A kind of liquid battery and preparation method thereof

A liquid battery and liquid technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of lower battery production efficiency, complicated battery formation process, long formation time, etc., to shorten the formation time, suppress interfacial tension, improve Infiltrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

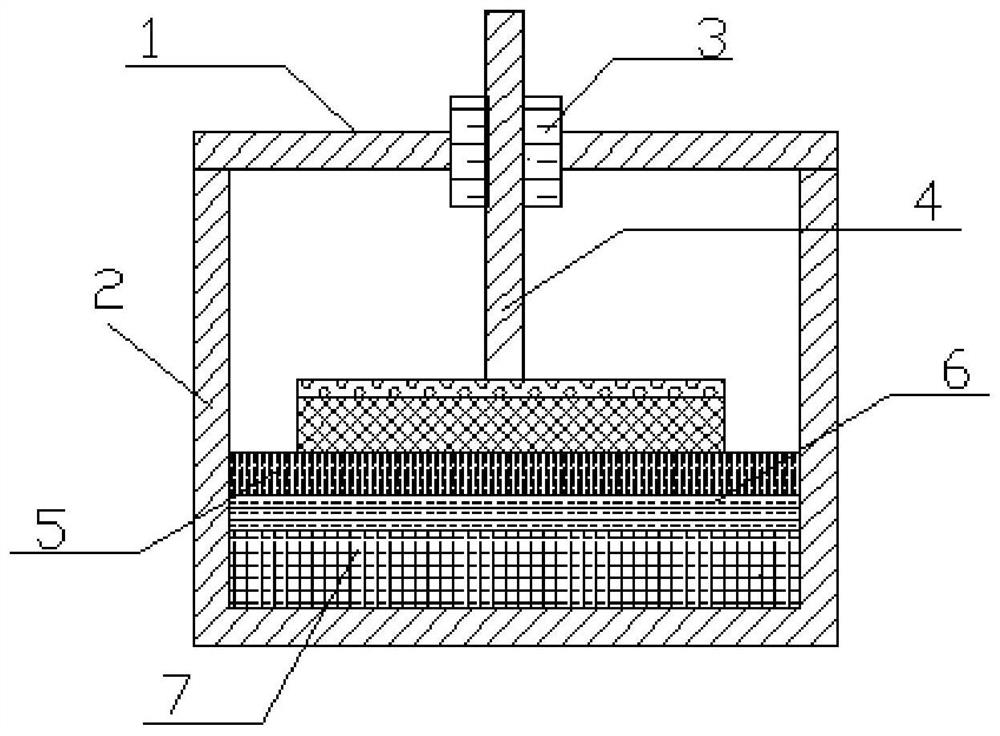

Image

Examples

Embodiment 1

[0047] This embodiment provides a kind of Li-Pb liquid metal battery, positive electrode material is Pb (180g), negative electrode material Li (2.6g), electrolyte material is the mixture (118g) of LiF, LiCl, LiBr of mass ratio 1:2:7 ), the transition material is zirconia (10.3g).

[0048]Step 1, making the positive electrode of the battery;

[0049] Mix 180g of battery positive electrode material Pb with a certain amount of the first electrolyte material and the first transition material zirconia to form a positive electrode mixture, heat the positive electrode mixture to a molten state, heat and stir for 15 minutes, then let it stand for 15 minutes, and then cool to room temperature;

[0050] Among them, 11.8g of the first electrolyte material in the positive electrode mixture is used in an amount of 10% of the rated amount of the battery electrolyte material; 9.6g of the first transition material zirconia is used in an amount of 5% of the sum of Pb and the first electrolyte ...

Embodiment 2

[0064] This embodiment provides a kind of Li-Pb / Sb liquid metal battery, positive electrode material Pb / Sb alloy (290g), negative electrode material Li (13g), electrolyte material is LiF, LiCl, LiBr of mass ratio 1:2:7 Mixture (326g), transition material gallium nitride alloy (40.1g).

[0065] Step 1, making the positive electrode of the battery;

[0066] Mix 290g of Pb / Sb alloy, the positive electrode material of the battery, with a certain amount of the first electrolyte material and the first transition material gallium nitride to form a positive electrode mixture, heat the positive electrode mixture to a molten state, heat and stir for 20 minutes, then let it stand for 20 minutes, and then cool to room temperature ;

[0067] Among them, the first electrolyte material in the positive electrode mixture is 48.9g, and the dosage is 15% of the rated dosage of the battery electrolyte material; the first transition material gallium nitride is 33.9g, and the dosage is the sum of ...

Embodiment 3

[0080] This embodiment provides a kind of Li-Sn / Sb liquid metal battery, positive electrode material Sn / Sb alloy (170g), negative electrode material Li (12g), electrolyte material is LiF, LiCl, LiBr of mass ratio 1:2:7 Mixture (mass ratio 1:2:7) (150g), transition material alumina (30g), boron nitride (6.3g).

[0081] Step 1, making the positive electrode of the battery;

[0082] Mix 170g of the positive electrode material Sn / Sb alloy of the battery with a certain amount of the first electrolyte material and the first transition material alumina to form a positive electrode mixture, heat the positive electrode mixture to a molten state, heat and stir for 25 minutes, then let it stand for 25 minutes, and then cool to room temperature;

[0083] Wherein, the first electrolyte material in the positive electrode mixture is 30g, and the dosage is 20% of the rated dosage of the battery electrolyte material; the first transition material alumina is 30g, and the dosage is 15% of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com