Process for high-temperature flue gas purification, white smoke elimination and waste heat recovery

A high-temperature flue gas and flue gas purification technology, applied in the field of flue gas or waste gas treatment, can solve problems such as energy waste, deterioration of ecological environment, air pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

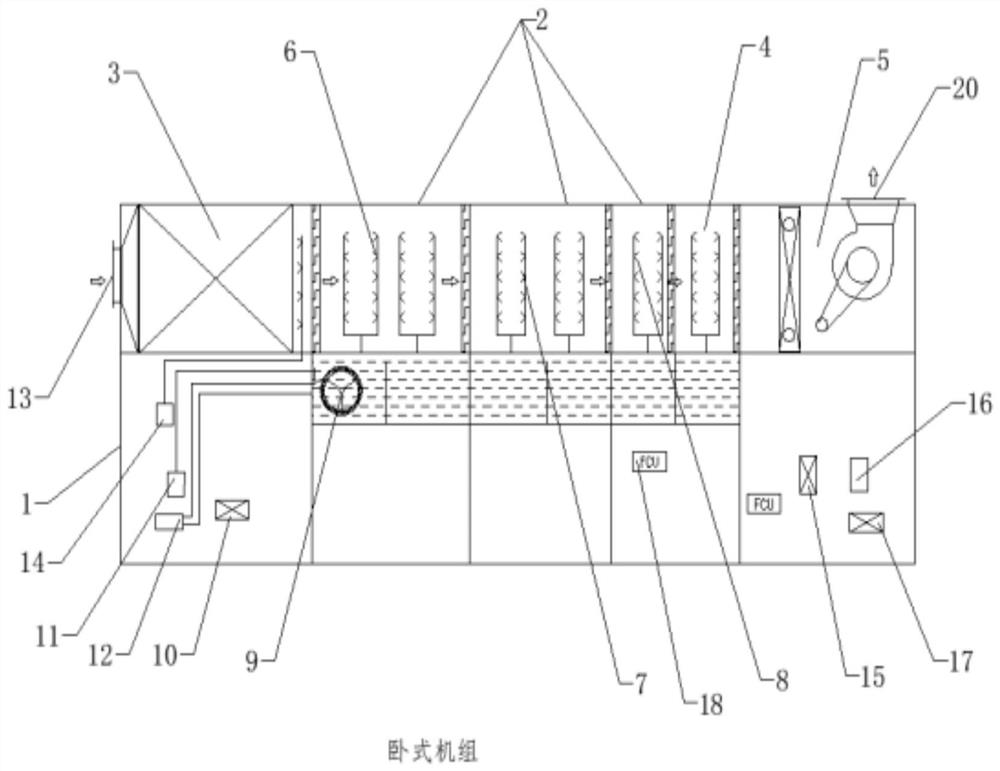

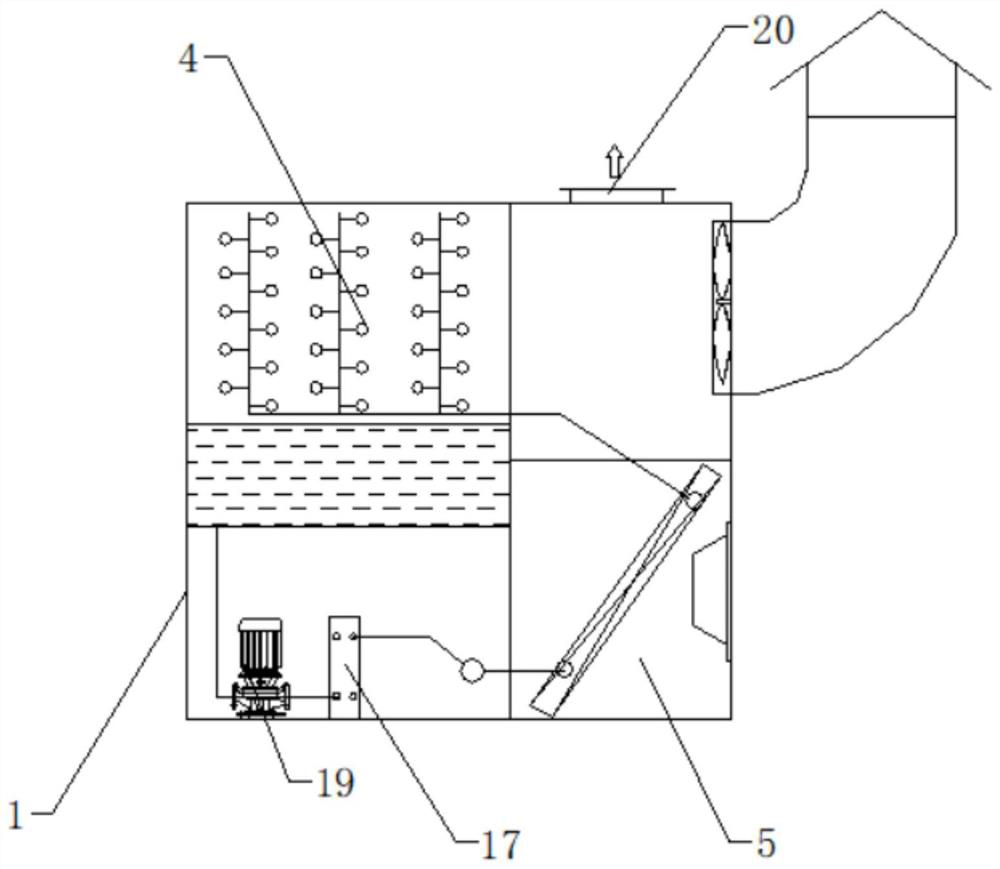

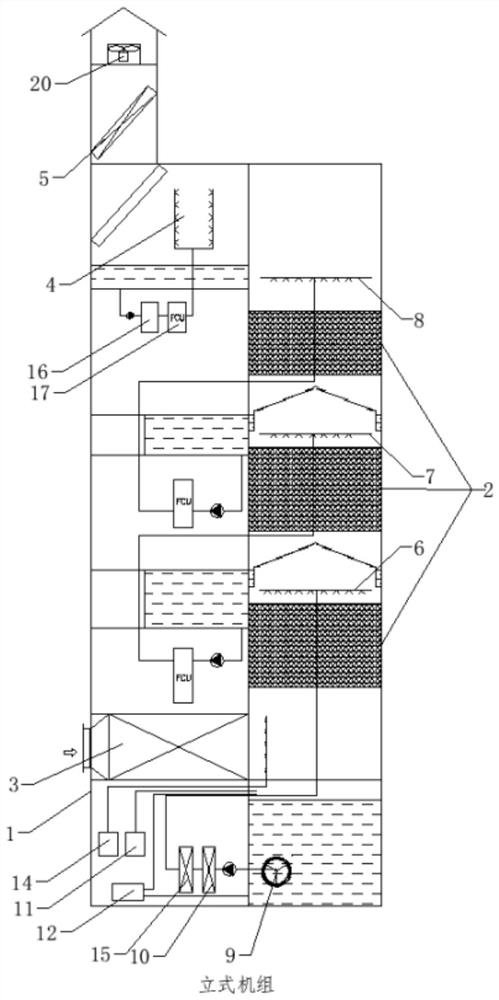

[0047] Example: Flue gas purification and white heat recovery integrated machine 1 includes heat recovery and dehumidification treatment:

[0048] The heat recovery work of flue gas purification and white heat recovery integrated machine 1 includes the following principles:

[0049] Flue gas sensible heat recovery device: high-temperature flue gas passes through the high-temperature side, water passes through the low-temperature side, and heat exchange is performed between them through professional stainless steel titanium plates;

[0050] Spray total heat recovery device: Water droplets are atomized through professional nozzles, and the atomized water droplets perform heat and moisture exchange with the flue gas in the water spraying chamber. The flue gas transfers a large amount of sensible heat and latent heat of vaporization to the circulating water, and the external cold source passes through Plate heat exchanger to recover heat from circulating water;

[0051] 1. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com