Online automatic measuring method for rubber hardness

An automatic measurement and hardness technology, applied in the field of rubber tire manufacturing, can solve problems such as random errors, affecting product quality, and different parts, achieving high precision, reducing safety hazards, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

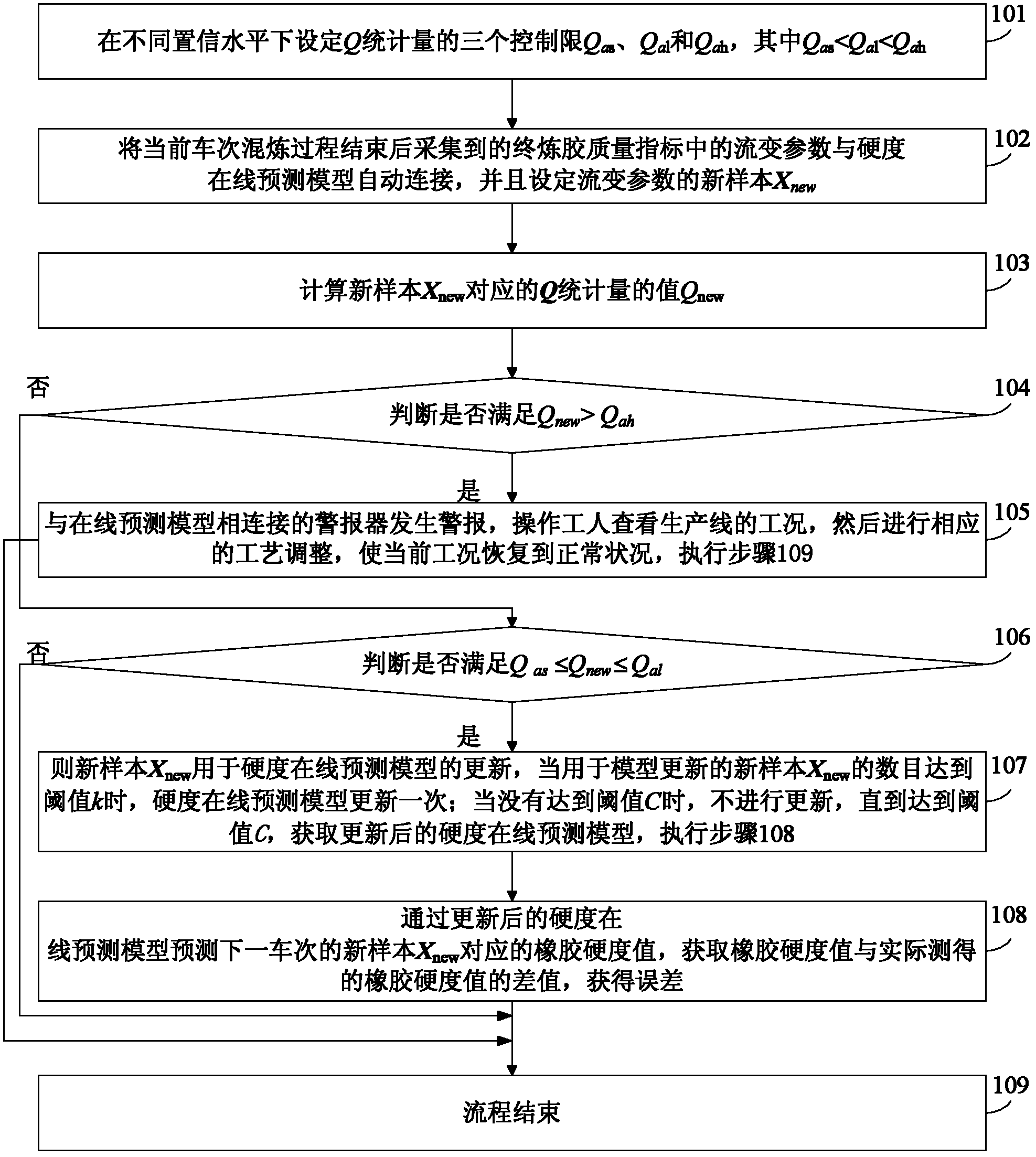

[0032] In order to improve production efficiency and product quality, and realize online automatic measurement, the embodiment of the present invention provides an online automatic measurement method for rubber hardness, see figure 1 , see the description below:

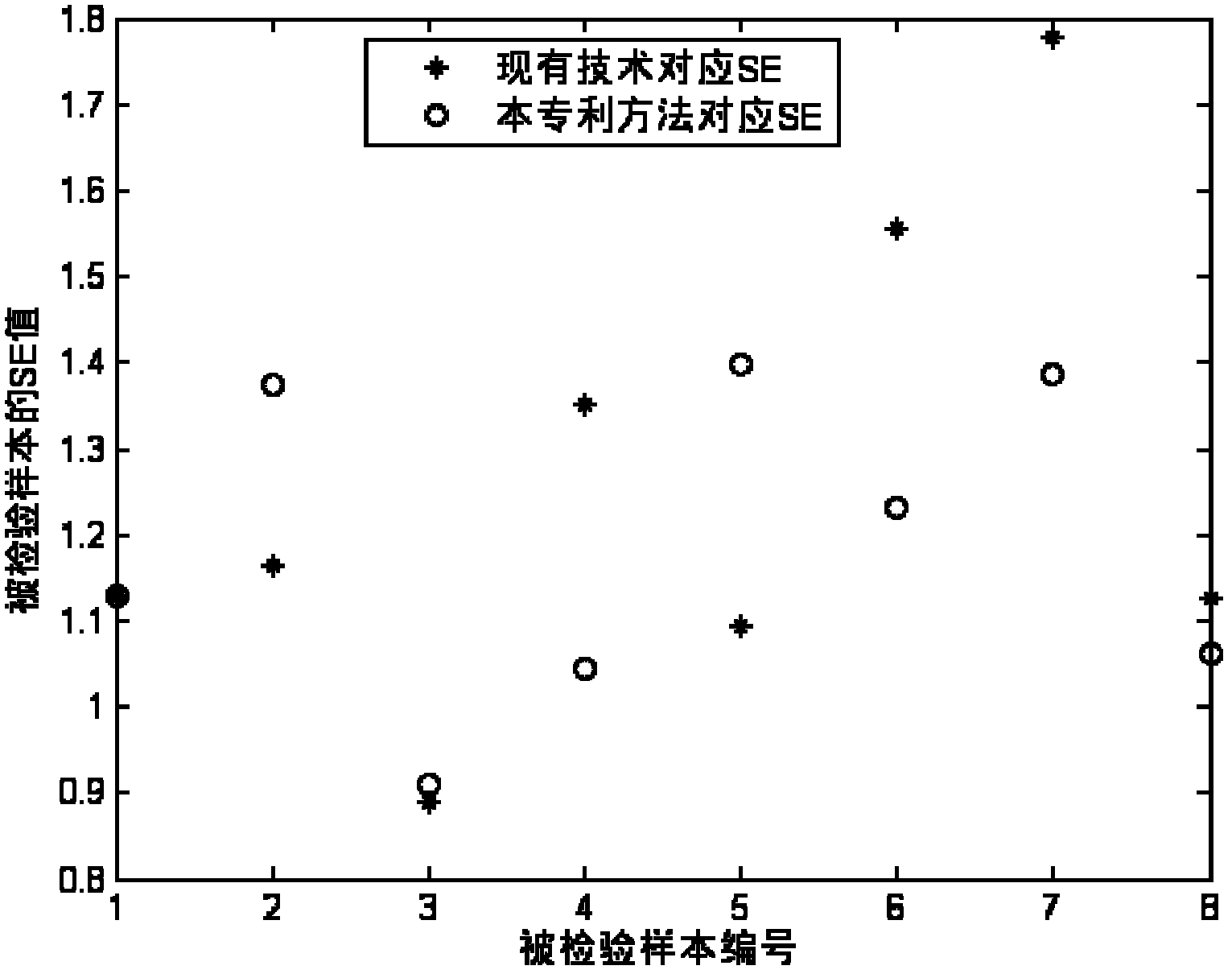

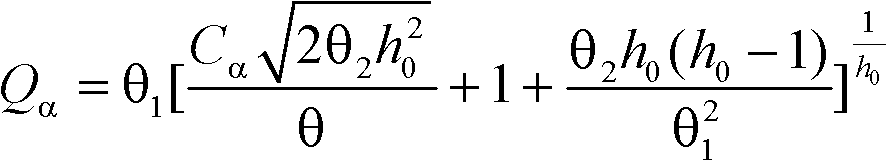

[0033] Rheological parameters of rubber quality indicators (mainly including minimum torque ML, maximum torque MH and vulcanization time parameters TC30, TC60 and TC90) are parameters that must be measured for each vehicle of rubber after mixing, and each measurement only needs 2 to 5 hours. Minutes, quick and easy detection. Considering the similarity in the working principles of Shore hardness testers and rheometers, and the strong correlation between rheological parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com