Mining elevator lapping platform suitable for flexible guide rail and mining elevator lapping method

A flexible guide rail and platform technology, which is applied to elevators in buildings, lifting equipment in mines, elevators, etc., can solve the problem of unsuitable intermediate multi-level working face overlapping, unsuitable mine elevator overlapping, inclined or partial Protrusions and other problems, to achieve the effect of facilitating the entry and exit of goods and personnel in and out of the elevator, reducing initial investment costs, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

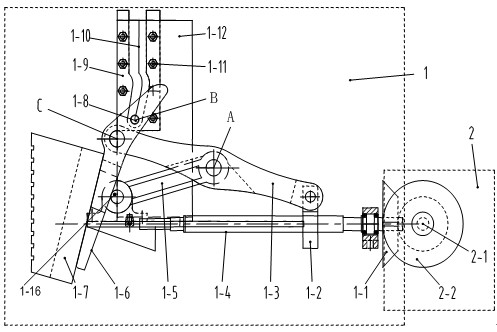

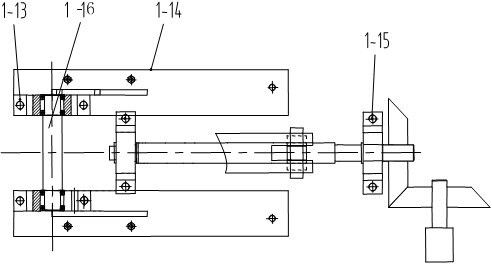

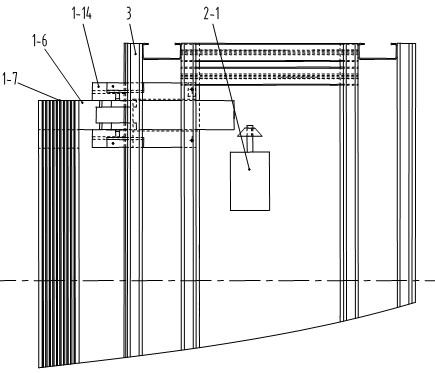

[0017] Below in conjunction with accompanying drawing, one embodiment of the present invention is further described:

[0018] like Figure 1~3 As shown in the figure, the present invention is suitable for a mining elevator lap platform with flexible guide rails, and is mainly composed of a claw group 1 and a power group 2. The claw group 1 and the power group 2 pass through the explosion-proof motor 2-1 shaft of the power group 2. The driving bevel gear 2-2 and the driven bevel gear 1-1 on the lead screw 1-4 of the push claw group 1 mesh with each other for transmission; the claw group 1 includes two installations symmetrically arranged on the cross beam 3 at the bottom of the car Plate 1-14, the left side between the two mounting plates 1-14 is provided with a supporting rod shaft 1-16 fixed by the mounting seat 1-13, and the middle of the two mounting plates 1-14 is provided with the supporting rod shaft 1-16 The lead screw bearing seat 1-15 with the vertical space position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com