Method and system for detecting local impedance change of objects

An object, to-be-detected technology, applied in the measurement of torque/torsional force during tightening, and the use of sonic/ultrasonic/infrasonic waves to analyze solids and other directions, can solve problems such as difficult defect detection, and achieve the effect of simple operation steps and easy-to-use equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

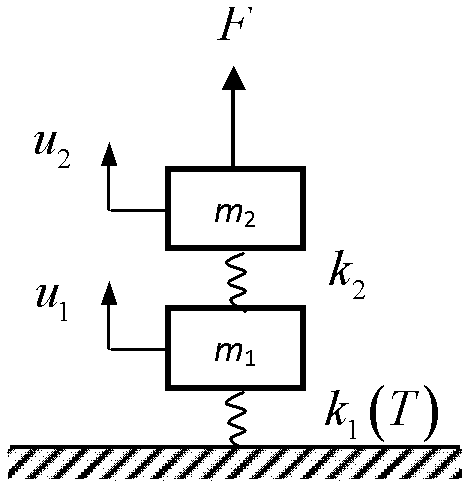

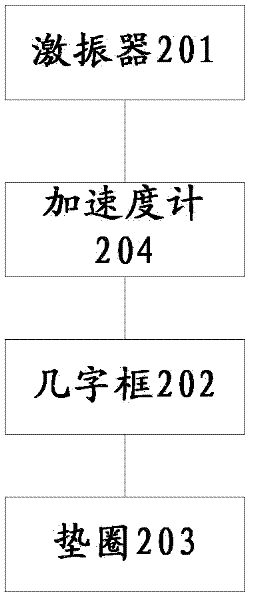

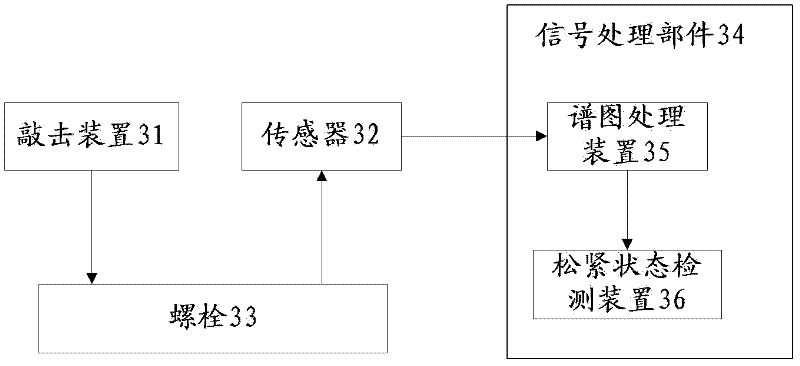

[0049]The equivalent stiffness and friction coefficient of bolts are not only related to material properties and geometric shapes, but also change with the tightening torque of bolts. The equivalent stiffness and damping of composite materials are not only related to the material properties and geometry of composite materials, but also related to the damage type and degree of composite materials. Therefore, to accurately describe the mechanical behavior of bolts or composite materials under the action of knocking force, very complex nonlinear dynamic analysis must be involved. The purpose of the present invention is to detect the degree of tightness of the bolt or the damage state of the composite material, so it is only trying to find a response that is sensitive to the tightening torque of the bolt or the damage state of the composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com