Metallic part provided with fibrous reinforcements and having a bevelled edge

一种加固件、金属坯件的技术,应用在金属部件领域,能够解决被拉出、变弱、破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following explanations, the manufacture of fiber reinforcements does not form the subject of the invention and is therefore not described in detail. See, for example, document WO 2009 / 034264, which describes several examples of such fiber reinforcements.

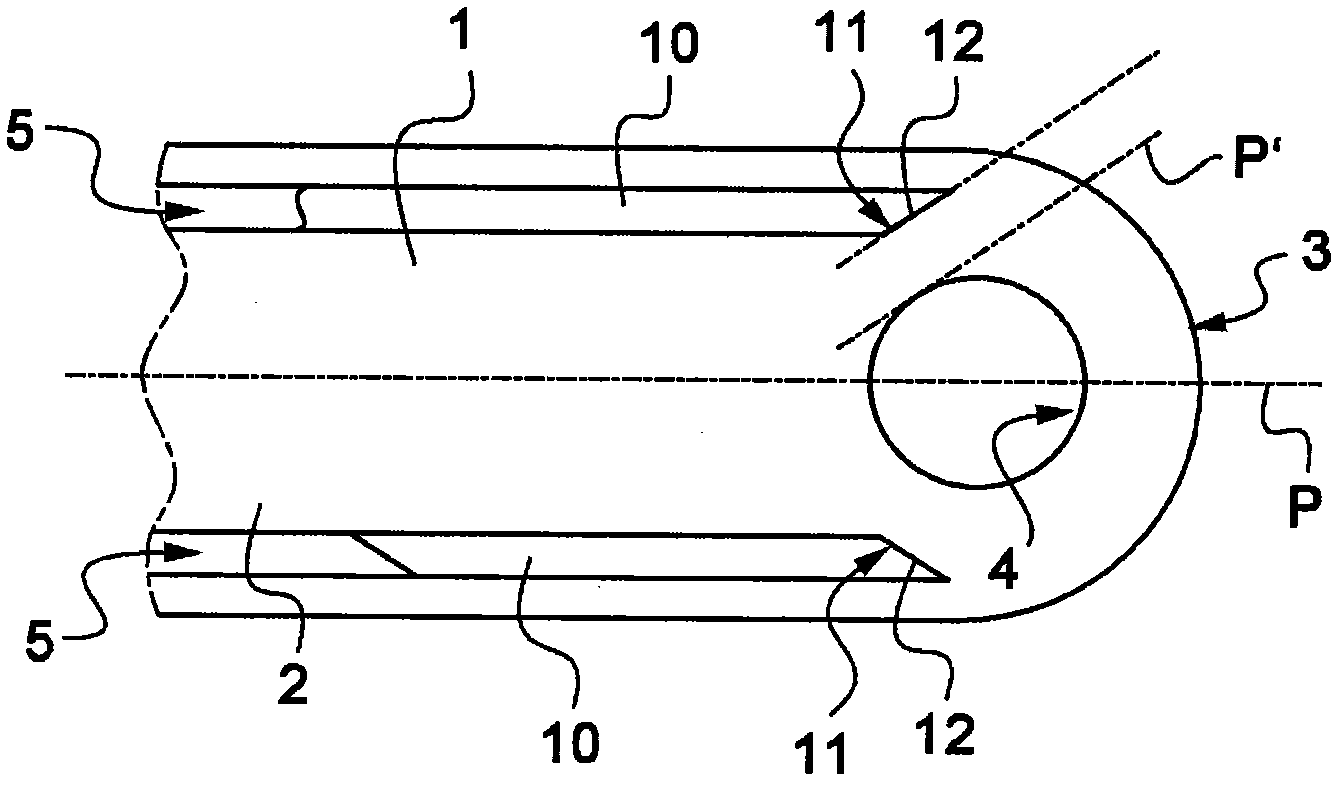

[0014] refer to figure 1 , in a first embodiment the connecting rod of the invention is made from a metal blank 1 having a generally flat shape with a main body part 2 of constant cross-section, which is terminated by two circular ends 3 , the two rounded ends 3 form end lugs and include through holes 4 . In this example, the blank is made of a titanium alloy.

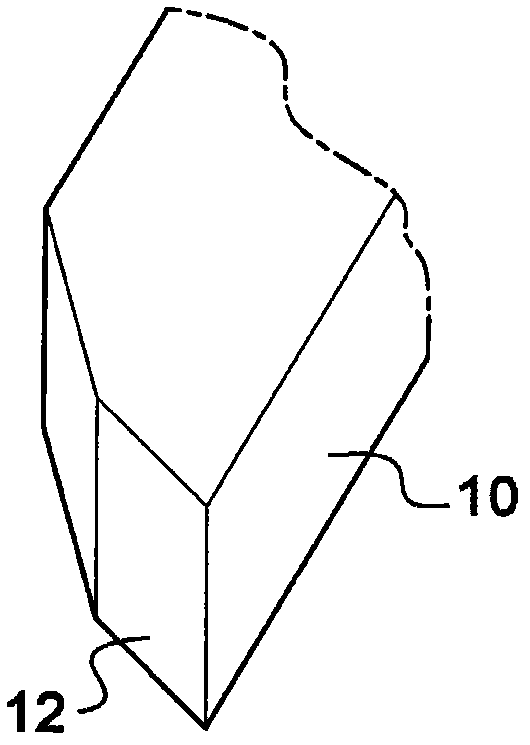

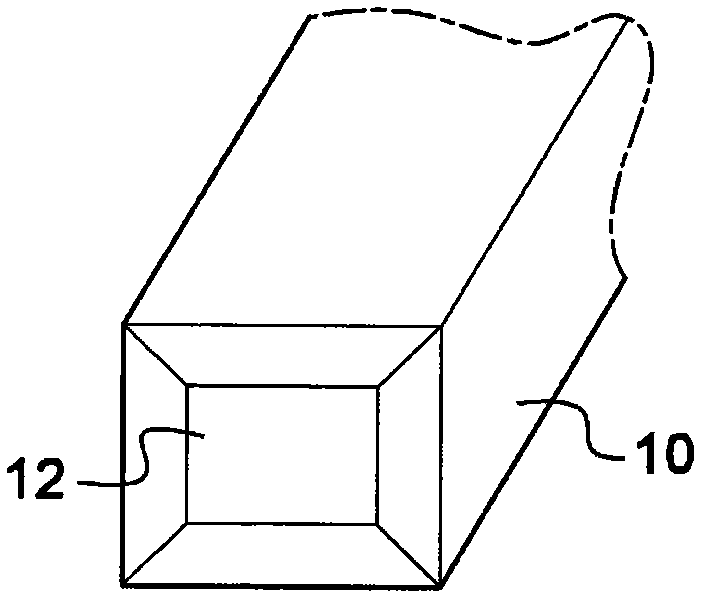

[0015] In this example, the longitudinal shells 5 extend from one end to the other of the blank 1 parallel to the plane of symmetry P of the blank 1, and they form a shell adapted to receive the part 10 of the fiber reinforcement (the part of the reinforcement is shown in Fig. are shown cut away to more clearly show the housing, but in fact they occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com