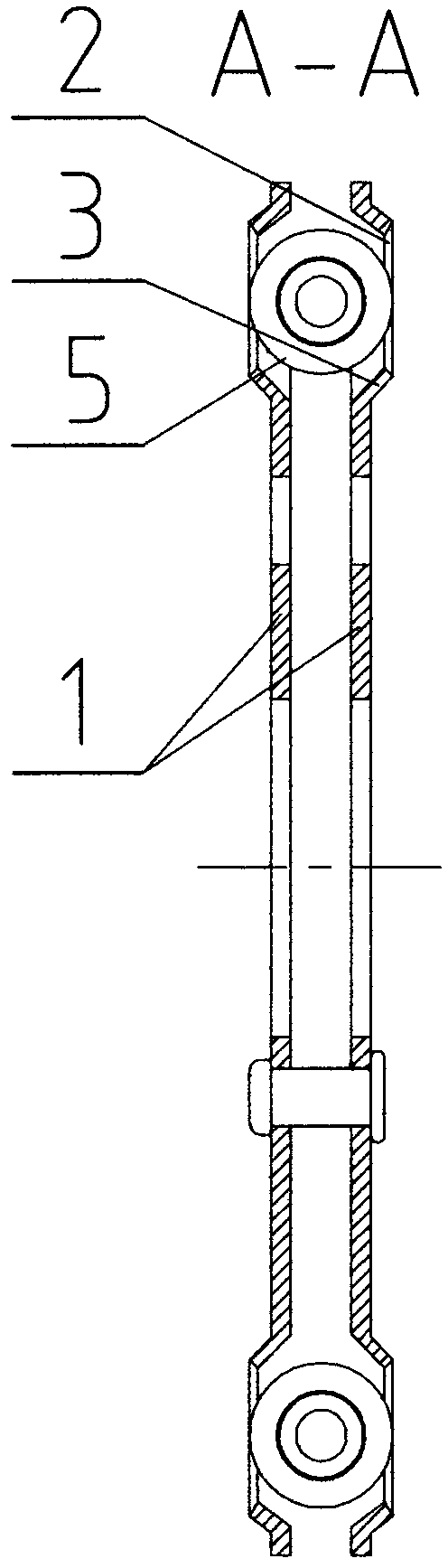

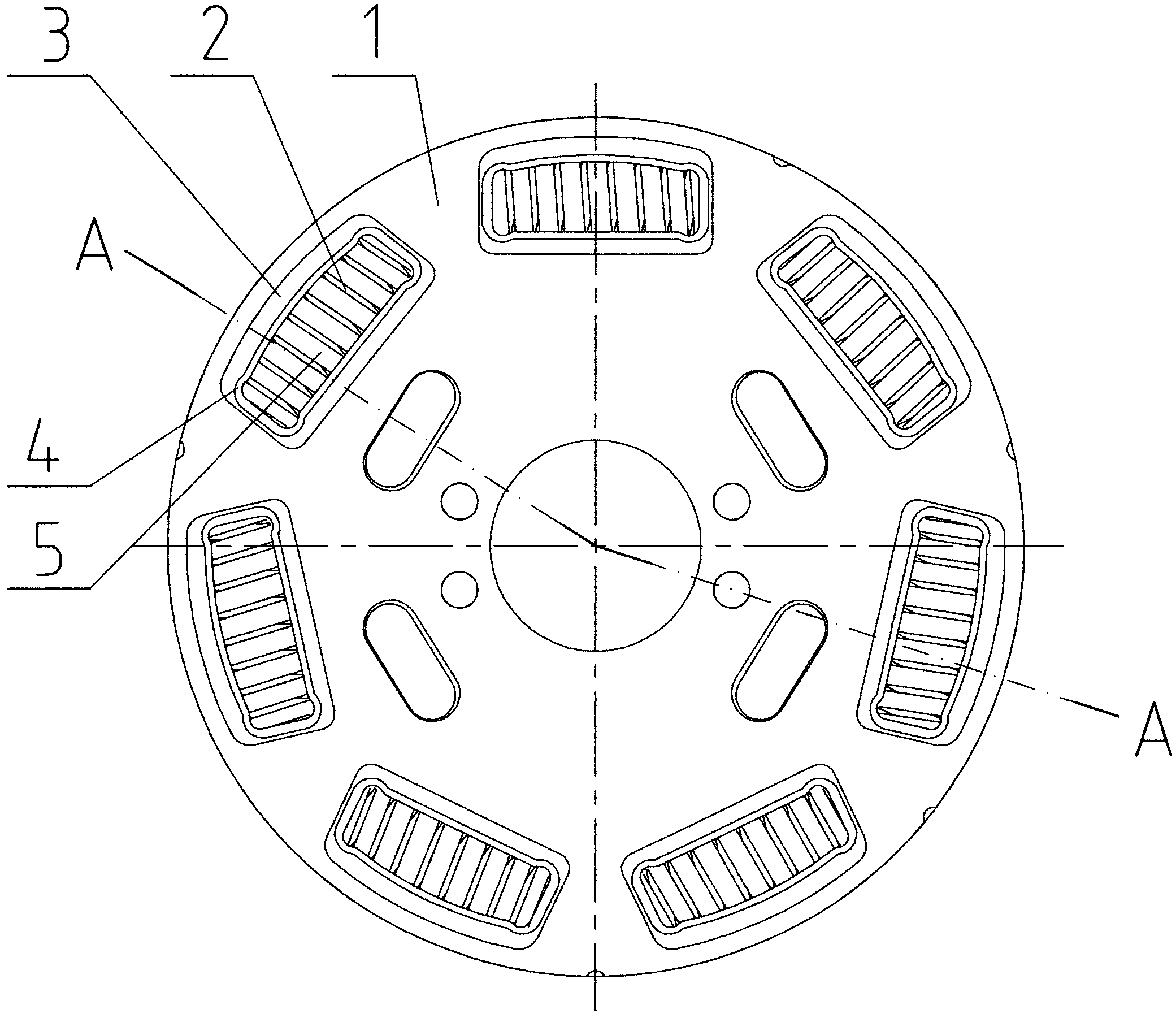

[0010] figure 1 and figure 2 Among them, a structure of a damping disc of an automobile clutch driven disc assembly, including a damping disc body 1, a rectangular window hole 2 is provided on the damping disc body 1, and flying Edge 3, the four corners of the peripheral flash 3 of the rectangular window hole 2 are all provided with arc-shaped openings 4 . In order to further improve the fluidity of the material at the four corners of the window hole 2, the lowest points of the arc openings 4 all provided with at the four corners of the flash edge 3 of the rectangular window hole 2 are lower than those of the flash edge 3 of the rectangular window hole 2. bottom edge. In the structure of the damping disc of the above-mentioned automobile clutch driven disc assembly, since the four corners of the flash 3 of the rectangular window hole 2 of the damping disc body 1 are provided with arc-shaped openings 4, it is greatly improved during the stamping process. The fluidity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com