Patents

Literature

40results about How to "Reduce initial investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for optimizing the capacity configuration of a combined cooling, heating and power system considering a translatable load

ActiveCN109242350AImprove absorption capacityReduce initial investment costsHeat storage plantsEnergy efficient heating/coolingSystem capacityCogeneration

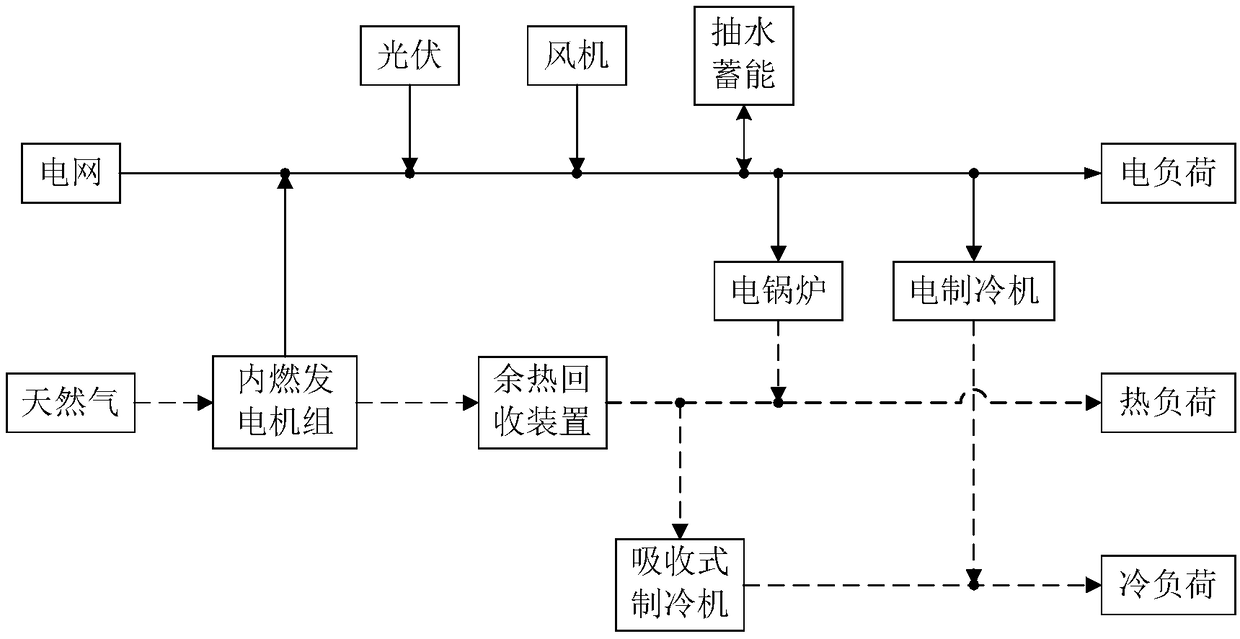

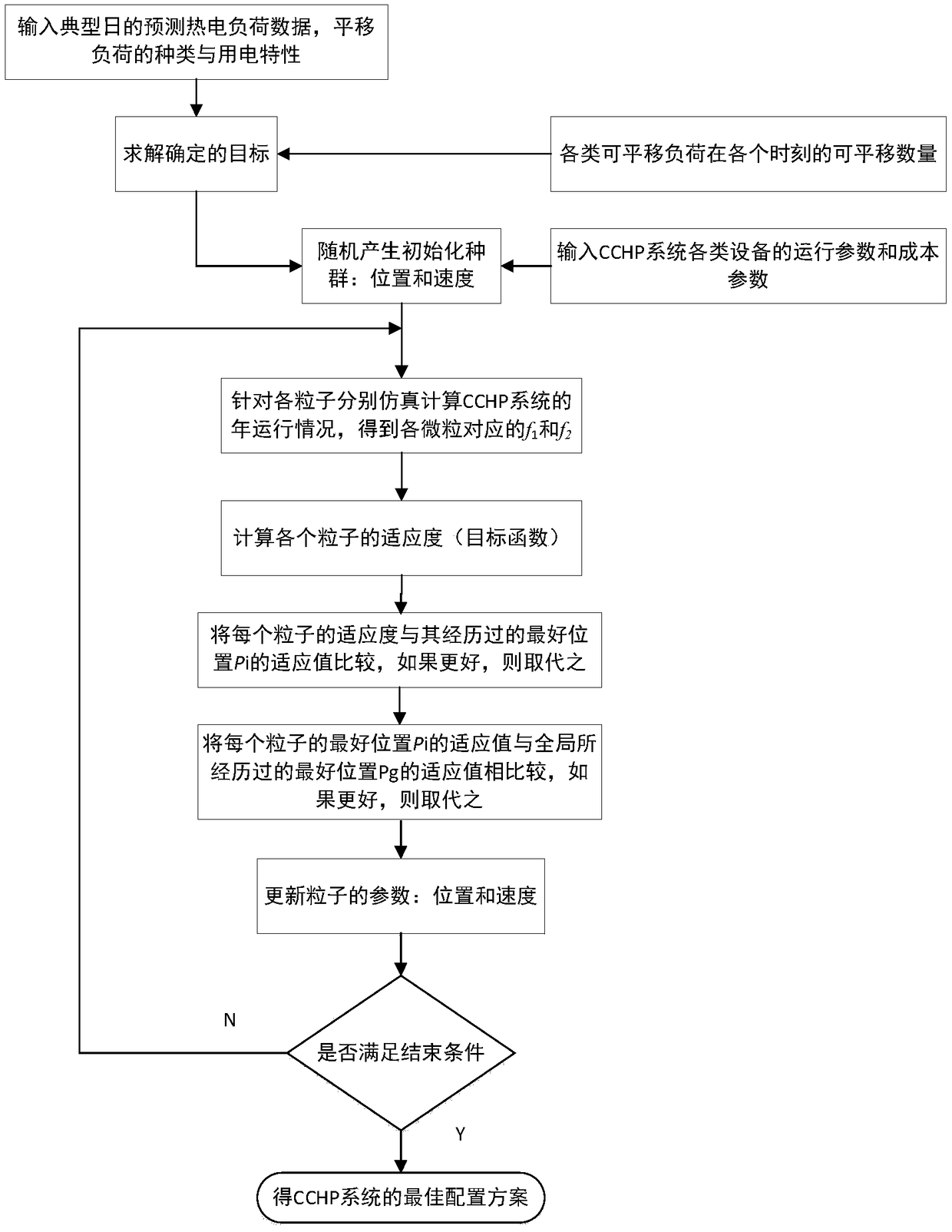

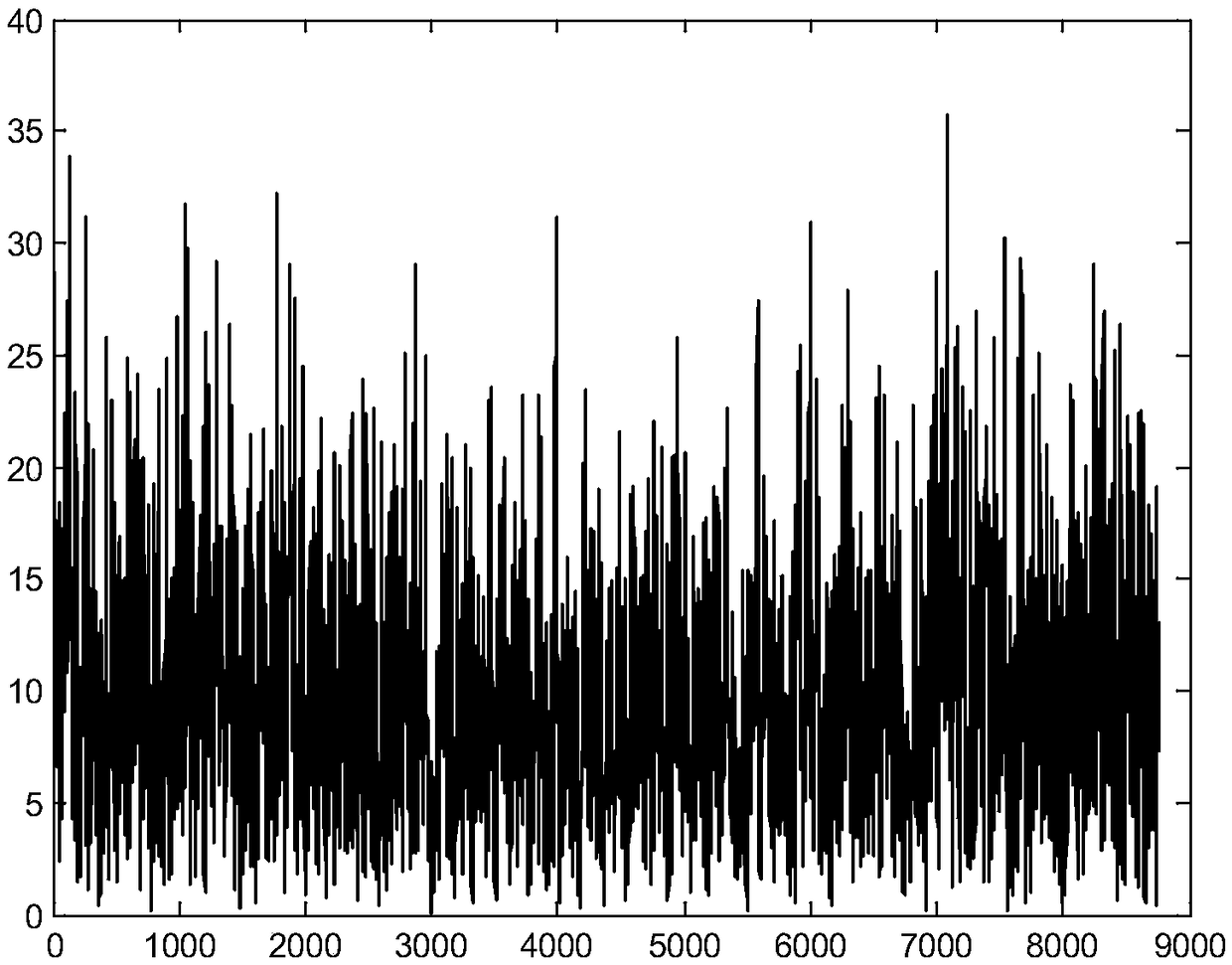

The invention discloses a method for optimizing the capacity configuration of a combined cooling, heating and power system considering a translatable load, which relates to the field of micro-grid design and planning. The invention adopts the pumped storage energy as the energy storage device of the system, and optimizes the capacity allocation method of the cogeneration system considering the energy management of the load side. Firstly, according to the translatable characteristics of the thermoelectric load, the energy management model of the user side is established, which takes into account the matching degree of the output of the distributed generation and the power demand of the user side, and the matching degree of the thermoelectric ratio of the energy supply side and the user side. A comprehensive index model of combined cooling, heating and power system considering economy and environmental protection is proposed, and the capacity of each equipment is optimized by particle swarm optimization algorithm. The simulation results show that the combined cooling, heating and power system can cut the peak and fill the valley of the distributed power output and reduce the comprehensive cost of the system after the load shifting and the introduction of pumped storage device, and the effectiveness of the model is verified.

Owner:榆林电力投资有限责任公司

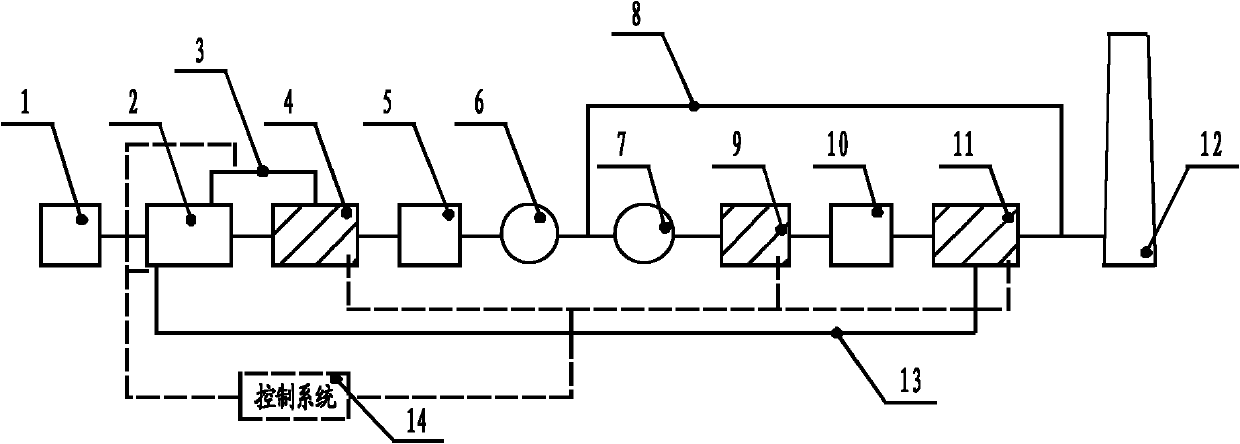

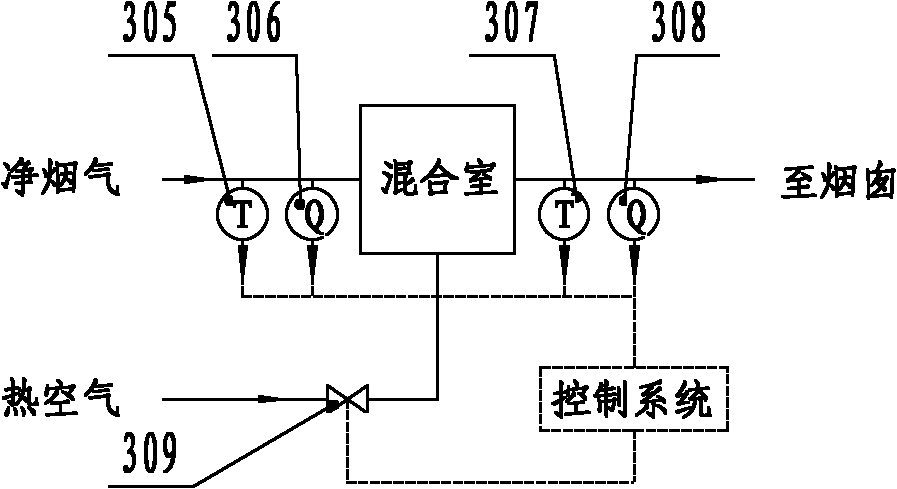

Energy and water saving desulphuration integrated system for power plant

InactiveCN101995028ARaise the outlet temperatureLow costCombustion processIndirect carbon-dioxide mitigationAir preheaterGas heater

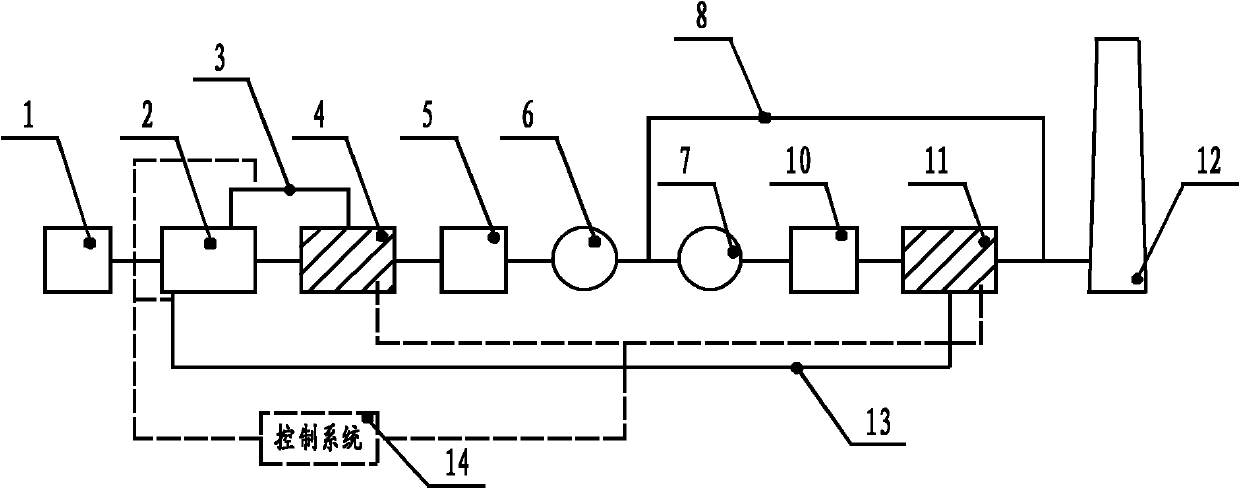

The invention discloses an energy and water saving desulphuration integrated system for a power plant in the technical field of heat transmission. The system comprises an I-level phase change heat exchanger, a mixing chamber and a control system, wherein the I-level phase change heat exchanger is arranged on the back of an air preheater arranged on a gas duct at the tail end of a boiler and then is connected with the mixing chamber through a pipeline, the mixing chamber is connected with the air outlet of the air preheater of a boiler system through a pipeline, and the I-level phase change heat exchanger and the mixing chamber are all connected with the control system through connecting wires; or an II-level phase change heat exchanger is arranged between the desulfurization fan and desulfurizing tower of the boiler system. In the invention, the phase change heat exchanger absorbs the energy of raw gas to heat clean air, and the heated clean air is mixed with the low-temperature clean gas after being further heated to a higher temperature by the air preheater, the gas outlet temperature of a chimney is increased, thus the problems of low temperature corrosion of the existing clean gas heater and invalid integral device caused by low temperature corrosion are avoided radically, the low temperature exhaust heat of the raw gas is used fully, the thermal efficiency of the integral electric generating system is improved, and meanwhile, the water resource is saved greatly.

Owner:杨本洛

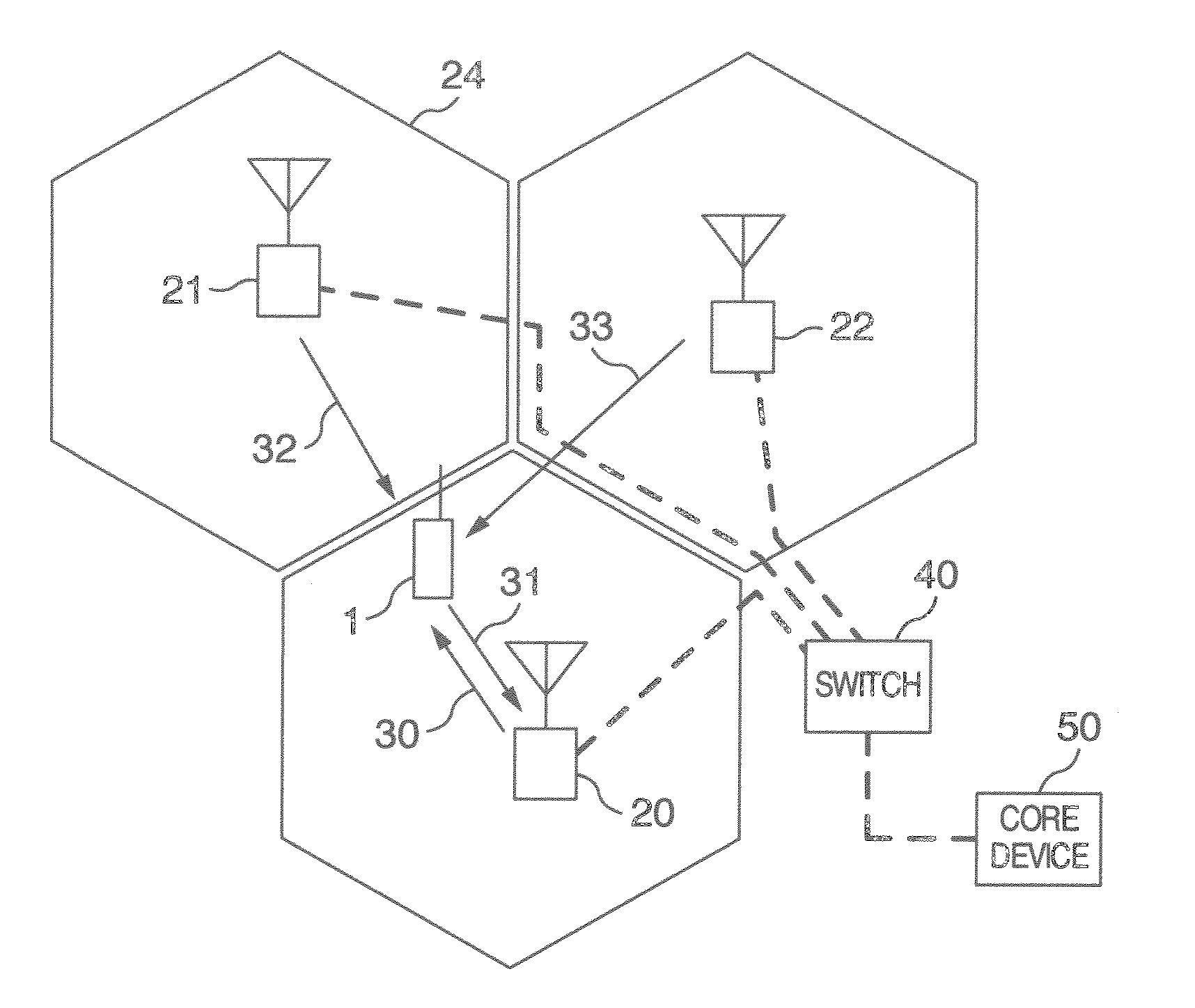

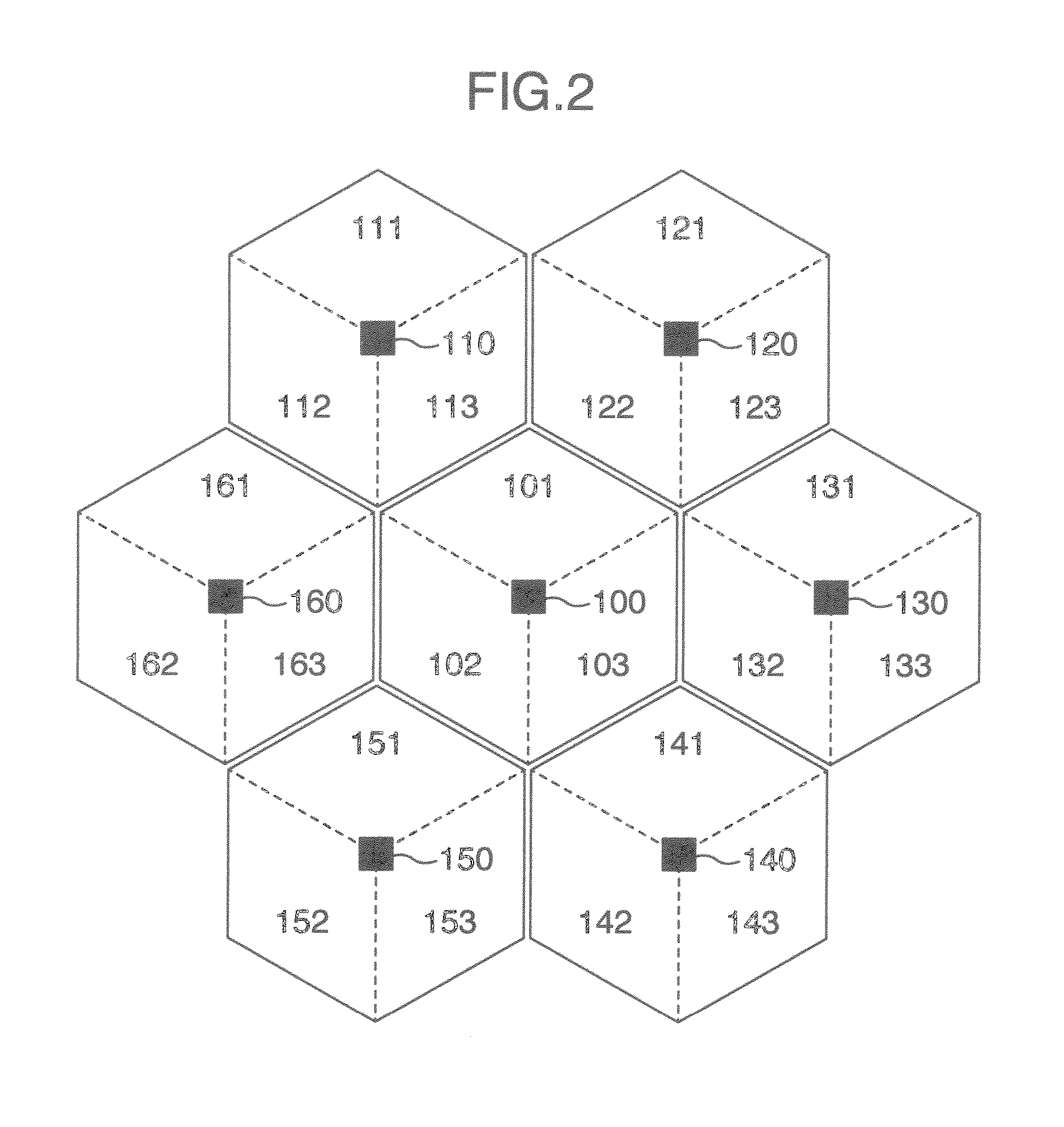

Wireless communication network, method of generating neighbor list in the wireless communication network, and control device therefor

InactiveUS20100322107A1Reduce initial investment costsSmoothly introducedData switching by path configurationSatellite radio beaconingWireless communication systemsControl equipment

In a wireless communication system, a base station control device has following two steps on the basis of latitude / longitude information obtained from a GPS, that is, a first step of recognizing, from the positional information obtained from the GPS, the fact that base stations in new and old systems are installed at the same location, and a second step of linking a neighbor list of the old system to a neighbor list of the new system with use of the result of the first step.

Owner:HITACHI LTD

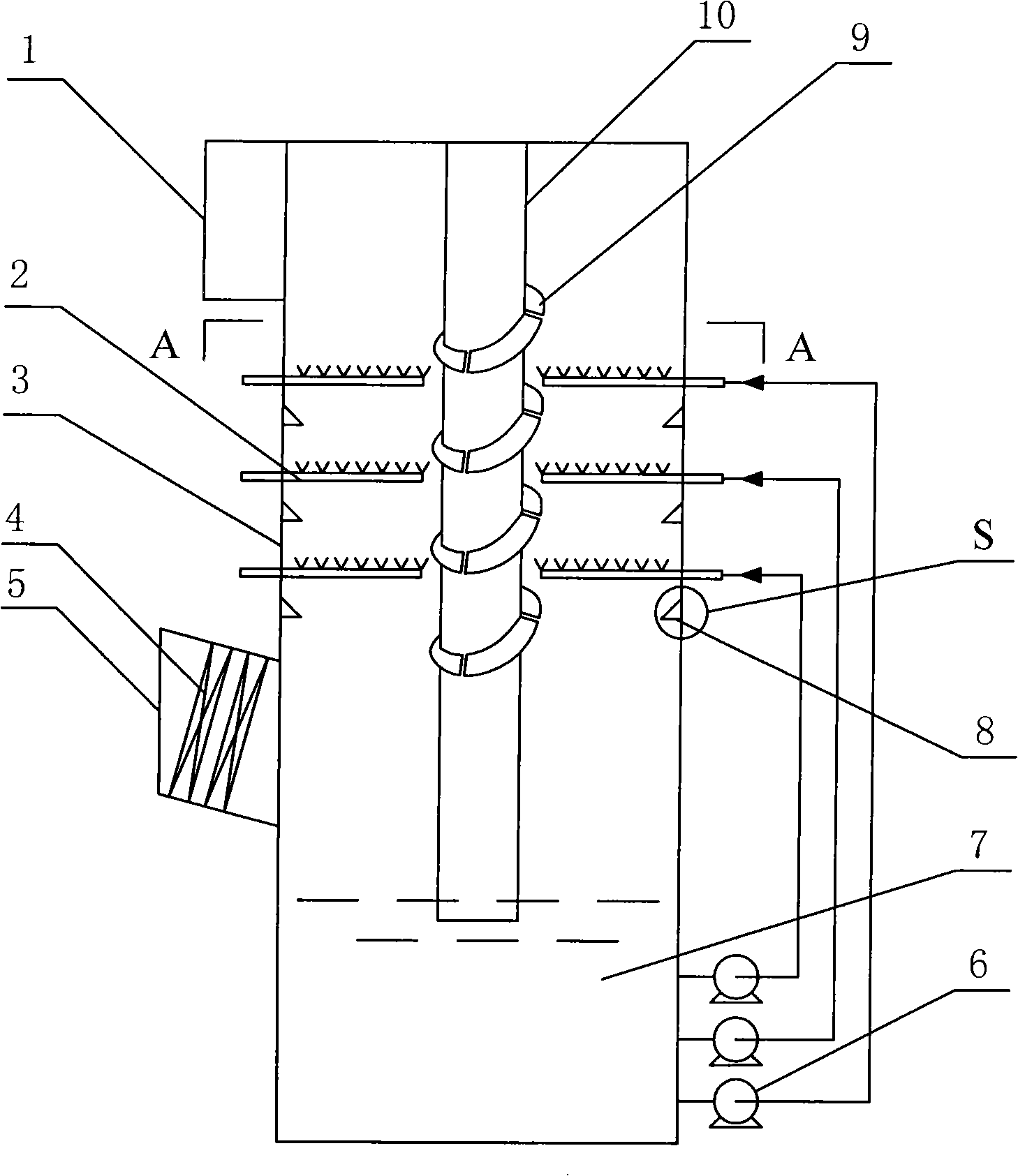

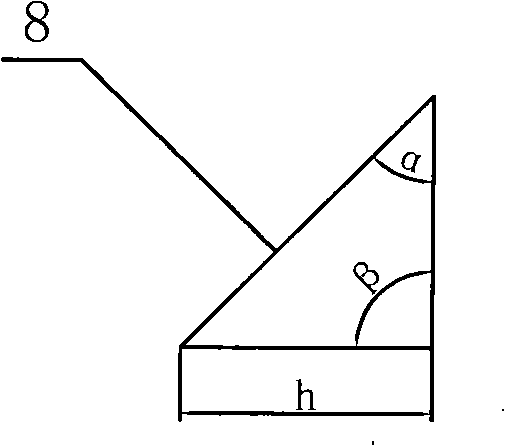

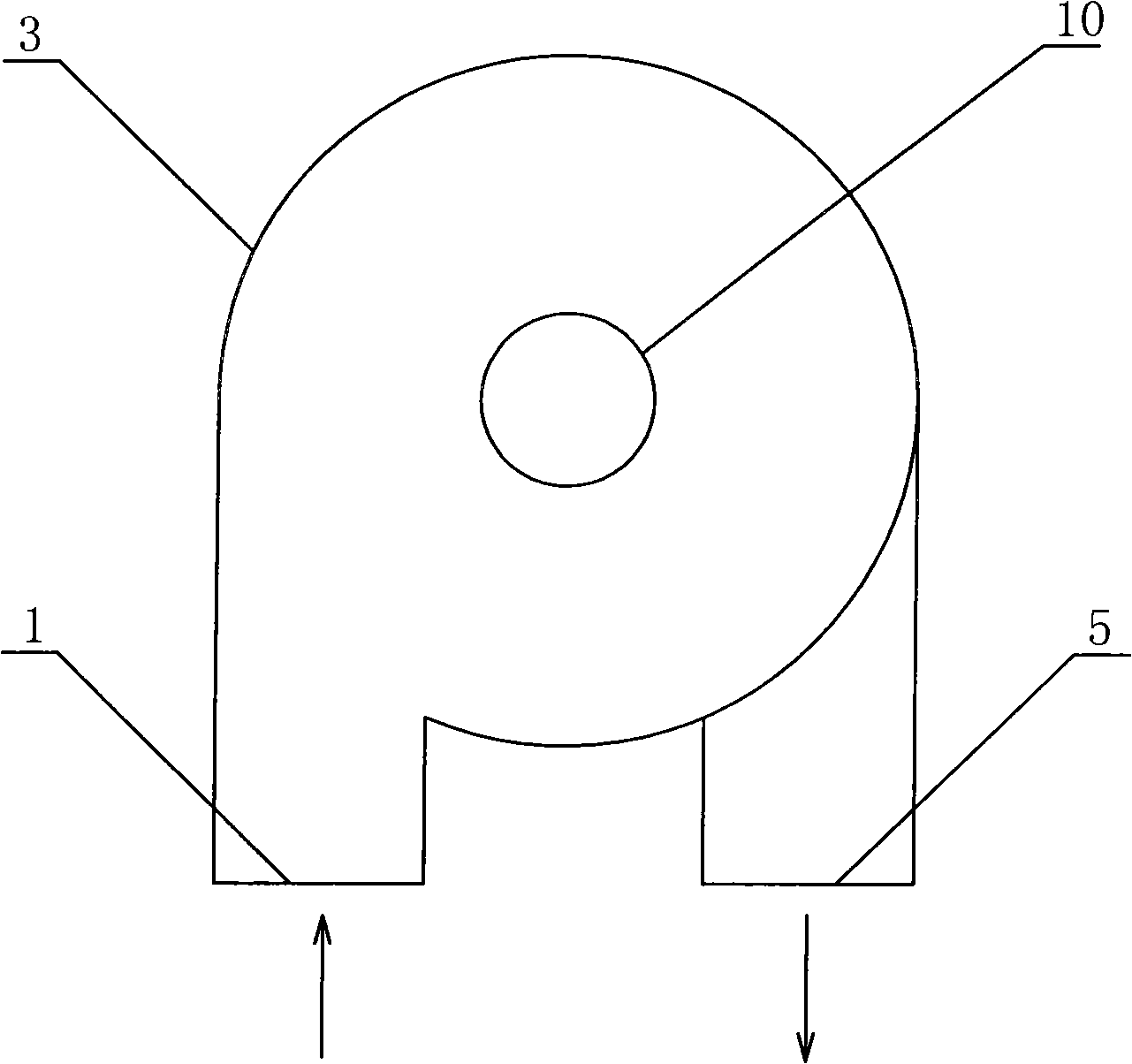

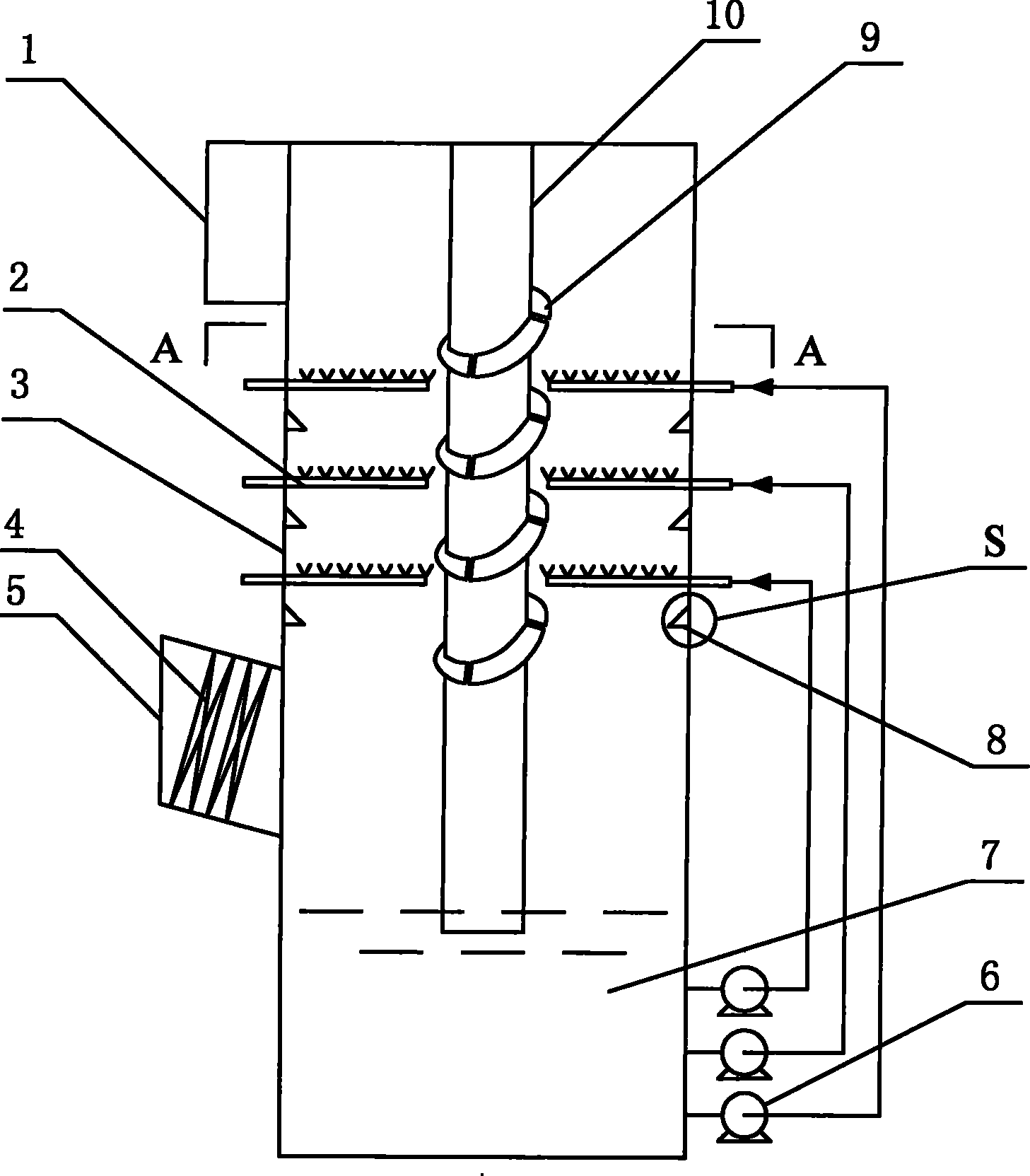

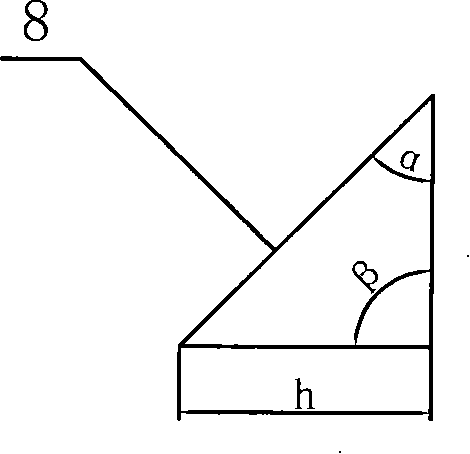

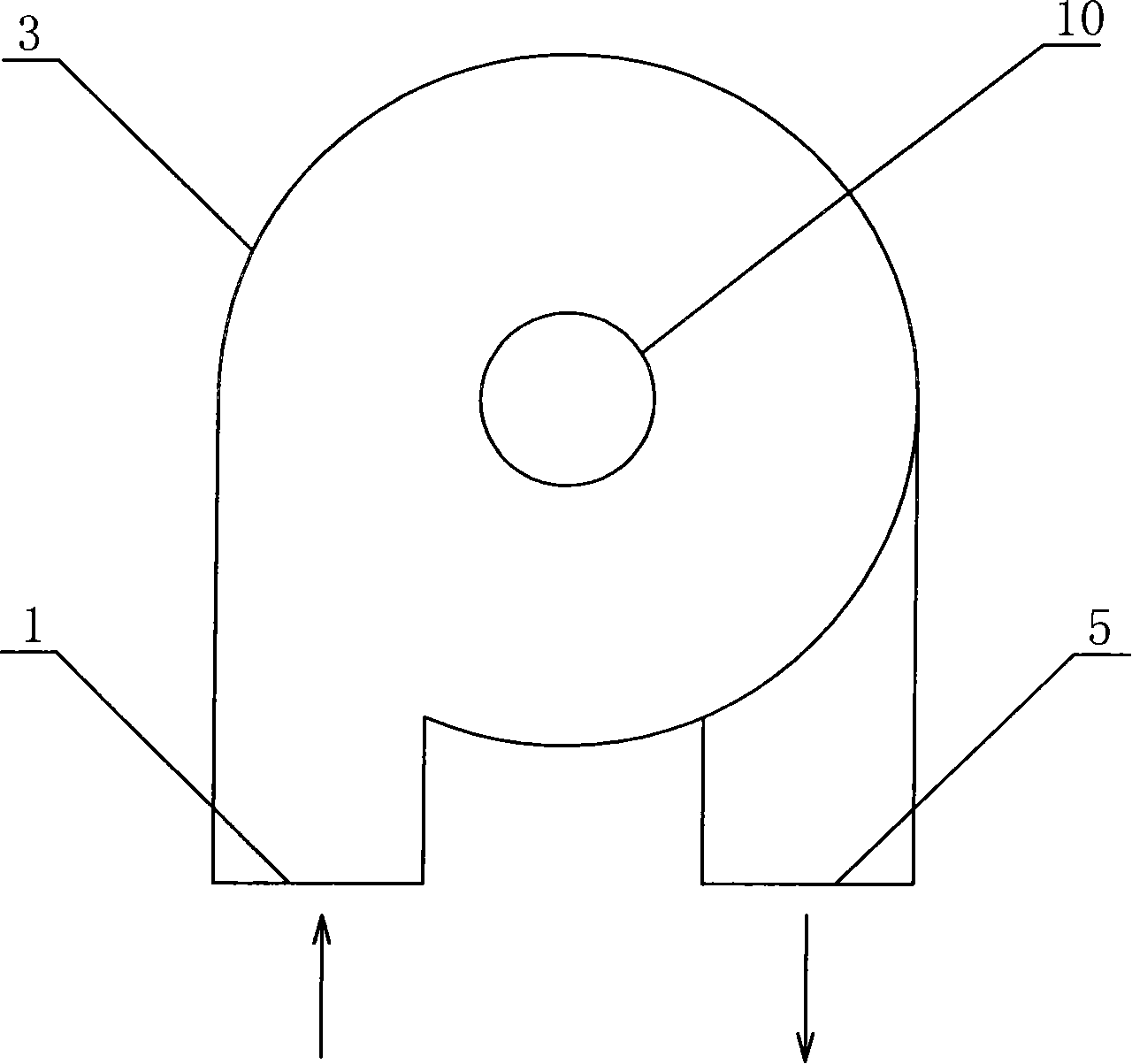

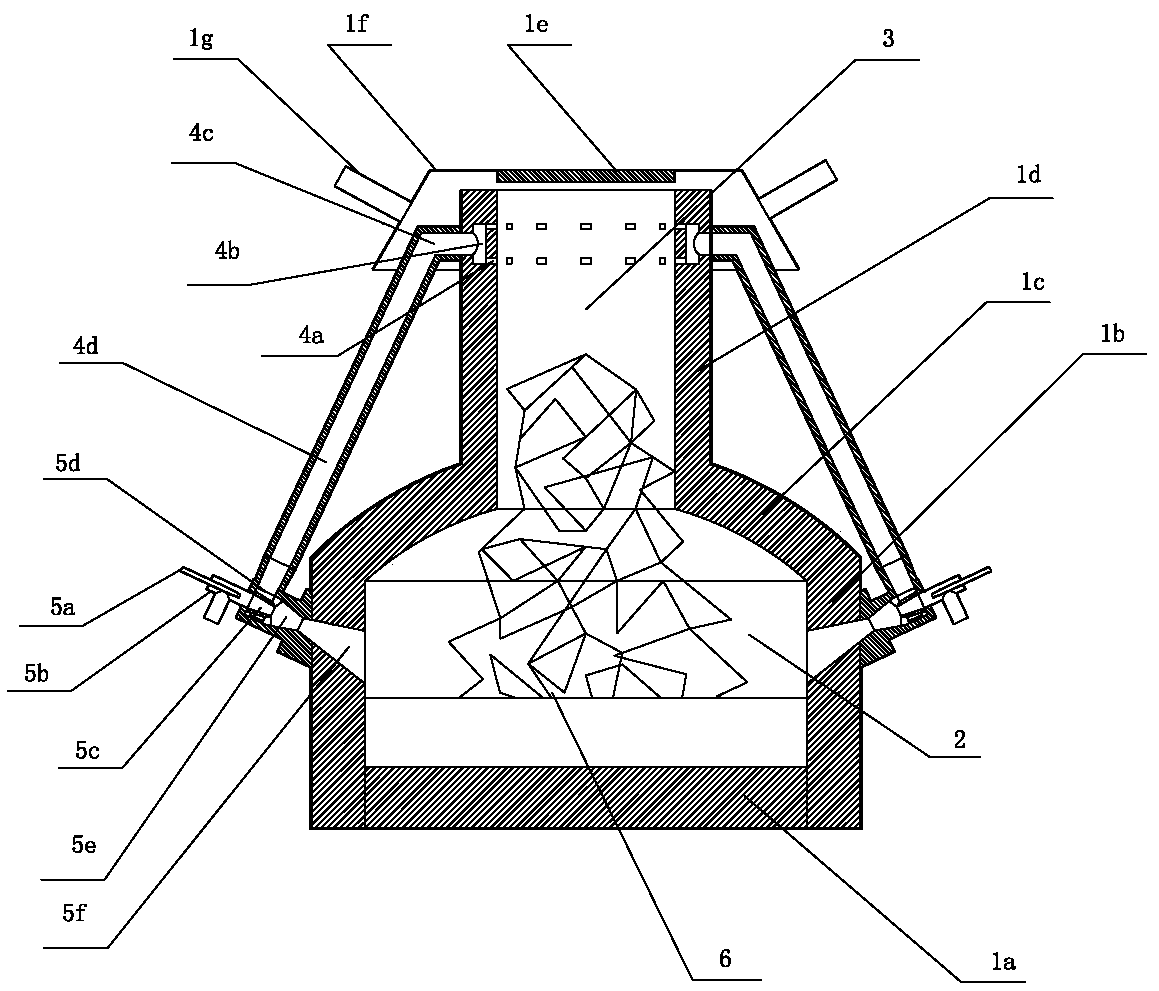

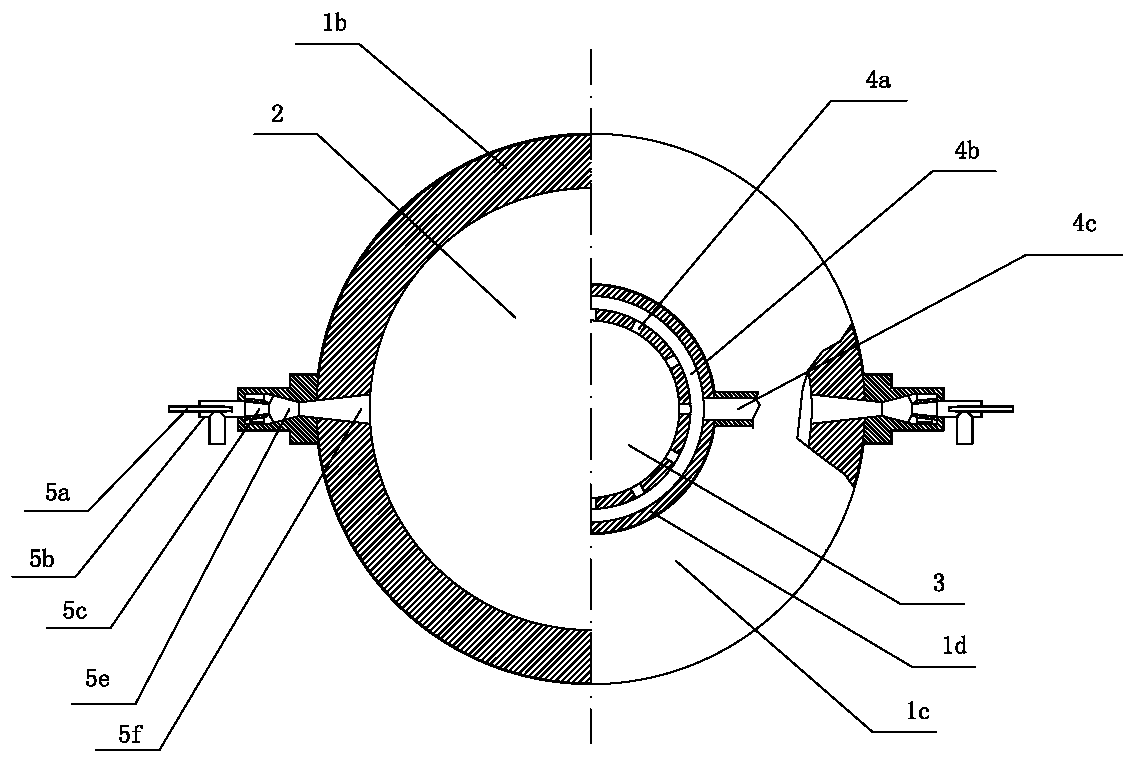

Helical airflow type wet method flue gas desulfurization process and spraying tower thereof

InactiveCN101279184ALow flow resistanceSimple processDispersed particle separationChemical reactionFlue gas

The invention provides a swirling air flow-type and wet flue gas desulfurization technique and a spraying tower thereof. The technique guides flue gases to enter tangentially from the upper part of a spraying tower shell; the flue gases swirl inside the spraying tower shell and leave tangentially from the lower part of the spraying tower shell; at the same time, limestone grout is sprayed upward and fog drips of the grout firstly touch the downward-swirling flue gas reverse flow, and then fall back owing to the effect of self-weight and drag force of the flue gas and then touch the forward flow of the flue gas, thus sulfur dioxide in the flue gases is absorbed owing to the quick chemical reaction with limestone grout fog drops. The spraying tower comprises a spraying tower shell; the spraying tower shell is provided with tangentially arranged flue gas inlet and outlet channels; a spraying device for spraying absorbing agents upwards is arranged between the flue gas inlet and outlet channels; a central tank is arranged in the center of the spraying tower shell; a flue gas guide plate showing a spiral descent structure is arranged on the central tank; a defroster is arranged in the flue gas inlet and outlet channels of the spraying tower shell. The desulfurization efficiency thereof is high, investment is small, and operation is safe and reliable.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

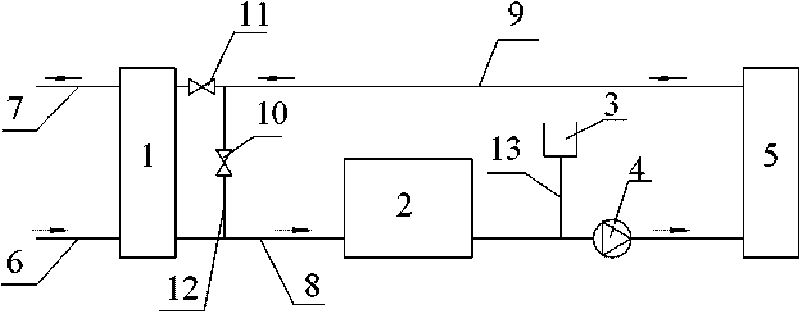

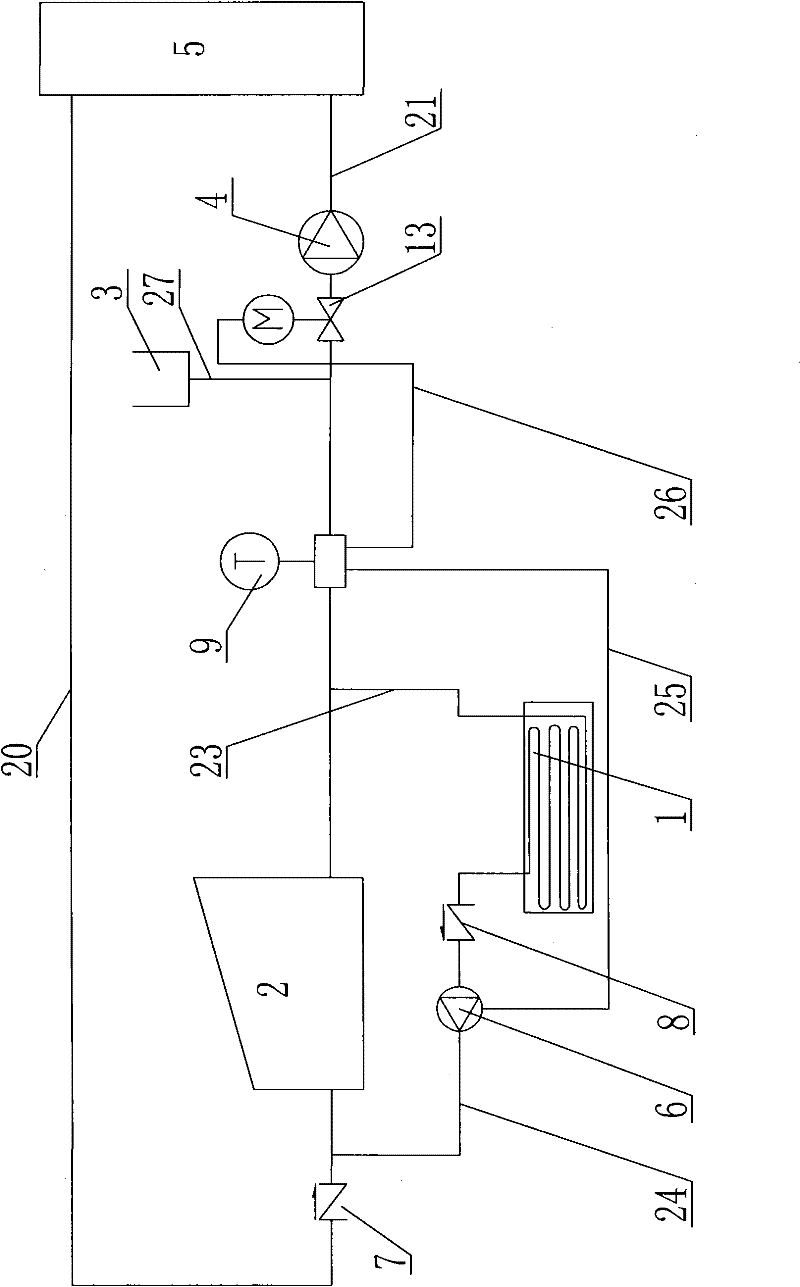

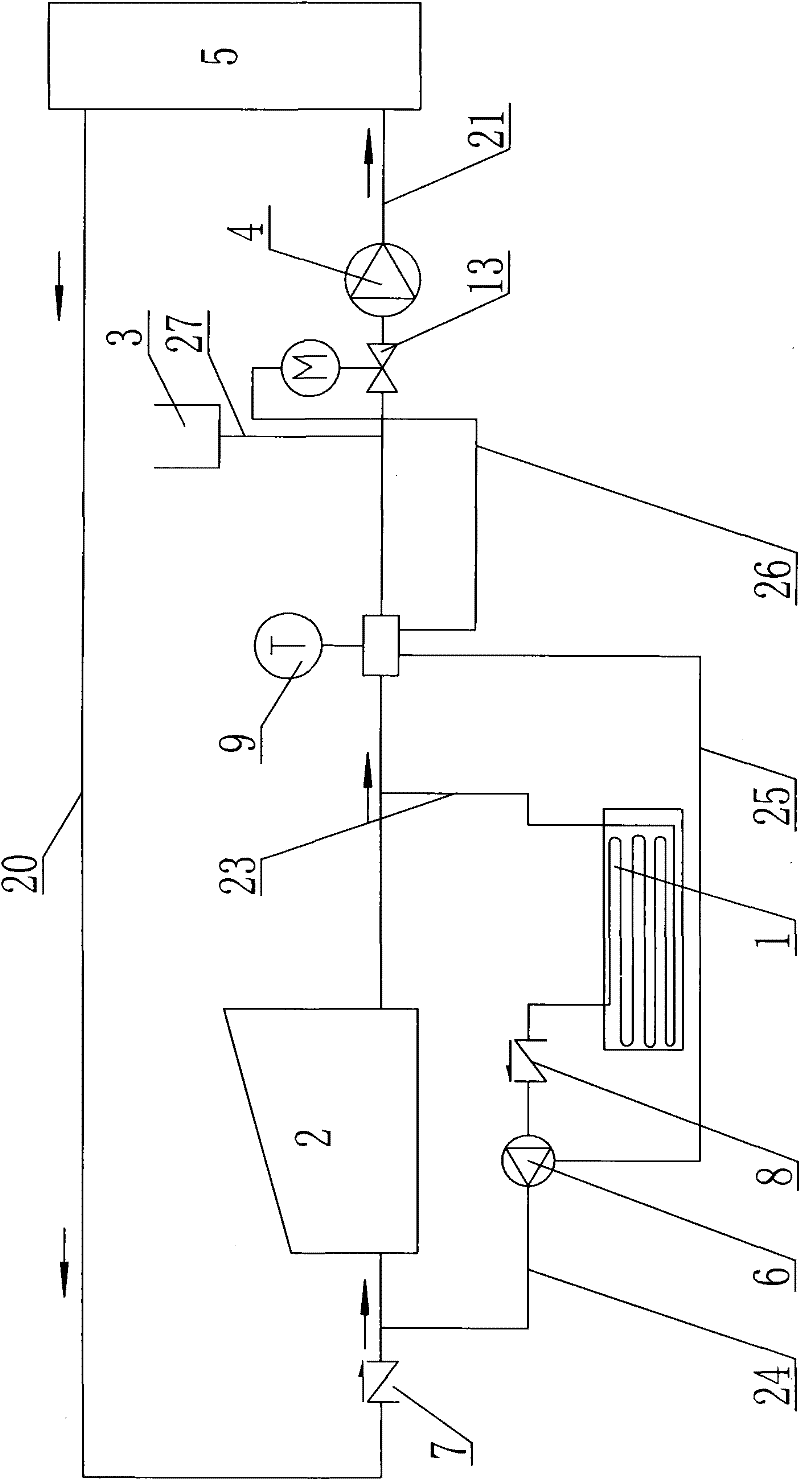

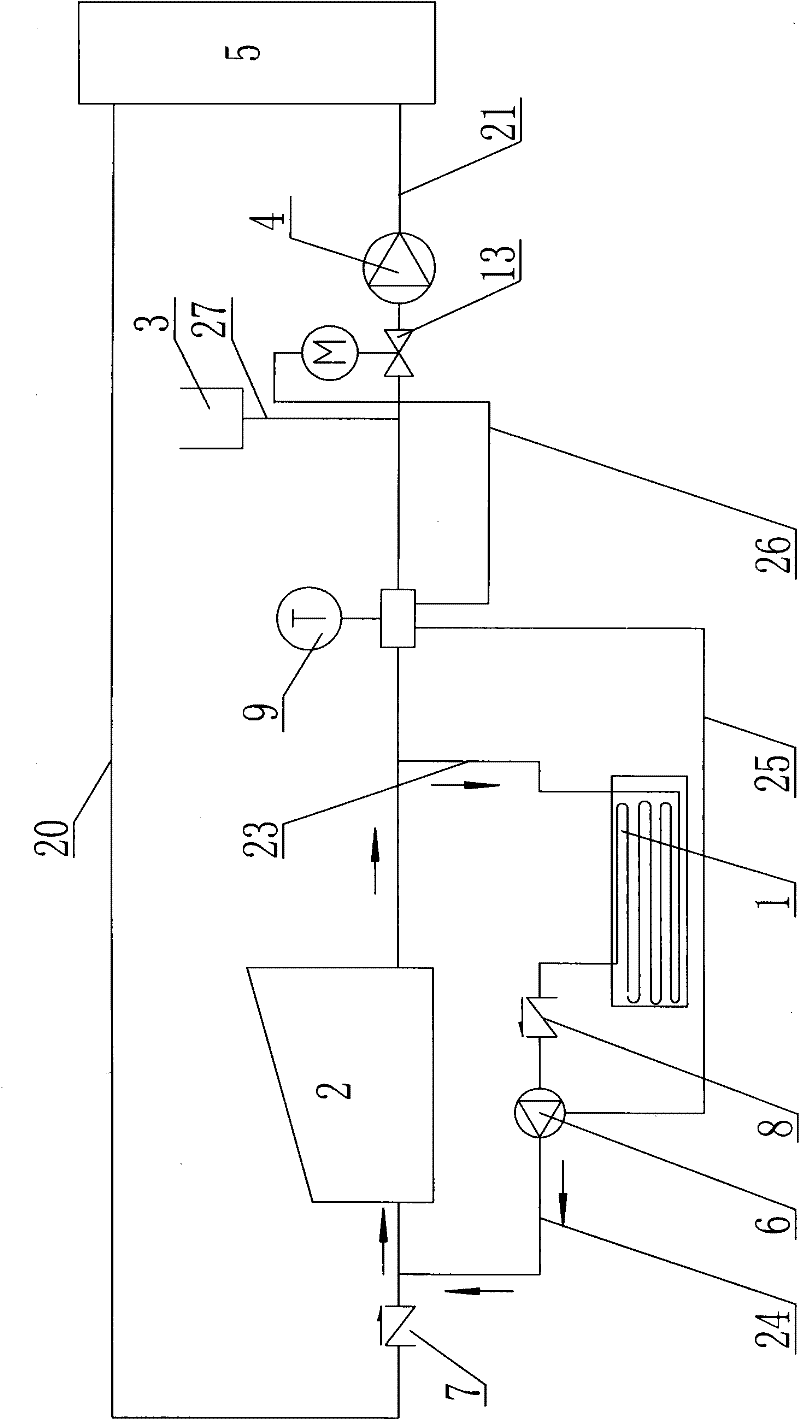

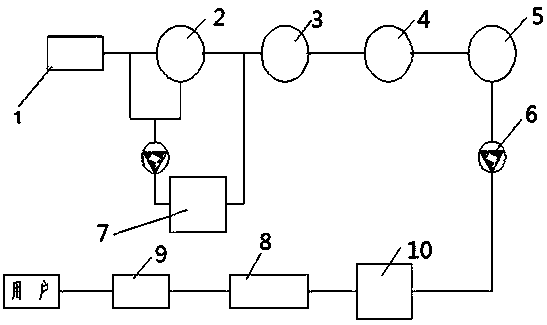

Solar thermal collector freezing prevention system

InactiveCN101718477AReduce initial investment costsSolve pollutionSolar heating energySolar heat devicesFrost crackFrost

The invention discloses a solar thermal collector freezing prevention system and relates to a thermal collector freezing prevention system. The invention solves the problem of frost cracks of valves and pipelines due to residual water in the system by a backflow and exhaust system and the problems of large initial investment and easy environmental pollution of a freezing prevention liquid system. A sewage heat exchanger, a solar thermal collector and the terminal of a heat user are sequentially communicated by a cycle working medium charge pipe; the sewage heat exchanger is communicated with the terminal of the heat user by a cycle working medium backflow pipe; a circulating water pump is installed on the cycle working medium charge pipe; one end of a first communicating pipe is communicated with the cycle working medium charge pipe, and the other end of the first communicating pipe is communicated with the cycle working medium backflow pipe; a first valve is installed on the first communicating pipe, a second valve is installed on the cycle working medium backflow pipe, and a high-temperature sewage pipe and a low-temperature sewage pipe are installed on the sewage heat exchanger. The invention reduces the initial investment of a freezing prevention liquid system of the solar thermal collector and solves the problems of environmental pollution and frost cracks of the pipelines and the valves.

Owner:HARBIN INST OF TECH

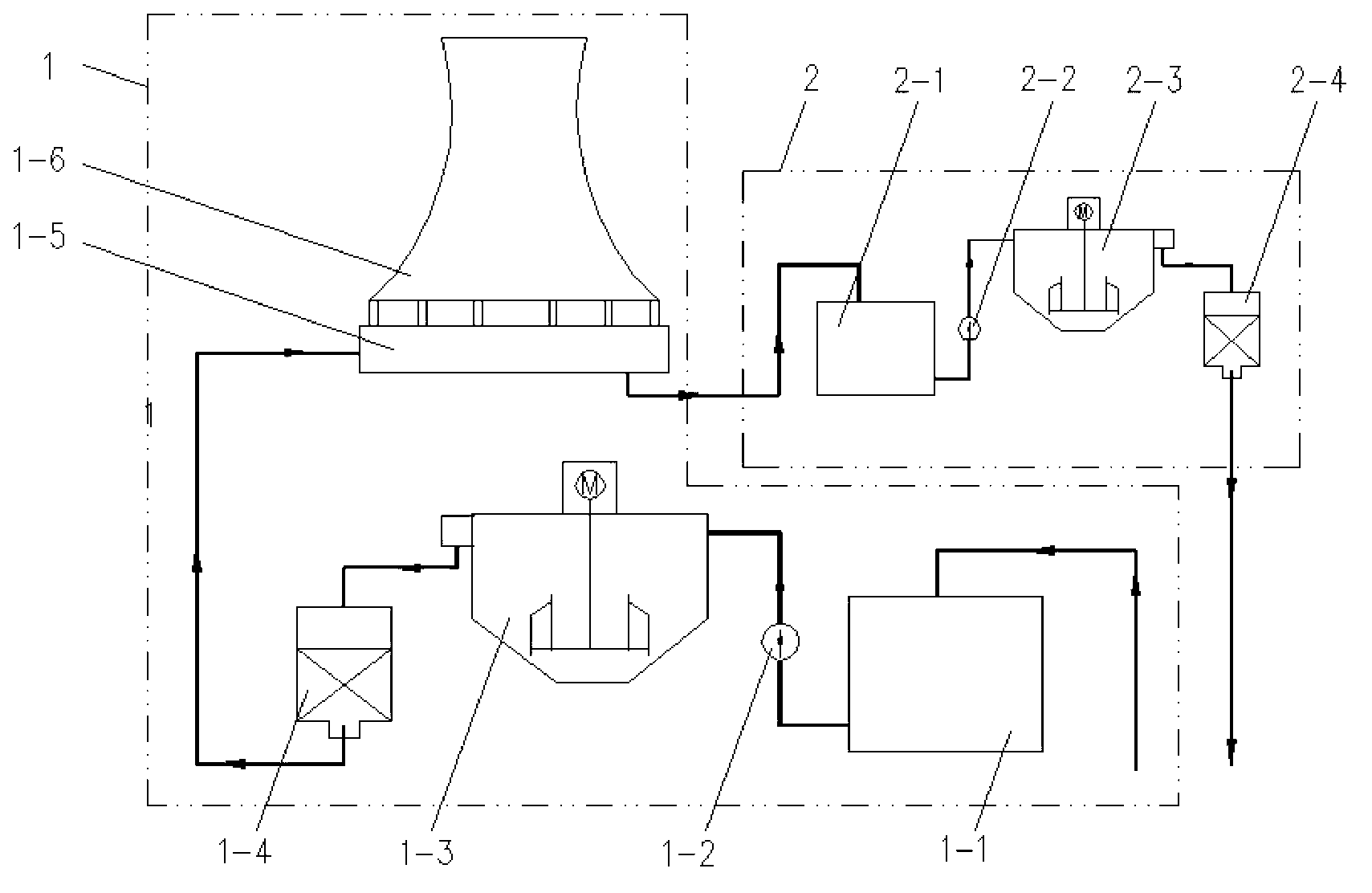

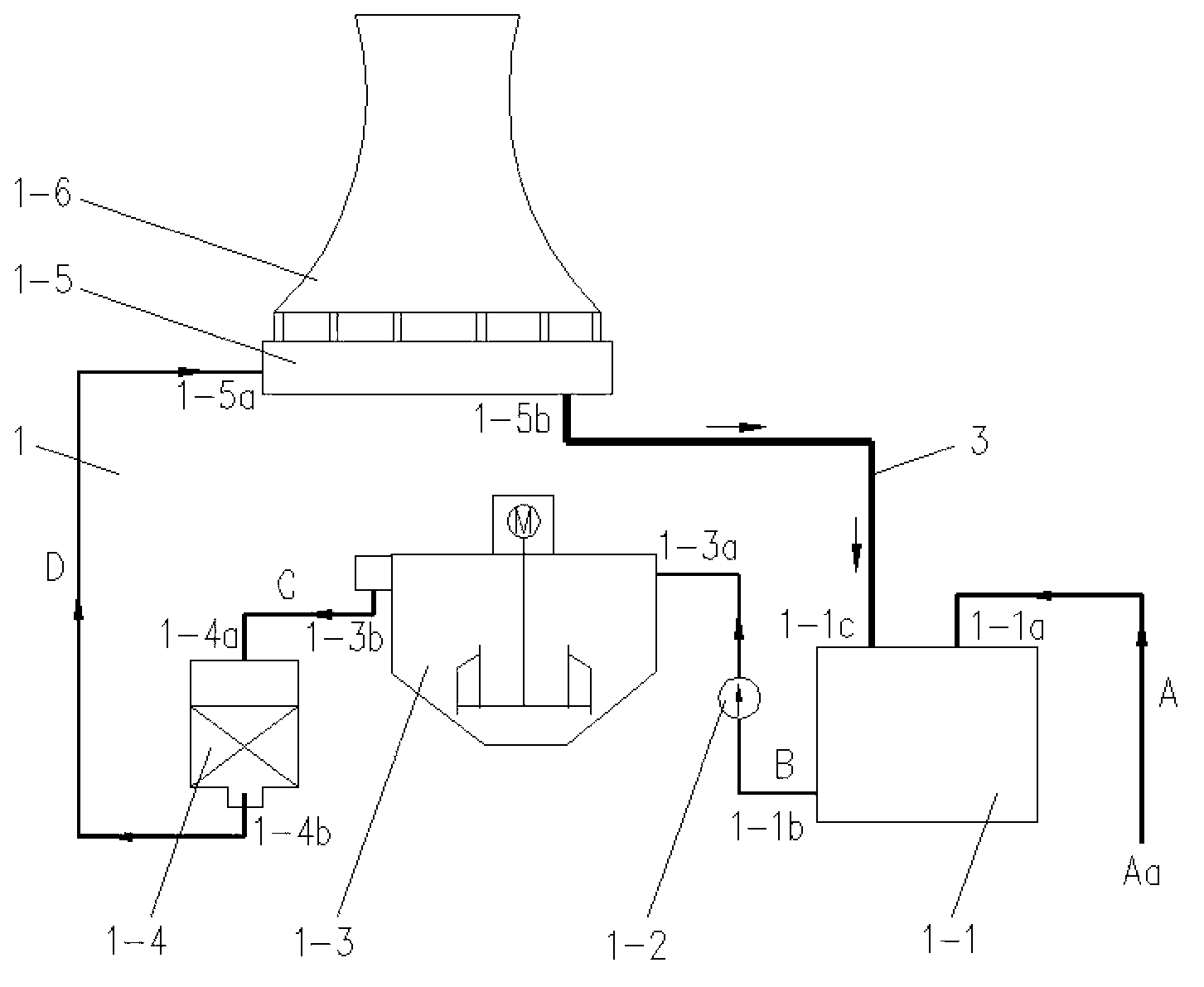

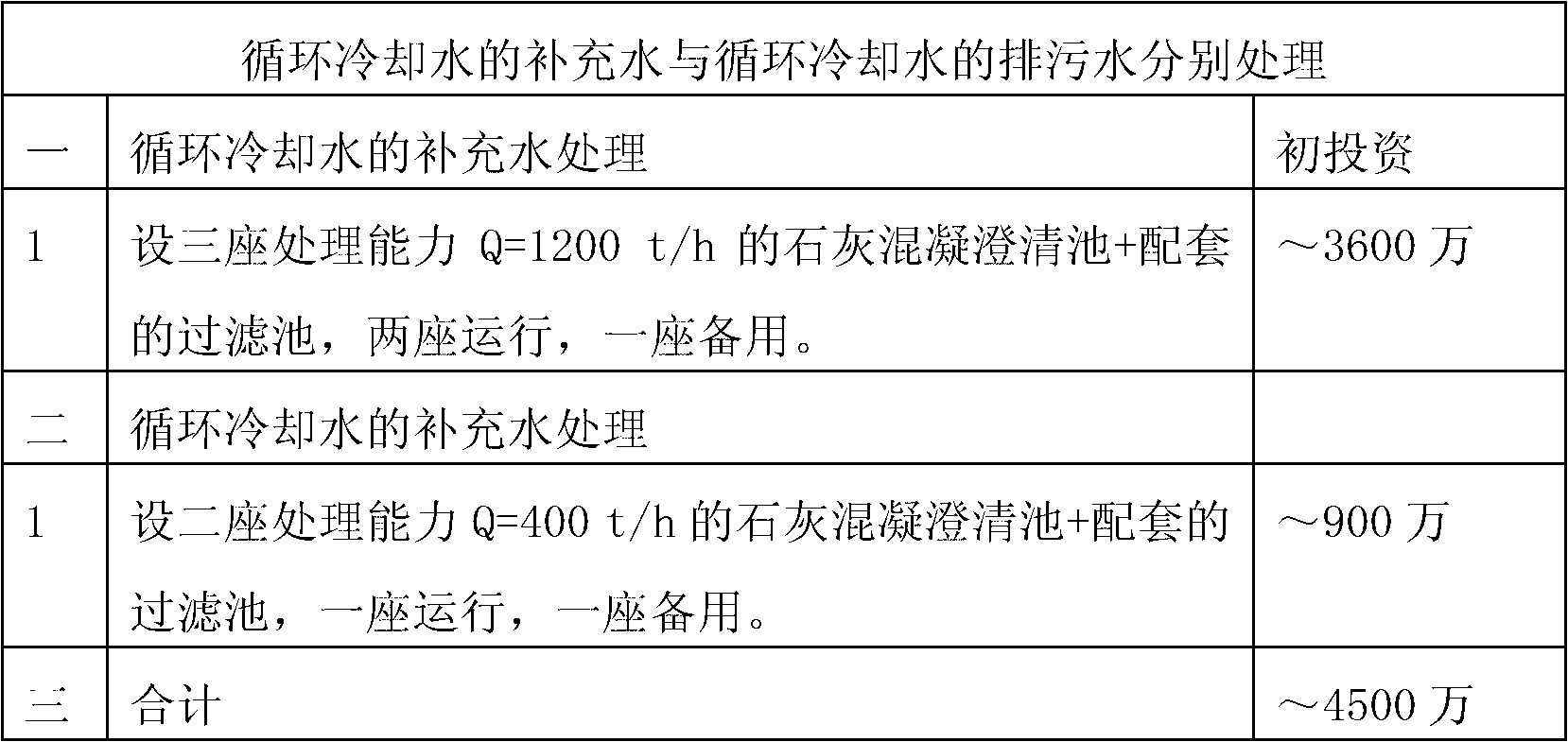

Treatment system for thermal power plant circulating water blowdown water

InactiveCN102795715AReduce initial investment costsSmall footprintMultistage water/sewage treatmentMunicipal sewageWater pipe

Belonging to the technical field of reclaimed water reuse, the invention discloses a treatment system for thermal power plant circulating water blowdown water. The treatment system is comprised of a make-up water system of circulating cooling water and a blowdown water pipeline of circulating cooling water. A circulating cooling water pool of the make-up water system of circulating cooling water is in connection with a buffer pool of the make-up water system of circulating cooling water through the blowdown water pipeline of circulating cooling water. According to the invention, the blowdown water of circulating cooling water is led into the reclaimed water buffer pool of the make-up water system of circulating cooling water, and is treated together with the reclaimed water from a municipal sewage treatment plant, so that a set of blowdown water treatment system of circulating cooling water can be saved, with the saved treatment system composed of a circulating water blowdown water buffer pool, a circulating water blowdown water lifting pump, a circulating water blowdown water lime coagulation and clarification pool, a circulating water blowdown water filtering pool and other equipment. Therefore, the system provided in the invention reduces the initial investment cost of a thermal power plant, saves land occupation, and is convenient for centralized arrangement, as well as centralized maintenance and management.

Owner:STATE NUCLEAR ELECTRIC POWER PLANNING DESIGN & RES INST CO LTD

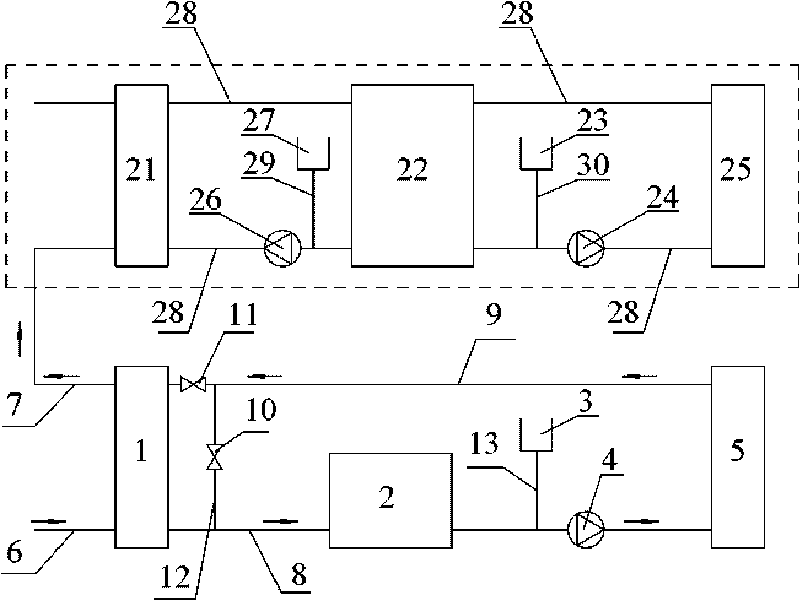

Heat accumulating type anti-freeze solar heat collector system

InactiveCN101825350AReduce initial investment costsEliminate environmental pollution problemsSolar heat devicesSolar thermal energy generationFrost crackLiquid system

The invention discloses a heat accumulating type anti-freeze solar heat collector system, relates to an anti-freeze solar heat collector system and aims to solve the problems of frost cracking of valves and pipelines because moisture is easy to remain in a returning and emptying system, frost cracking of the pipelines due to the solidification of circulating working fluid at an extremely low temperature, high primary investment in the anti-freeze liquid system and easy environment pollution. A first cut-off valve and a temperature sensor of the system are sequentially arranged on a circulating working fluid inflow pipe along the flowing direction of the circulating working fluid; a second check valve and a second circulating water pump are sequentially arranged on a circulating working fluid return pipe along the flowing direction of the circulating working fluid; first and second communicating pipes are arranged on the two sides of the first cut-off valve in parallel; the upper ends of the first and second communicating pipes are communicated with the circulating working fluid inflow pipe; and the lower ends of the first and second communicating pipes are communicated with the inlet end and the outlet end of a heat accumulating tank made of a phase-change material respectively. The system reduces the primary investment in the anti-freeze liquid system of the heat collector, avoids pollution and solves the problems of frost cracking of the pipelines and the valves.

Owner:HARBIN INST OF TECH

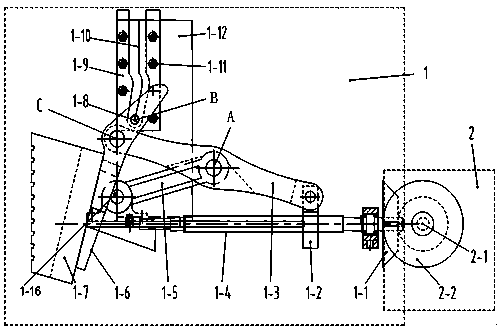

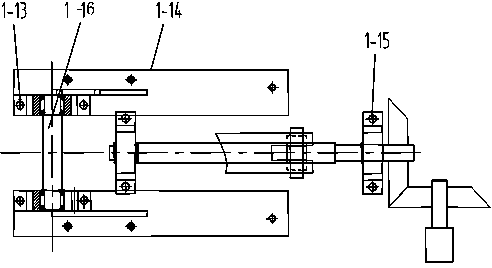

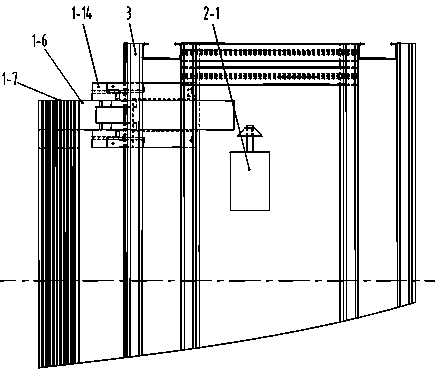

Method for processing screw bevel gear

InactiveCN101214565AComplete identityReduce initial investment costsGear teethNumerical controlGear wheel

The invention relates to a processing method for a spiral bevel gear which applies a CAM software to program an NC program and controls a five shaft link numerical control machine through the NC program to adopt an ordinary milling cutter to finish the rough processing or fine processing on the surface of the spiral bevel gear. The invention can effectively reduce the manufacture cost, shorten the manufacture preparing time, expand the processing range and improve the manufacture efficiency. The invention is in particular suitable for the processing of a big diameter spiral bevel gear.

Owner:秦川机床工具集团股份公司

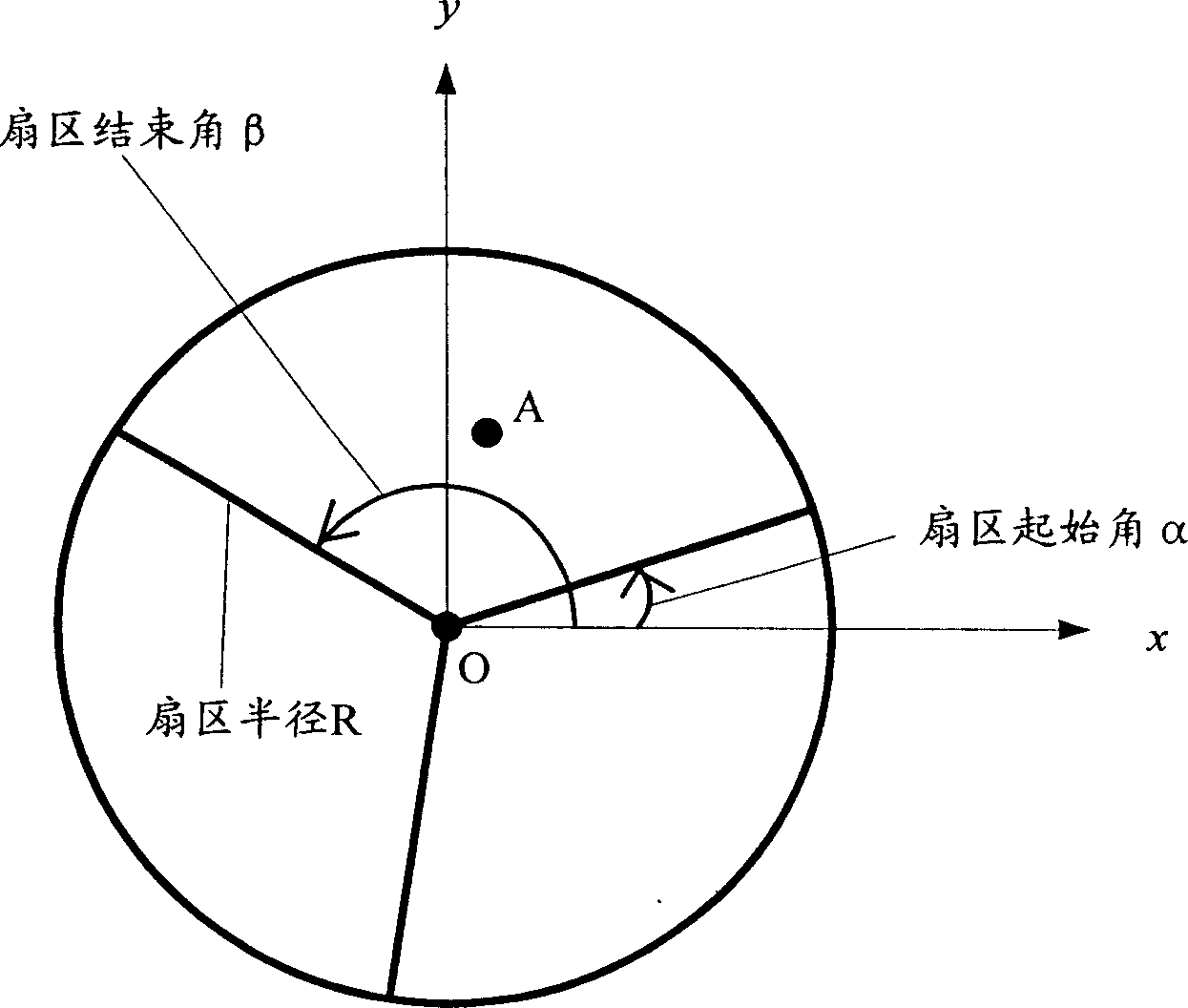

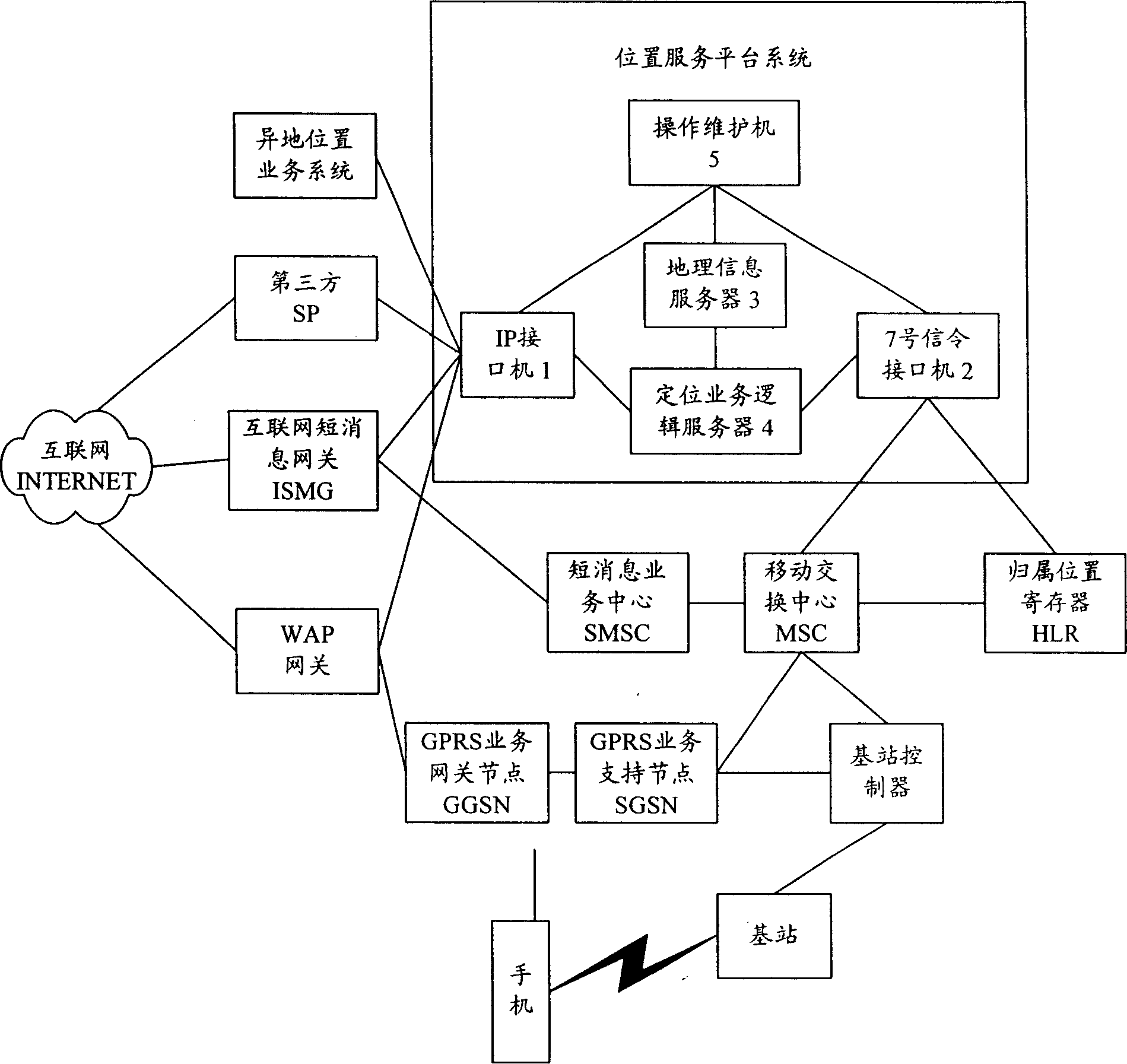

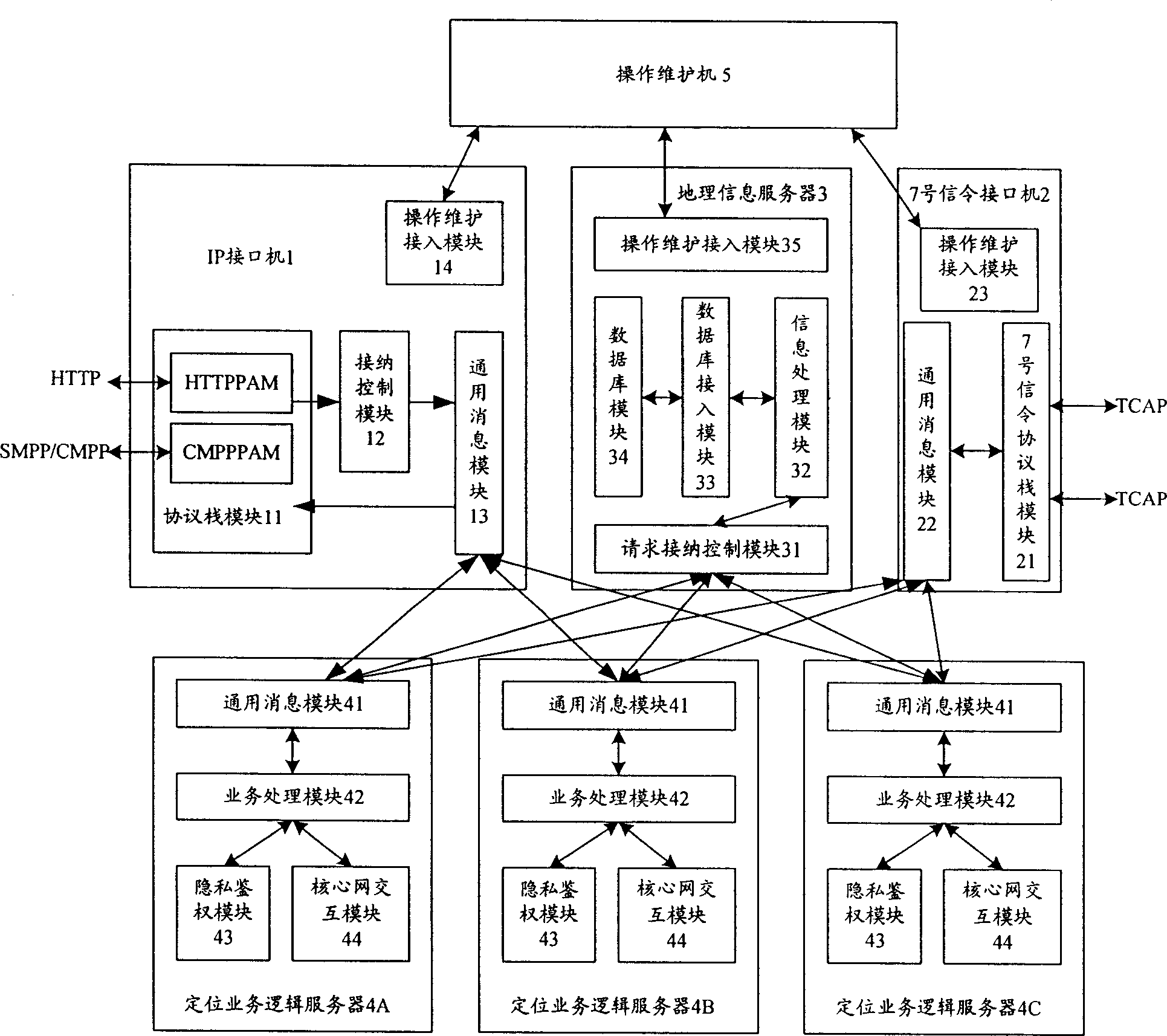

Positioning service platform with position and service functions integration and sector optimization

InactiveCN1713777AReduce initial investment costsRealize interconnectionRadio/inductive link selection arrangementsWireless communication3g mobile communicationsThird generation

The invention consists of IP interface message processor, signaling system 7 interface message processor, geo information server, location service logical server and operation maintaining machine. The system supports 2G, 2.5G, 3G mobile communication network, and supports opening interface for third party. It accords with GMLC criteria in 3GPP. The invention also provides a sector optimize method used in locating service: the geometric center point in sector where mobile terminal locates replaces the location of base station in center of cell, and is taken as current location of the mobile terminal.

Owner:BEIJING UNIV OF POSTS & TELECOMM

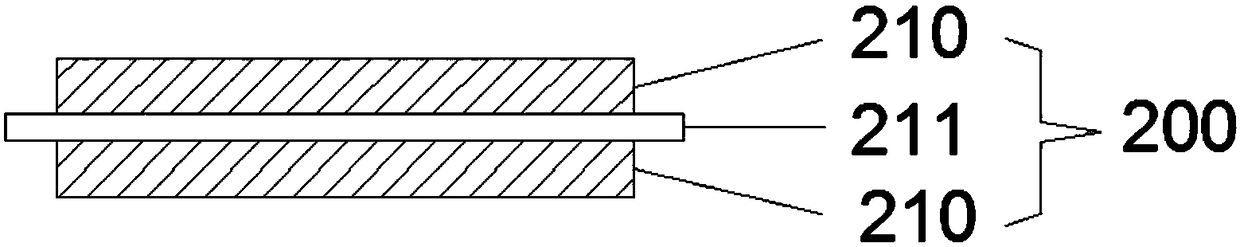

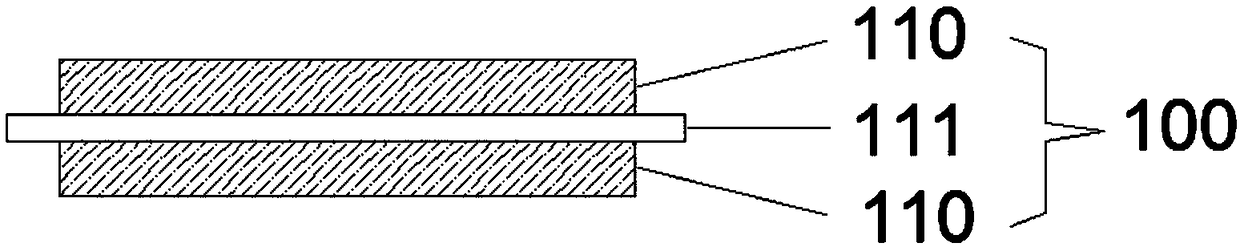

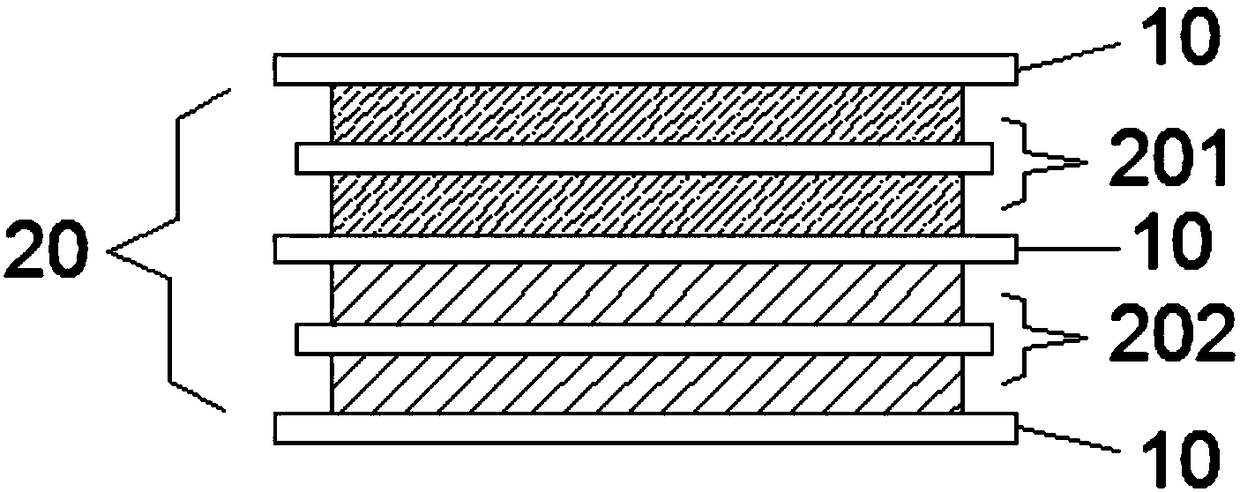

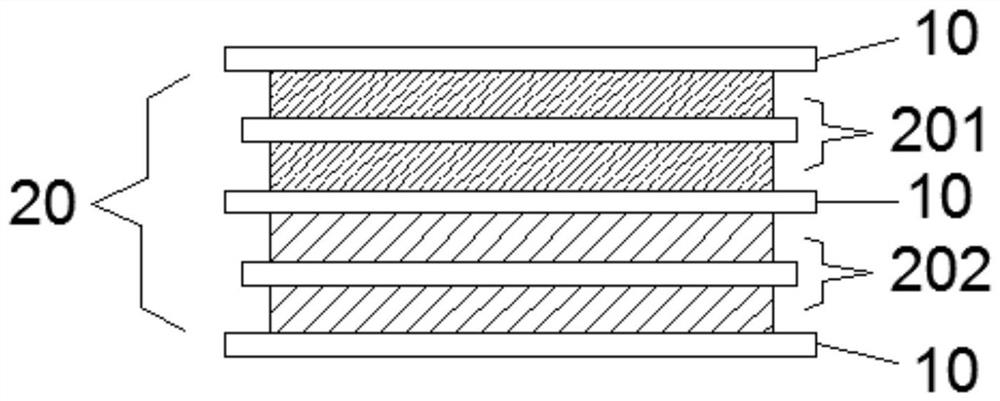

Alternately-stacked laminated secondary battery and manufacturing method thereof

ActiveCN108808059AReduce reworkSimplify the manufacturing processLarge-sized flat cells/batteriesFinal product manufactureElectrical batteryManufactured apparatus

The present invention relates to an alternately-stacked laminated secondary battery and a manufacturing method thereof. The disclosed secondary battery is formed by alternately stacking integrally formed monopolar groups and positive and negative monopolar sheets, thereby reducing cases where the battery performance is not satisfactory due to poor positive and negative monopolar sheets. The existing problems can be effectively solved by manufacturing the laminated secondary battery according to the method provided by the present invention. The monopolar groups and the pole pieces are alternately stacked, and the manufacturing process of the monopole groups and the pole pieces is relatively simple. In the process, the defective products can be effectively screened in advance, and the reworkfrequency can be significantly reduced. Moreover, the invention uses a monopolar group and monopolar sheet stacking method, which can effectively reduce the initial investment cost of a monopole group and the monopole sheet manufacturing apparatus.

Owner:李嫊罗

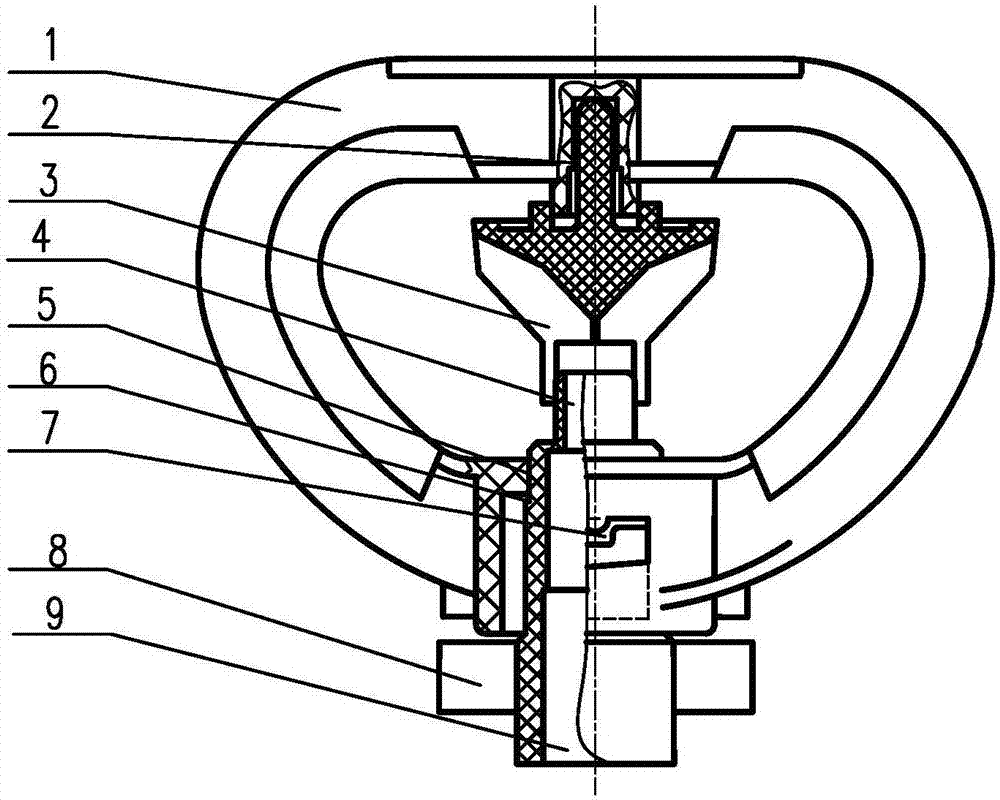

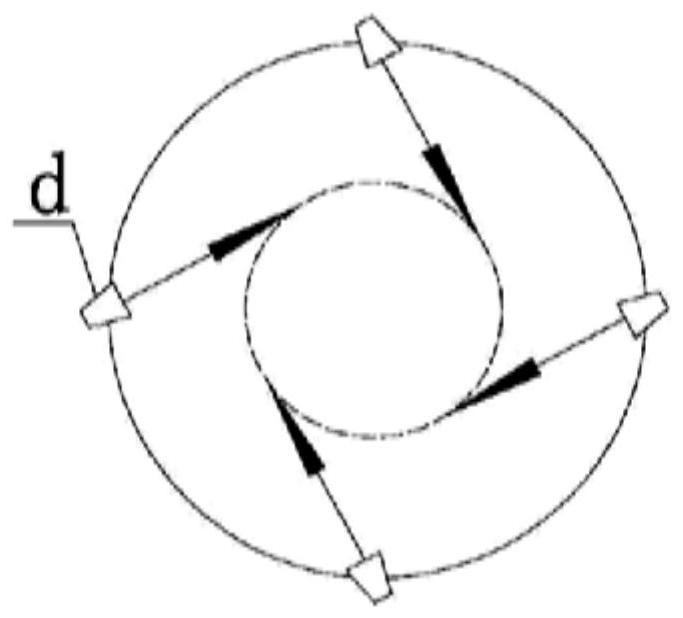

Double-part support rotary micro-sprinkler

ActiveCN107442309ALarge spraying radiusSpray evenlyMovable spraying apparatusWater diversionEngineering

The invention discloses a double-part support rotary micro-sprinkler. The double-part support rotary micro-sprinkler comprises a support, a rotary body and a nozzle, wherein the support is a double-part support, a positioning hole is formed in the upper end of the support, and a sleeve is arranged at the lower end of the support; the rotary body comprises a water inlet hole, a water diversion baffle, runners and a rotary shaft which are designed in sequence from bottom to top; and the runners include the first runner and the second runner, the elevation of the first runner is larger than that of the second runner, the first runner and the second runner each have an deflection angle, and the deflection angle of the first runner is smaller than that of the second runner. The double-part support rotary micro-sprinkler has the advantages that the sprinkling radius is large, sprinkling is uniform, and the effect that in a certain pressure range, support deformation caused by high pressure does not occur, and rotation of the rotary body is not affected is achieved; the micro-sprinkler is convenient and fast to mount and dismount; due to large sprinkling width, the number of sprinklers adopted per mu on average is small, and first-time investment cost of micro-irrigation projects is reduced; and sprinkling is uniform in the sprinkling width direction, so that moisture and nutrients obtained by crops are uniform, the growing vigor is uniform, and high-yield and high-quality agricultural products can be easily achieved.

Owner:HOHAI UNIV +1

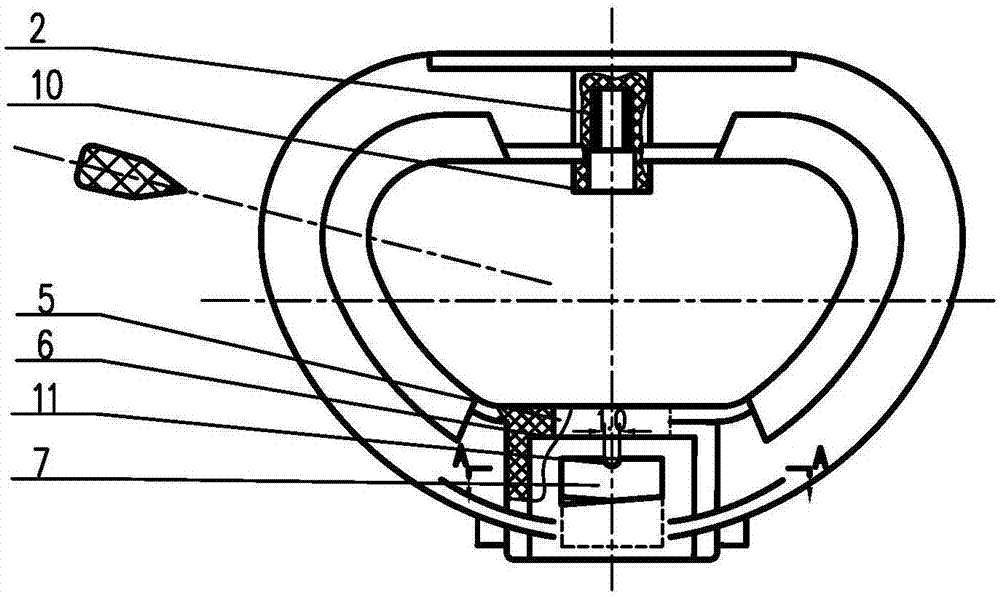

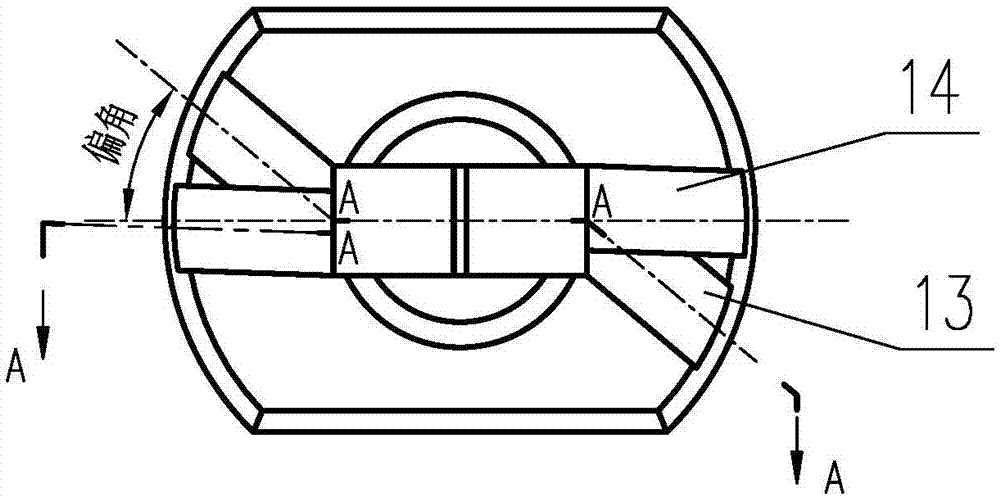

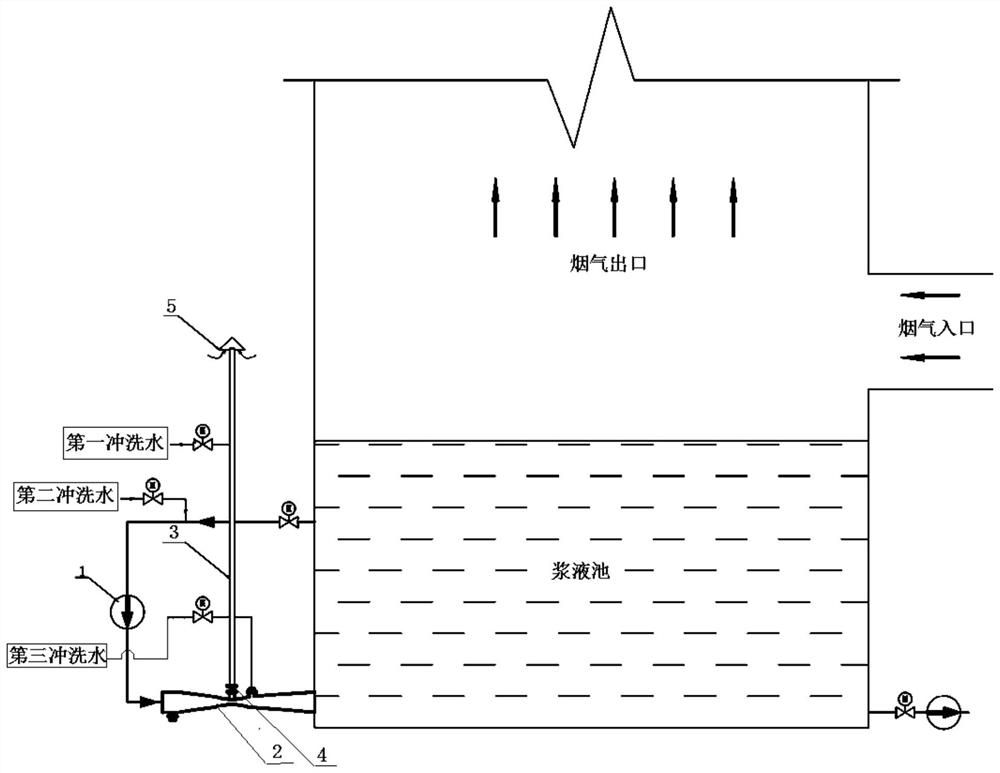

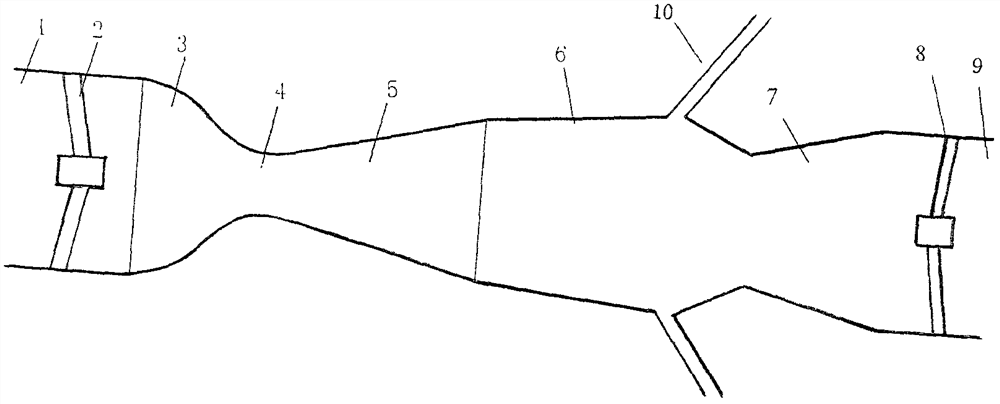

Slurry oxidation device and method for jet air exhaust desulfurization tower

PendingCN112827344AReduce energy consumptionLess power consumptionGas treatmentFlow mixersEngineeringSlurry

The invention discloses a slurry oxidation device and method for a jet air exhaust desulfurization tower. The device comprises a desulfurization tower and a slurry tank at the lower part of the desulfurization tower. A plurality of jet flow oxidation devices are tangentially arranged along the circumference of the slurry tank. The jet flow oxidation devices firstly extract the slurry in the slurry tank, the slurry is mixed and oxidized with air in the jet flow oxidation devices, high-pressure mixed fluid is jetted into a neutralization area in the tangential direction, a uniform swirling flow field is formed in the slurry in the inscribed circle direction and re-oxidization is carried out, so that the jet flow oxidation devices can replace a stirrer and a large oxidation fan. The method and the device not only solve the problems of oxidation air pipe blockage, non-uniform oxidation flow field and high slurry temperature of the traditional oxidation device, but also improve the oxidation efficiency, and have the characteristics of small occupied space, low energy consumption, simple system and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

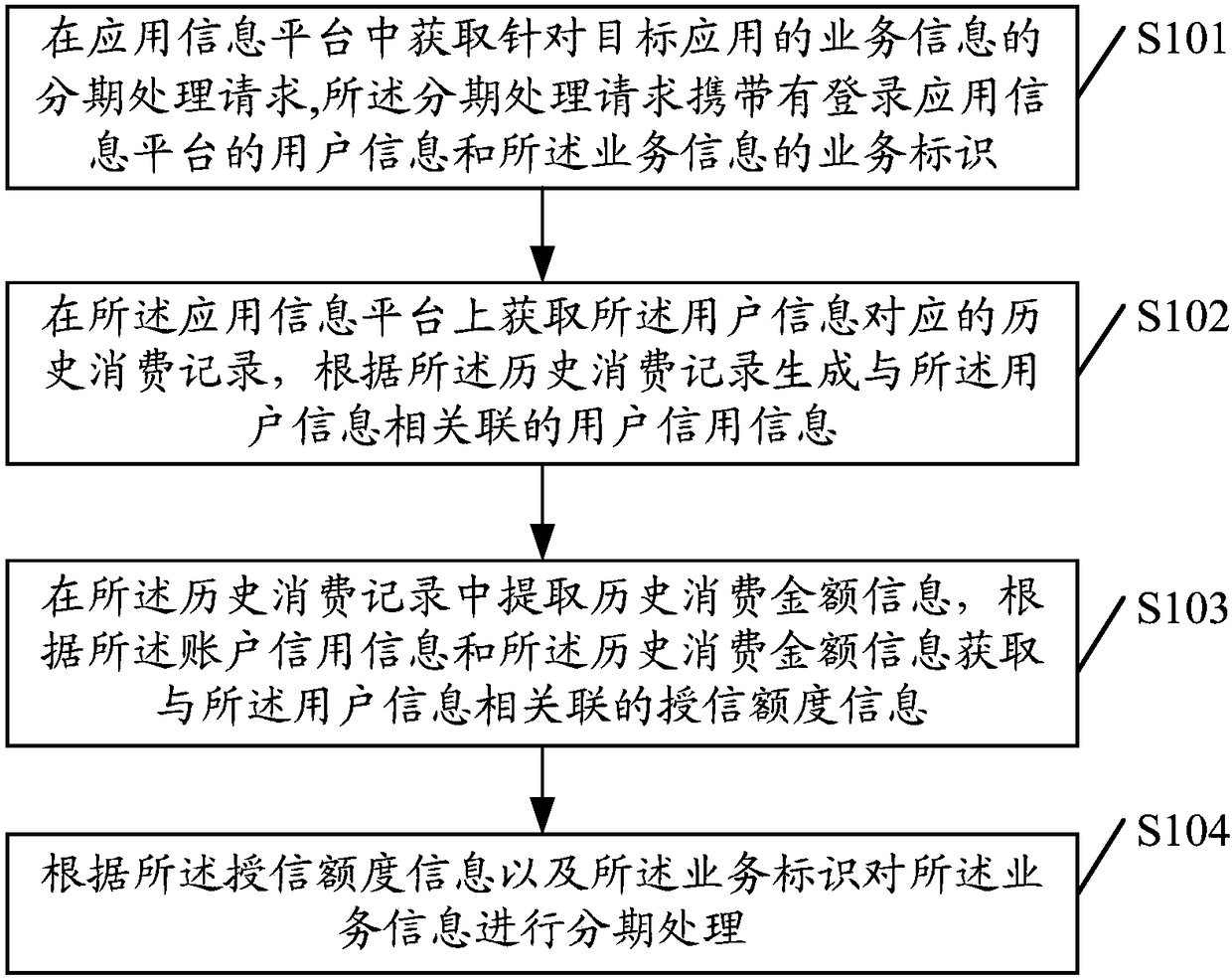

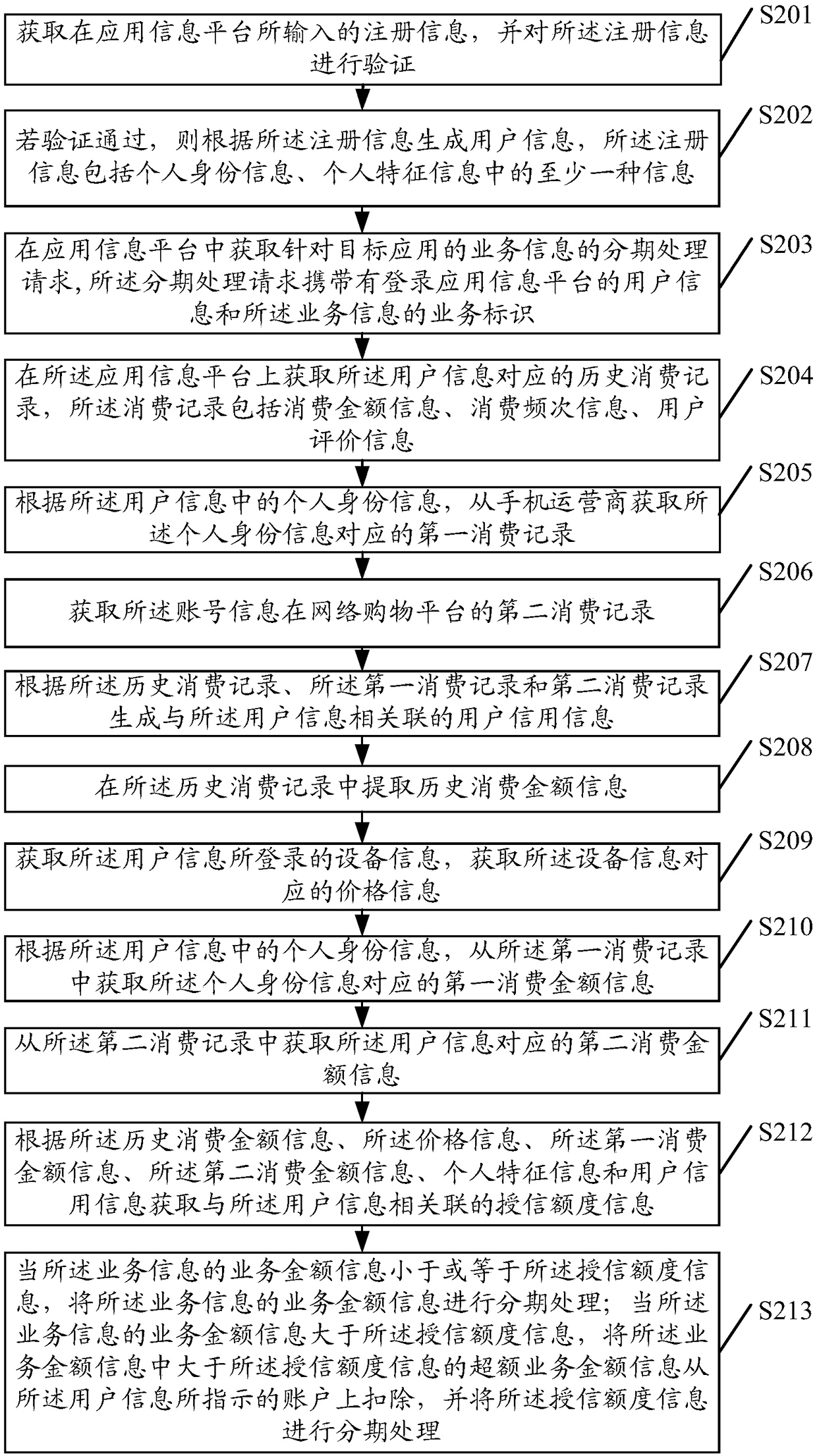

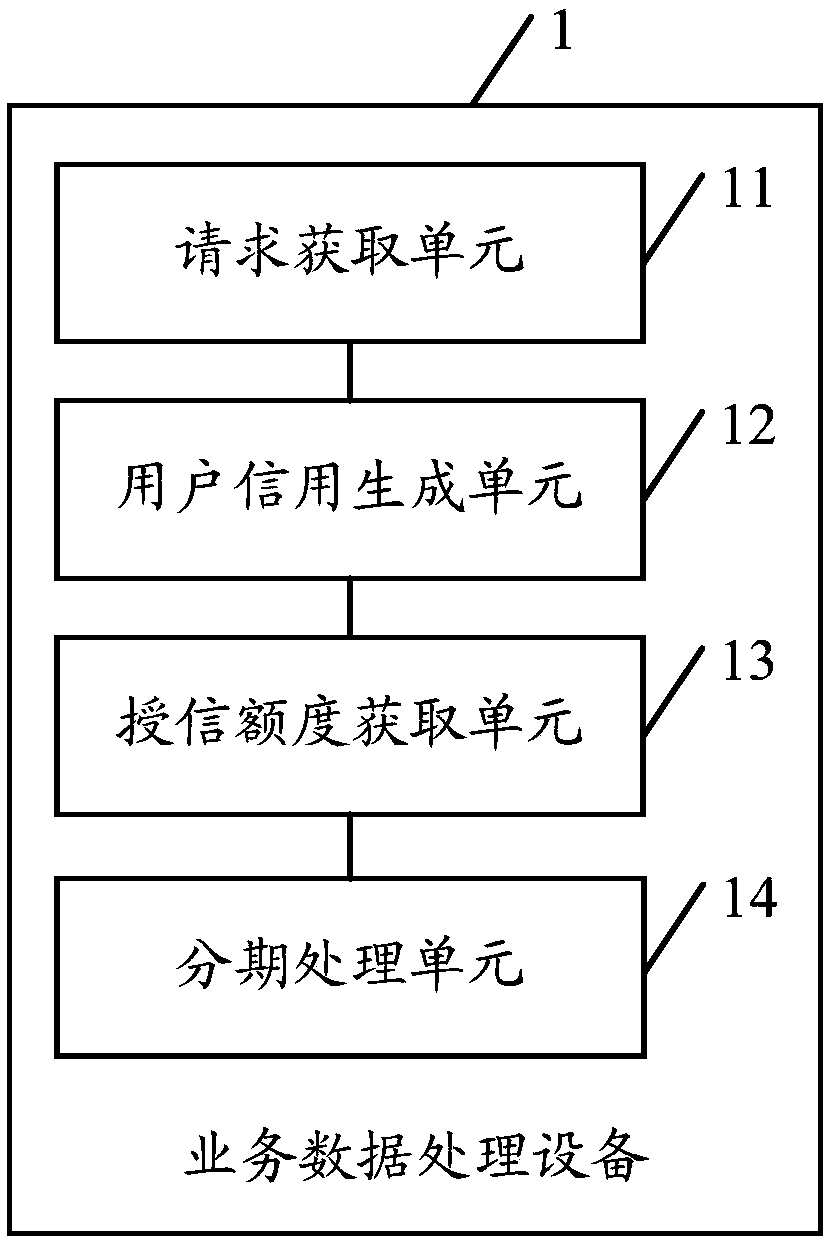

Service data processing method and equipment

InactiveCN108364228AReduce initial investment costsReduce churnFinanceCredit lineService information

The embodiment of the invention discloses a service data processing method and equipment. The method comprises the following steps that a staging processing request for service information of a targetapplication is obtained from an application information platform, wherein the staging processing request carries user information logging in the application information platform and a service identification of the service information; a historical consumption record corresponding to the user information is obtained from the application information platform, and user credit information related tothe user information is generated according to the historical consumption record; historical consumption amount information is extracted from the historical consumption record, credit line informationrelated to the user information is obtained according to the user credit information and the historical consumption amount information; and staging processing is carried out on the service information according to the credit line information and the service identification. The service data processing method and equipment have the advantages that the initial input cost of a user can be reduced, the loss of users can be reduced, the user stickiness can be increased, and the utilization rate of the business capital can be increased.

Owner:SHENZHEN MAIMAITI INFORMATION TECH CO LTD

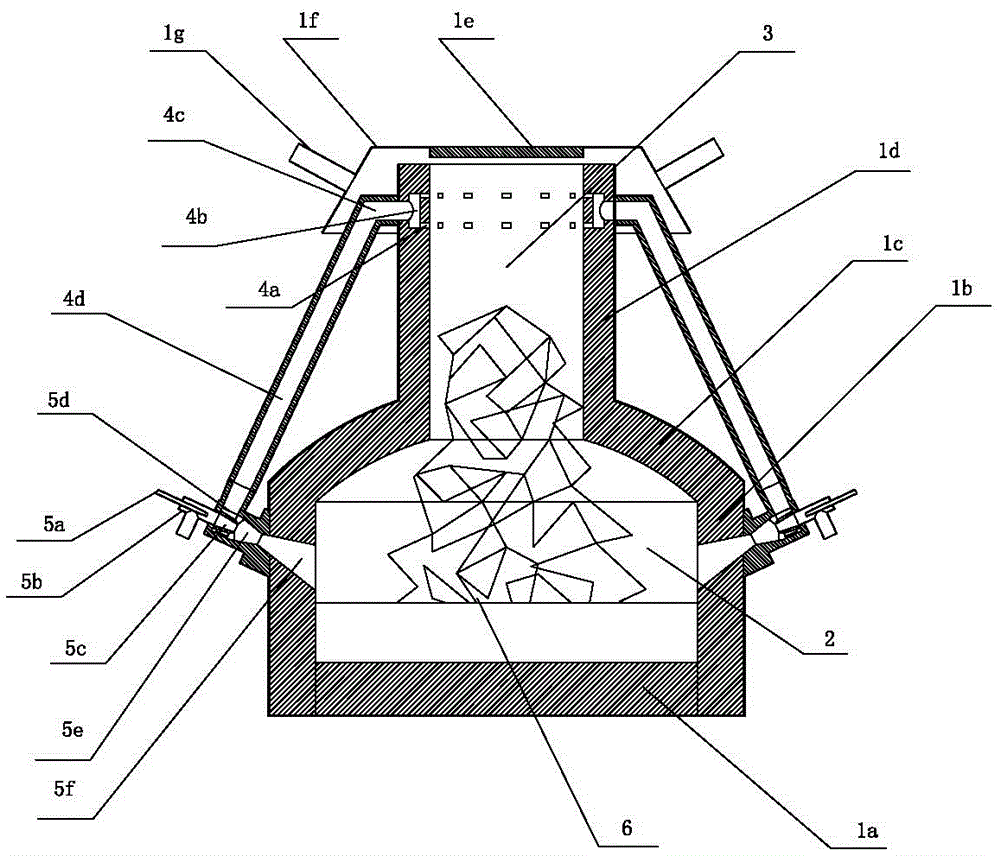

Aluminum melting furnace capable of performing low-oxygen high-temperature combustion through flue gas reflowing

ActiveCN106766901AImprove heat transfer performanceReasonable distributionCrucible furnacesIndirect carbon-dioxide mitigationTemperature controlCombustor

The invention relates to an aluminum melting furnace capable of performing low-oxygen high-temperature combustion through flue gas reflowing, and aims to effectively realize temperature control, decrease the content of nitrogen oxide and save energy in the melting process of the aluminum melting furnace. The aluminum melting furnace is characterized in that the top of an annular furnace wall surrounding the bottom of the furnace is provided with an annular arc-shaped top cover; a middle charging channel wall body is formed in a through hole in the middle part of the top cover; a charging and flue gas discharging channel is formed inside the middle charging channel wall body; a combustion melting hearth is formed in the annular furnace wall; the middle part of an exhaust hood on the top of the charging and flue gas discharging channel is provided with a furnace top cover; the periphery of the exhaust hood is provided with an exhaust hood outlet pipe; a combustor is arranged in the circumferential direction of the annular furnace wall; a flue gas outlet on the inner wall of the charging channel wall body is connected with the charging and flue gas discharging channel; the outer end of the flue gas outlet is connected with an inner ring of a flue gas converging annular channel; a flue gas converging main pipe communicating with an outer ring of the annular channel is connected with a flue gas reflow inlet through a flue gas reflow communication pipe; the annular furnace wall is provided with an operation furnace door and a molten liquid discharging hole. By adopting the aluminum melting furnace, control of the combustion temperature is realized, the combustion temperature is lowered, control of the content of the nitrogen oxide is realized, and the using amount of coal gas is reduced.

Owner:郑州釜鼎热能技术有限公司

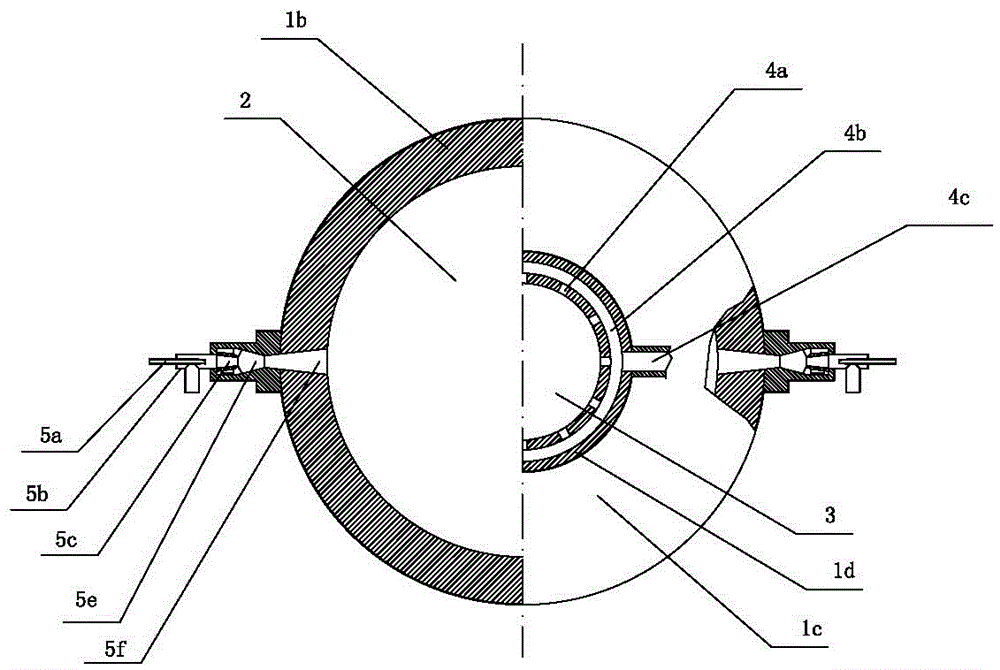

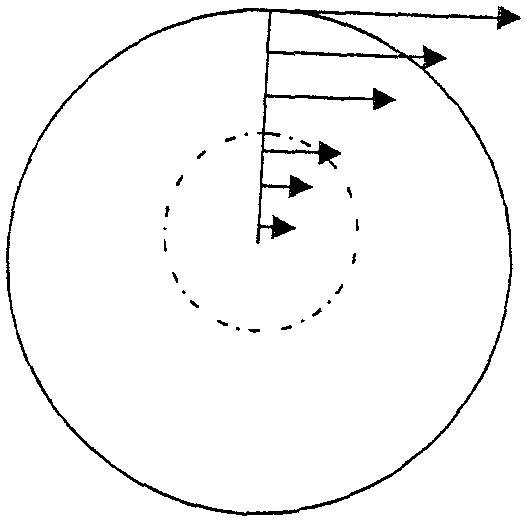

Ground-source heat pump system allowing refrigerant to directly exchange heat with soil

InactiveCN105135576AOvercome the problem of thermal resistanceMeet cooling and heating needsMechanical apparatusCompression machinesFour-way valveGeothermal heat pump

The invention relates to a ground-source heat pump system allowing refrigerant to directly exchange heat with soil. The ground-source heat pump system comprises a compressor, a four-way valve, a user side heat exchanger, a throttling mechanism and a ground-source side efficient heat exchange device. The outlet of the compressor is connected with the first end of the four-way valve. The inlet of the compressor is connected with the second end of the four-way valve. The third end of the four-way valve, the user side heat exchanger, the throttling mechanism, the ground-source side efficient heat exchange device and the fourth end of the four-way valve are sequentially connected. The ground-source side efficiency heat exchange device is embedded in soil. By means of the ground-source heat pump system, the number of embedded pipes can be greatly decreased, and the defects that the ground-source heat pump well digging area is not enough, the number of dug wells is large, and the earlier-stage construction cost is high can be effectively overcome. The ground-source heat pump system is small in area occupied by dug wells, simple in structure, low in cost, reliable in performance, high in heat exchange efficiency and high in overall energy efficacy ratio.

Owner:宝莲华新能源技术(上海)股份有限公司

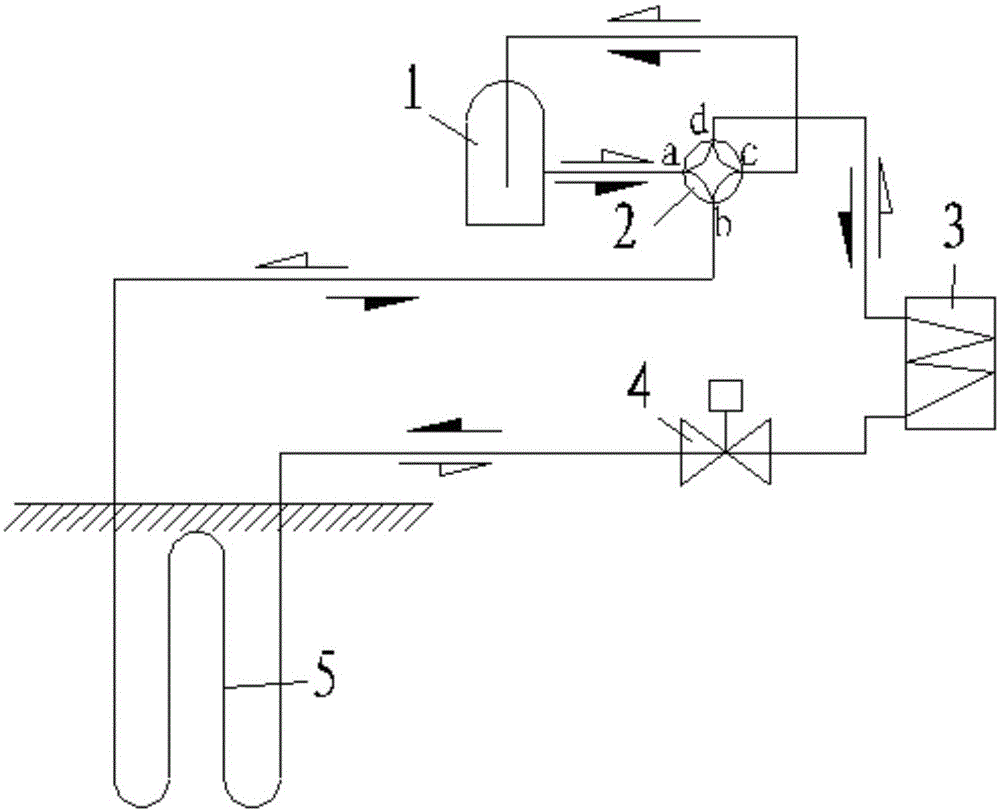

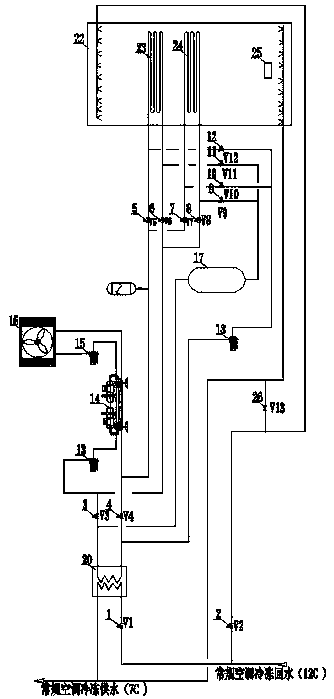

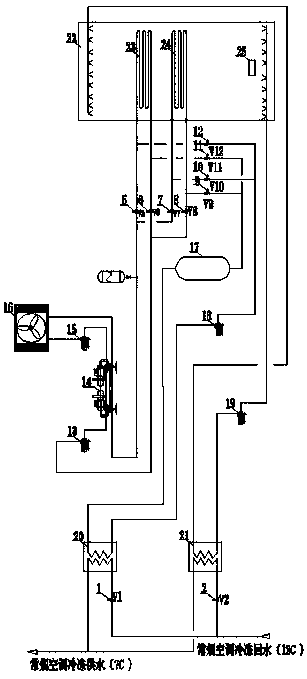

High-efficiency ice storage system method

ActiveCN110186131AEasy to make iceEasy off iceLighting and heating apparatusAir conditioning systemsIce storageEngineering

The invention discloses a high-efficiency ice storage system method. The method specifically comprises the steps of 1, a conventional air-conditioning refrigeration and ice-making unit combined cold working condition; 2, a conventional air-conditioning refrigeration and ice-making unit ice storage working condition; 3, an ice-making unit independent ice storage working condition; 4, an ice storagedevice independent cold working condition, and 5, a conventional air conditioner and ice storage device combined cold working condition. The invention relates to the technical field of air conditioner ice storage. With the high-efficiency ice storage system, an auxiliary device is added to help an ice-making coil to be more prone to ice making and de-icing, chilled water is utilized to transfer the heat to a refrigerant or an ethylene glycol solution through a plate exchanger to realize de-icing, and the cold capacity released by the ice-making coil during de-icing is directly absorbed by thechilled water for air-conditioning refrigeration, so that the refrigerating cold capacity is not wasted; extra heat source for deicing does not need to be additionally added during de-icing, an ice maker works in an ice-making state all the time, and the conversion is not needed; and the ice-making amount is large, the efficiency is high, the cold storage capacity per unit capacity of an ice storage device is large, and the cold capacity released during de-icing can be stored as needed.

Owner:广东腾源蓄冷节能科技有限公司

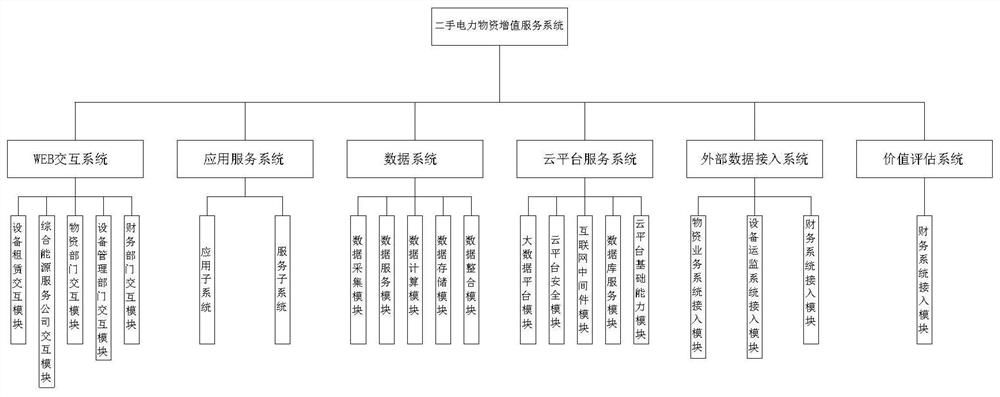

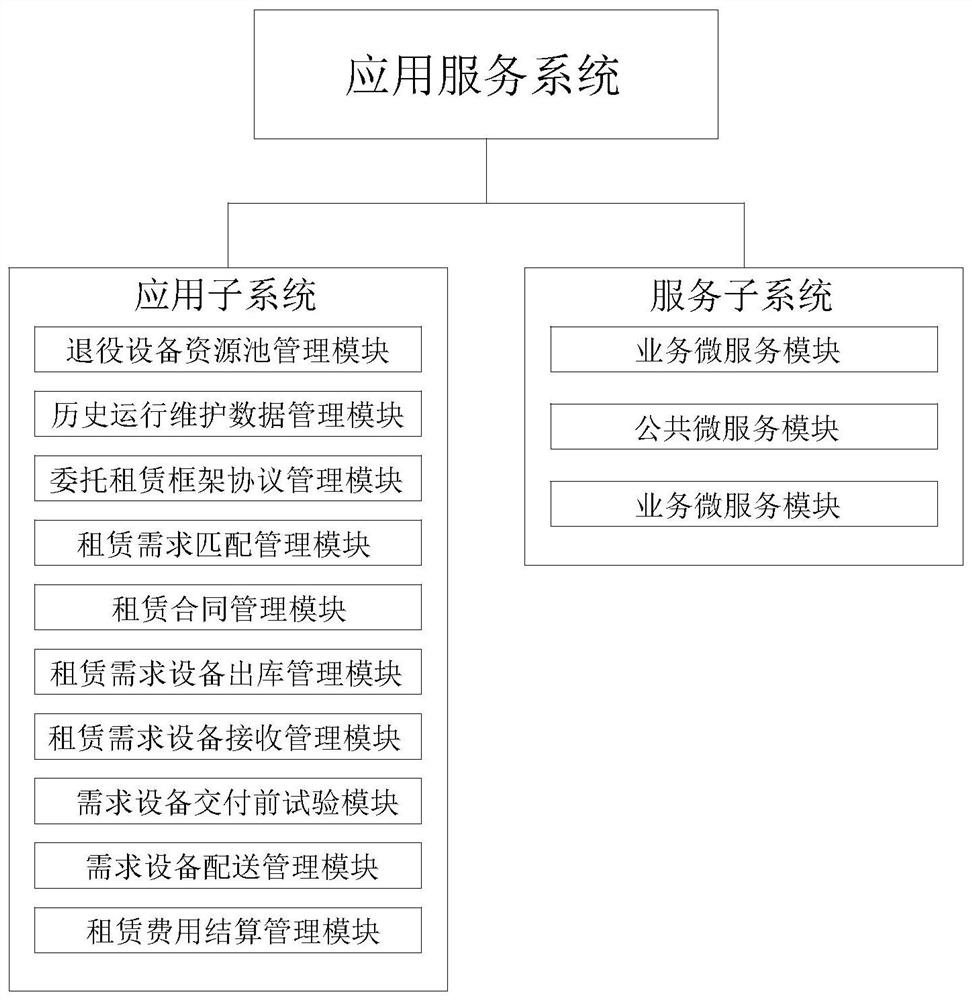

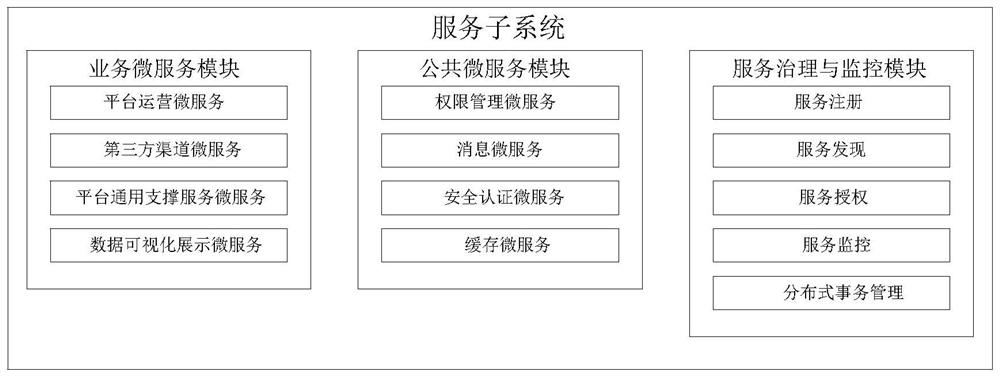

Second-hand electric power material value-added service system based on Internet of Things and value evaluation method

PendingCN112465559AImprove management levelImprove the sense of power acquisition in the business environmentProduct appraisalInformation technology support systemResource informationExternal data

The invention discloses a second-hand electric power material value-added service system based on the Internet of Things and a value evaluation method, and belongs to the technical field of second-hand electric power material value-added services. A second-hand electric power material value-added service system based on the Internet of Things is characterized by comprising a second-hand electric power material value-added service system, and the second-hand electric power material value-added service system is connected with a WEB interaction system, an application service system, a data system, a cloud platform service system, an external data access system and a value evaluation system. Meanwhile, the invention further provides a second-hand electric power material value evaluation method based on the Internet of Things. The method is applied to a second-hand electric power material value-added service system based on the Internet of Things. According to the invention, a retired material resource allocation system is constructed, resource information sharing is realized, and value evaluation and reutilization of second-hand electric power material equipment are effectively promoted.

Owner:国网浙江省电力有限公司双创中心 +1

Helical airflow type wet method flue gas desulfurization process and spraying tower thereof

InactiveCN101279184BLow flow resistanceSimple processDispersed particle separationChemical reactionEngineering

The invention provides a swirling air flow-type and wet flue gas desulfurization technique and a spraying tower thereof. The technique guides flue gases to enter tangentially from the upper part of a spraying tower shell; the flue gases swirl inside the spraying tower shell and leave tangentially from the lower part of the spraying tower shell; at the same time, limestone grout is sprayed upward and fog drips of the grout firstly touch the downward-swirling flue gas reverse flow, and then fall back owing to the effect of self-weight and drag force of the flue gas and then touch the forward flow of the flue gas, thus sulfur dioxide in the flue gases is absorbed owing to the quick chemical reaction with limestone grout fog drops. The spraying tower comprises a spraying tower shell; the spraying tower shell is provided with tangentially arranged flue gas inlet and outlet channels; a spraying device for spraying absorbing agents upwards is arranged between the flue gas inlet and outlet channels; a central tank is arranged in the center of the spraying tower shell; a flue gas guide plate showing a spiral descent structure is arranged on the central tank; a defroster is arranged in the flue gas inlet and outlet channels of the spraying tower shell. The desulfurization efficiency thereof is high, investment is small, and operation is safe and reliable.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

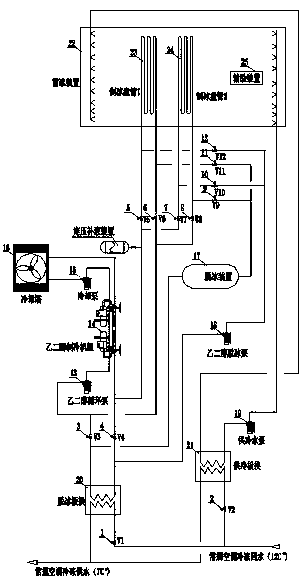

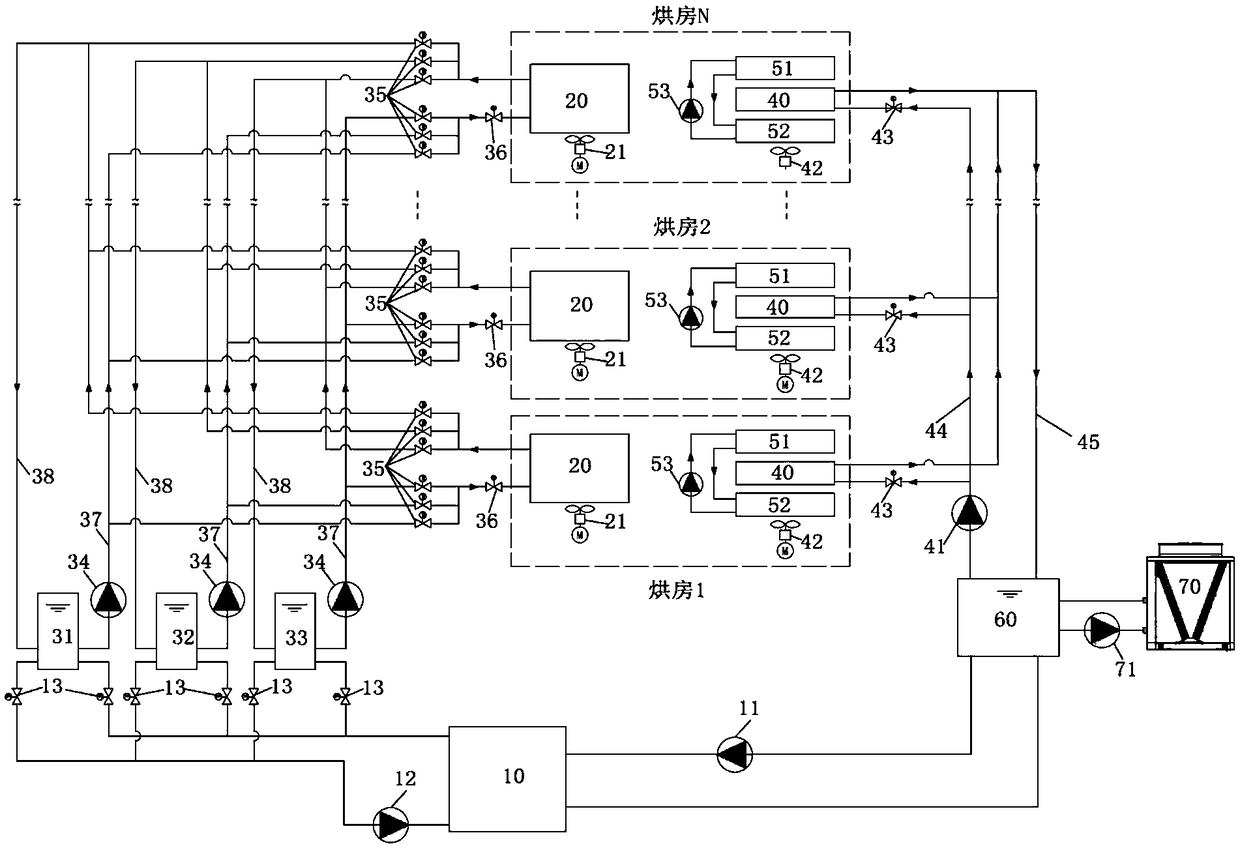

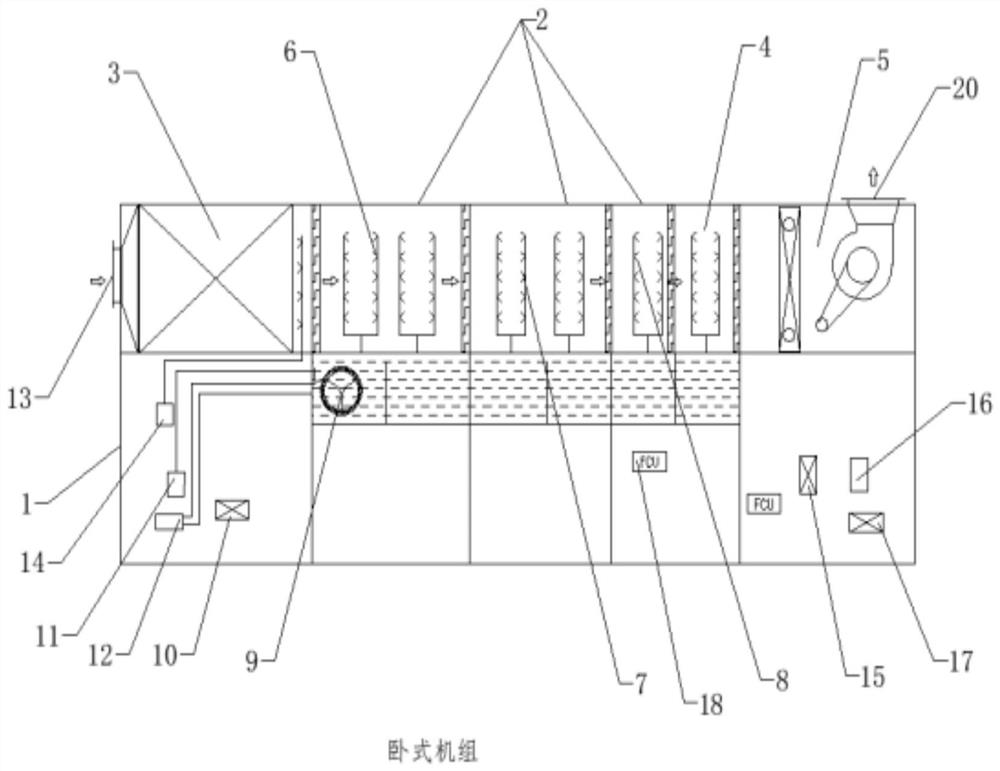

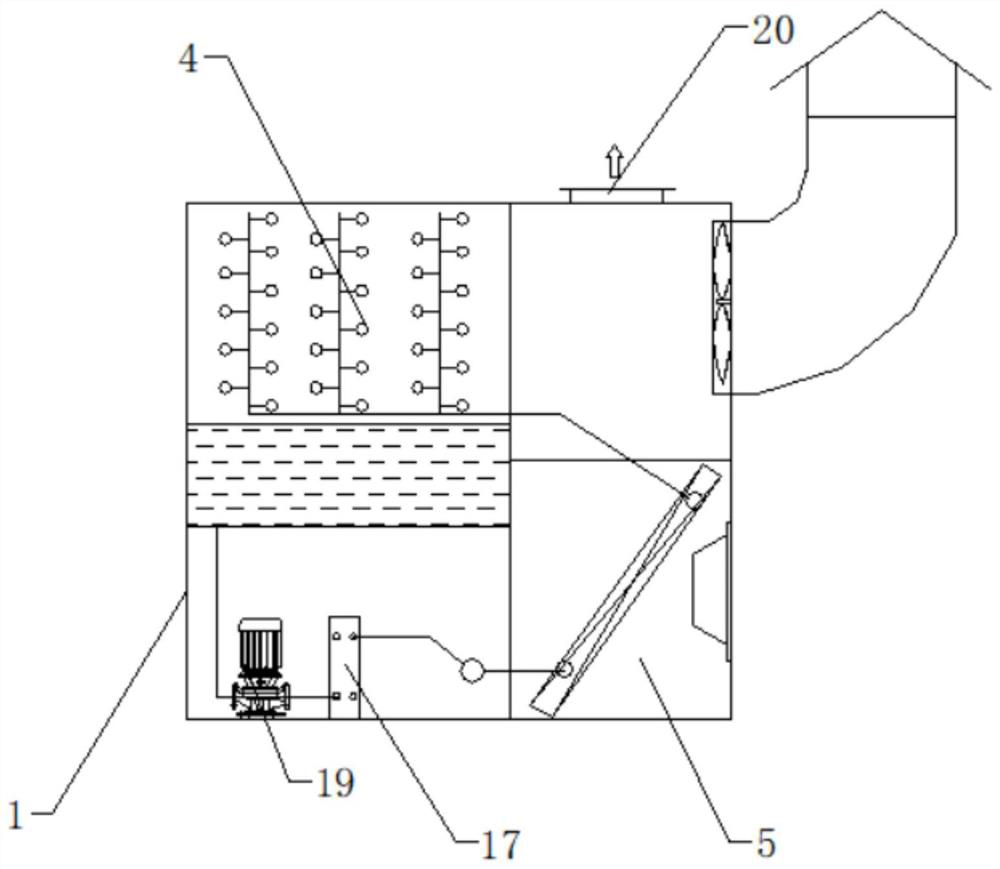

Closed dehumidification water-water heat pump drying system with multiple drying rooms

InactiveCN108759328AAchieve mutual exchangeImprove the quality of finished productsDrying machines with local agitationDrying machines with materials at restEvaporationChilled water

The invention relates to a closed dehumidification water-water heat pump drying system with multiple drying rooms. The closed dehumidification water-water heat pump drying system comprises a water-water heat pump, a hot water tank, an energy storage water tank and a plurality of drying rooms. A heating coil, a heating axial flow fan, a dehumidification coil and a dehumidification fan are arrangedin each drying room. Hot water generated by the water-water heat pump enters the hot water tank through a pipeline, the hot water in the hot water tank is pumped into each heating coil by a heating water pump through a heating water pipeline, and the hot water conducts heat exchange through the heating coil and then returns to the hot water tank through a first water return pipeline. The water inthe hot water tank enters the water-water heat pump through a water pump on a condensation side. Chilled water generated by the water-water heat pump enters the energy storage water tank through a pipeline. The cold water in the energy storage water tank is pumped into each dehumidification coil by a dehumidification water pump through a dehumidification pipeline, and the cold water conducts heatexchange through the dehumidification coil and then returns to the energy storage water tank through a second water return pipeline. The cold water in the energy storage water tank enters the water-water heat pump through a water pump on an evaporation side. The system saves energy, is environmentally friendly and has high drying quality.

Owner:江苏必领能源科技有限公司

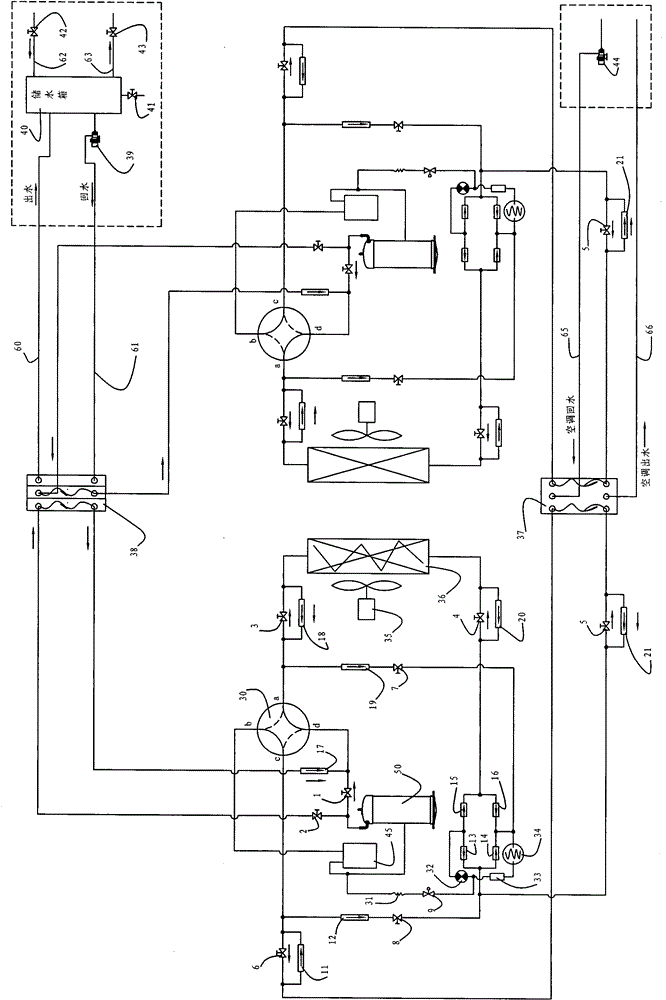

Hot-water air conditioning unit

ActiveCN101907372BEmission reductionSolve difficult problems that require the use of different productsFluid circulation arrangementCompression machines with reversible cycleVapor–liquid separatorBusiness efficiency

The invention discloses a hot-water air conditioning unit, comprising a compressor, an indoor heat exchanger, an outdoor heat exchanger, a four-way valve and a hot-water heat exchanger, wherein the high-pressure outlet of the compressor is connected with the fourth interface of the four-way valve via a first electromagnetic valve; a second electromagnetic valve, the hot-water heat exchanger and the seventh single-way valve are connected in series to form a subcircuit, one end of the subcircuit is connected between the high-pressure outlet of the compressor and the first electromagnetic valve via the second electromagnetic valve, and the other end of the subcircuit is connected between the first electromagnetic valve and the fourth interface of the four-way valve via a seventh single-way valve; the second interface of the four-way valve is connected with one end of a gas-liquid separator, the other end of the gas-liquid separator is connected with the low-pressure interface of the compressor; and the first interface of the four-way valve is connected with a third electromagnetic valve, the outdoor heat exchanger, a fourth electromagnetic valve, a sixth single-way valve, a liquid receiver, a filter, a ninth electromagnetic valve and a capillary. The invention has the characteristics of simple and reasonable structure, flexible operation, high energy efficiency ratio and wide application range.

Owner:GUANGDONG GALANZ GRP CO LTD

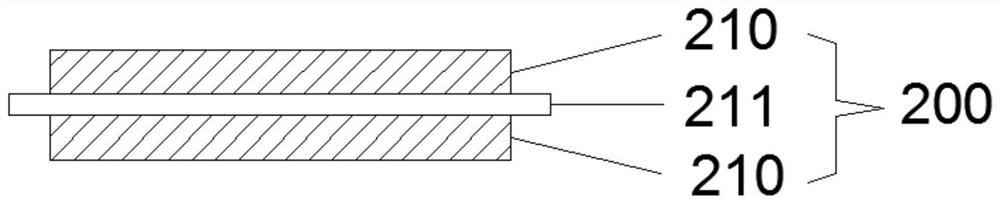

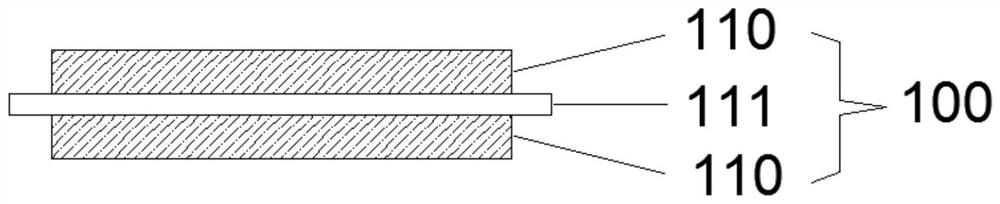

A laminated secondary battery based on cross-stacking and its preparation method

ActiveCN108808059BReduce reworkSimplify the manufacturing processLarge-sized flat cells/batteriesFinal product manufactureElectrical batteryPole piece

The invention discloses a laminated secondary battery based on cross-stacking and a preparation method thereof. The disclosed secondary battery is formed by cross-stacking a monopole group and positive and negative monopole sheets, and the monopole group is integrally formed. It effectively reduces the situation where the battery performance does not meet the requirements due to bad positive and negative monopole plates. Preparing laminated secondary batteries according to the preparation method provided by the present invention can effectively solve existing problems. The monopole set and pole pieces are alternately stacked. The production process of the monopole set and pole pieces is relatively simple. In this process, defective products can be effectively screened out in advance and the frequency of rework can be significantly reduced. Moreover, this invention adopts a stacking method of monopole groups and monopole sheets, which can effectively reduce the initial investment cost of monopole group and monopole sheet manufacturing equipment.

Owner:李嫊罗

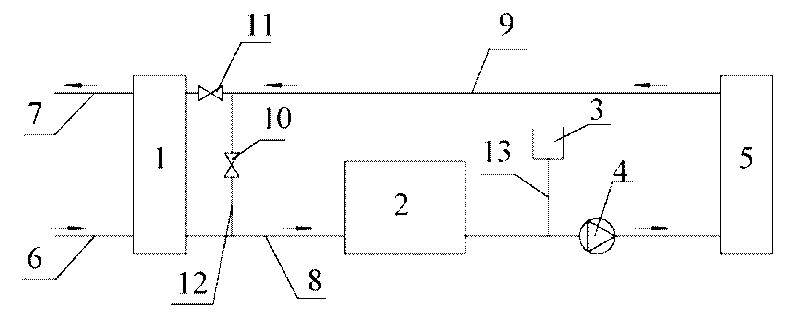

Air heated anti-freezing solar energy collector system

InactiveCN101818941BReduce initial investment costsSolve pollutionOther heat production devicesSolar heat devicesFrost crackFrost

The invention discloses an air heated anti-freezing solar energy collector system, relating to an anti-freezing solar energy collector system. The system aims at the problems that water is remained extremely easily in an exhaust and evacuation system to cause the frost cracking of valves and pipelines, relatively low temperature makes a circulating working medium solidified to cause the frost cracking of the pipelines and the antifreeze liquid system has large initial cost and easily causes environment pollution. A temperature sensor is mounted on a circulating working medium inlet pipe between an electric disconnecting valve and a solar energy collector; the upper end of a first communicating pipe is communicated with the circulating working medium inlet pipe; the lower end of the first communicating pipe is communicated with the inlet end of a wind power heater; the upper end of a second communicating pipe is communicated with a circulating working medium outlet pipe; the lower end of the second communicating pipe is communicated with the outlet end of the wind power heater; and a second check valve and a second circulating water pump are mounted on the second communicating pipealong the flow direction of the circulating working medium in sequence. By the invention, the initial cost of the collector anti-freezing system is decreased, and the problems of pollution and the frost cracking of the pipelines and the valves are avoided.

Owner:HARBIN INST OF TECH

Mining elevator lapping platform suitable for flexible guide rail and mining elevator lapping method

Owner:CHINA UNIV OF MINING & TECH +1

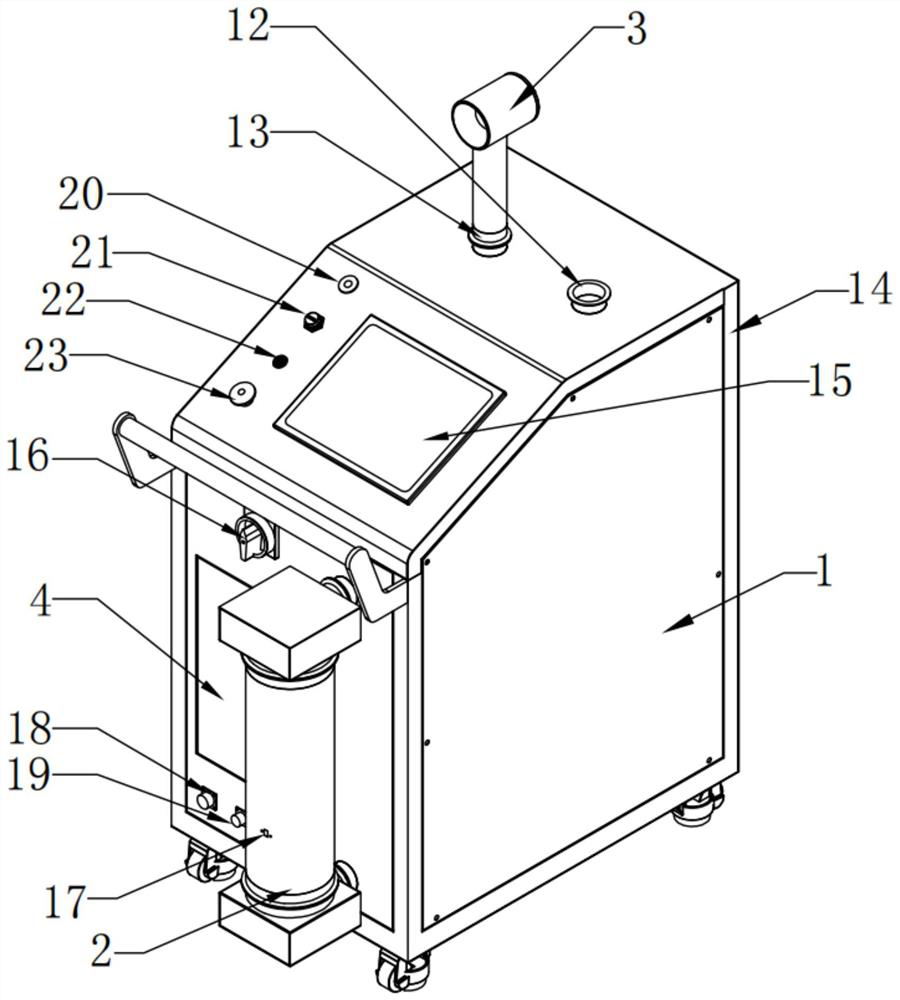

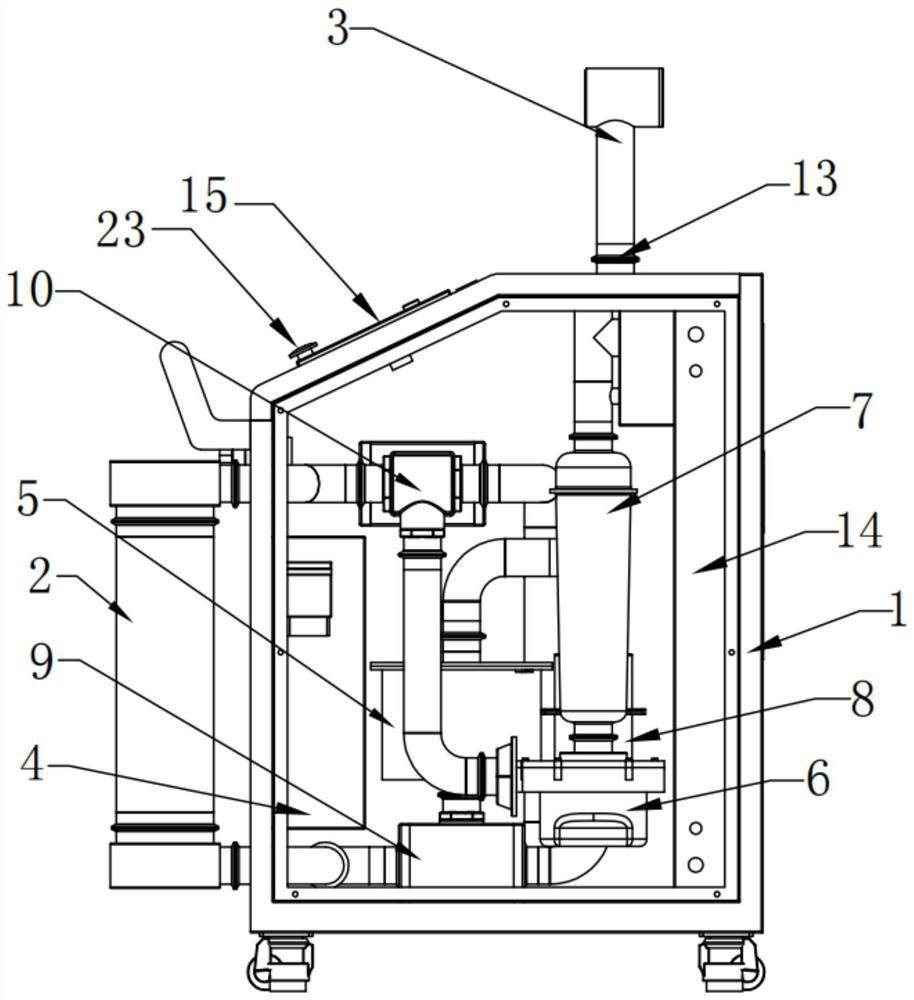

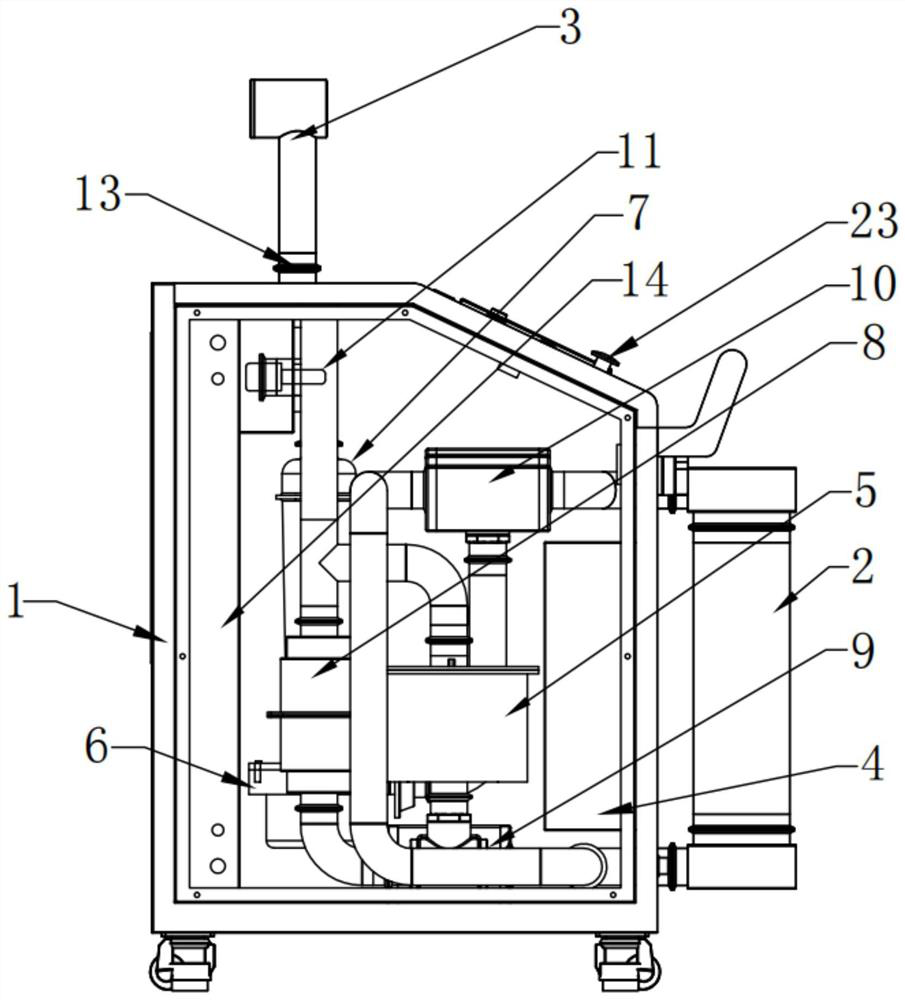

Multifunctional VHP sterilizer

PendingCN113375265AAvoid damageGood process repeatabilityMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringAir blower

The invention provides a multifunctional VHP sterilizer. The multifunctional VHP sterilizer comprises a machine body, an external drying system and a hydrogen peroxide solution cabinet are arranged on one side of the machine body, a Venturi nozzle is arranged at the top of the machine body, a VHP flash evaporator, a speed regulation air blower, a filter and a degradation device are arranged in the machine body, the VHP flash evaporator, the speed regulation air blower, the filter and the degradation device are all communicated with the external drying system and the hydrogen peroxide solution cabinet through parallel pipelines, the degradation device is communicated with the Venturi nozzle, and a first electric ball valve, a second electric ball valve and a three-in-one concentration probe are arranged on the parallel pipelines. The multifunctional VHP sterilizer provided by the invention has the advantages that the multifunctional VHP sterilizer can be used at room temperature, the sterilization period is short, the damage to a human body, equipment and the surrounding environment is reduced after operation, the penetrability to HEPA is relatively high, and the initial investment cost of the equipment is relatively low.

Owner:中科圣杰(深圳)科技集团有限公司

Process for high-temperature flue gas purification, white smoke elimination and waste heat recovery

InactiveCN111939730AImprove heat recovery efficiencyGood whitening effectGas treatmentDispersed particle separationIndustrial wasteFlue gas

The invention relates to the technical field of flue gas or waste gas treatment, in particular to a process for high-temperature flue gas purification, white smoke elimination and waste heat recovery.The process comprises a flue gas purification, white smoke elimination and heat recovery all-in-one machine. The all-in-one machine comprises a total heat recovery device, a high-temperature sensibleheat recovery device, a salt solution moisture absorption device and a reheating air supply device. The total heat recovery device comprises a high-temperature total heat recovery device, a medium-temperature total heat recovery device and a low-temperature total heat recovery device. The high-temperature total heat recovery device comprises an ash-water separation device and a high-temperature heat recovery plate heat exchanger A. The ash-water separation device comprises a full-automatic rotary cage type filter unit and a filter press. The salt solution moisture absorption device is provided with a solution regeneration device. The purification and white smoke elimination effects on high-temperature dusty smoke (or high-temperature industrial waste gas) are well achieved through a whitesmoke elimination unit, the ideal environment-friendly effect is achieved, meanwhile, waste heat in the smoke is recycled to the maximum degree, and economic benefits and social benefits are improved.

Owner:常州康德净化节能科技有限公司

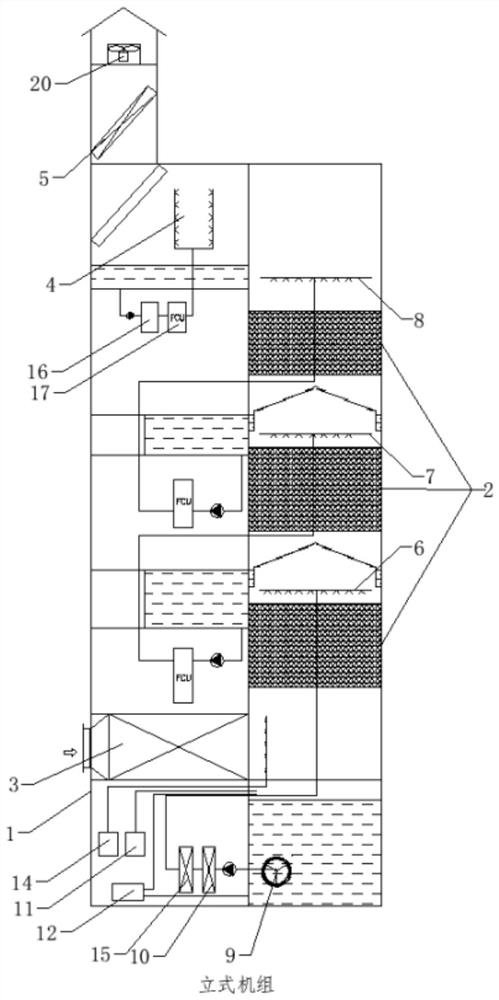

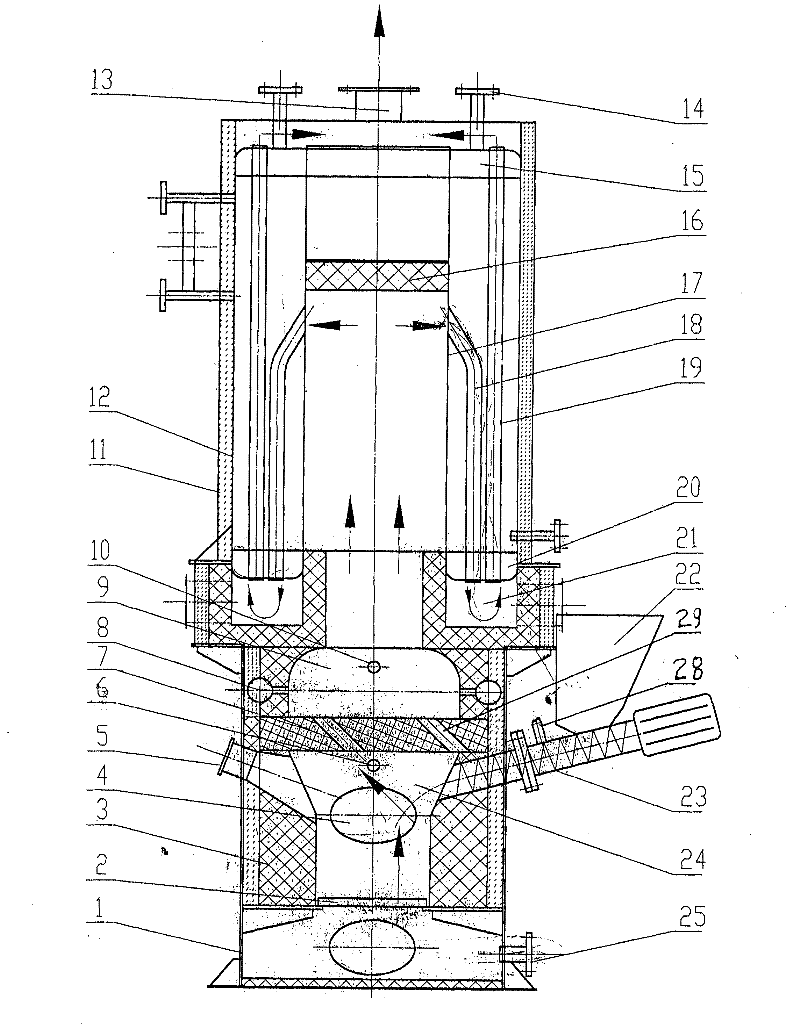

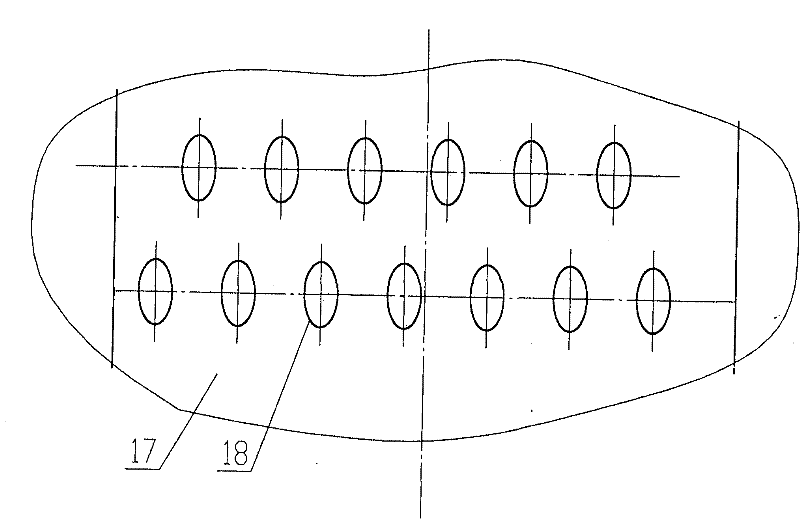

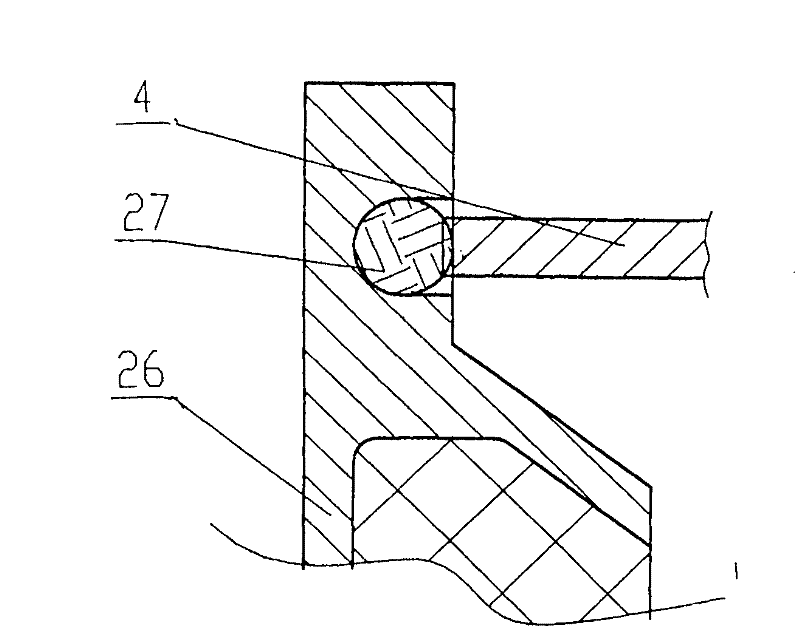

Vertical environment-friendly boiler for triple dedusting burning wood and biomass particle fuel in boiler

InactiveCN101907292BFully embersFully vaporizedSolid fuel combustionCasings/liningsDust controlHearth

The invention relates to a vertical environment-friendly boiler for triple dedusting burning wood and biological particle fuel in a boiler, belonging to heating technology. The invention is used for burning wood and biological particles to obtain hot water or steam, and overcomes the defects of black smoke emission, low thermal efficiency, and the like of the similar traditional boilers. The boiler comprises a wind chamber, a fire grate, a carbon powder and gas burning hearth, a first wind inlet, a secondary wind inlet, and a heat exchanger above the hearth. The boiler is characterized in that the hearth is provided with a porous boiler crown of an inclined air vent; the upper end of an inner liner is provided with a smoke blocking wall; a downward screwed smoke tube is arranged between the wall of the inner liner and a lower end socket; an upward screwed smoke tube penetrates through an upper closing plate and a lower closing plate; and a heat exchanger seat of a smoke diversion dedusting chamber in the shape of a ring cavity is arranged on the circumference of the lower end of the heat exchanger. The invention has the advantages of sufficient burning of carbon powders, sufficient gasification and high thermal efficiency. Smoke is dedusted three times in the boiler, and the exhausted smoke has low dust capacity. The invention can be manufactured in a split mode, and is convenient to transport. The tonnage can be greatly increased.

Owner:袁福林

A cooling water treatment system for refrigeration units in dry season

ActiveCN105347557BSave energyLow running costChemical industryMultistage water/sewage treatmentSiphonChemical industry

The present invention relates to the textile chemical industry energy saving field, particularly relates to a cooling water treatment system, and more particularly relates to a cooling water treatment system of a refrigerating unit in dry season, and the cooling water treatment system comprises a pump boat, a grit pool, a machine pool, a siphon pool, a clean water pool, a clear water pump, a refrigeration unit, an ion exchanger, a soft water pipe network and an old refrigeration station.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

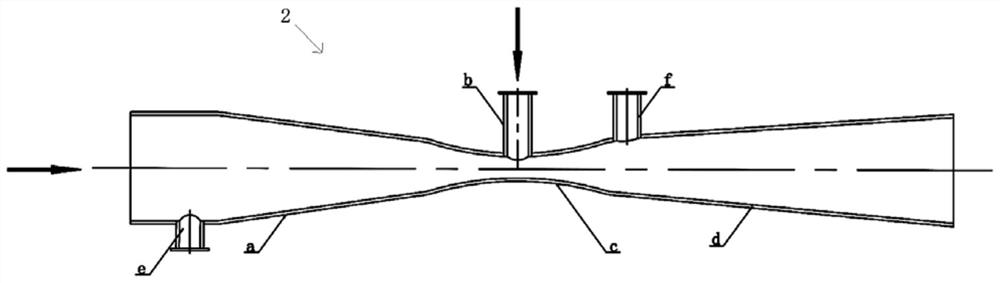

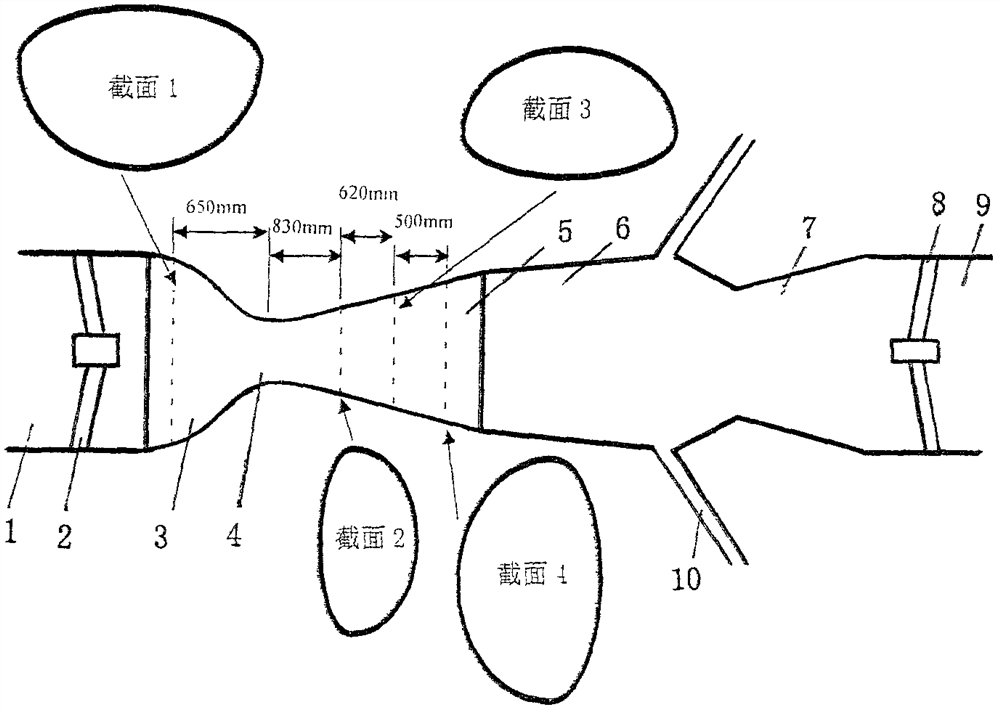

A high-speed vortex flow gas separation device

ActiveCN108514805BEasy to separateImprove separation efficiencyGas treatmentGaseous fuelsLiquid hydrocarbonsEngineering

A high-speed vortex flow gas separation device, comprising a device inlet port (1), a device nozzle (3, 4, 5, 6), a device diffuser section (7) connected to the device nozzle, and a device Outlet end (9); said device nozzle (3, 4, 5, 6) is sequentially composed of constriction section (3), throat (4), expansion section (5) and working section (6); The cross-sections of the device nozzles (3, 4, 5, 6) are not concentric circular cross-sections, but non-concentric deformed cross-sections, which eliminate the vortex stagnation in the central area of each cross-section of the flow channel of the device nozzles zone; the high-speed vortex flow gas separation device obtains a dry gas production rate of 98.5%-99.5%; in the feed gas, the total proportion of liquid hydrocarbons above carbon-3 is 5.52%, through the high-speed After separation by the vortex flow gas separation device, the removal amount of liquid hydrocarbons above carbon-3 is 4.02%-5.02%.

Owner:闫家义 +1

An aluminum melting furnace using flue gas backflow low oxygen high temperature combustion

ActiveCN106766901BImprove heat transfer performanceReasonable distributionCrucible furnacesIndirect carbon-dioxide mitigationRefluxTemperature control

The invention relates to an aluminum melting furnace capable of performing low-oxygen high-temperature combustion through flue gas reflowing, and aims to effectively realize temperature control, decrease the content of nitrogen oxide and save energy in the melting process of the aluminum melting furnace. The aluminum melting furnace is characterized in that the top of an annular furnace wall surrounding the bottom of the furnace is provided with an annular arc-shaped top cover; a middle charging channel wall body is formed in a through hole in the middle part of the top cover; a charging and flue gas discharging channel is formed inside the middle charging channel wall body; a combustion melting hearth is formed in the annular furnace wall; the middle part of an exhaust hood on the top of the charging and flue gas discharging channel is provided with a furnace top cover; the periphery of the exhaust hood is provided with an exhaust hood outlet pipe; a combustor is arranged in the circumferential direction of the annular furnace wall; a flue gas outlet on the inner wall of the charging channel wall body is connected with the charging and flue gas discharging channel; the outer end of the flue gas outlet is connected with an inner ring of a flue gas converging annular channel; a flue gas converging main pipe communicating with an outer ring of the annular channel is connected with a flue gas reflow inlet through a flue gas reflow communication pipe; the annular furnace wall is provided with an operation furnace door and a molten liquid discharging hole. By adopting the aluminum melting furnace, control of the combustion temperature is realized, the combustion temperature is lowered, control of the content of the nitrogen oxide is realized, and the using amount of coal gas is reduced.

Owner:郑州釜鼎热能技术有限公司

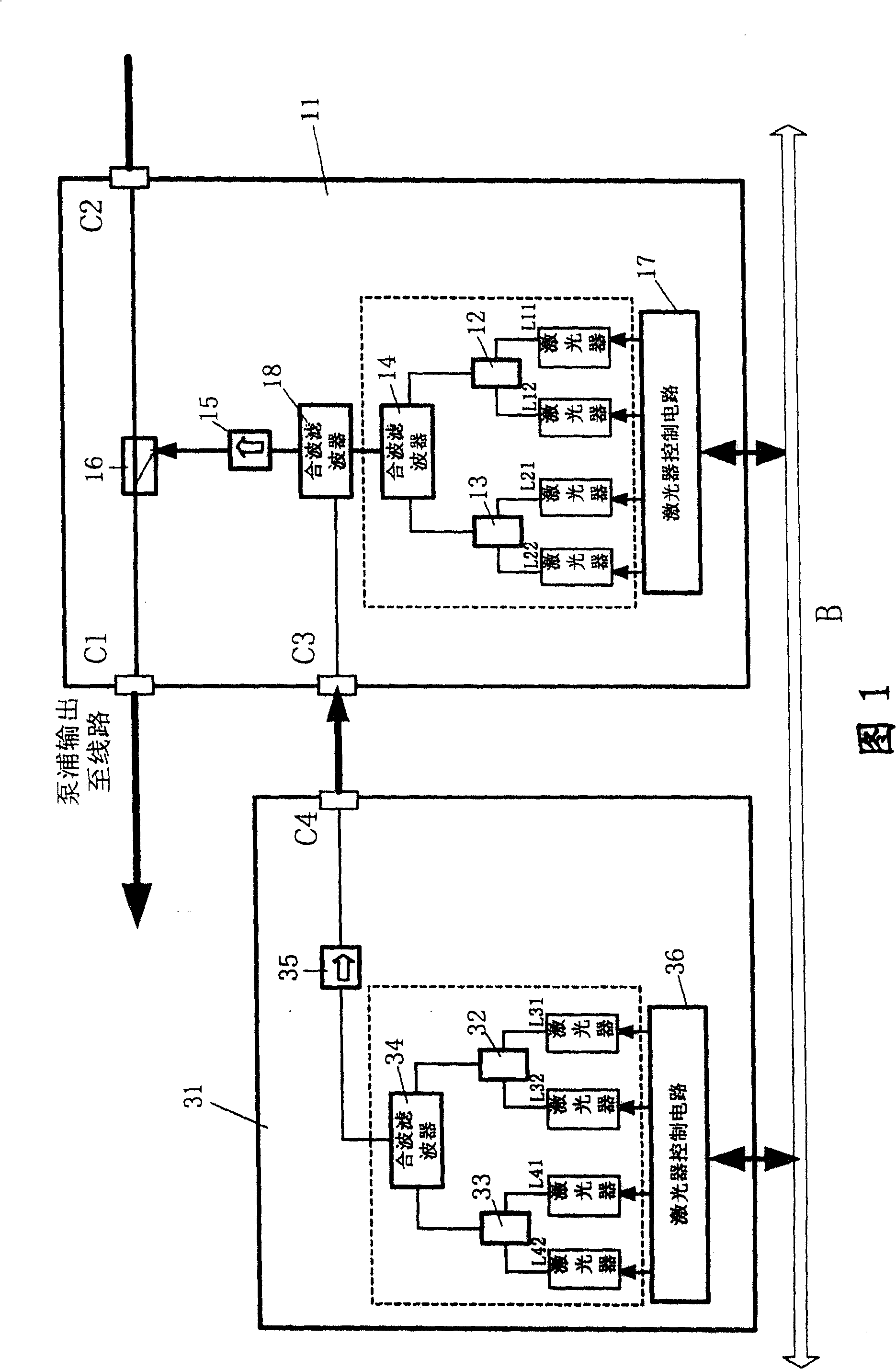

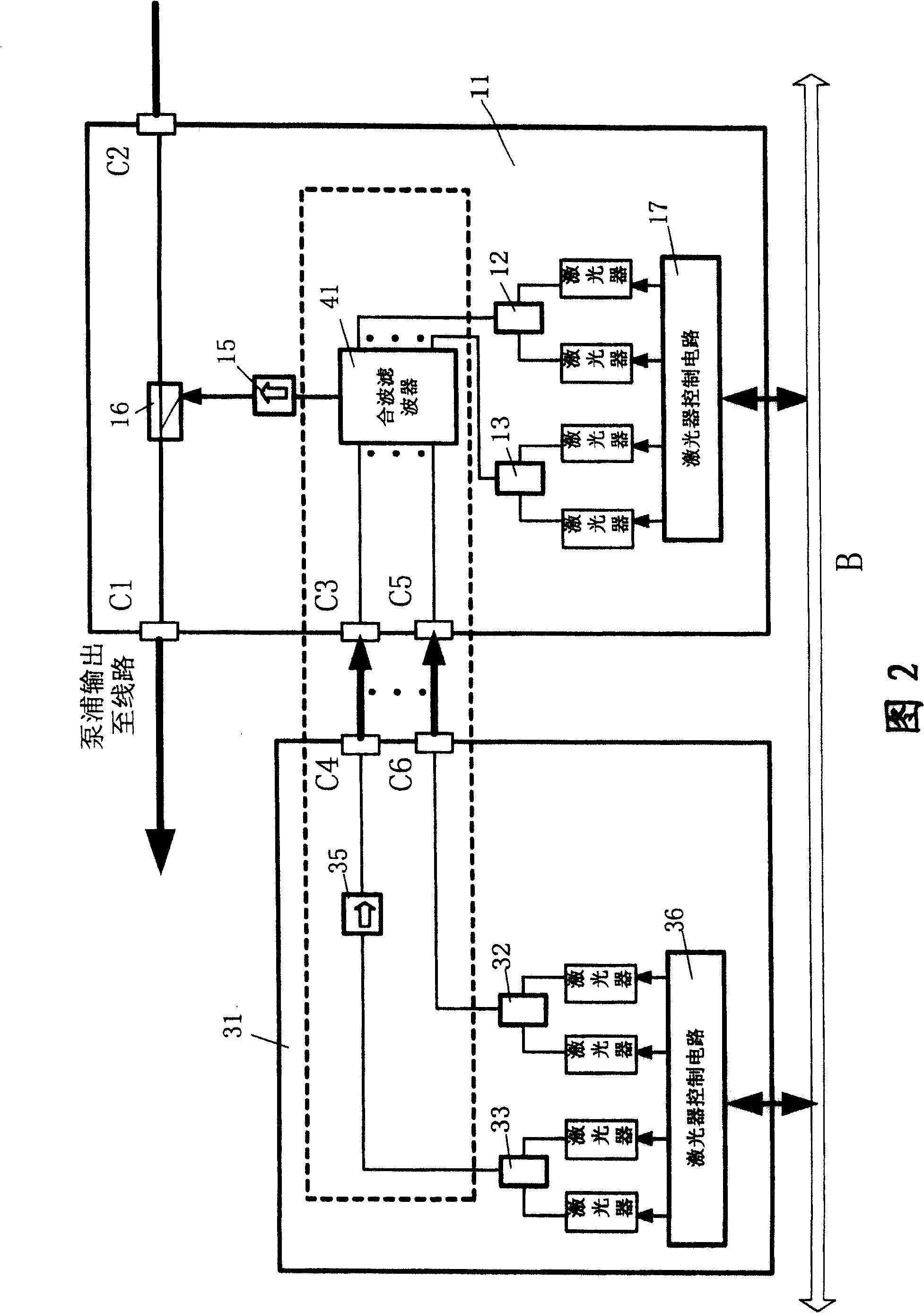

Extendible Ruman amplifier and control method thereof

InactiveCN100454127CReduce initial investment costsFlexible working bandwidthLaser using scattering effectsElectromagnetic transmissionWave bandEngineering

This invention relates to an expanded Raman amplifier including a master amplifier and a subamplifier. They are composed of a pump laser providing pump light source, a wave synthesizer and a laser control circuit connecting with the equipment communication bus via an interface, the pump source of the sub amplifier is input to the master via the fiber interface after synthesis and input to transmission fiber together with the master pump light via the synthesized filter and interface of the master amplifier. They can be connected or separated physically due to the light interface like a flexible jumper and a luggable electric interface and flexiblly mounted or dismantled.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com