Safety hand wheel hand-operation and automatic-operation switching mechanism of pneumatic actuator

A technology of pneumatic actuators and switching handles, which is applied to engine components, devices that prevent accidental or unauthorized actions, and mechanical equipment, etc., can solve problems such as reduced reliability and no safe switching function, and achieve reliable and safe work. High performance, strong integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

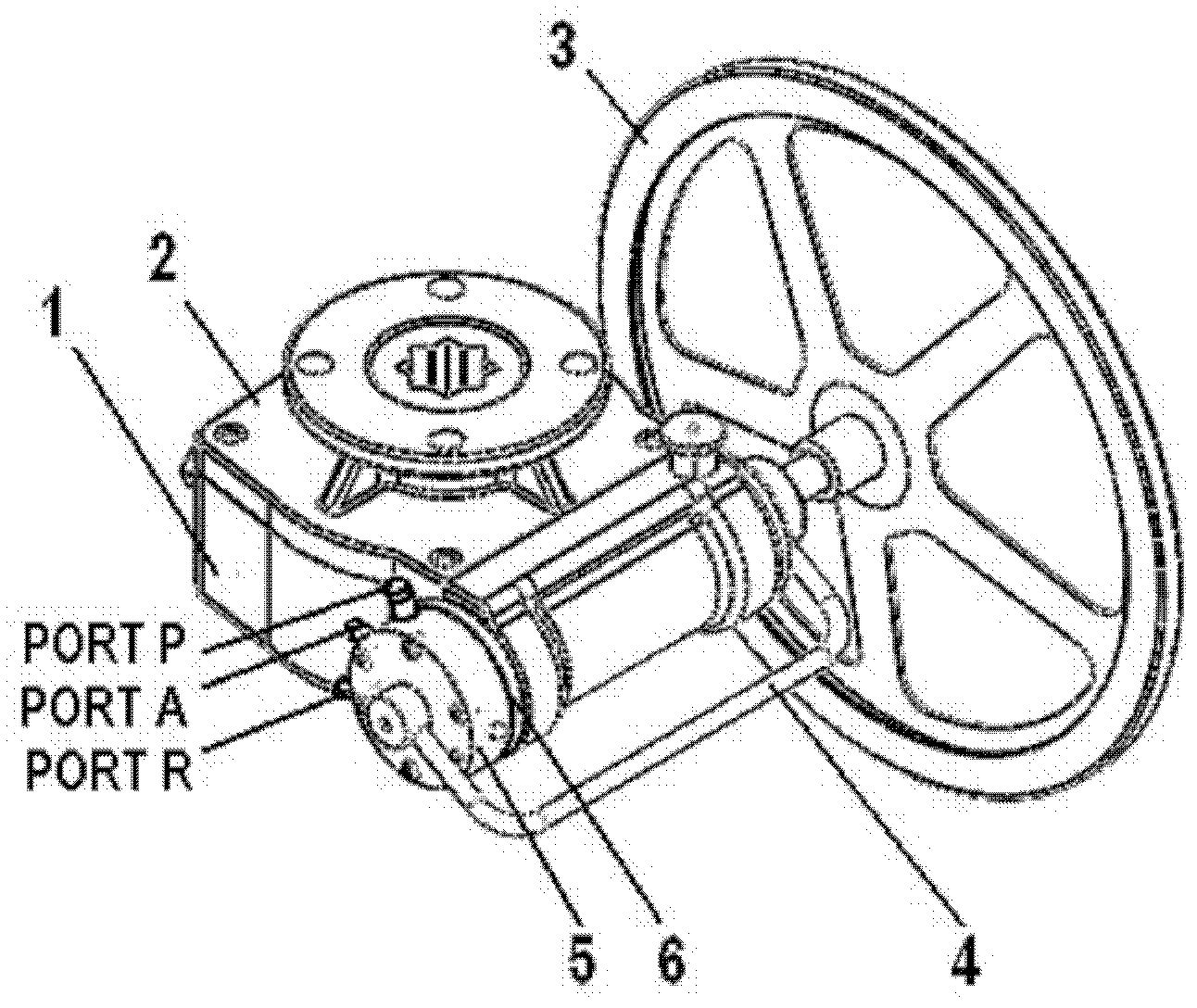

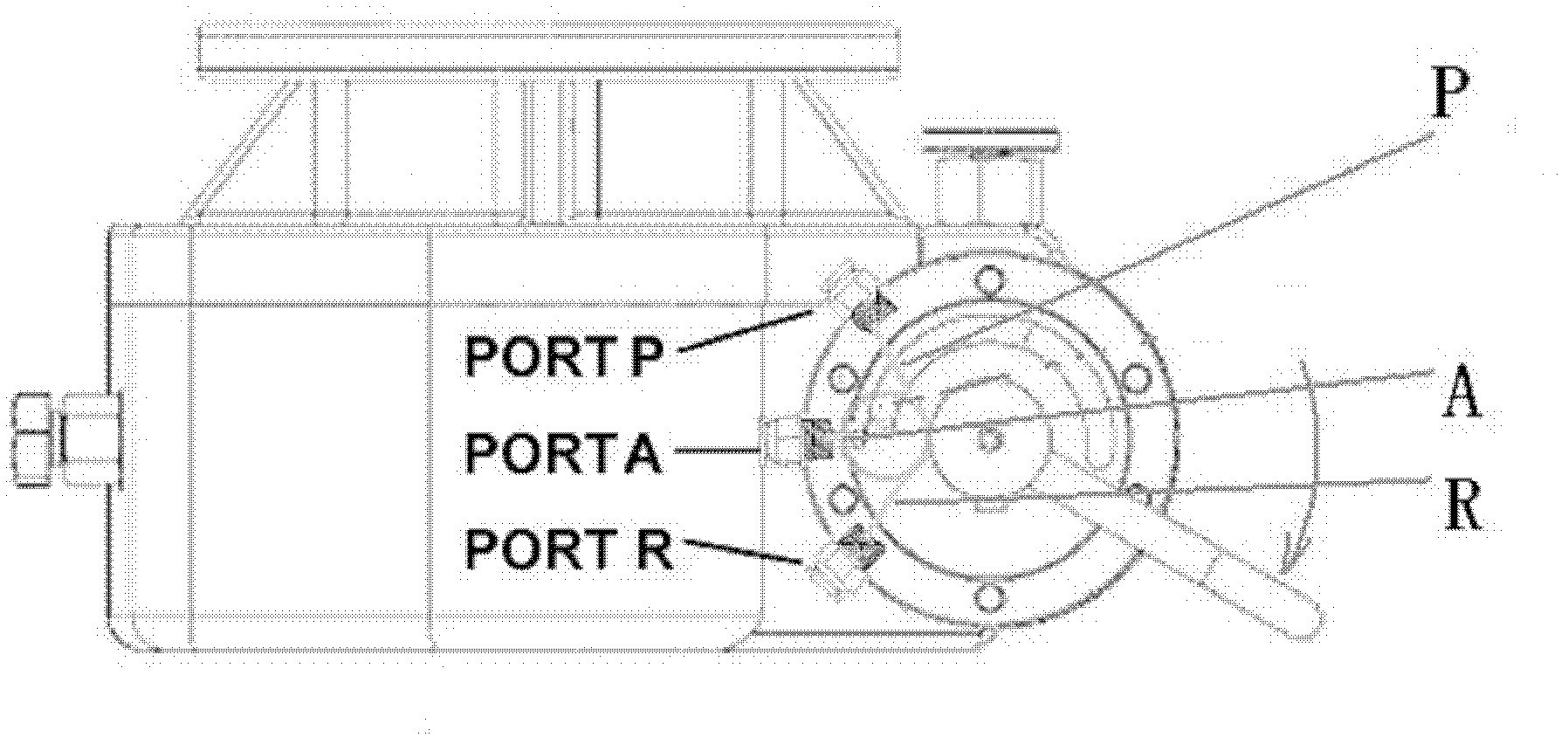

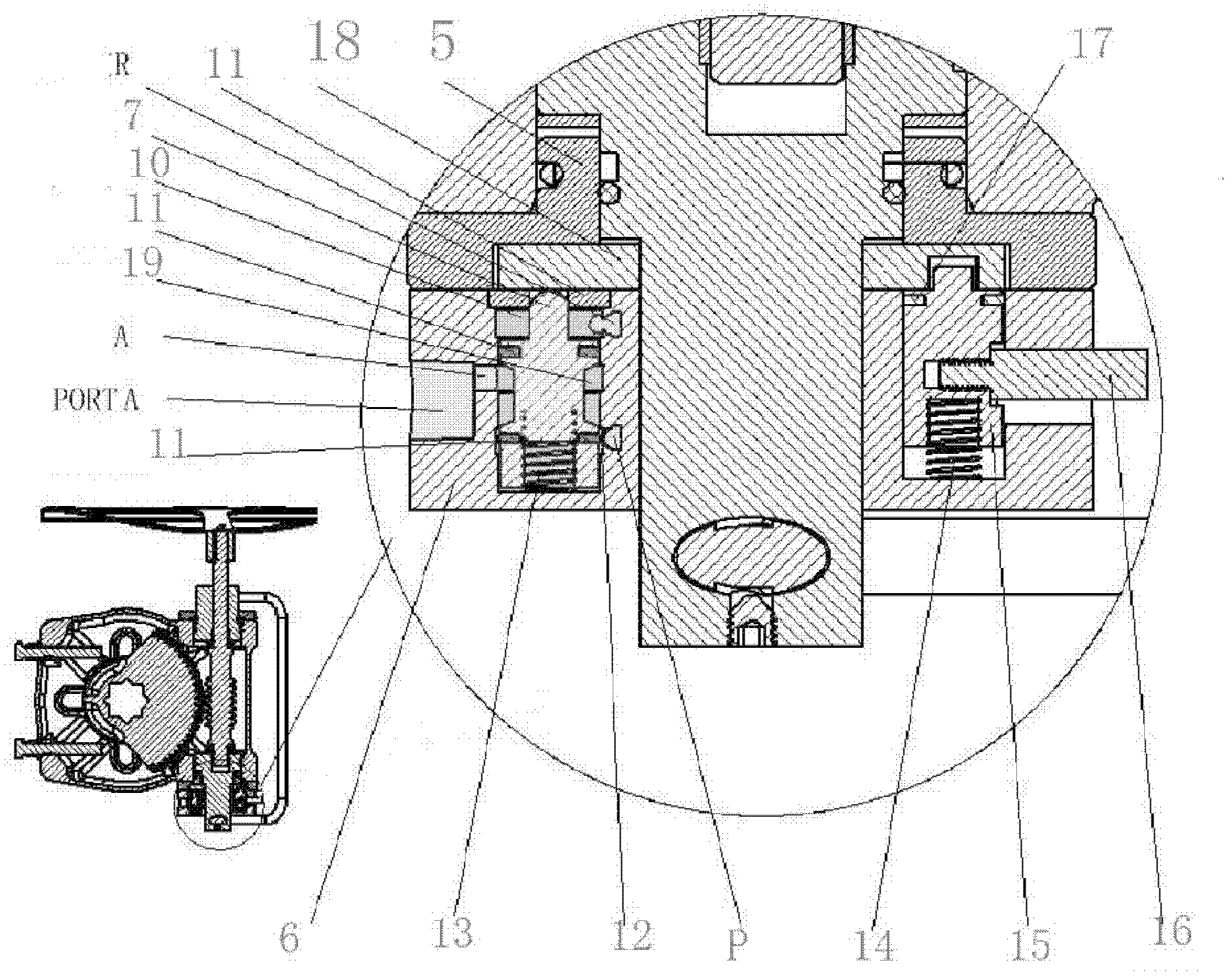

[0023] Next, the manual and automatic safety switching handwheel mechanism of the pneumatic actuator of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] The manual and automatic safety switching handwheel mechanism of the pneumatic actuator includes the handwheel 3, the handle 4, the box body 1, the box cover 2, and the worm gear and worm gear set in the inner cavity formed by the box body and the box cover, wherein the worm 8. Both ends are respectively connected with a hand wheel and an eccentric shaft. One end of the switching handle is connected to the eccentric shaft sleeve where the worm close to the hand wheel is located, and the other end is connected to the eccentric shaft where the safety switching device is located; An integrated safety protection device is provided on the eccentric shaft of the valve body, including valve body 6, valve core 7, valve seat 18, two sealing rings 11, left end cover 5, left end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com