Optical vernier and method for detecting planeness and gradient using same

A technology for detecting plane and inclination, which is applied in the direction of measuring inclination, using optical devices, measuring devices, etc., can solve the problems of low accuracy of flatness detection data, low vertical accuracy of ruler body and low accuracy of marking line aiming, and achieves erection operation. Convenience, reduced manual grinding workload, and reliable accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

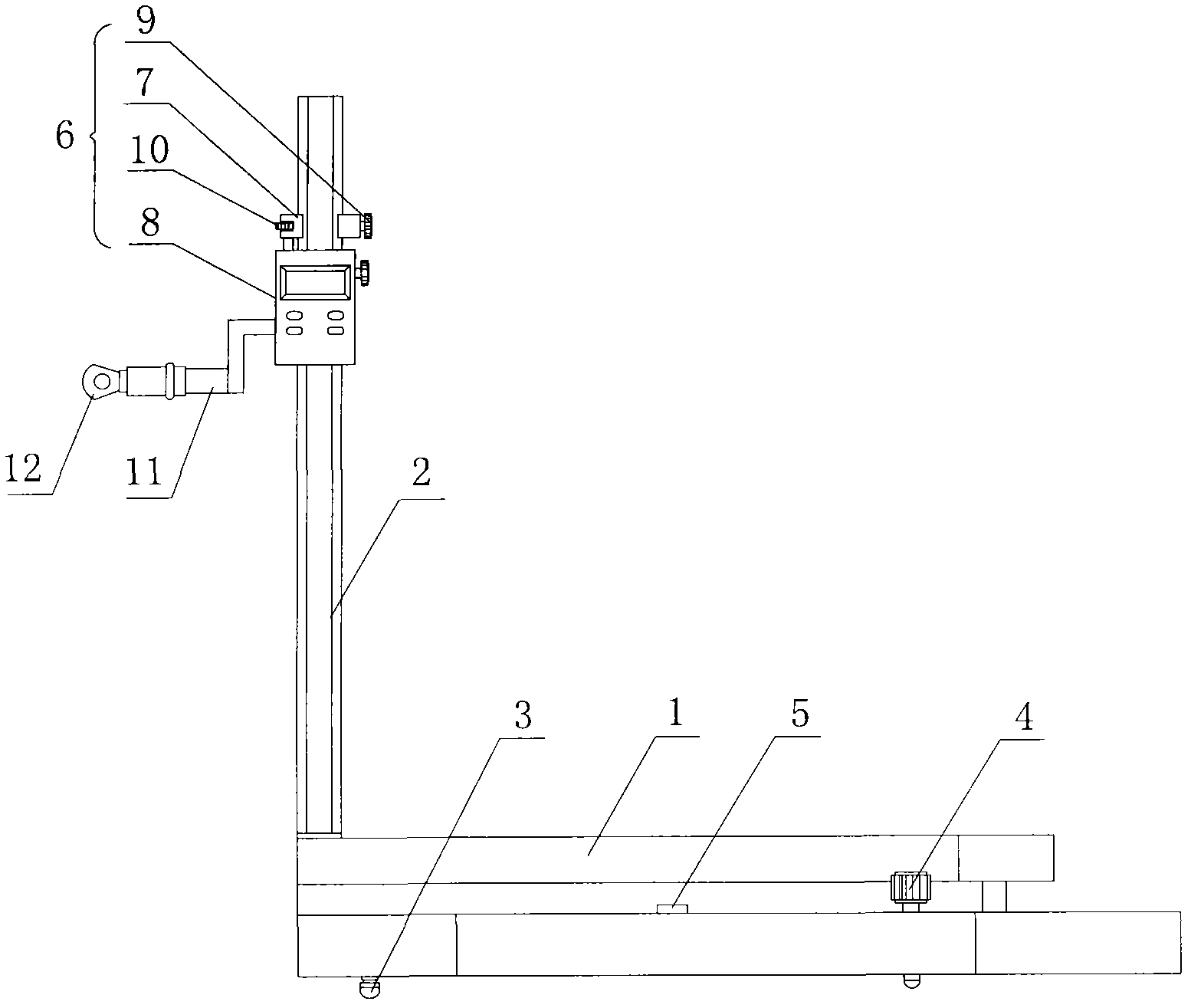

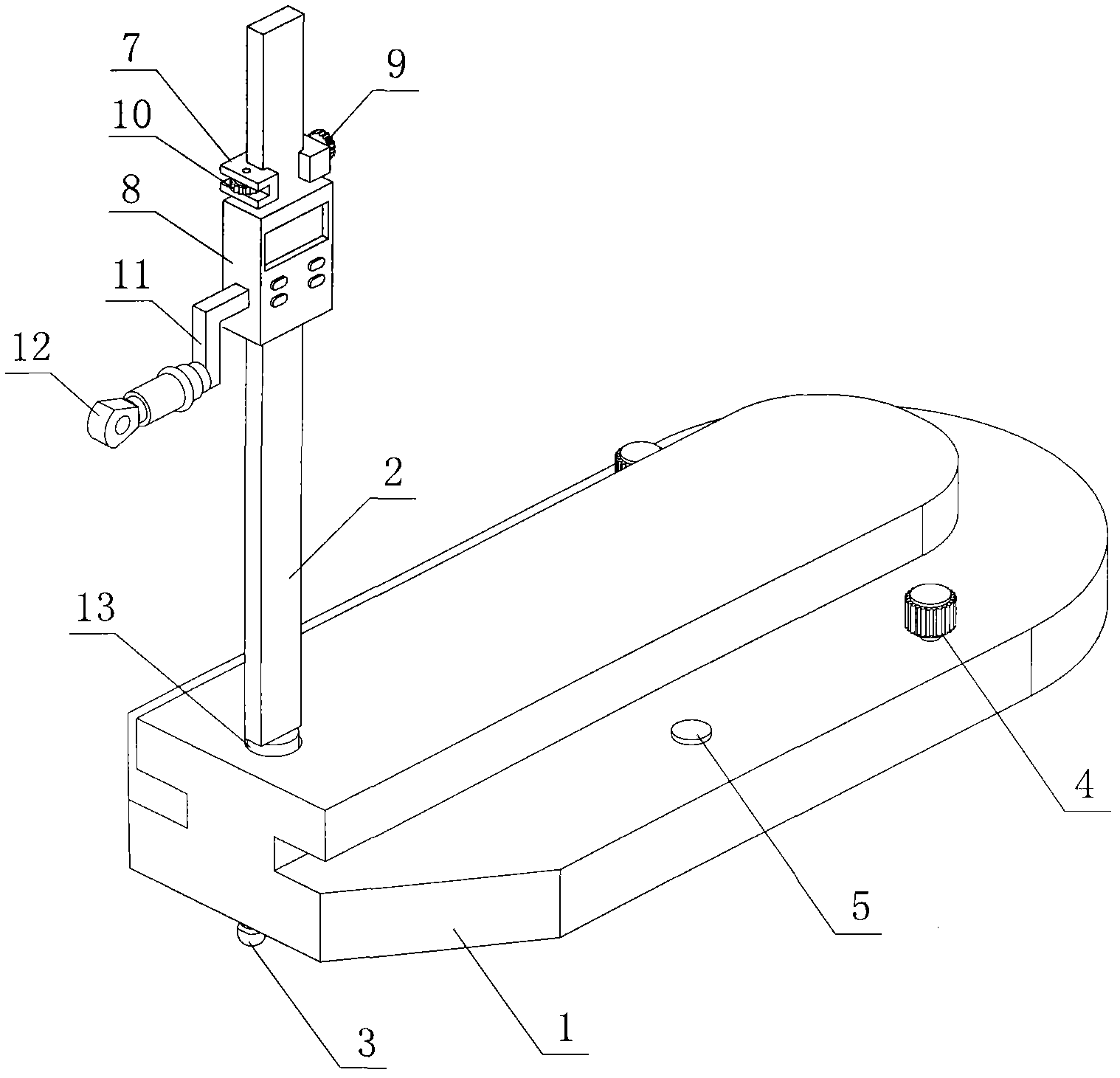

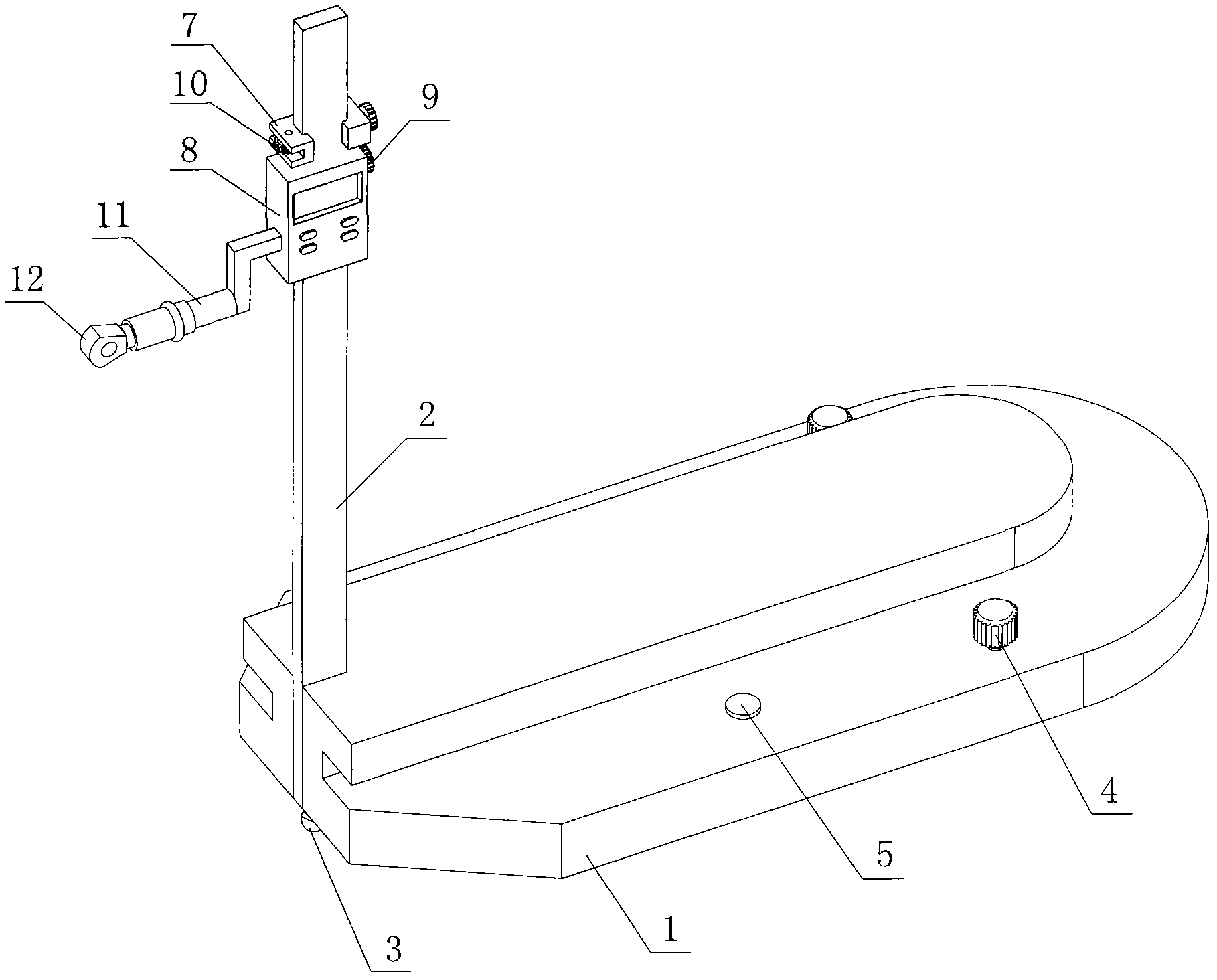

[0030] like figure 1 and figure 2 As shown, it is the first embodiment of the optical scale of the present invention. The optical scale of the present invention includes a base 1 and a ruler body 2 vertically arranged on the base 1. A fixing screw 3 is provided on the bottom surface of the base 1, and the fixing screw 3 Located directly below the ruler body 2. The other end of the base 1 away from the ruler body 2 is provided with two adjustment screws 4, and the two adjustment screws 4 are symmetrically distributed on both sides adjacent to the base 1, and the connecting line of the two adjustment screws 4 is perpendicular to the ruler body 2. , The upper surface of the base 1 is also provided with a bubble level 5 to facilitate the leveling of the base 1 .

[0031] The upper part of the ruler body 2 is covered with a digital cursor 6, which can slide on the ruler body 2. The digital cursor 6 includes a vernier 7 and a digital display reading unit 8 connected thereto. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com