Ground-source heat pump system allowing refrigerant to directly exchange heat with soil

A ground source heat pump and refrigerant technology, applied in refrigerators, air-conditioning systems, refrigeration components, etc., can solve the problem of increasing the cost of drilling wells for the ground source heat pump system and the initial investment cost of the system, and increasing the heat transfer resistance between the refrigerant and the soil , Increase the work of ground source hot water pumps, etc., to achieve the effect of reducing initial investment costs, occupying less well drilling area, and reducing the number of well drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

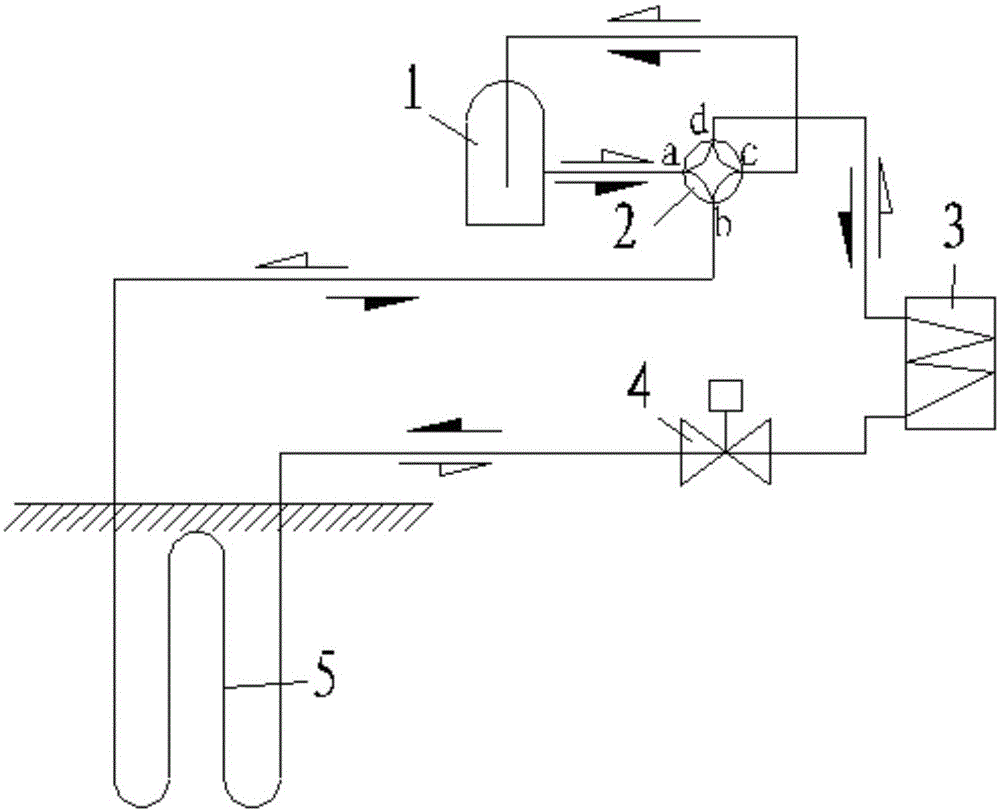

[0016] see figure 1 , an embodiment of the present invention, a ground source heat pump system that directly exchanges heat between refrigerant and soil, including a compressor 1, a four-way valve 2, a user-side heat exchanger 3, a throttling mechanism 4, and a ground-source side high-efficiency heat exchange system device 5. The outlet of the compressor 1 is connected to the first end a of the four-way valve 2, and the inlet of the compressor 2 is connected to the second end c of the four-way valve 2; the third end d of the four-way valve 2, the user-side heat exchanger 3 , the throttling mechanism 4 , the ground-source side high-efficiency heat exchange device 5 and the fourth end b of the four-way valve 2 are sequentially connected; the ground-source s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com