Car lamp manufacturing method and car lamp manufactured by same

A manufacturing method and technology for vehicle lights, which are applied in the directions of motor vehicles, road vehicles, and electric lamp circuit layout, etc., can solve the problems of unsatisfactory brightness and uniformity, inconvenient installation and maintenance, and affecting driving safety, etc., and achieve improved distribution. Light effect, prolong service life, and ingenious effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

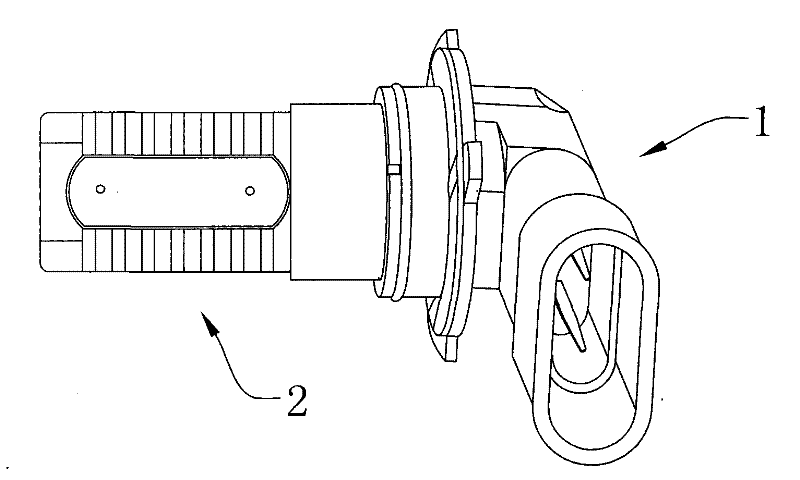

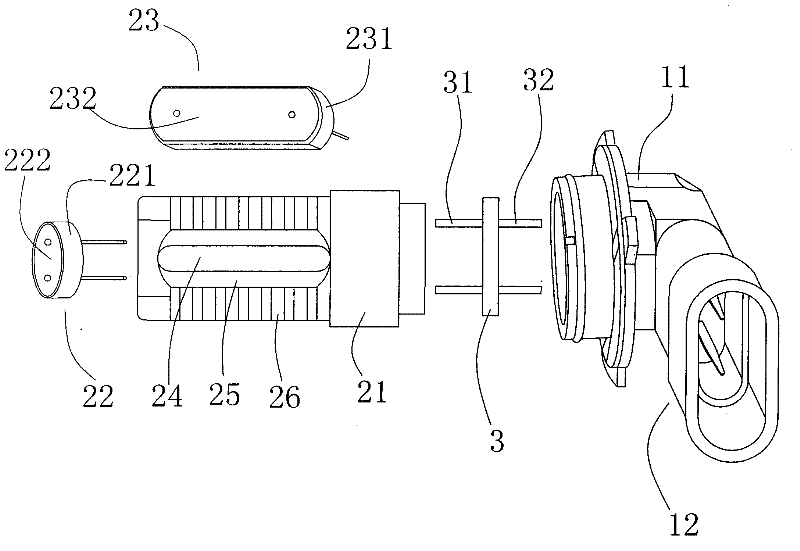

[0034] Example: see Figure 1 to Figure 4 , an embodiment of the present invention provides a method for manufacturing a vehicle lamp, which includes the following steps:

[0035] (1) Prepare a multi-angle light source module 2;

[0036] (2) Prepare a constant current drive circuit board 3 capable of driving the multi-angle light source module 2 to work, the front end of the constant current drive circuit board 3 is provided with an outgoing line 31, and the tail end is provided with an incoming line 32;

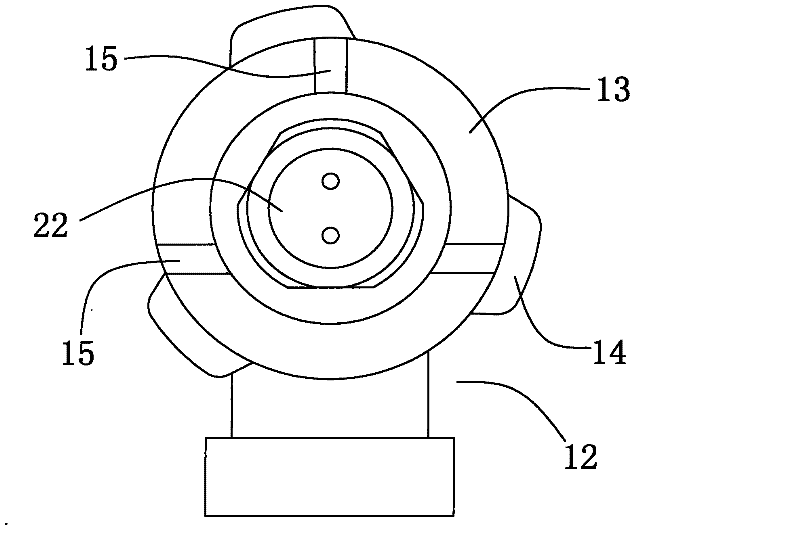

[0037] (3) prepare a lamp holder 1, the lamp holder 1 includes a mounting part 11 and a plug part 12 connected to the tail of the mounting part 11, the front part of the mounting part 11 is used to install the multi-angle light source module 2 , the middle part is provided with a cavity matching the outline of the constant current drive circuit board 3, and the plug part 12 is used to connect with a power socket;

[0038] (4) Fix the multi-angle light source module 2 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com