Straightener with digital displays

A digital display and straightening machine technology, applied in the field of straightening machines, can solve the problems of low working precision, troublesome adjustment, inconvenient operation, etc., and achieve the effect of improving work efficiency, simple and ingenious structure, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

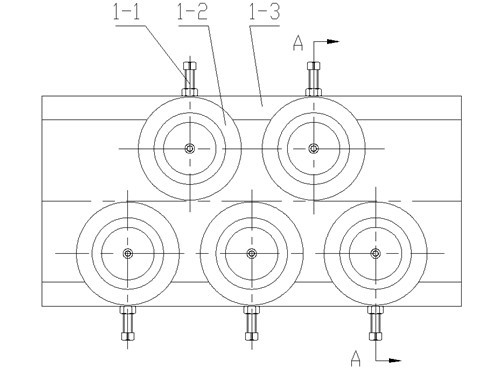

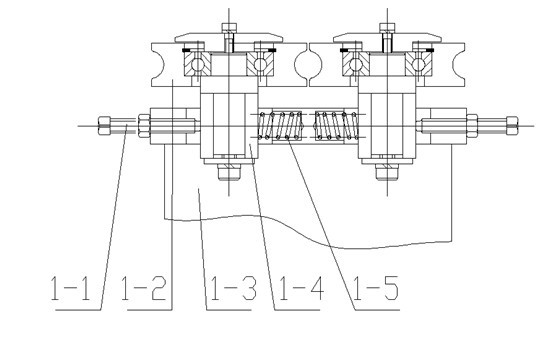

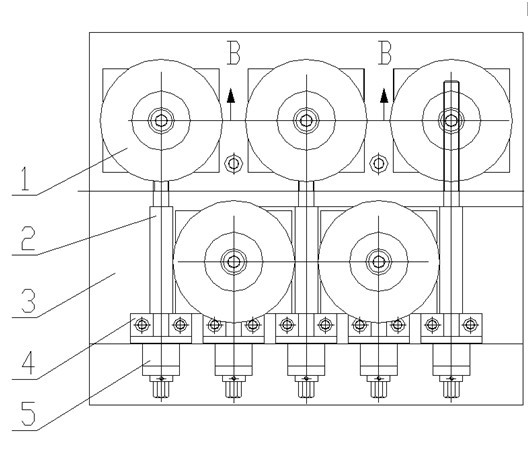

[0018] Such as figure 2 with image 3 As shown, the present invention provides a kind of straightening machine with digital display, comprising support 3, two rows of sliding seats 9 and two rows of straightening wheels 1 installed on the sliding seats, guide rail 8 is installed on the said support, through The sliding seat is installed on the guide rail. Each straightening wheel is fastened on the sliding seat by the fixing bolt 6 through the gland 7. An adjusting bolt 2 is arranged on the sliding seat below each straightening wheel. One end of each adjusting bolt passes through the support Seat 4 is fixed with a digital display 5.

[0019] The working principle of the present invention is: the straightening wheel is fastened on the sliding seat through the gland, and the distance between the two rows of sliding seats is adjusted by adjusting the depth of the bolt screwed into the sliding seat, thereby realizing the adjustment of the distance between the two rows of straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com