Gas-solid phase pipe flow static measuring appliance and measuring method

An electrostatic measurement, gas-solid technology, applied in the direction of electrostatic field measurement, electrostatic instruments, etc., can solve the problems of accurate measurement of pipelines, ignoring the influence of electrostatic measurement accuracy, and easy interference of measurement results, so as to ensure accuracy and measurement methods Simplify and reduce the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

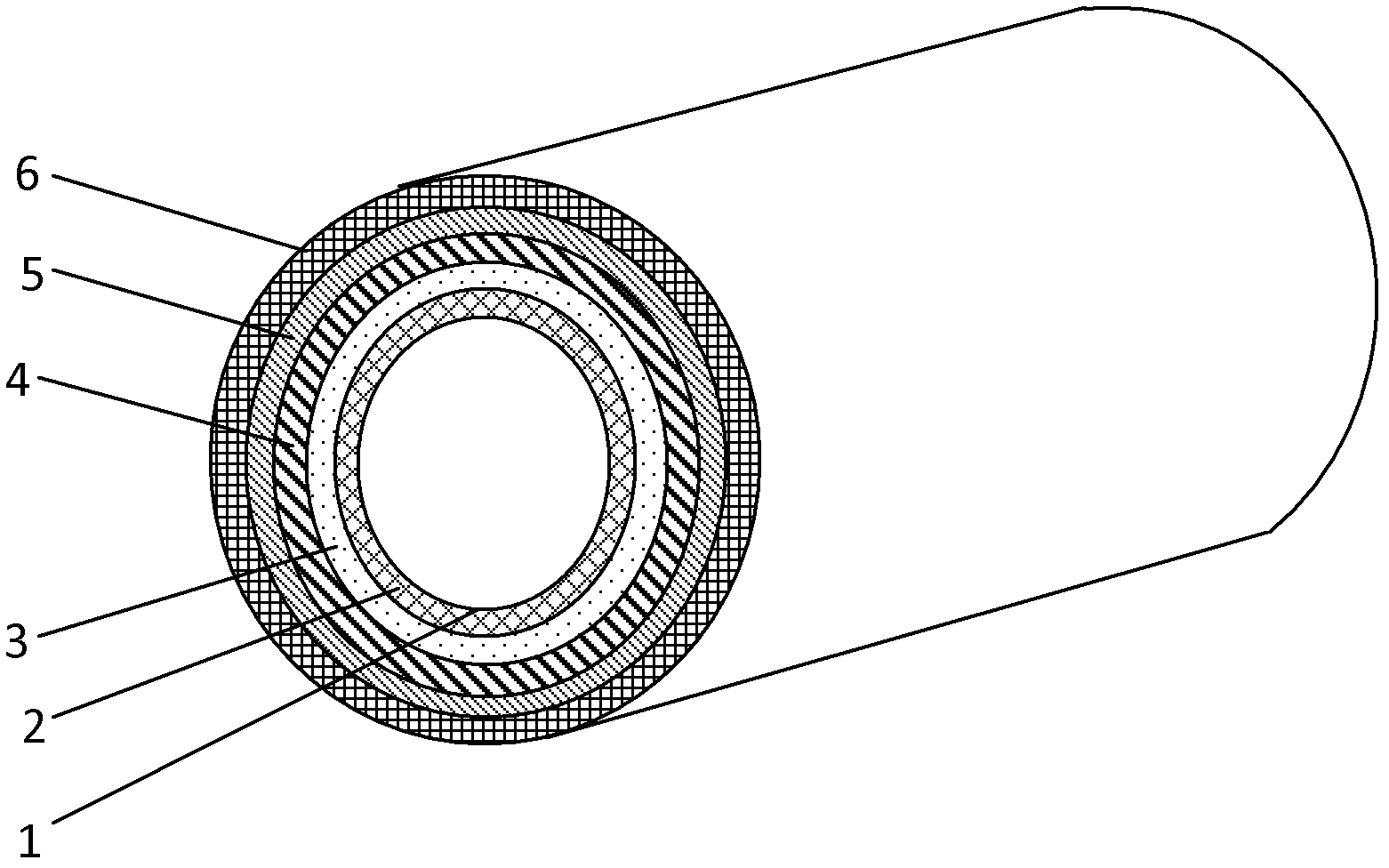

[0020] see figure 1 , the embodiment of the gas-solid two-phase pipe flow electrostatic measurement device is provided with an inner shielding metal layer 2, a first insulating layer 3, a metal layer 4, a second insulating layer 5 and an outer shielding metal layer 6 from the inside to the outside; The inner shielding metal layer 2 is provided with an electrode, and the electrode is drawn out by a wire and grounded; the metal layer 4 is provided with a measuring electrode, and the measuring electrode is externally connected to an electrostatic measuring instrument; ground connection; during measurement, the inner shielding metal layer 2 is closely attached to the outer wall of the pipeline 1 under test.

[0021] The diameter of the inner shielding metal layer 2 may be 0.005-4m.

[0022] The pipeline to be tested can be various metal pipelines and insulating pipelines, and the length of the pipeline to be tested can be 0.05-1m.

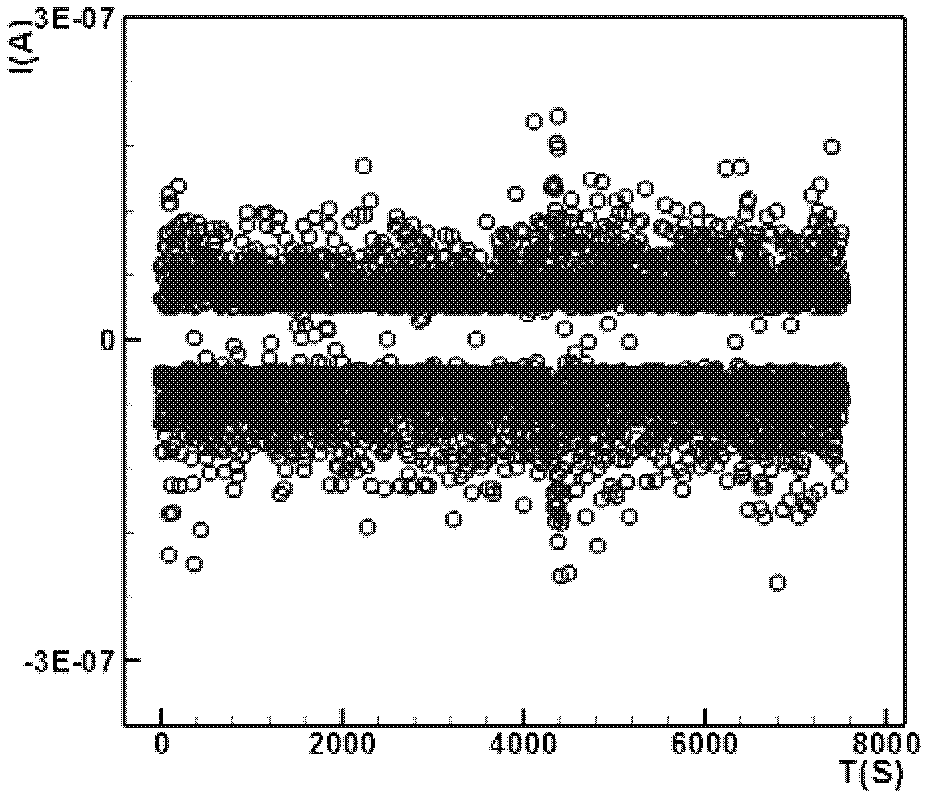

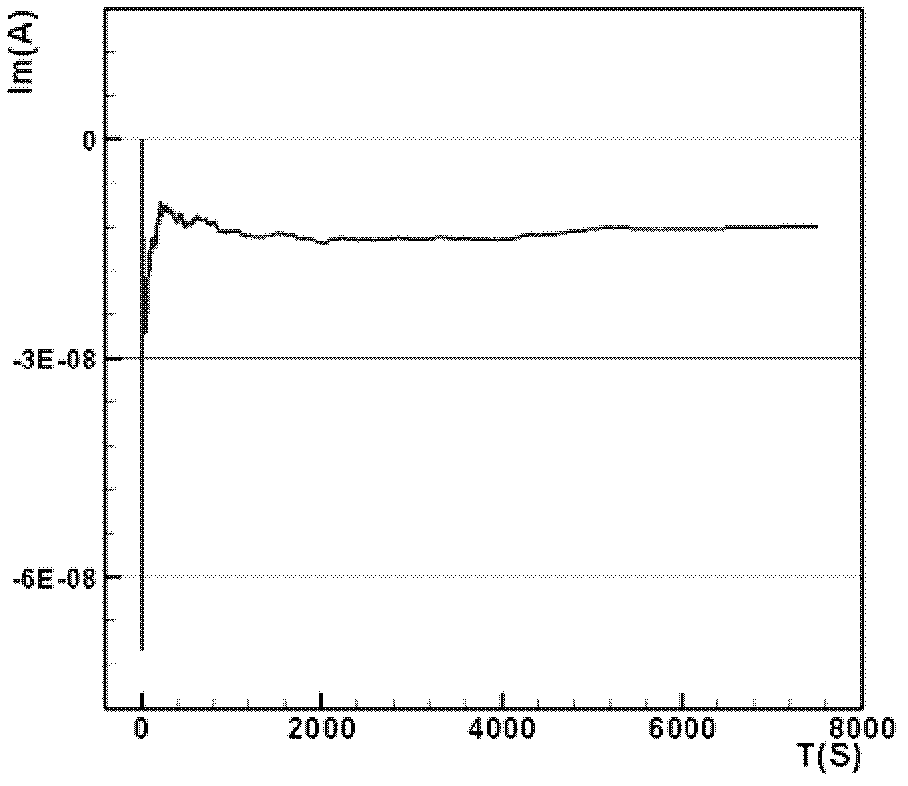

[0023] In the gas-solid two-phase pipe flow el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com