Screw socket hexagon punching die

A punching die and screw technology, which is applied in the field of punching dies for hexagonal punching of the screw head, can solve the problems of poor surface roughness, low service life and easy breakage of the die, so as to ensure product quality, improve service life and avoid breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

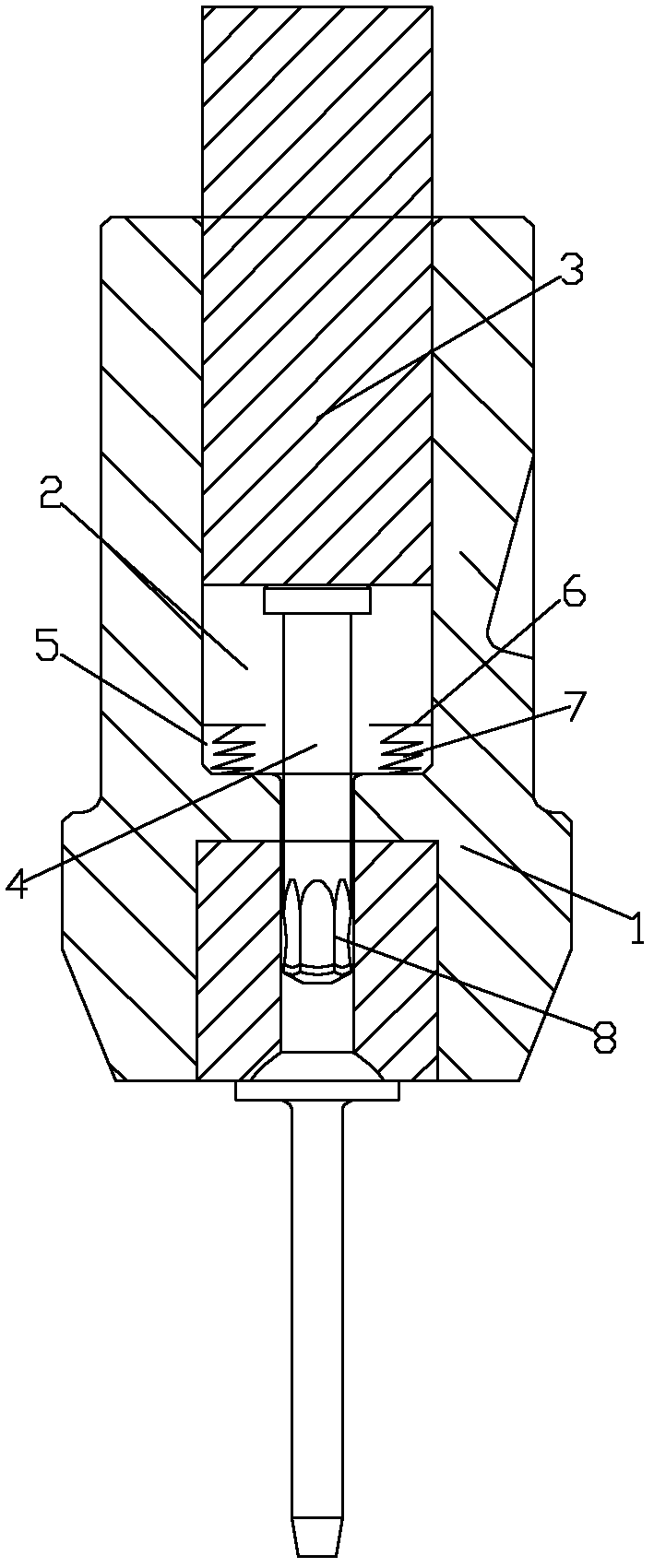

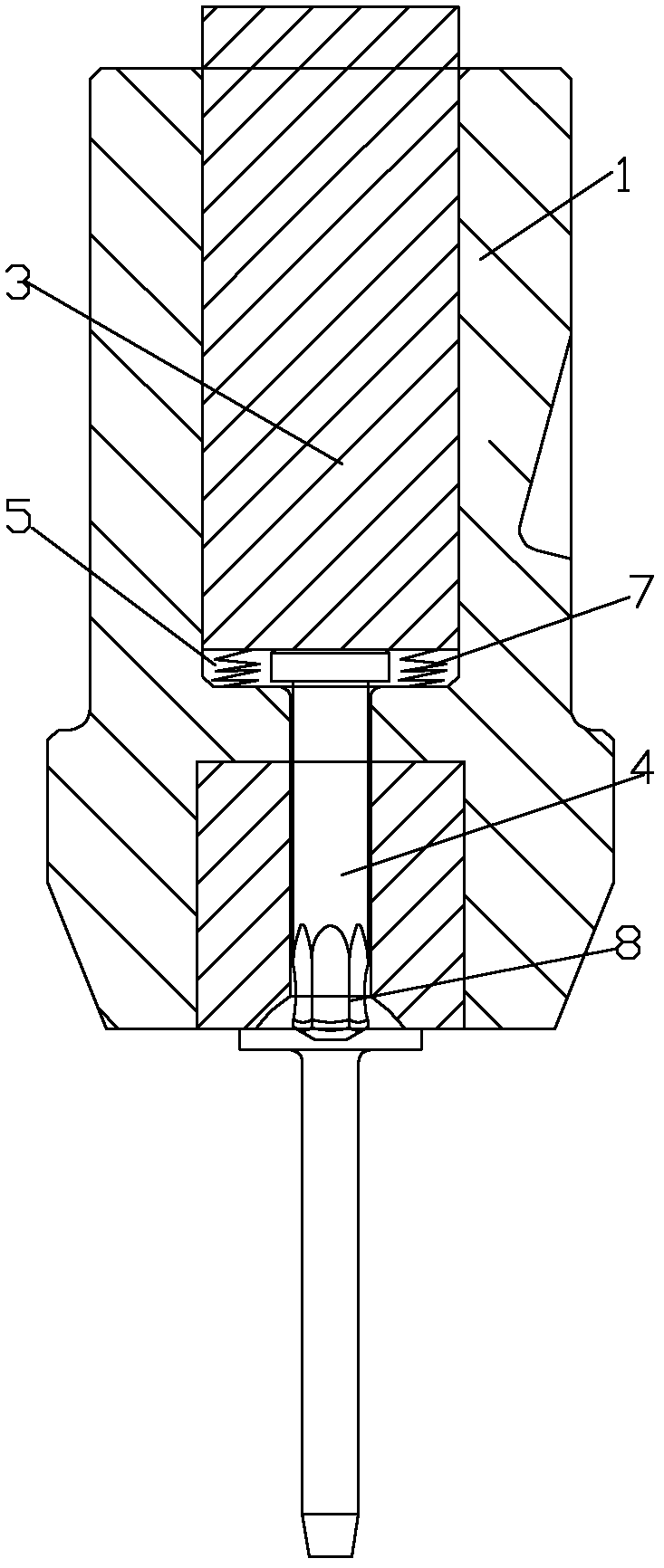

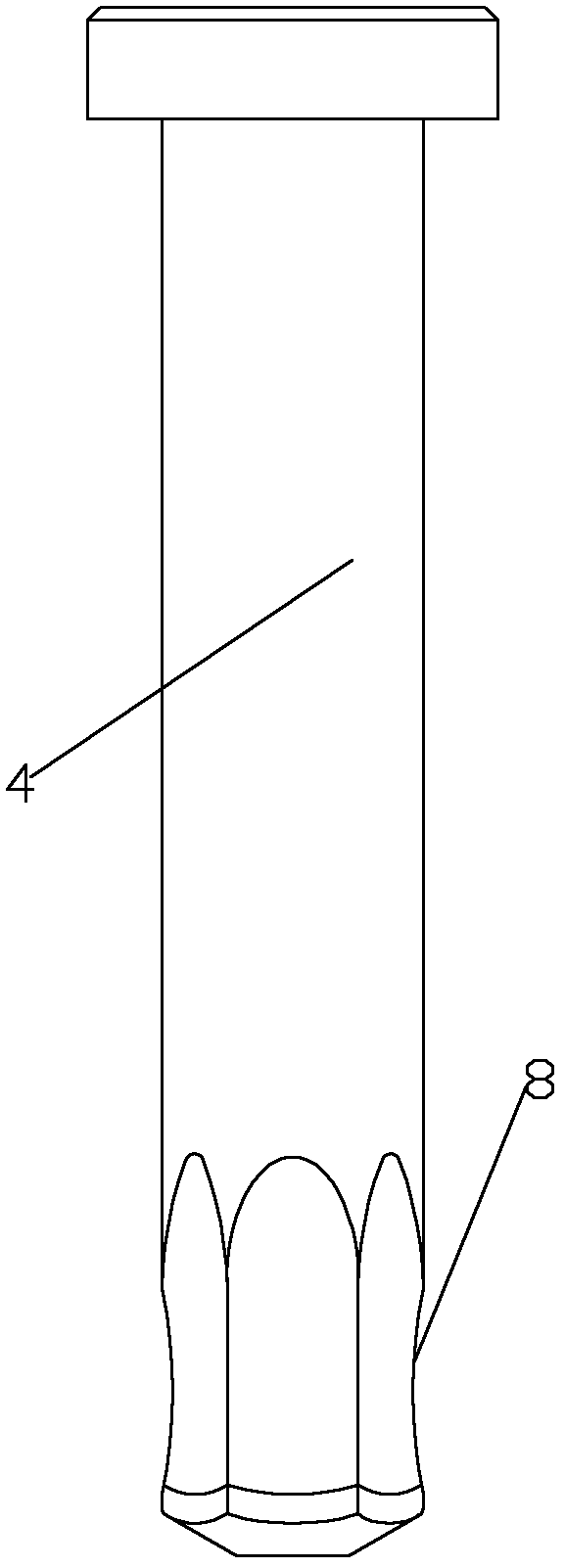

[0015] attached figure 1 , 2 , 3 is a screw hexagon socket punching die according to the present invention, including a punching die body 1, a die cavity 2 is provided in the die die body 1, and a punch that can slide up and down along the die cavity 2 is provided in the die cavity 2 3; the bottom of the punch 3 is coaxially provided with a punch 4; the outer diameter of the punch 3 is larger than the outer diameter of the punch 4; an elastic device 5 is provided in the mold cavity 2 and below the punch 3 . The elastic device 5 is composed of a connecting plate and a spring 7 arranged at the bottom of the connecting plate 6; the elastic device 5 has two groups, which are symmetrically arranged on both sides of the punching needle 4; the head end of the punching needle 4 is provided with Six cutting edges 8.

[0016] The above-mentioned embodiments are only to illustrate the technica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap