Staged synchronous compressor and expansion valve control method for thermostatic and humidistatic air conditioning unit

A constant temperature and humidity, compressor technology, used in heating and ventilation control systems, applications, home heating and other directions, can solve the problems of lag or overshoot, difficulty in ensuring that the refrigeration system runs in the best state, and the air-conditioning environment is changeable. , to achieve the effect of alleviating the delay and overshoot phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

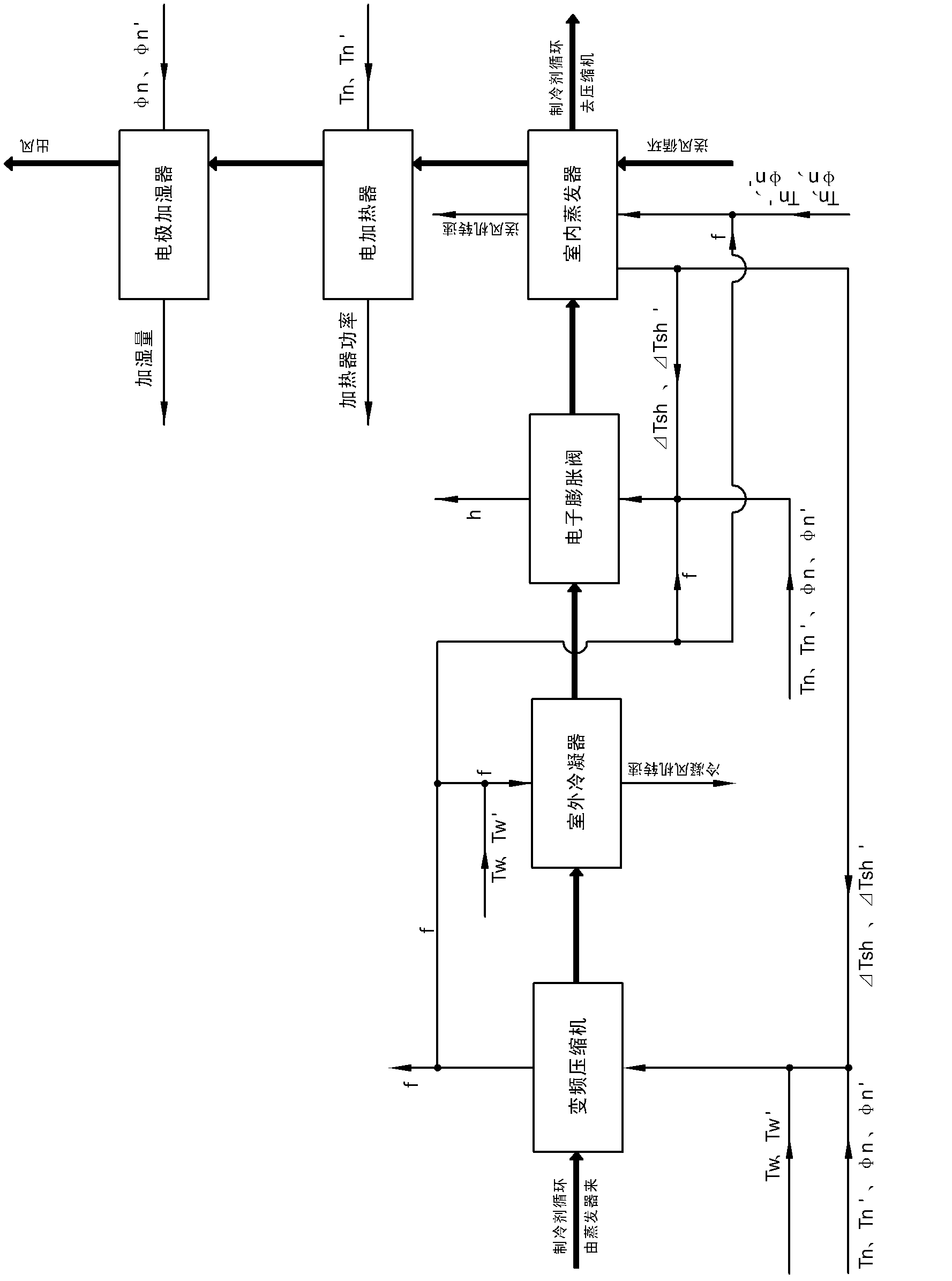

[0014] refer to figure 1 , In the staged compressor-expansion valve synchronous control process, including frequency conversion compressor, outdoor condenser, electronic expansion valve, evaporator, electric heater and electrode humidifier. The refrigerant passes through the inverter compressor, and the high-temperature and high-pressure refrigerant from the compressor enters the condenser to release heat, and then is throttled and depressurized by the electronic expansion valve to the evaporator, and the low-temperature and low-pressure refrigerant absorbs heat through the evaporator, and then Back to the compressor, and then realize the circulation of the refrigeration system; the return air with high temperature and high humidity in the controlled environment is cooled and dehumidified by the evaporator, and after being heated and humidified by the heater and humidifier, it is sent to the controlled environment to maintain the temperature of the environment. Humidity requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com