Contact-exposing-type screw conveying apparatus using a bearing

A technology for conveying equipment and screws, applied in the field of contact-visible bearing screw conveying equipment, can solve the problems of increasing the number of parts and errors, difficult to process a cylindrical body, and impossible to identify the contact state between the radial bearing and the screw shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

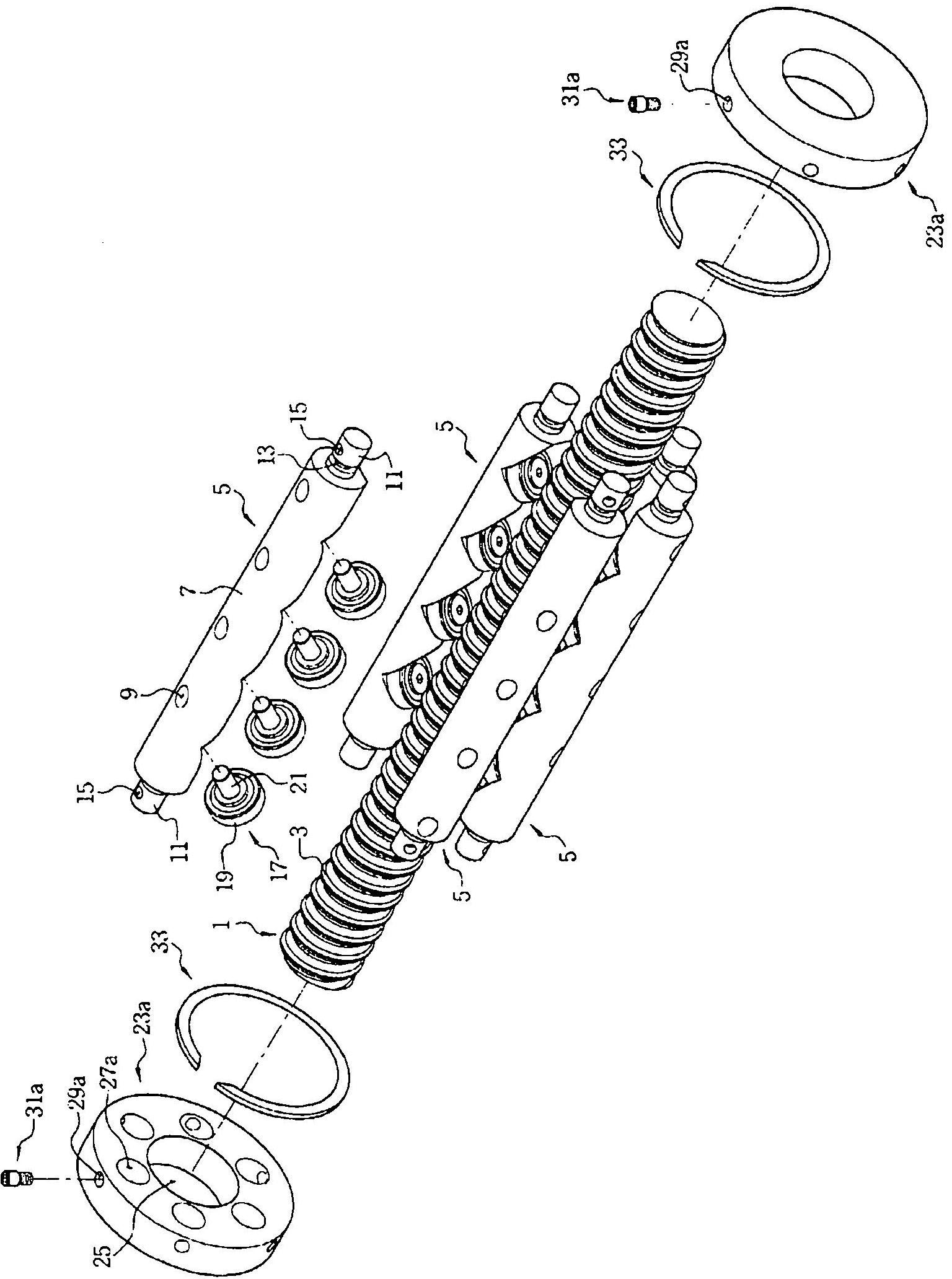

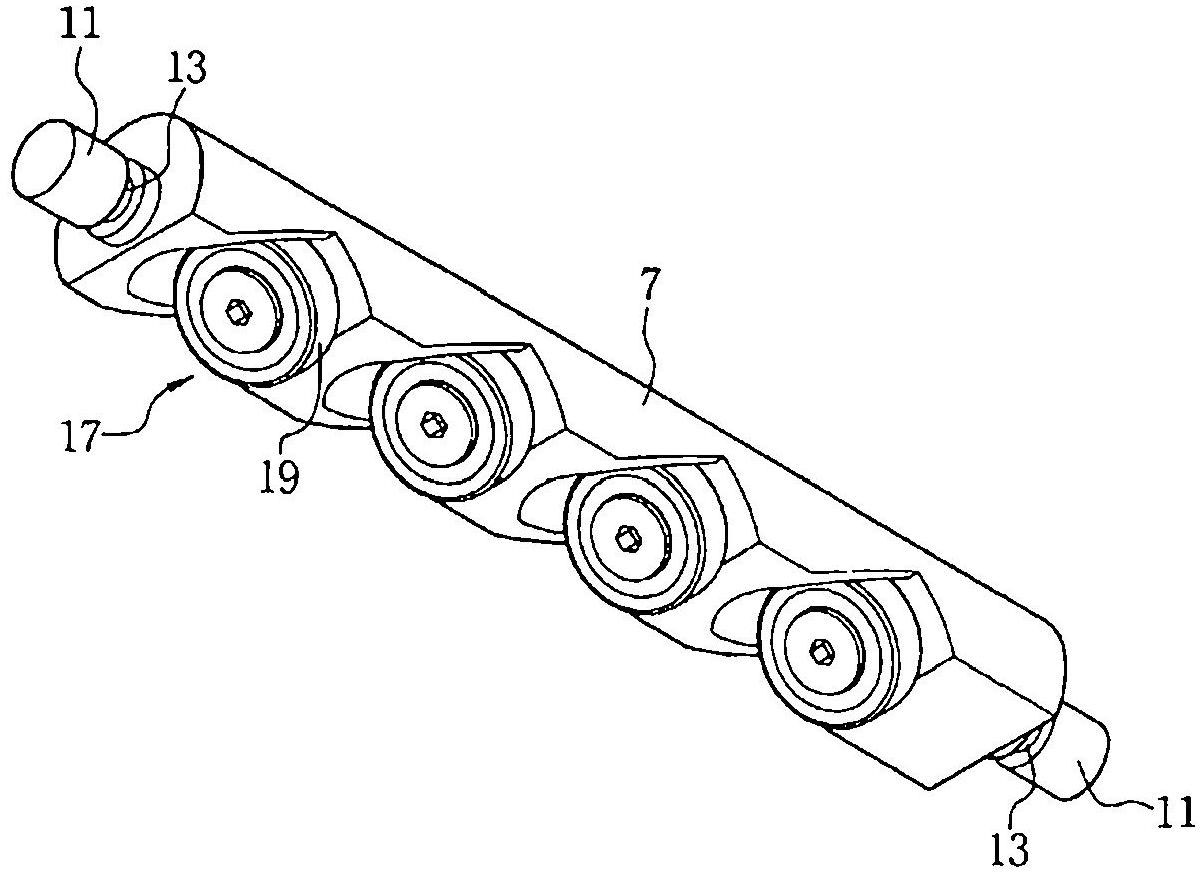

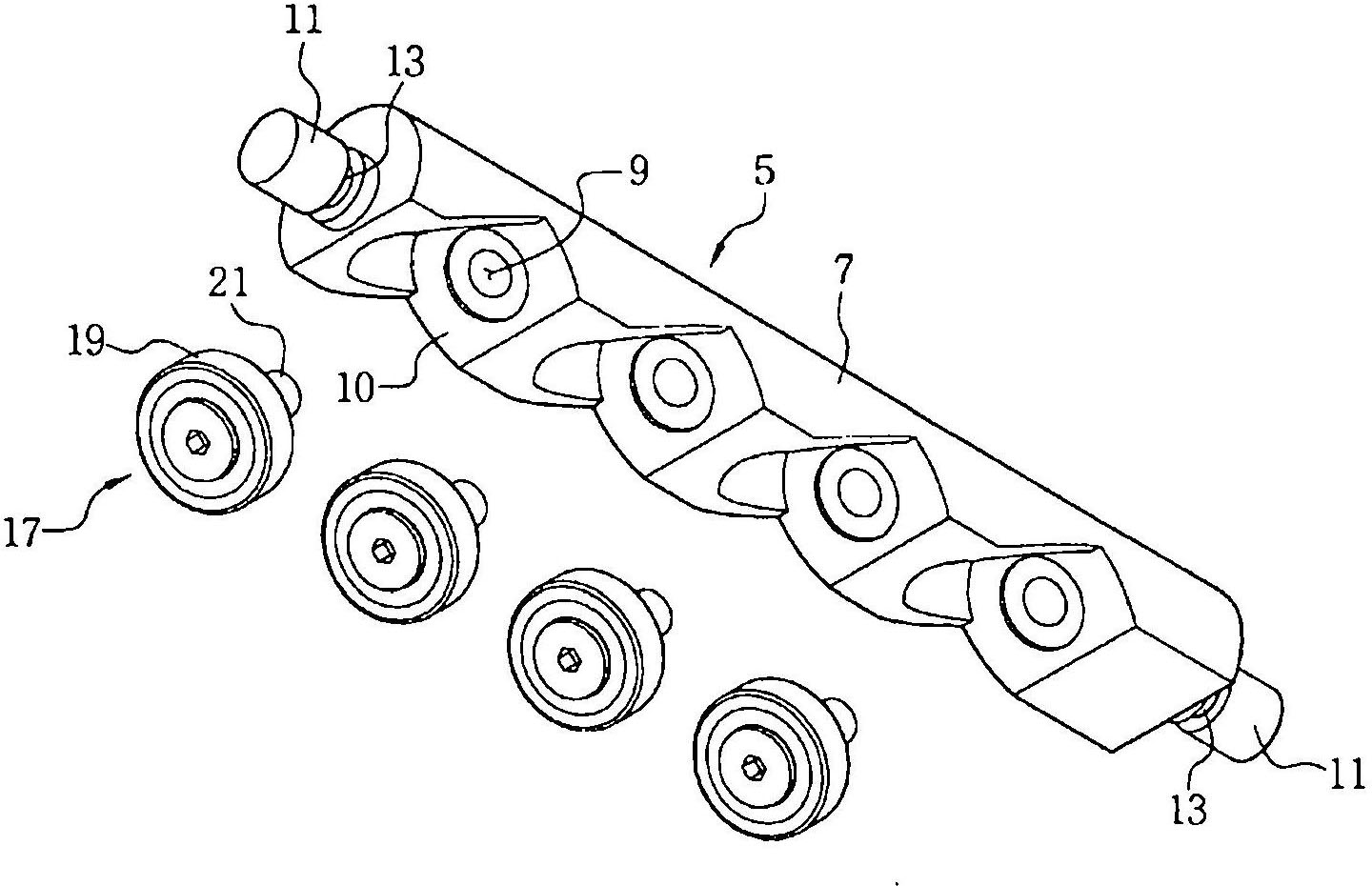

[0055] First, refer to Figure 5 ,From Figure 5 It can be seen that the contact-visible bearing screw conveying device of the present invention includes: a screw shaft 1 formed with external threads 3 at its outer circumferential surface; and a rod-type bearing bracket nut in which a plurality of radial bearings 17 are mounted on the helical path corresponding to the external thread 3 while forming multiple pairs with each other. A feature of the present invention is to provide a rod bearing bracket nut.

[0056] refer to figure 1 Or 4, the contact-visible bearing screw conveying device according to the first embodiment of the present invention includes: a screw shaft having external threads 3 formed on its outer circumferential surface, and a plurality of rod-type bearing brackets 5, the plurality of which The rod bearing brackets are arranged at a predetermined distance in the circumferential direction at the outer peripheral side of the screw shaft 1, while opposite end...

no. 2 example

[0070] The second to fourth embodiments of the present invention are characterized in that the rod bearing brackets 5a and 5b are displaced in the longitudinal direction of the screw shaft 1 so that the surface of the external thread 3 and the radial bearing 17 can be identified from the outside with the naked eye. Adjust the contact preload between the external thread 3 of the screw shaft 1 and the radial bearing 17 while adjusting the contact state between them.

[0071] Figure 6 and 7 A contact-visible bearing screw conveying device according to a second embodiment of the present invention is illustrated. The contact-visible bearing screw conveying device according to the second embodiment of the present invention also includes a screw shaft 1 and a rod-type bearing bracket nut, the screw shaft is formed with external threads at its outer peripheral surface, and the rod-type bearing bracket nut is screwed to screw shaft 1. The rod bearing bracket nut includes radial bea...

no. 3 example

[0080] Figure 8 and 9 A contact visible type bearing screw conveying device according to a third embodiment of the present invention is illustrated. Such as Figure 8 and 9 As shown in, in the third embodiment of the present invention, the ends of the rod bearing brackets 5a and 5b can be inserted into the bracket mounting hole 27b formed at the spacer 23b so as to pass through the spacer , the bracket mounting holes 27b are respectively formed with threaded openings 29b at predetermined depths at portions outside the inner wall thereof, and the preload adjustment screws 39 are threadedly fastened to the threaded openings 29b of the bracket mounting holes 27b so that the screw shafts 1 are respectively threaded in the longitudinal direction. Push rod bearing brackets 5a and 5b. The bracket mounting holes 27b having the same number of spacers 39 as the mounted rod bearing brackets 5a and 5b are formed to be spaced apart from each other by a predetermined distance. Each ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap