Locking mechanism of lifting appliance for metro segments

A subway segment and locking mechanism technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as increased repair costs, segment drop, increased labor intensity of workers, etc., to reduce maintenance costs and improve appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

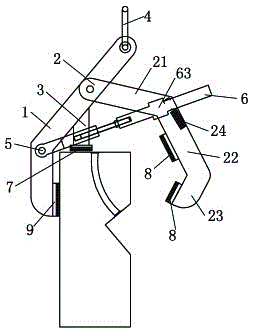

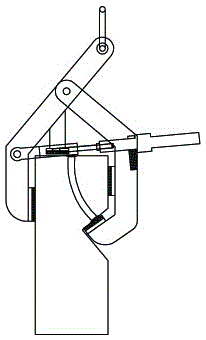

[0012] Combine below Figure 1 to Figure 3 Specific description embodiment:

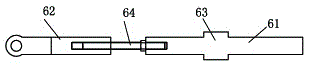

[0013] Such as Figure 1 to Figure 3 As shown, the herringbone spreader for the subway segment, the herringbone spreader for the subway segment comprises a fixed arm 1 and a movable arm 2, and the fixed arm 1 and the movable arm 2 are arranged in a herringbone shape; the fixed arm The lower part of the side of 1 is provided with a support frame 3, one end of the fixed arm 1 is connected with a suspension ring 4, and the other end of the fixed arm 1 is articulated with a locking device 6 through a pin shaft 5, and the locking device 6 includes The locking arm 61 and the adjusting nut 62, the locking arm 61 is provided with a block 63, and the locking arm 61 and the adjusting nut 62 are connected by an adjusting screw 64; the fixed arm 1 is hingedly connected with the movable arm 2, The movable arm 2 includes a connecting plate 21, a locking plate 22 and a hook head 23. The connecting plate 21, the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap