Method for monitoring on-line quality and updating prediction model of rubber hardness

A prediction model and quality monitoring technology, applied in the field of rubber tire manufacturing, can solve the problems that the time-varying characteristic system of the intermittent process cannot carry out effective online monitoring, cannot automatically update the model in real time, and affects the accuracy of rubber hardness prediction, etc., to achieve The effect of reducing computer storage, reducing potential safety hazards, and reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

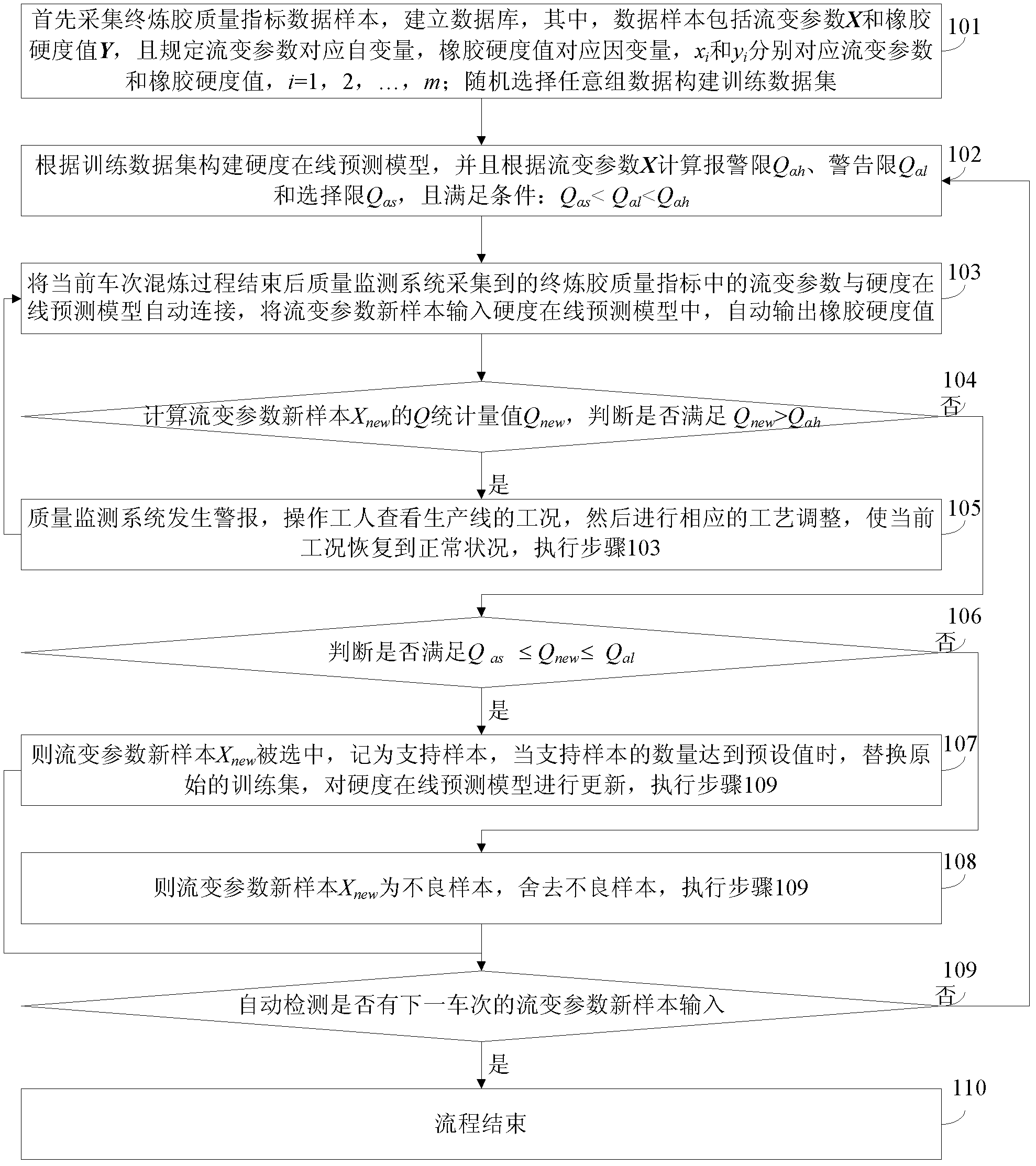

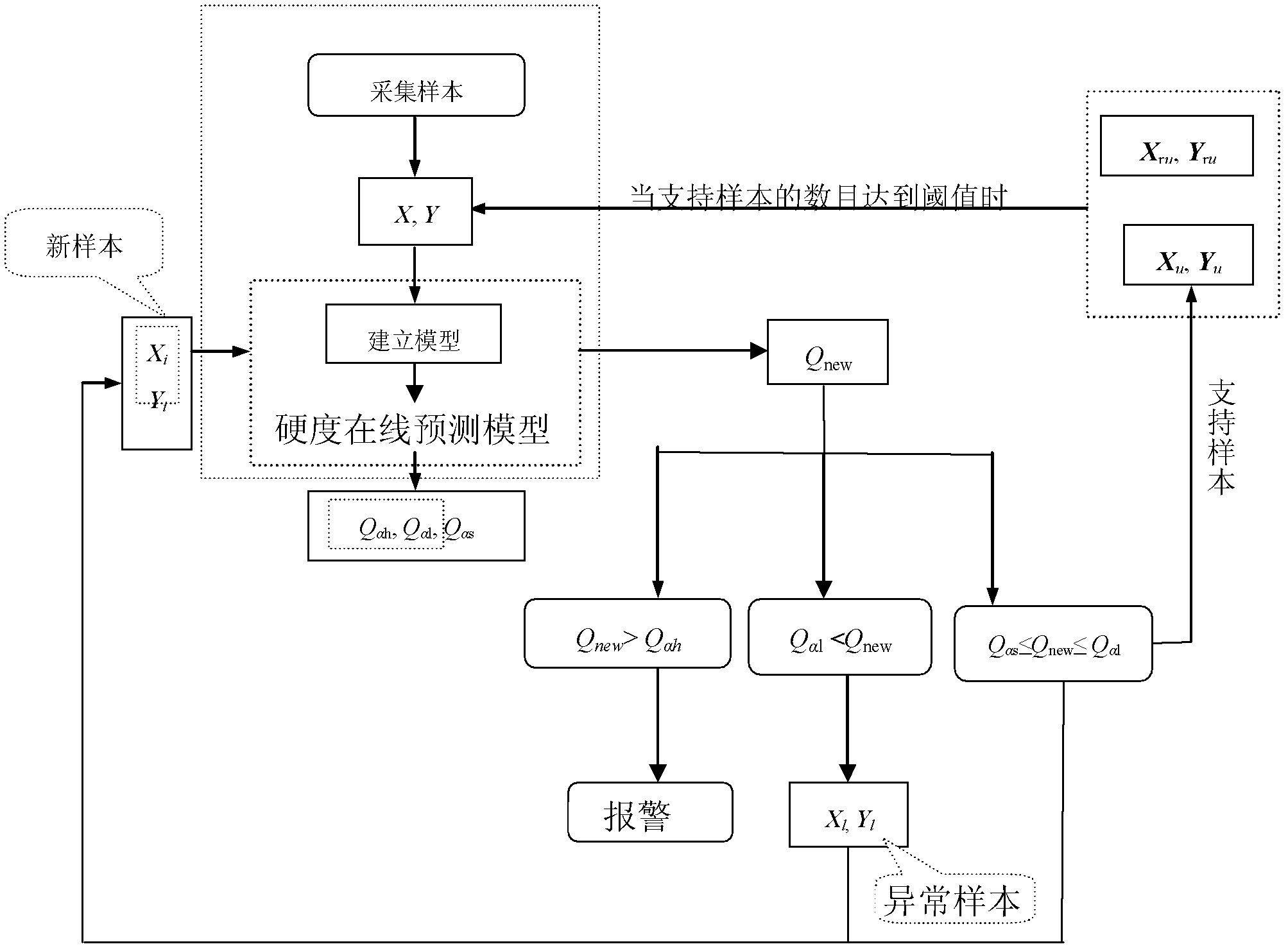

[0042] In order to solve the quality monitoring problem of rubber time-varying intermittent industrial process, realize the effective monitoring of rubber production process, improve the quality and life of rubber, and reduce the measurement error of rubber hardness, the embodiment of the present invention provides an online quality monitoring of rubber hardness and methods for predictive model updates, see figure 1 and figure 2 , see the description below:

[0043] Kernel Partial Least Squares (KPLS) is a non-linear extension of Partial Least Squares (PLS). The kernel method is to project the original data into a high-dimensional space (Hilbert space), usually called a feature space, and the nonlinear problem in the original space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com