Lens, hologram projection production system and method thereof

A technology for making systems and holograms, applied in the field of holography, can solve problems such as low efficiency, complex structure, and inability to obtain ideal effects, and achieve the effect of reducing complexity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

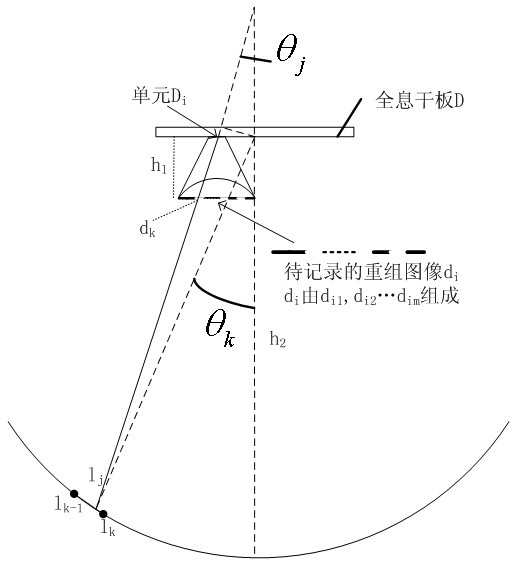

[0041] We only take the horizontal parallax hologram as an example to illustrate its production method. For the full parallax composite hologram, it is only necessary to carry out the same design in the vertical direction.

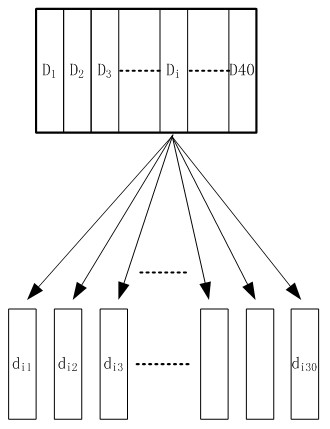

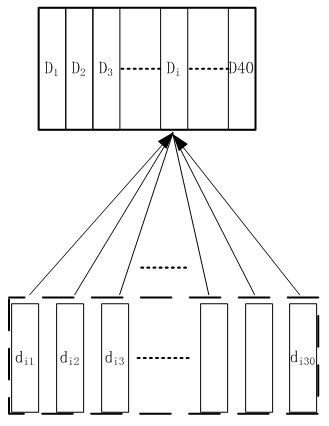

[0042] Such as figure 1 and 2 As shown, there is a holographic dry plate D, to record a three-dimensional image d on it, we can divide the holographic dry plate D into 40 small units D 1 、D 2 、D 3 …D 40 Recorded separately, the corresponding stereo image d is also divided into d 1 、d 2 、d 3 … d 40 40 sections, of which d i corresponds to D i . Such as figure 1 As shown, for the i-th unit D of the holographic dry plate D i , the images formed on the sampling points with equiangular distribution are respectively d i1 、d i2 、d i3 … d i30 . Therefore, it is only necessary to convert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com