Patents

Literature

45results about How to "Improve the quality of finished products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

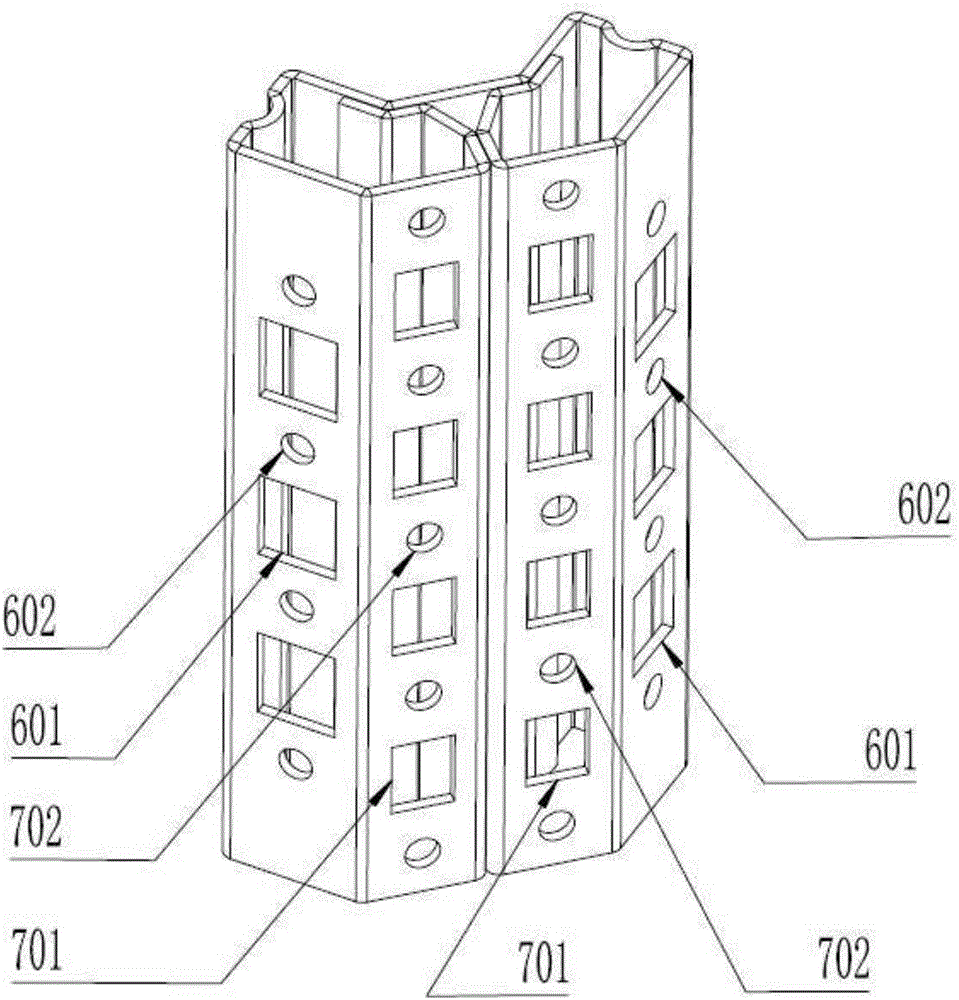

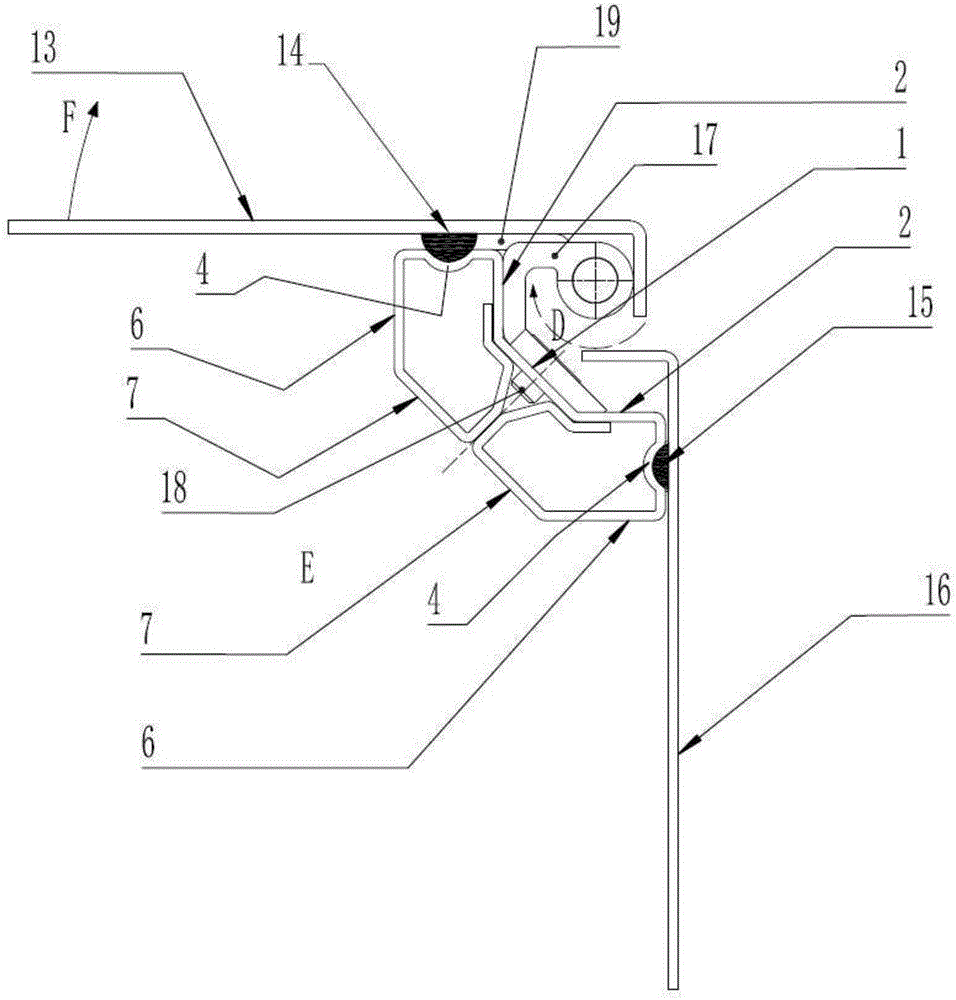

Section steel for equipment cabinet frame

ActiveCN106852049AHigh strengthImprove torsion resistanceCasings/cabinets/drawers detailsRack/frame constructionStructural engineeringMechanical engineering

Owner:WUXI KANGBEI ELECTRONICS EQUIP

Celery planting method

InactiveCN107094477AImprove fertilityImprove compactionAgriculture tools and machinesPlant cultivationSoil mixingCrop cultivation

The invention relates to the technical field of crop planting, particularly a celery planting method. The method particularly comprises the steps of soil preparation, construction of seedbed, manufacturing of reagent-mixed soil, seed selection, seed soaking and pregermination, seed sowing, thinning, insect killing, field planting, watering, fertilizing, and harvesting. According to the celery planting method provided by the invention, the soil conditioner added in the soil preparation process can effectively enhance the adaptability of plants to soil and promote the healthy and fast growth of plants. The reagent / sandy soil mixing ratio and the composition and proportion of the reagent can enhance the germination rate of seeds. The celery grown by the celery planting method has the advantages of high germination rate and high yield. The method is scientific and reasonable, is simple and easy to operate, and has the advantages of short culture period, high operability, great market potential and wide prospects.

Owner:蒙运绍

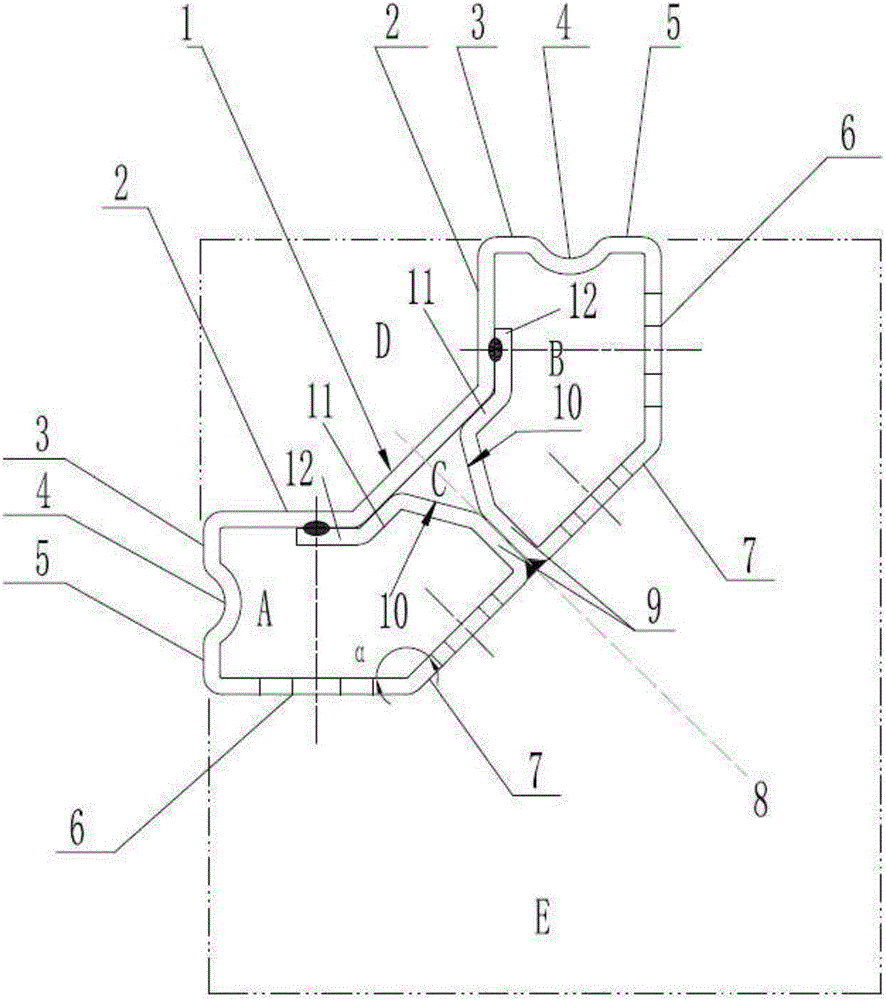

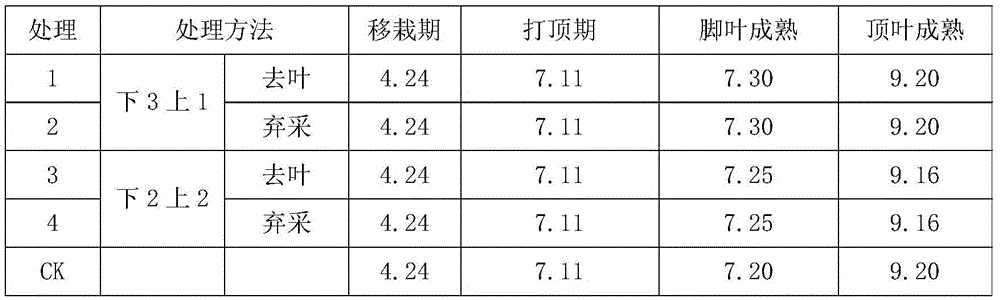

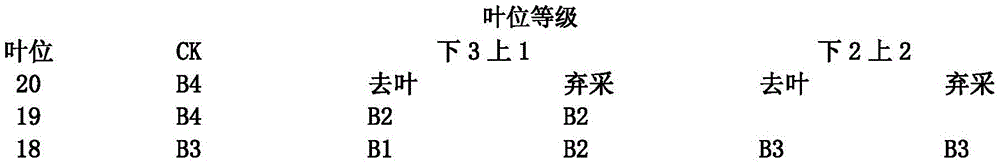

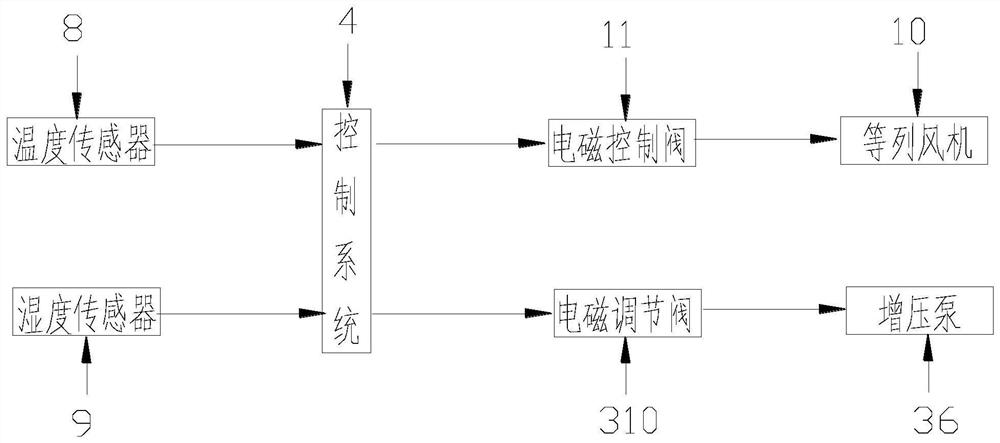

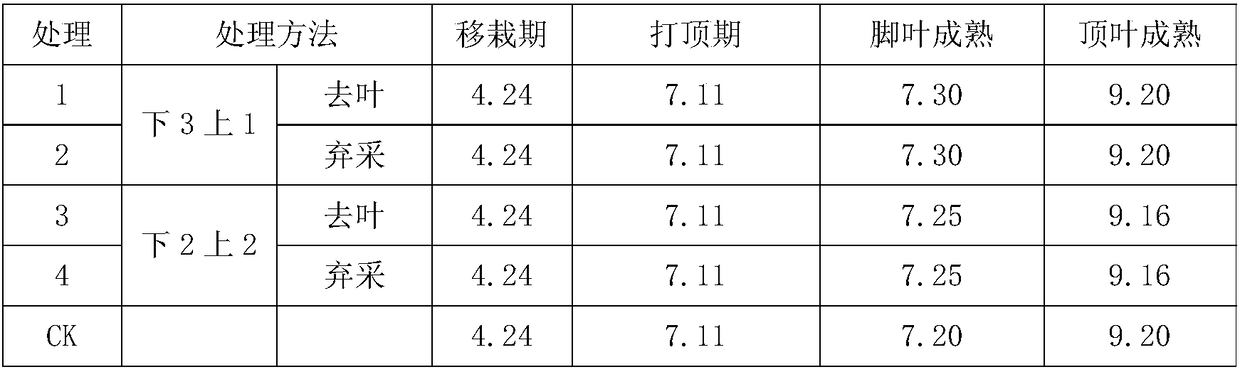

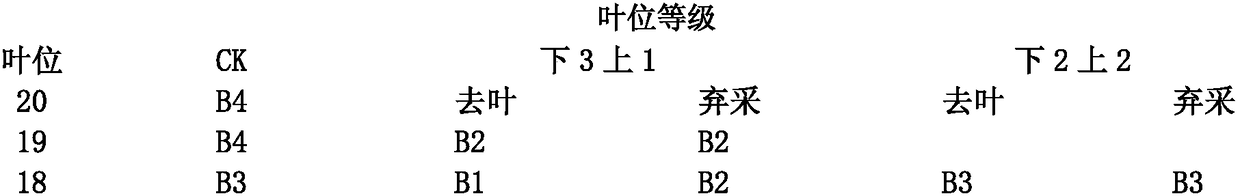

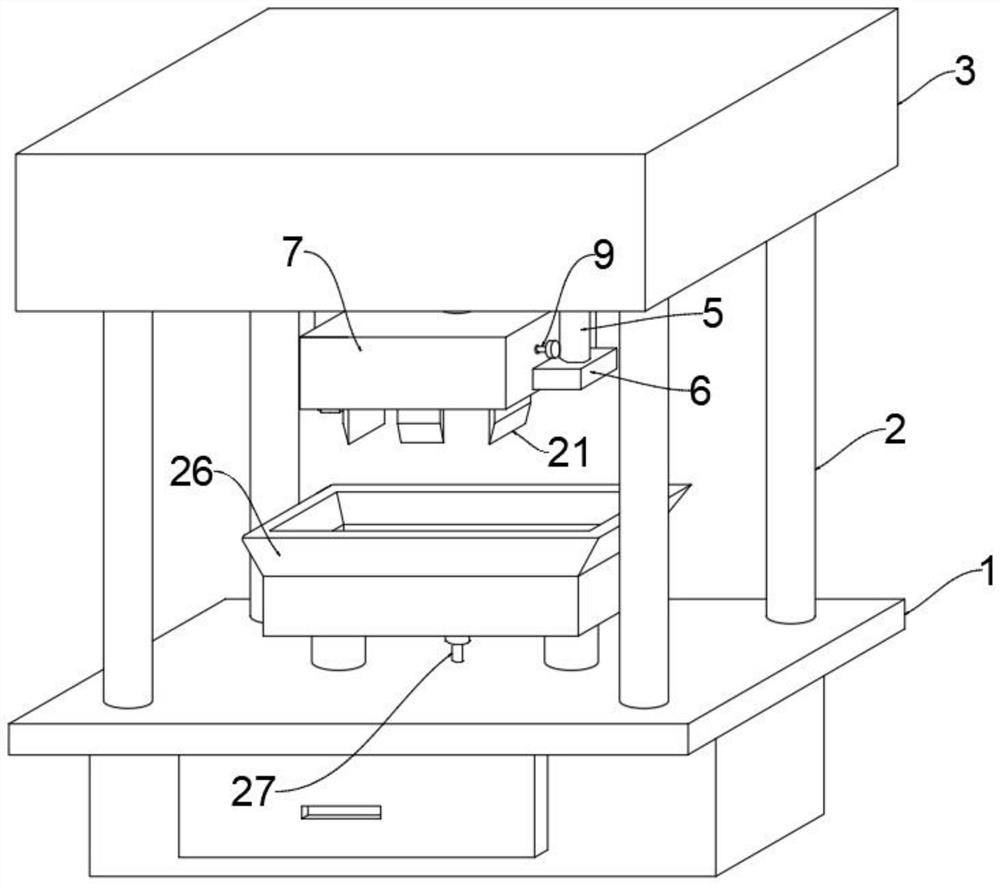

Control method for improving finished product tobacco leaf quality based on leaf position characteristics

InactiveCN105580628AAvoid unnecessary consumptionImprove sensory qualityPlant cultivationCultivating equipmentsTobacco leafManufacturing engineering

The invention discloses a control method, particularly discloses a control method for improving finished product tobacco leaf quality based on leaf position characteristics, and belongs to the technical field of tobacco cultivation technology. The control method for improving finished product tobacco leaf quality based on the leaf position characteristics controls the number of tobacco leaves to improve the finished product tobacco leaf quality in the growth process of tobacco. According to the control method, after the working procedure of topping and reserving 20 blades is executed, the finished product tobacco leaf quality is improved through the working procedure of removing part of blades at the leaf positions on the top and / or bottom again.

Owner:INST OF TOBACCO ANHUI ACADEMY OF AGRI SCI +1

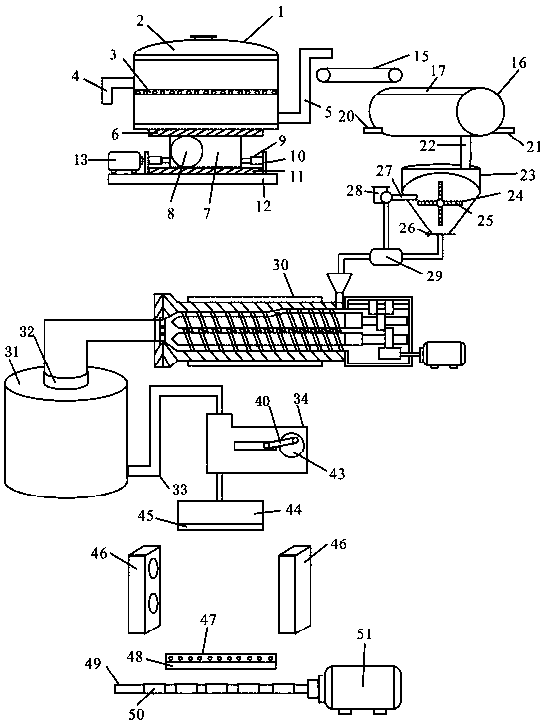

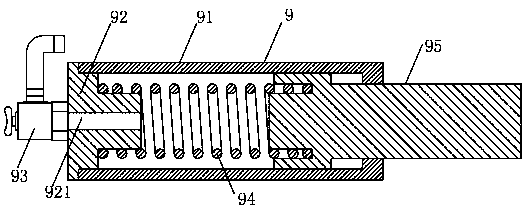

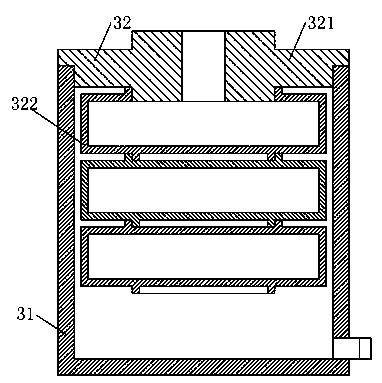

High-performance polyester POY preparation device and method

ActiveCN110938882AImprove qualityImprove product qualitySpinning solution de-aeratingFilament forming substance formingPolyesterPolymer science

The invention discloses a high-performance polyester POY preparation device and method. The high-performance polyester POY preparation device comprises a vibration impurity removal device, a crystallization device, a drying device, a screw extrusion device, a filtering device, a melt metering pump, a heat preservation box, a spinning assembly, a side air blowing device, a filament guide device, anoiling device and a winding device, wherein a polyester slice is subjected to vibration and impurity removal; a melt is filtered through the filtering device and then is subjected to spinning; the whole process flow comprises twice filtering and impurity removal, so that the production quality of the polyester POY is improved. The high-performance polyester POY preparation device and method provided by the invention have the advantages of being reasonable in structure, convenient to use, high in finished product quality and the like, and effectively solve the problem that the conventional polyester POY production process does not involve screening of materials in a former procedure, so that impurities are easily doped in the raw materials, and the quality of the polyester POY is affected.

Owner:诸暨市百乐化纤有限公司

Preparation method for water-soluble sesamin

The invention relates to a preparation method for water-soluble seamin. The preparation method comprises the following steps: selecting sesame seed meal as a raw material; performing secondary enzymatic hydrolysis, water washing, solvent extraction, active carbon treatment, cyclodextrin inclusion, membrane separation and freeze drying technology to obtain a water-soluble sesamin product of which the sesamin content is not lower than 65 percent by weight and the sesamin recovery rate is higher than 95 percent. The method is simple and convenient in steps; moreover, the conventional method using a toxic reagent, namely, diethyl ether or n-hexane is abandoned, so that the finished product quality of the sesamin product is ensured well, the water-soluble sesamin product is obtained directly, and subsequent production and utilization of the sesamin product are facilitated well.

Owner:内蒙古昶辉生物科技股份有限公司

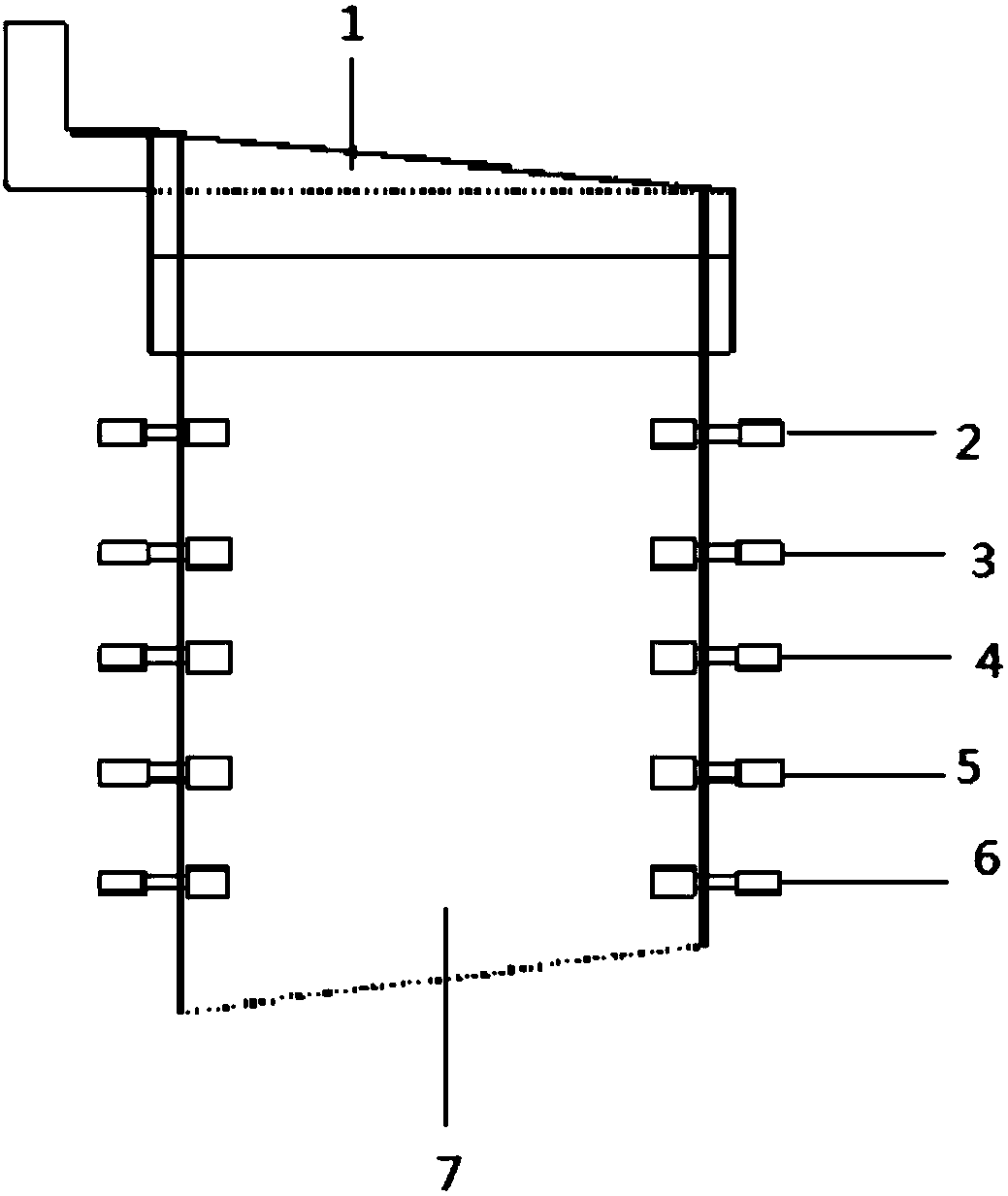

Control system and control method for sheet glass quality stability

InactiveCN107601825AOpportunity to increase shape and sizeImprove the quality of finished productsGlass forming apparatusEngineeringMechanical engineering

The invention relates to a control system and a control method for sheet glass quality stability. The control system comprises a plurality of groups of short roller traction roller assemblies for applying traction force to a glass tape, a horizontal position adjusting device, an angle adjusting device, a speed adjusting device and a clamping force adjusting device. The control method mainly comprises the step of adjusting the horizontal positions, angles and speeds of the traction roller assemblies and clamping force for the glass belt. Due to the fact that the technical scheme for the short roller traction roller assemblies and combination adjusted control system parameters is adopted, the angles, horizontal and vertical positions and rotating speeds of roller components with the glass belt and the clamping force for the glass belt can be adjusted independently in the process that the glass belt is manufactured into sheet glass, the opportunity of controlling the shape and size of C shape is increased, and the quality of the finished product can be improved. The control system has the characteristics of reasonable structure, convenient implementation and good effect for stabilizing the quality of the finished product.

Owner:彩虹(合肥)液晶玻璃有限公司

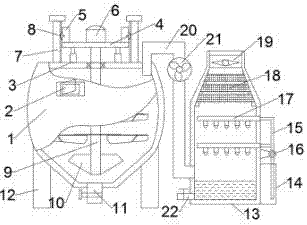

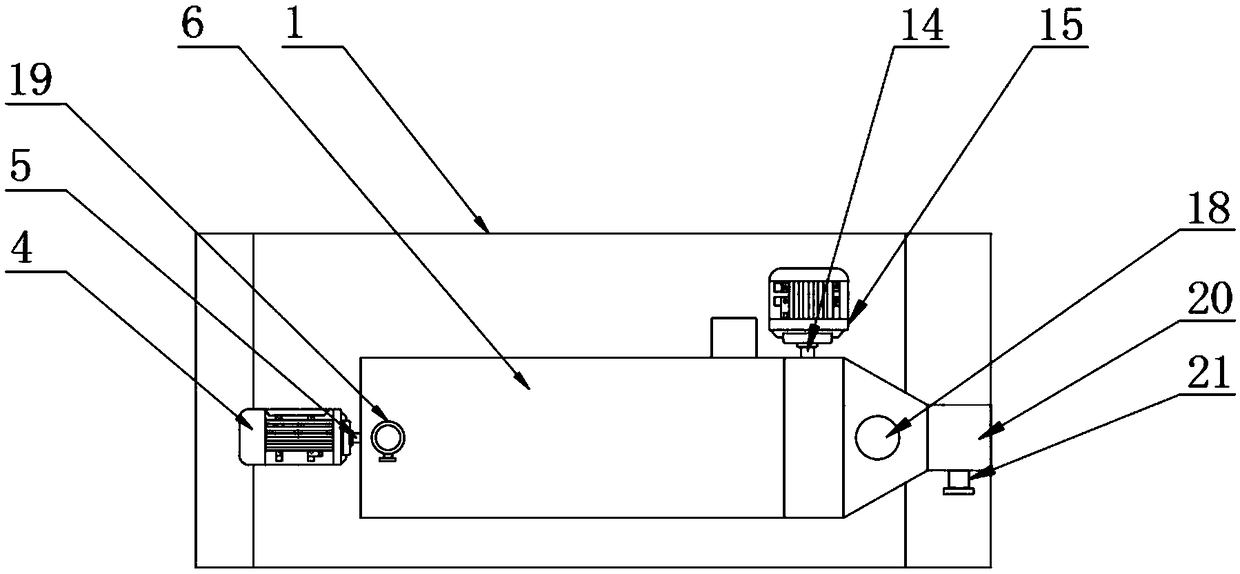

Pollution-free construction concrete mortar slurry stirring equipment

InactiveCN106976163AImprove the quality of finished productsAvoid harmUsing liquid separation agentCement mixing apparatusPulleyPollution

The invention discloses pollution-free construction concrete mortar slurry stirring equipment. The stirring equipment comprises a stirrer shell, vertical sliding rods are arranged on the two sides of the outer side wall of the top of the stirrer shell respectively, a center rotating shaft of a rolling pulley is fixedly hinged to a supporting convex block, electric telescopic rods are arranged on the left side and the right side between the bottom side surface of a plate body of a lifting supporting plate and the outer side wall of the top of the stirrer shell respectively, the bottom end of a waste gas extraction guide pipe is connected to the left side wall of the lower portion of a waste gas treatment box, and two spraying coil pipes are horizontally arranged in the inner cavity of the middle of a box body of the waste gas treatment box. According to the pollution-free construction concrete mortar slurry stirring equipment, the defect that the effect is different due to the long-time processing in the same direction is overcome, the quality of finished products of processed slurry is effectively improved, the waste gas is prevented from being discharged into the surrounding air, thus serious damage to the atmosphere is avoided and the body health of workers beside the equipment is guaranteed, and the construction work of the building is guaranteed to be carried out smoothly.

Owner:林娟娟

Preparation method for aluminum zinc phosphate

InactiveCN109534311AThe design of the preparation process is reasonableImprove the quality of finished productsPhosphorus compoundsPhosphoric acidChemistry

The invention belongs to the technical field of production of aluminum zinc phosphate, and specifically discloses a preparation method for the aluminum zinc phosphate. The preparation method comprisesthe following steps: step 1, adding a certain amount of zinc oxide and a proper amount of water into a reaction kettle through a feed box, and carrying out slow stirring so as to obtain a zinc oxideslurry; step 2, adding certain amounts of aluminum oxide and phosphoric acid into the reaction kettle; step 3, adding a zinc dihydrogen phosphate solution into a zinc oxide reaction kettle in batches;step 4, transferring a reacted feed liquid to a centrifuge through a pipeline so as to remove moisture and impurities; step 5, drying an obtained water-containing solid through a dryer; and step 6, allowing a dried solid to pass through a crushing device and a gas cyclone device so as to obtain qualified aluminum zinc phosphate. The preparation method for the aluminum zinc phosphate provided by the invention has the following beneficial effects: the preparation process for the aluminum zinc phosphate is reasonable in flow design; a finished aluminum zinc phosphate product has high quality andhigh production efficiency; the loss of raw materials for preparation of the aluminum zinc phosphate is reduced; economic benefit is improved; and the cost of labor is saved.

Owner:JIANGSU SHENLONG ZINC IND

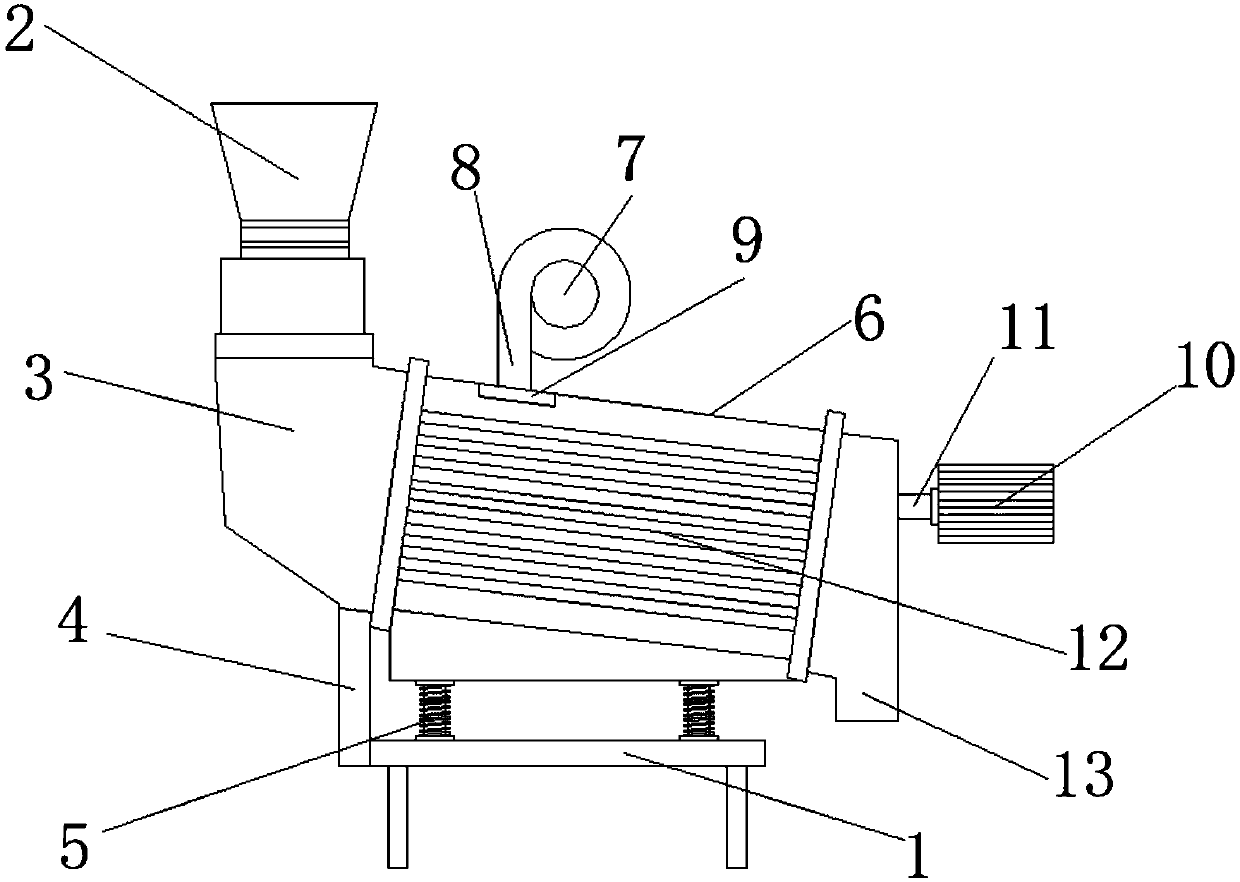

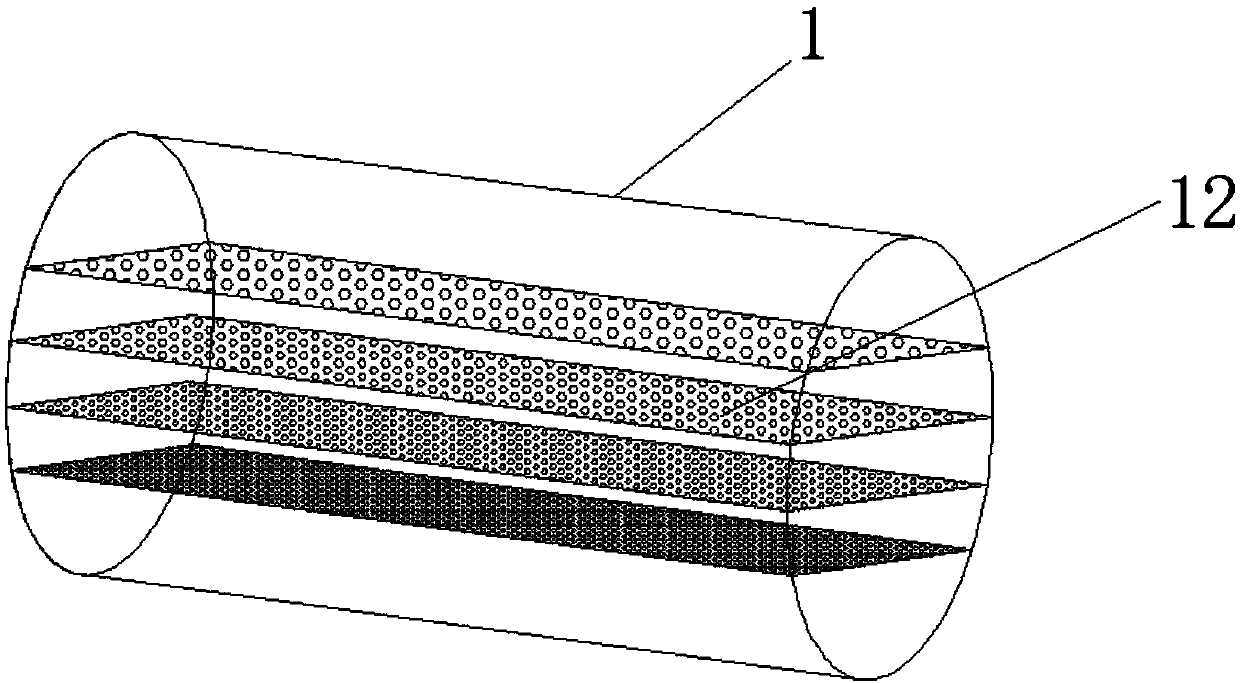

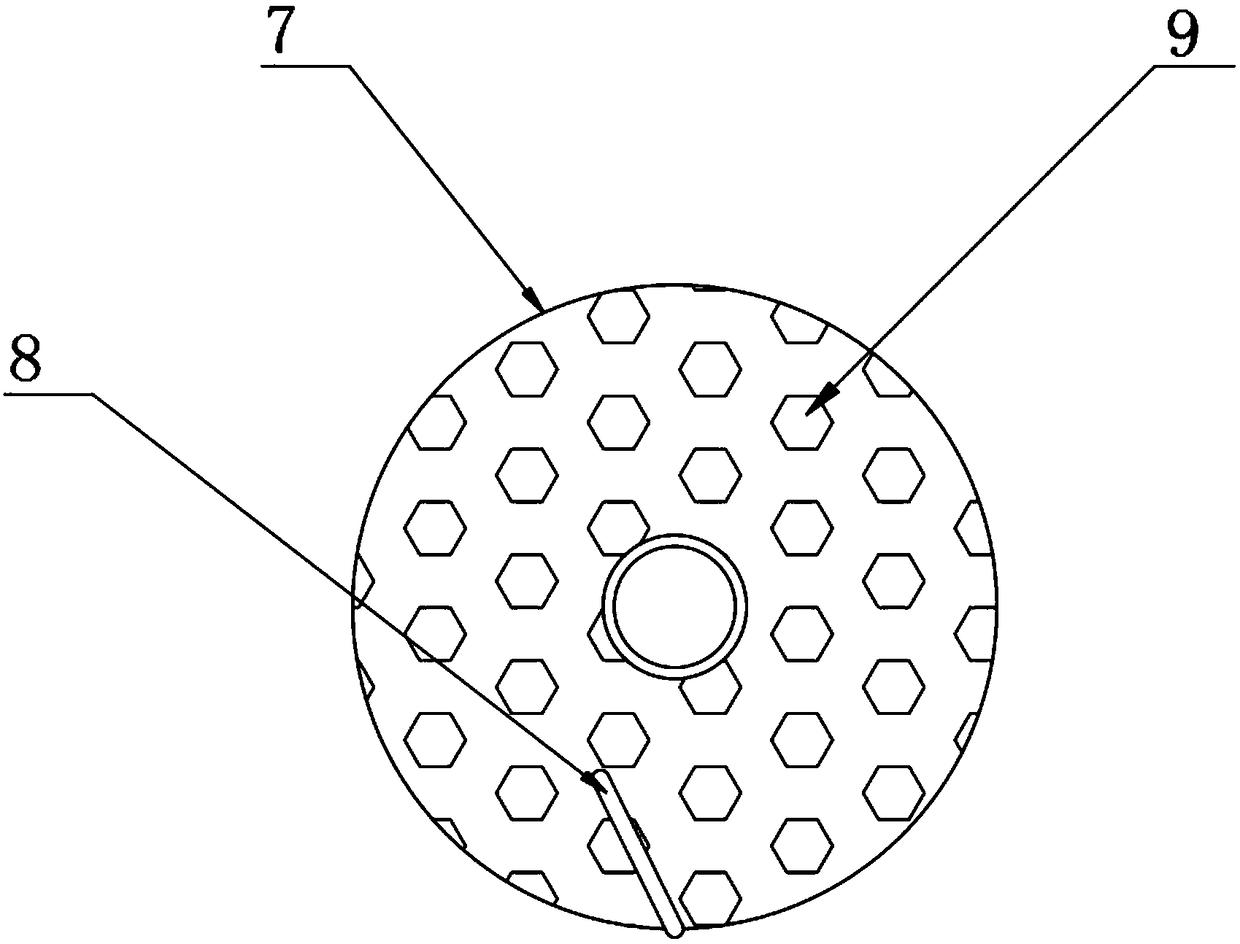

Separator for brown rice and rice husk

PendingCN107583861AEasy to separateGuarantee the quality of finished productsSievingGas current separationHuskEngineering

The invention discloses a separator for brown rice and rice husk. The separator comprises a base, damping pillars are arranged at the upper end of the base, a sifting bin is arranged at the upper endsof the damping pillars, a feeding pipe is arranged at one end of the sifting bin, a feeding hopper is arranged at the upper end of the feeding pipe, a fixed block is arranged at the lower end of thefeeding pipe, an air blower is arranged above the sifting bin, an air pipe is arranged at the lower end of the air blower, an air inlet area is arranged at the lower end of the air pipe and is locatedinside the sifting bin, and a discharging pipe is arranged at the other end of the sifting bin. Through the arranged air blower and a vibration motor, the brown rice and rice husk can be quickly separated, the quality of finished product of cereals is guaranteed, several sets of sifting plates are arranged, the size of the sifting holes of the sifting plates are set to be increasingly smaller from top to bottom, so that the brown rice and rice husk can be more finely sifted, and the quality of the finished product of the cereals is improved. The separator for the brown rice and rice husk is simple in structure and convenient to use, the quality of the cereals is effectively guaranteed, the maintenance and overhaul frequency of the machine is lowered, and thus the separator is beneficial to application and popularization.

Owner:颍上县皖润米业有限公司

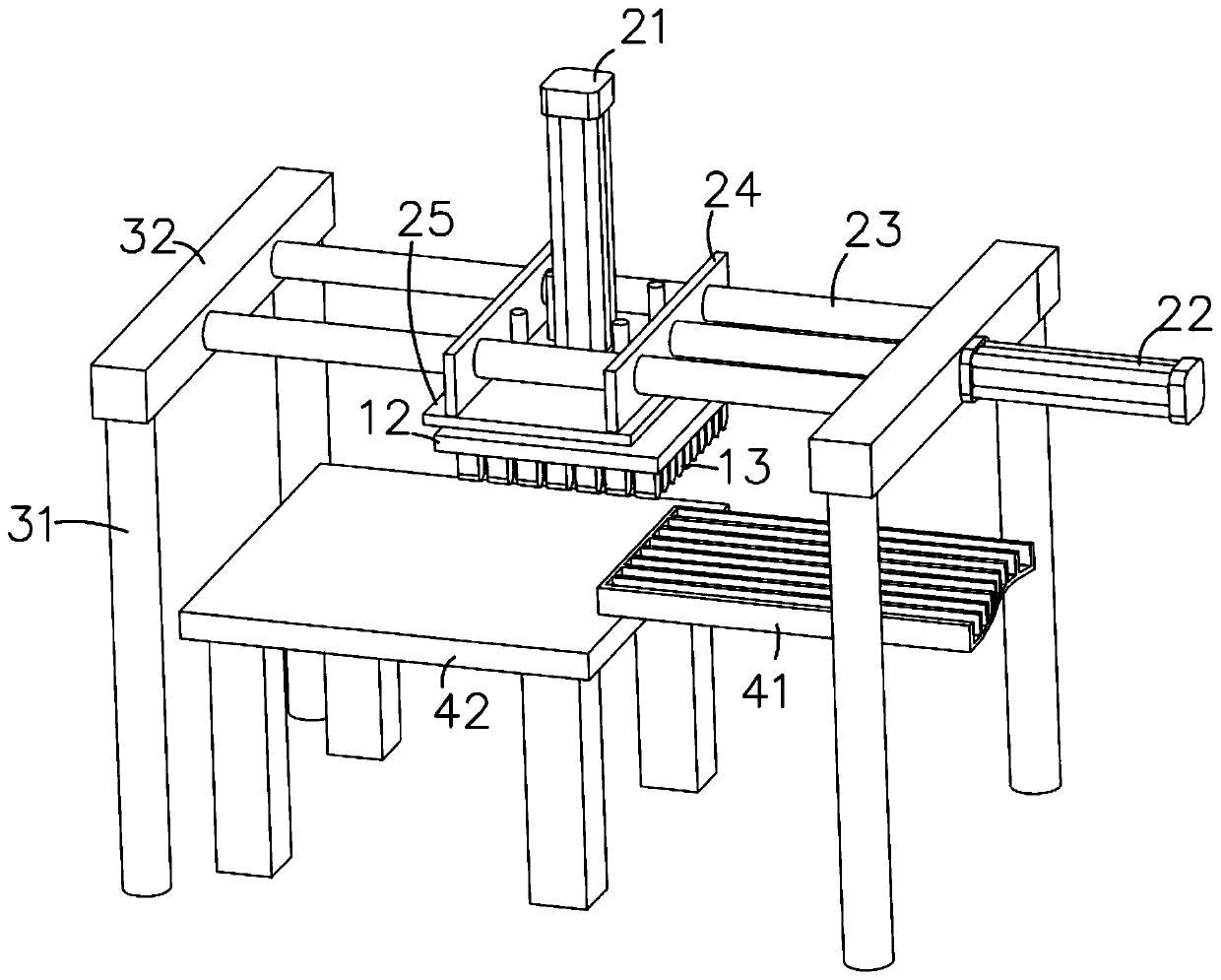

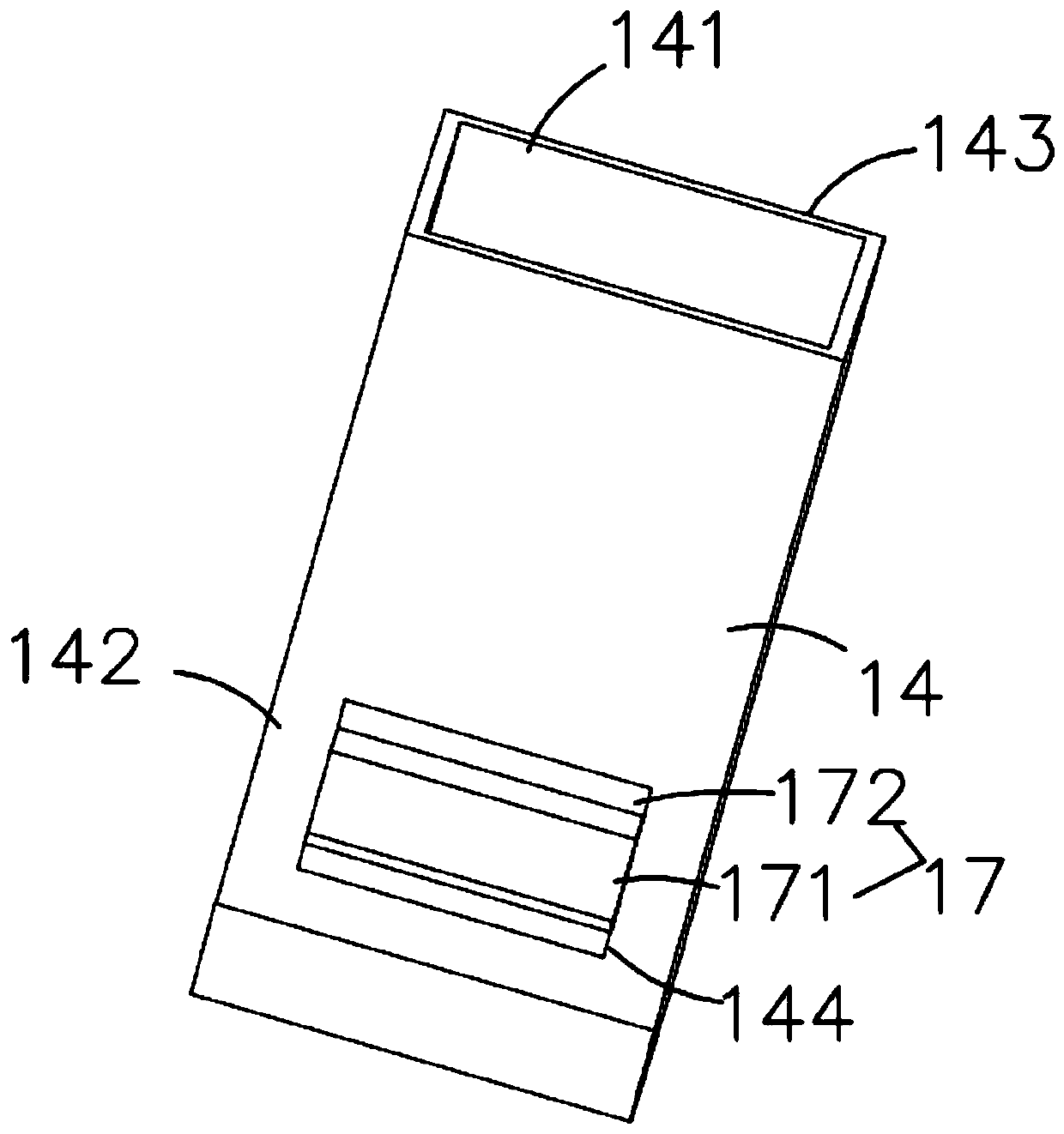

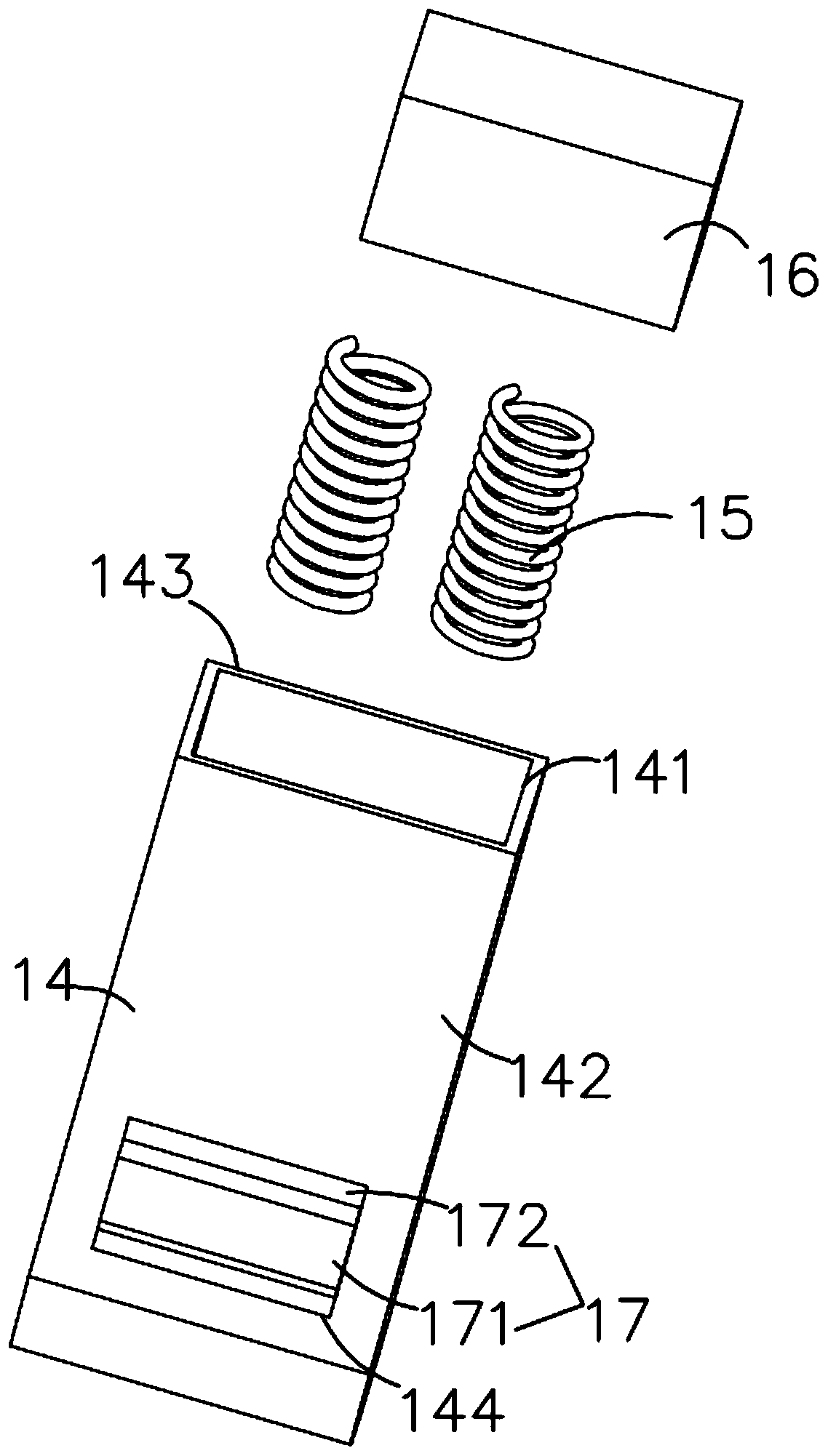

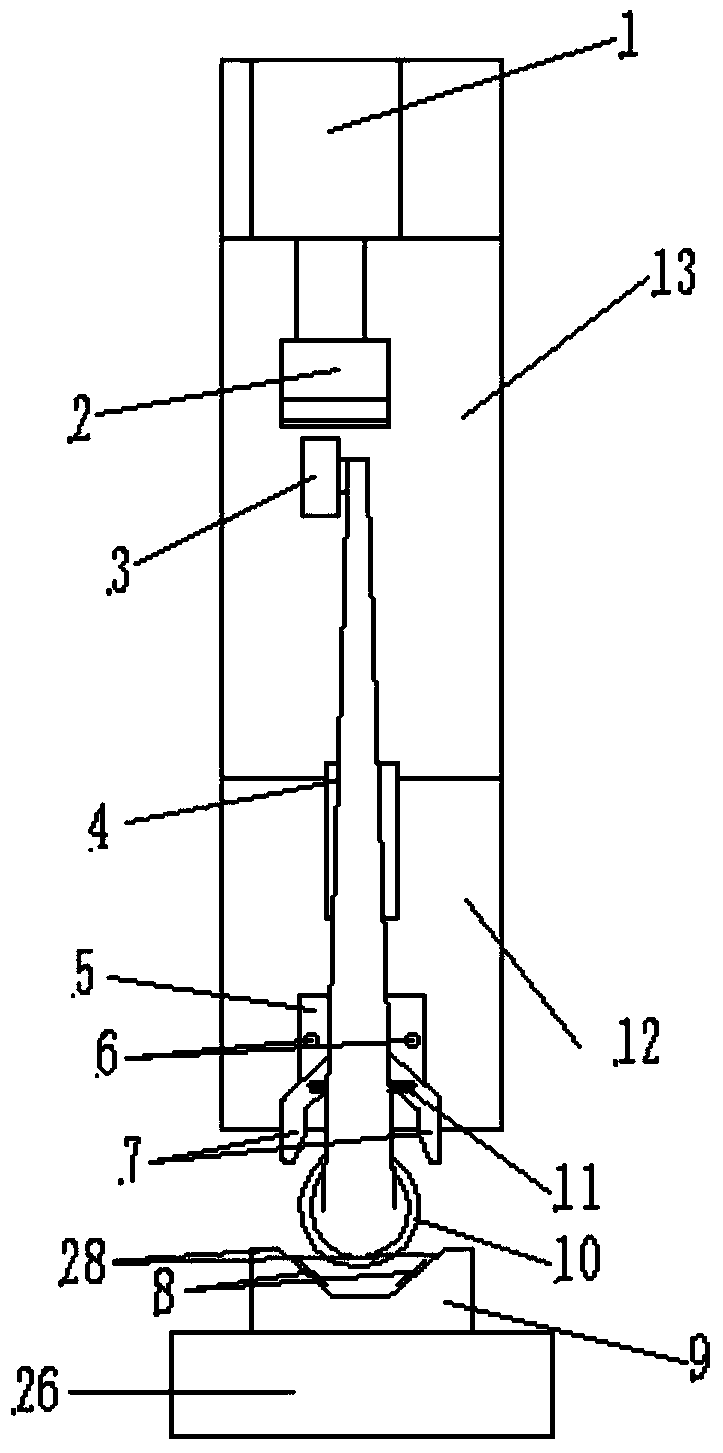

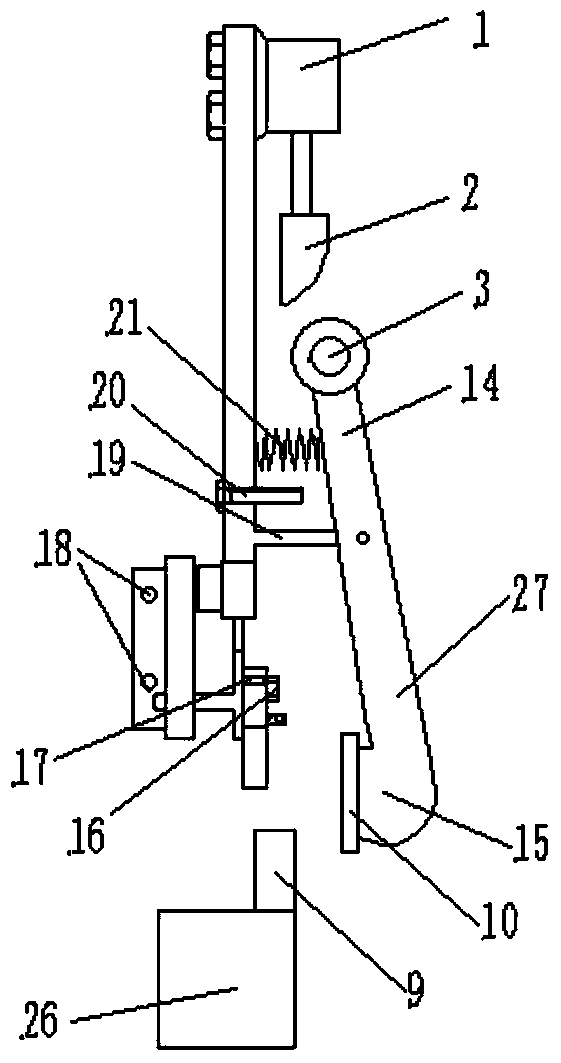

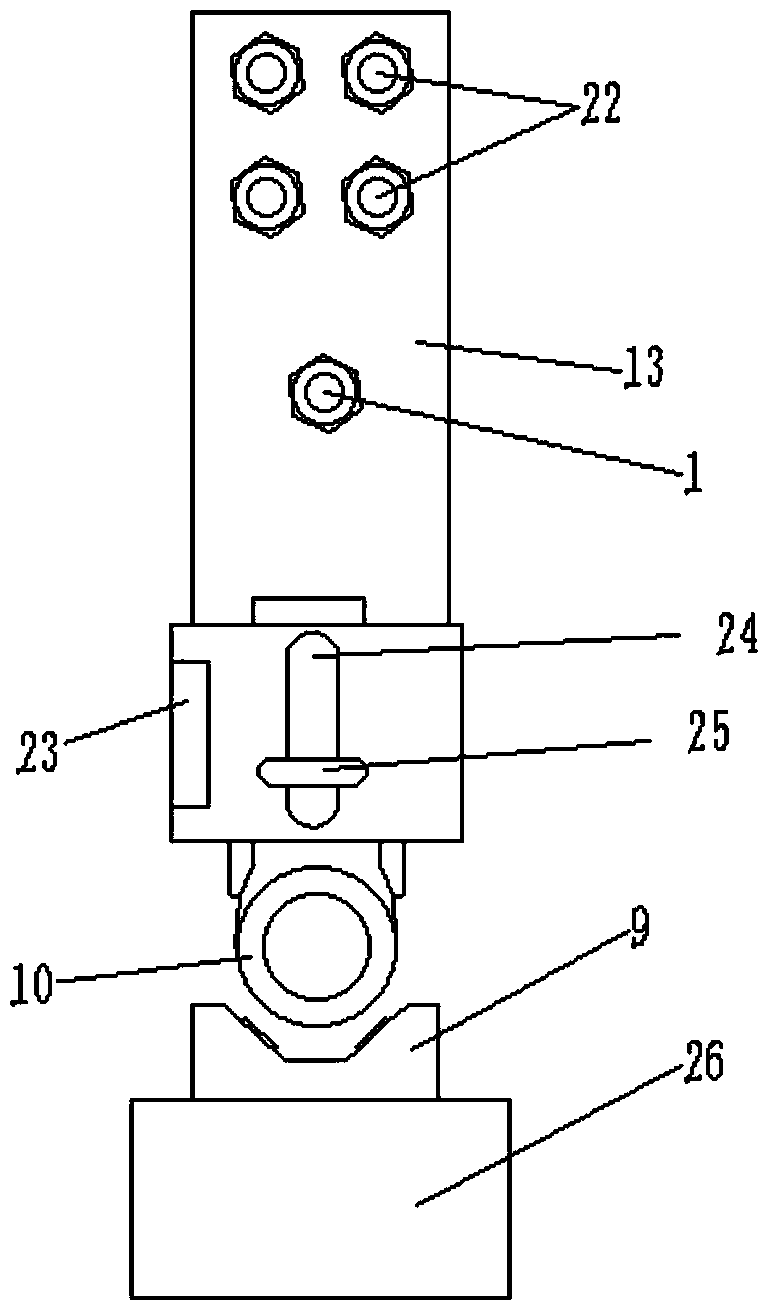

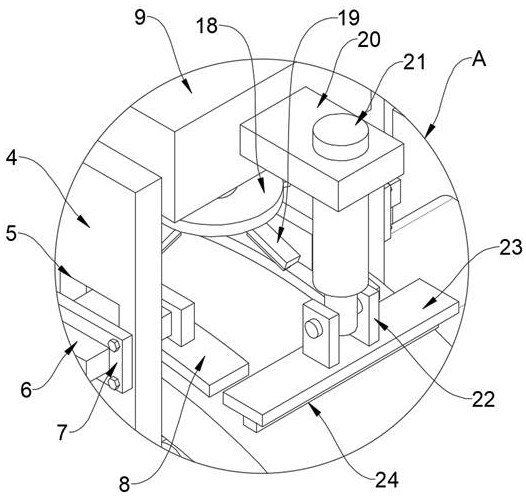

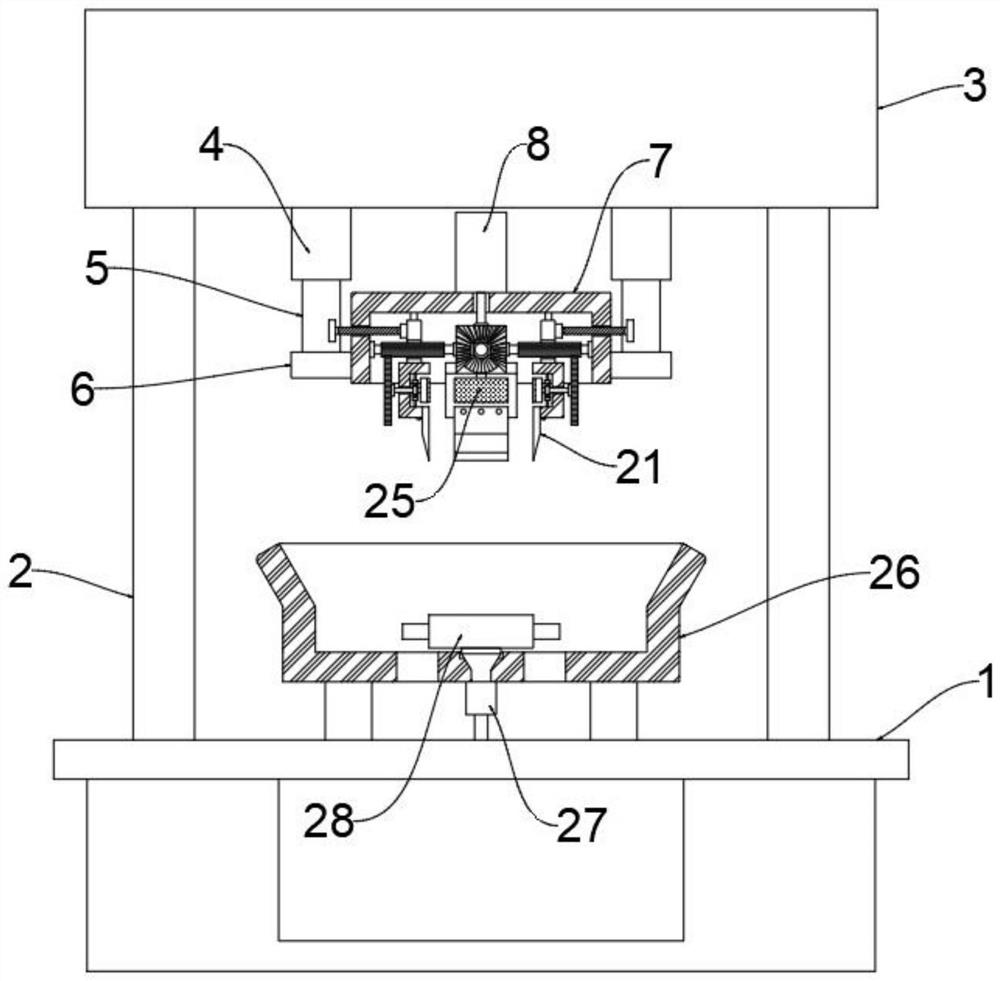

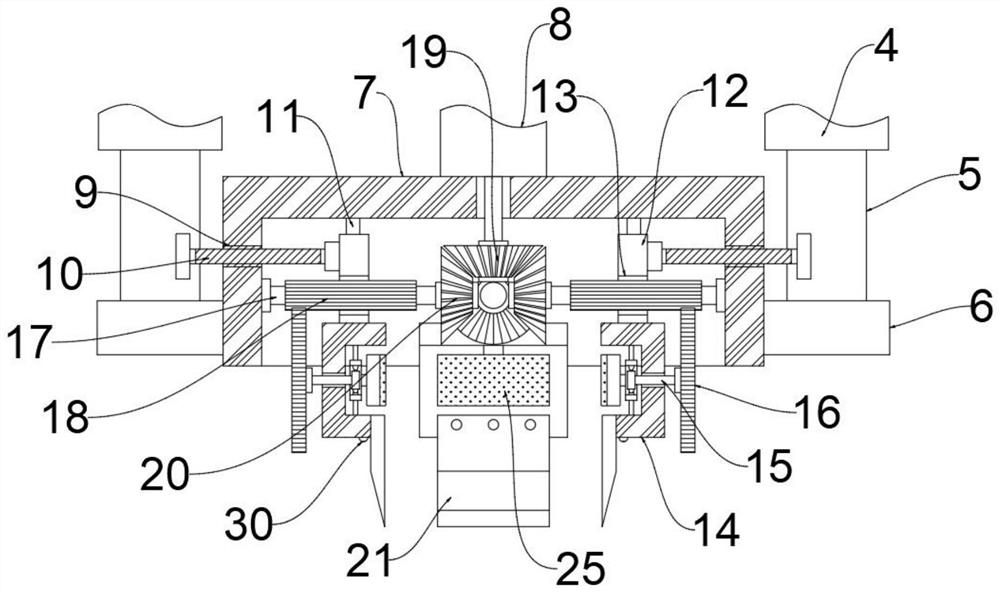

Material taking device for production of lighter assembling line

InactiveCN111099344AImprove the quality of finished productsReduce damage rateConveyor partsEngineeringMachine

The invention discloses a material taking device for production of a lighter assembling line. The material taking device for production of the lighter assembling line comprises a machine frame, a motion assembly and a material taking assembly; the motion assembly is arranged on the machine frame; the material taking assembly comprises a gas source, a gas pipe, a gas collecting cavity and a material taking head; one end of the gas pipe is connected with the gas source and the gas collecting cavity; the material taking head comprises a shell, an elastic piece, a sliding piece and an abutting block; an opening is formed at the upper end of the shell and an open hole is formed in the side part of the shell; the abutting block comprises a block body and a connecting side connected with the periphery of the block body; the connecting side is hermetically connected with the edge of the open hole; the elastic piece is fixed at the inner bottom of the shell; the bottom of the sliding piece is connected with the upper end of the elastic piece; the side wall of the sliding piece hermetically adheres to the inner wall of the shell and can slide up and down along the inner wall of the shell; and the opening is connected with the gas collecting cavity. Compared with the prior art, the material taking device for production of the lighter assembling line has the following advantages: transferof a lighter shell is realized through contact between the abutting block and the lighter shell, and the damage probability of the lighter shell can be effectively reduced, so that the finished product quality of the lighter is effectively improved.

Owner:HUNAN DONGYI ELECTRIC CO LTD

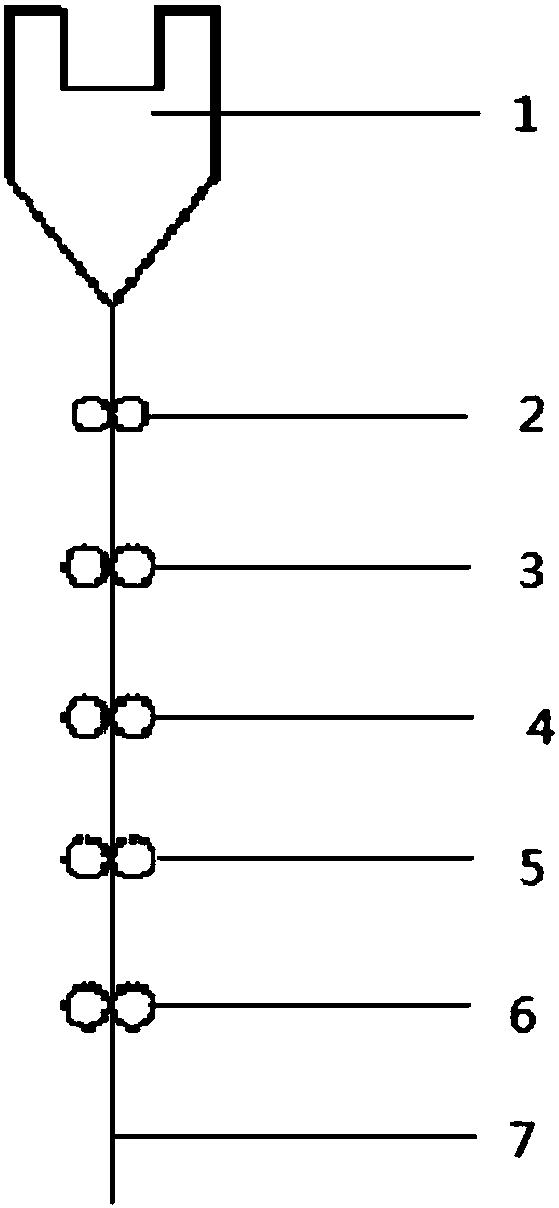

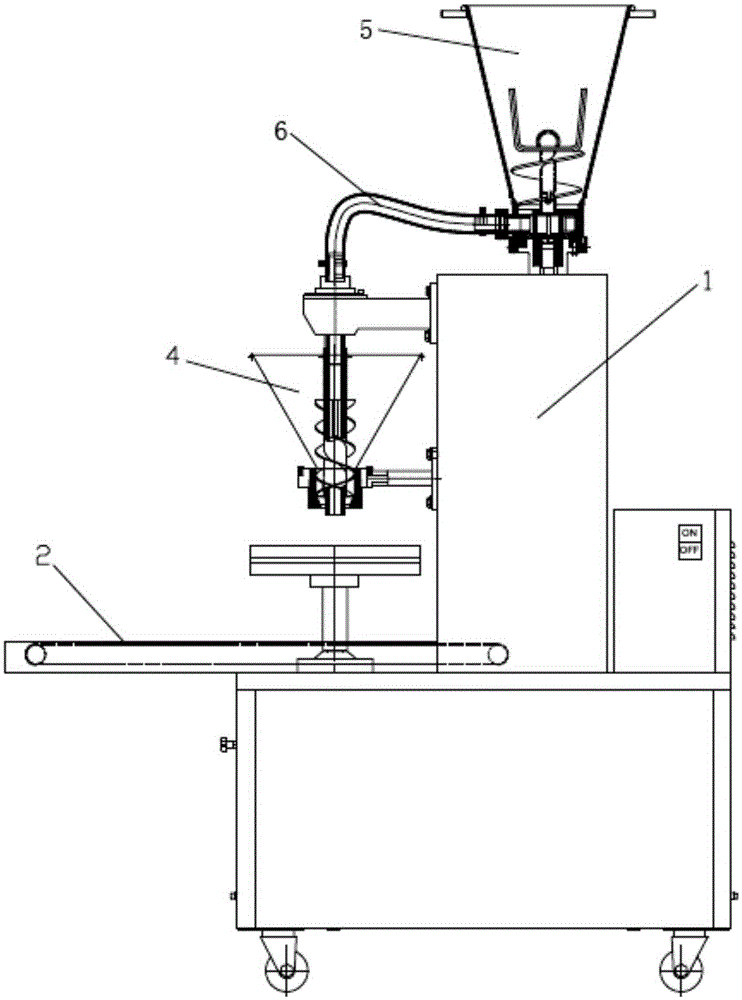

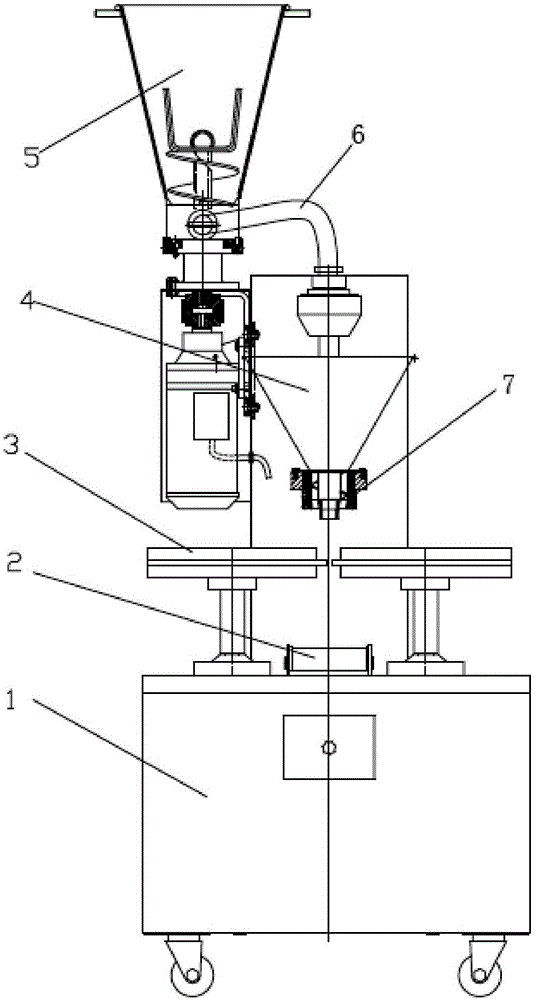

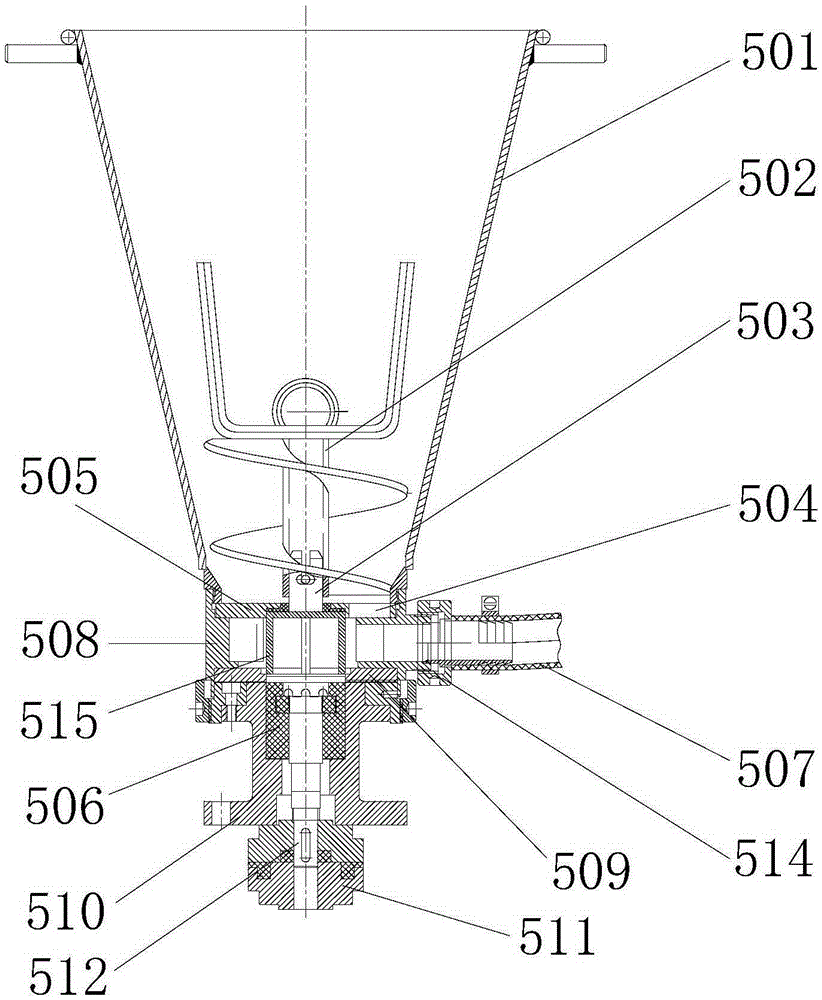

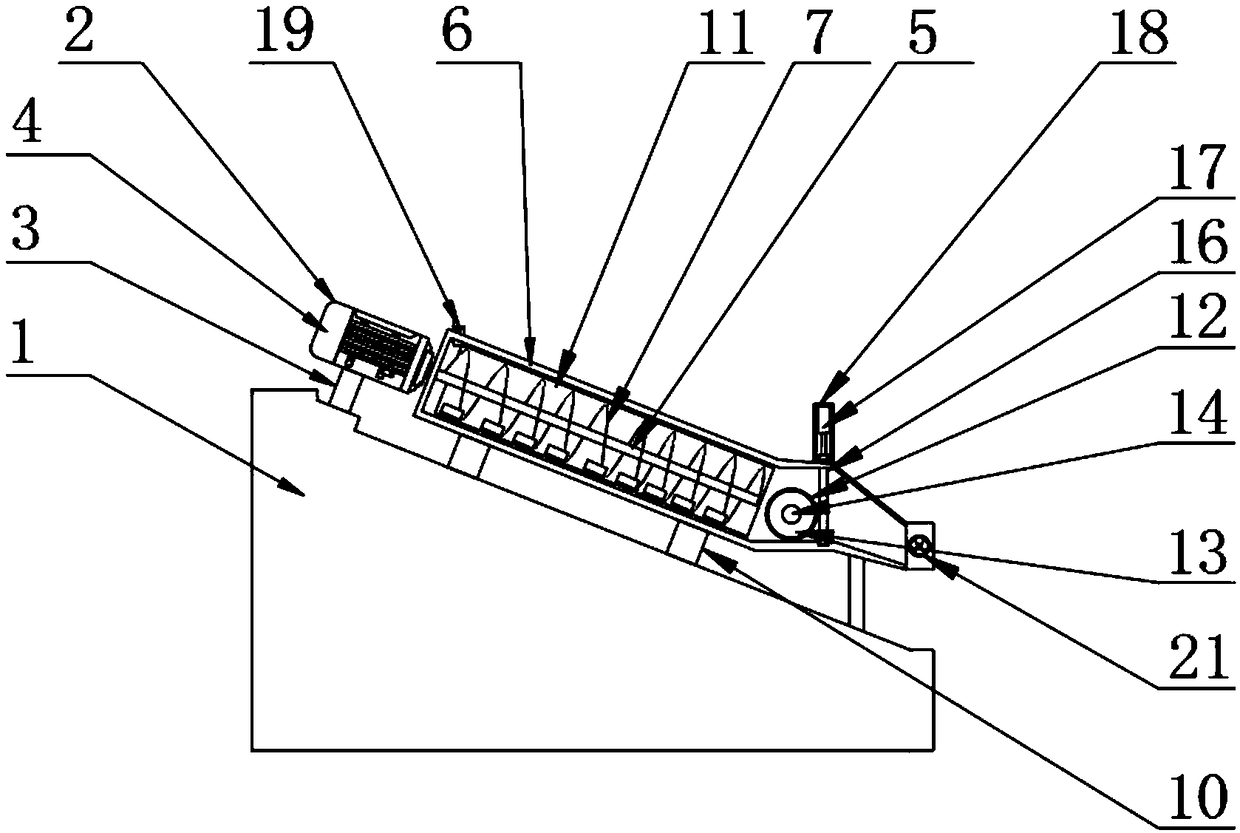

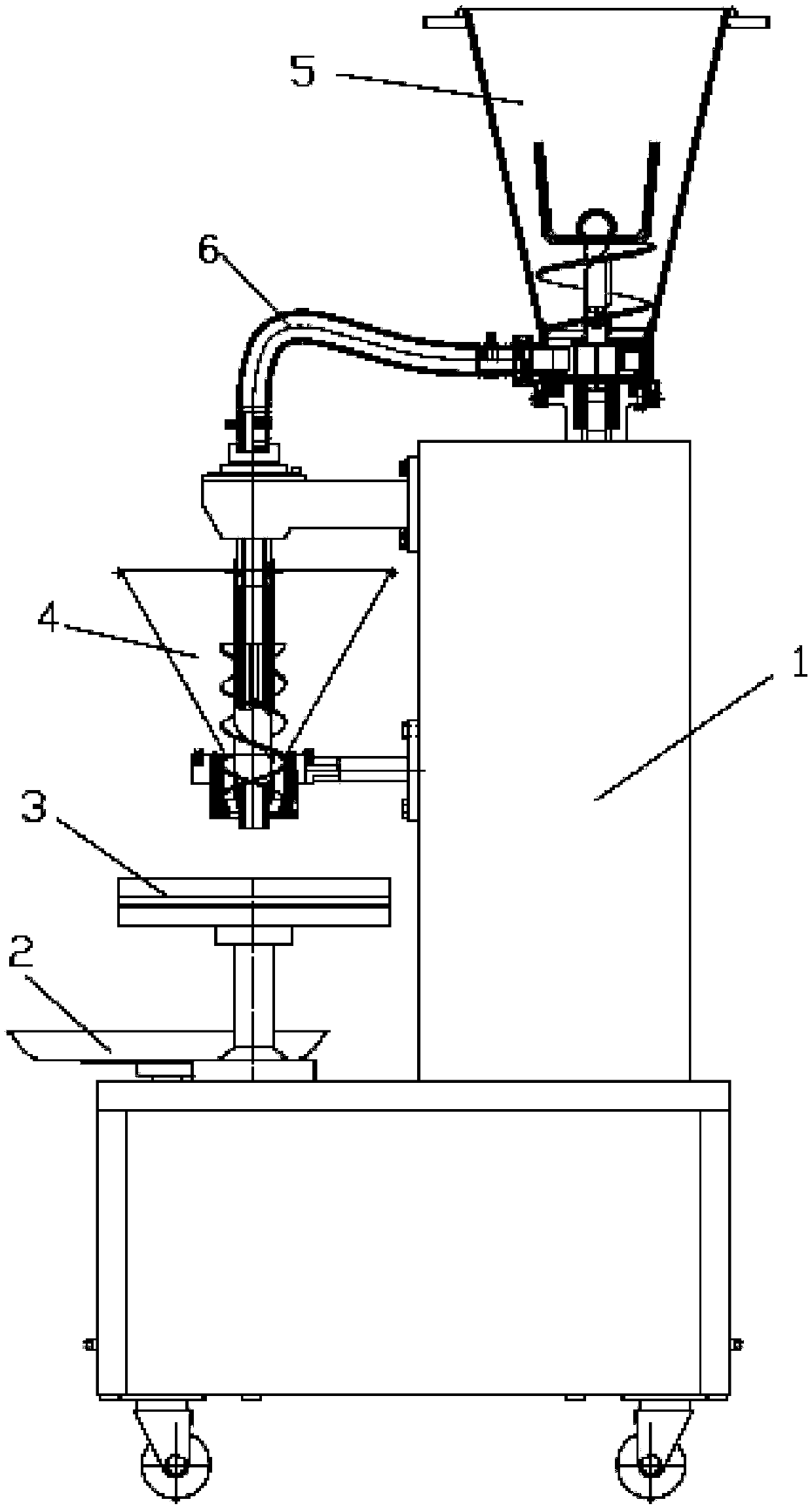

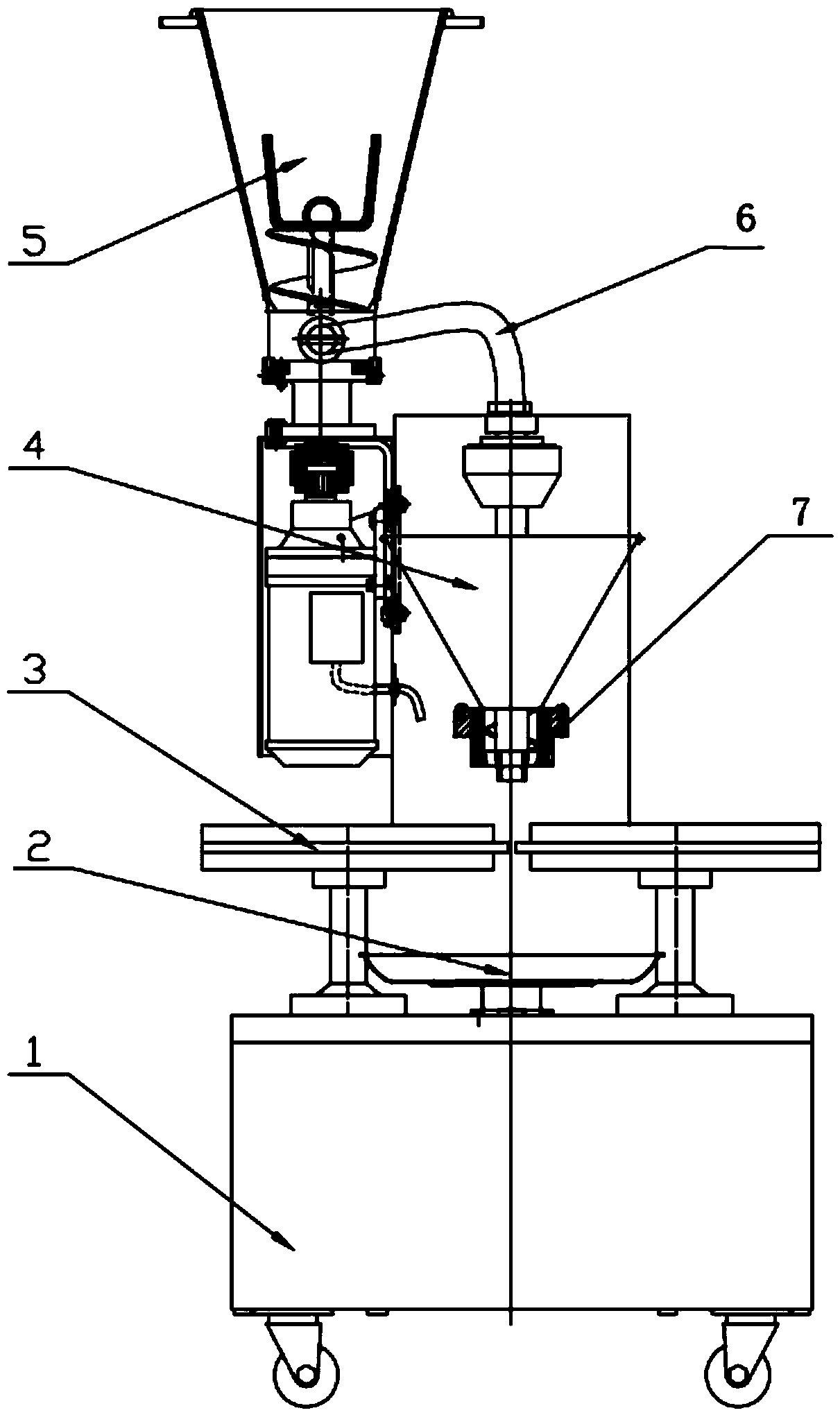

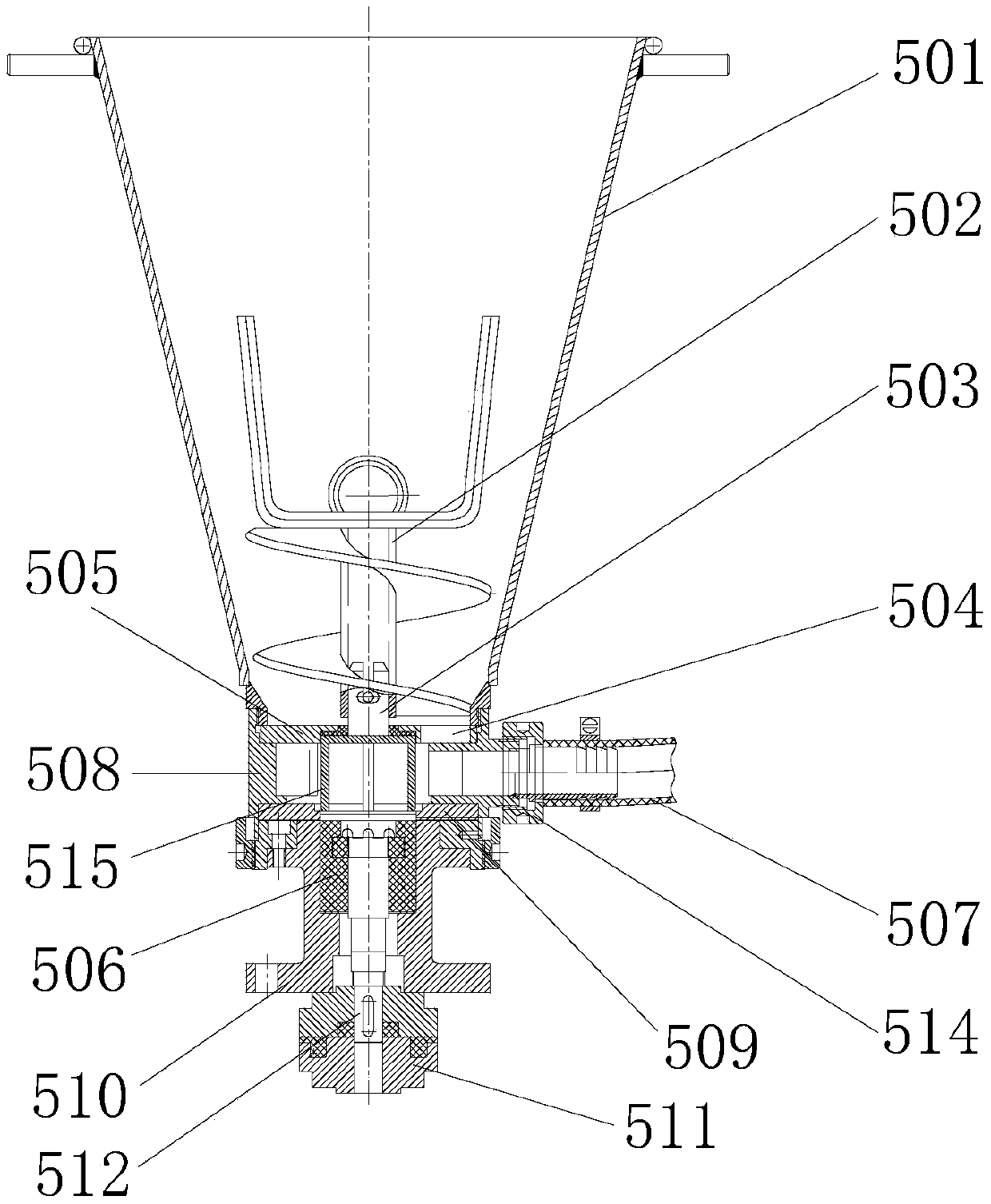

Single-screw-rod middle-size rice dumpling making machine

ActiveCN105309540AImprove the quality of finished productsPrevent shrinkageDough processingEngineeringNozzle

The invention discloses a single-screw-rod middle-size rice dumpling making machine. The single-screw-rod middle-size rice dumpling making machine comprises a single-screw-rod flour conveying system and a conveying system, wherein the single-screw-rod flour conveying system comprises a stuffing pipe cap and a combined flour nozzle structure matched with the stuffing pipe cap; an annular channel with a hollow flour pipe is formed between the combined flour nozzle structure and the stuffing pipe cap and dough passes through the annular channel; and the stuffing pipe cap is provided with an internally-arranged section which is inserted into the combined flour nozzle structure and an externally-arranged section which stretches out of the combined flour nozzle structure and is used for supporting the hollow flour pipe. According to the single-screw-rod middle-size rice dumpling making machine, the stuffing pipe cap is provided with the externally-arranged section which stretches out of a flour outlet nozzle and the externally-arranged section can be used for providing a radial supporting force to the hollow flour pipe which stretches out from the annular channel, so that the hollow flour pipe keeps an unfolded state, and stuffing in the stuffing pipe can easily enter the hollow flour pipe; a phenomenon that the hollow flour pipe is extruded out from the annular channel and is retracted without supporting can be avoided; and shearing and molding of a shearing and molding system on the lower side can be facilitated, so that the shape of a flour product is not changed and the quality of the finished product is improved.

Owner:日照新睿招商发展有限公司

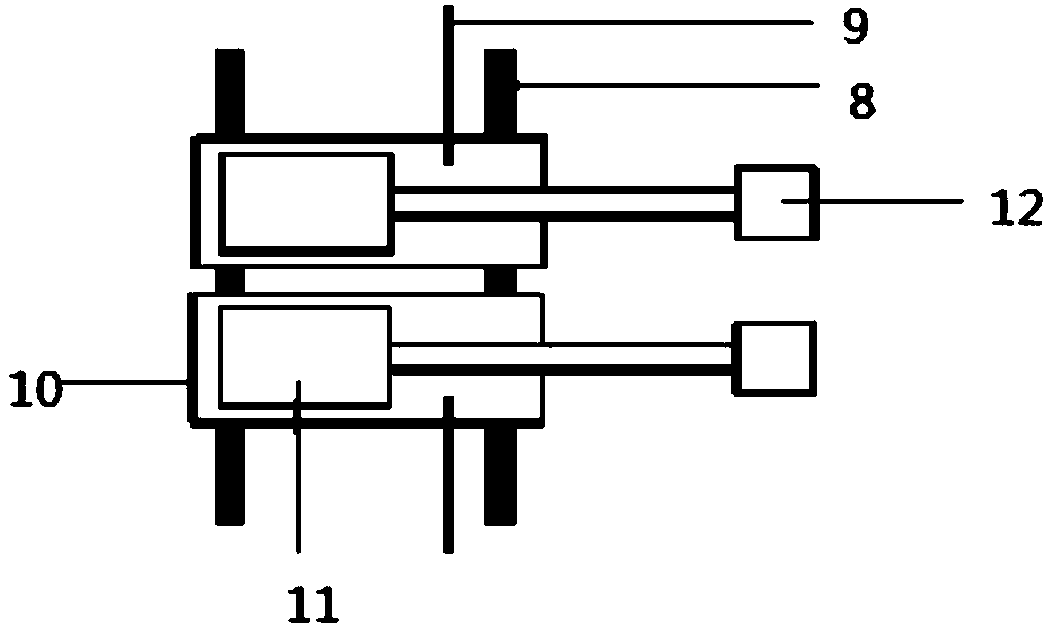

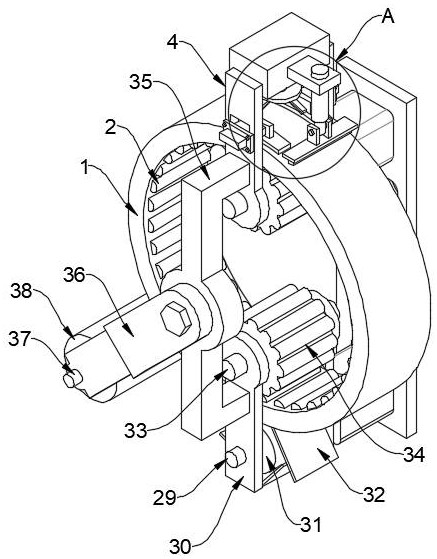

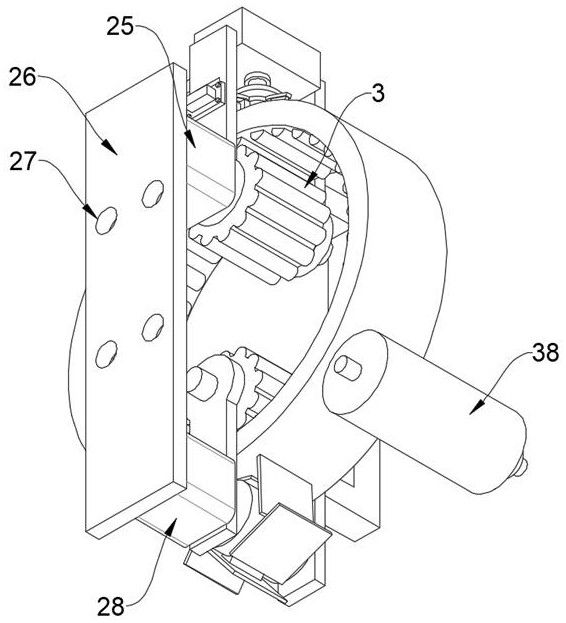

Bearing turning feeding mechanism

ActiveCN103934477AIncrease productivityImprove the quality of finished productsAutomatic conveying/guiding stockPistonPiston cylinder

The invention discloses a bearing turning feeding mechanism which comprises an air cylinder, a wedge-shaped block, a roller, a supporting plate, a fixing clamping groove, a pressing ring, a clamping device, a pressing plate, a piston cylinder, a connecting supporting frame, a clamping mechanism and a lathe body. According to the bearing turning feeding mechanism, in every step of machining process of bearing blank, movement of the piston cylinder is used for pushing the clamping mechanism to move, a clamping jaw on the clamping mechanism is used for clamping workpieces, the roller is driven to make displacement through movement of the piston cylinder, the pressing ring is made to make certain distance displacement through the pressing plate, the blank is pressed to a turning lathe in the right stress direction, the production efficiency of the lathe and the quality of finished products are improved, the workloads of workers are reduced, the efficiency of mass production of an enterprise is improved, and the production cost is lowered.

Owner:新昌新天龙纽尚精密轴承有限公司

High-temperature-resistant precise grinding abrasive cloth circulating type glue scraping device

InactiveCN114082609AImprove scraping efficiencyImprove the quality of finished productsLiquid surface applicatorsAbrasion apparatusElectric machineryEngineering

The invention discloses a high-temperature-resistant precise grinding abrasive cloth circulating type glue scraping device, relates to the related field of glue scraping devices, and aims to solve the problem that the phenomenon of uneven glue scraping is difficult to prevent when an existing glue scraping device is used in the prior art. Meshing teeth are arranged on a rotating ring, the meshing teeth and the rotating ring are arranged into a whole, a first meshing wheel is arranged on the inner side of the rotating ring, the first meshing wheel is meshed with the meshing teeth, a second meshing wheel is arranged at the lower end of the first meshing wheel, the second meshing wheel is meshed with the meshing teeth, a second motor is arranged at the rear end of the first meshing wheel, the second motor is connected with the first meshing wheel through a rotating shaft, a connector is arranged at the upper end of the rotating ring, a plurality of glue scraping pieces are arranged on the connector, the glue scraping pieces are arranged in a circumferential shape, and the glue scraping pieces are fixedly connected with the connector.

Owner:HENAN WANGPAI ABRASIVE CLOTH MFG

Device and method for preparing graphene

InactiveCN109231189AImprove reaction efficiencyImprove shapeGrapheneAgricultural engineeringMotor drive

The invention discloses a device and method for preparing graphene. The device comprises a base, wherein a reaction device is arranged at the top of the base, the reaction device comprises a first supporting rod, the first supporting rod is fixedly connected with the base, a first motor is arranged at the top of the first supporting rod, a first rotary shaft is arranged on one side of the first motor, an output shaft of the first motor is fixedly connected with the first rotary shaft, a reaction box is arranged on one side of the first rotary shaft, the first rotary shaft penetrates through the reaction box and extends into the reaction box, a spiral blade is arranged on the outer side of the first rotary shaft, and a stirring plate is arranged on one side of the spiral blade. By arrangingthe reaction device, the first motor drives the spiral blade to rotate reversely, so that a graphite raw material is evenly distributed in the reaction box, meanwhile, the graphite raw material is heated by a heater, the reaction efficiency is advantageously improved, the graphite raw material is dispersed through leaking holes in the surface of the spiral blade, and meanwhile the stirring platestirs the graphite raw material to a position above the reaction box.

Owner:大连铭垭网络科技发展有限公司

Calcination equipment for mullite brick processing

InactiveCN109595939AImprove the quality of finished productsHeating up fastCharge supportsFurnace typesCombustion chamberEngineering

The invention discloses calcination equipment for mullite brick processing, comprising a first combustion chamber, a second combustion chamber, a third combustion chamber, a first calcining frame, a second calcining frame, a first bottom plate and a second bottom plate; wehrein the first calcining frame surrounds the first combustion chamber, the second combustion chamber surrounds the first calcining frame, the second calcining frame surrounds the second combustion chamber, the third combustion chamber surrounds the second calcining frame; a pluraity of uniformly distributed rectangular through holes are formed in the first calcining frame and the second calcining frame; the first calcining frame is equipped with a first hanging ring, the second calcining frame is equipped with a secondhanging ring, the bottom of the second combustion chamber is equipped with the first bottom plate, a third hanging ring is arranged on the first bottom plate; the bottom of the third combustion chamber is equipped with the second bottom plate; a fourth hanging ring is arranged on the third bottom plate; and ventilation holes are formed in the side walls of the first combustion chamber, the secondcombustion chamber and the third combustion chamber. Compared with the prior art, the equipment provided by the invention improves the product quality of the mullite brick and reduces energy consumption.

Owner:靖州县新球实业有限责任公司

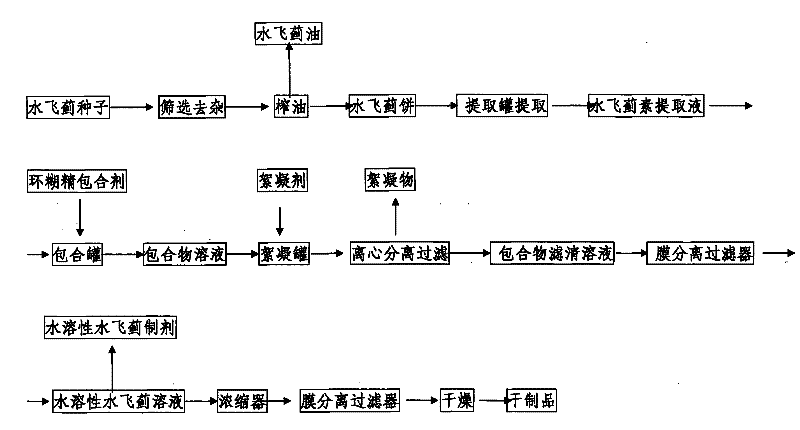

Water-soluble silymarin and preparation method thereof

InactiveCN101810660BNo residueImprove qualityOrganic active ingredientsMetabolism disorderSolubilitySilybum Marianum Seed

The invention discloses water-soluble silymarin, which is an inclusion compound that takes cyclodextrin as main molecules and silymarin as guest molecules; and the inclusion compound contains 12 to 20wt % of silybinin. The preparation method thereof comprises the following steps: silybum marianum seeds are squeezed into silybum marianum cakes; the silybum marianum cakes are added into alkali water ethanol solution and are heated to 75DEG C to 85DEG C, the constant temperature is kept for 1.5-2.5 hours, and silybum marianum extracting solution is prepared after 2-4 times of continuous extraction; the silybum marianum extracting solution is added with the cyclodextrin for inclusion, thus obtaining inclusion compound solution; flocculant is added, standing after being well stirred; after flocculate is filtered out, membrane separation process is carried out, thus obtaining water-soluble silymarin solution; and after the membrane separation process, the water-soluble silymarin solution isconcentrated and dried, thus obtaining the dried product of the water-soluble silymarin. The water-soluble silymarin prepared by the method has the advantages of high solubility, good quality, good drug stability and high bioavailability.

Owner:江苏健佳药业有限公司

Single-screw miniature glue pudding machine

InactiveCN105495664AImprove the quality of finished productsPrevent shrinkageFood shapingDough extruding machinesEngineeringComing out

The invention discloses a single-screw miniature glue pudding machine. The single-screw miniature glue pudding machine comprises a stuffing conveying system and a single-screw dough conveying system connected with the stuffing conveying system, wherein the single-screw dough conveying system comprises a stuffing pipe cap and a combined dough mouth structure matched with the stuffing pipe cap; an annular channel allowing a dough to pass and forming a hollow dough pipe is formed between the combined dough mouth structure and the stuffing pipe cap; the stuffing pipe cap is provided with an internal section inserted into the combined dough mouth structure and an external section extending out of the combined dough mouth structure and used for supporting the hollow dough pipe. According to the single-screw miniature glue pudding machine, the stuffing pipe cap is provided with the external section extending out of a dough outlet mouth, and the external section can provide a radial supporting force for the hollow dough pipe coming out of the annular channel to enable the hollow dough pipe to keep in a prop-open state, so that stuffing in a stuffing pipe can conveniently enter the hollow dough pipe, the hollow dough pipe is prevented from contraction caused by loss of supporting after being squeezed out of the annular channel, shearing forming of a shearing forming system below is facilitated, dough products cannot be deformed, and the quality of end products is improved.

Owner:郯城县金顺达机械厂

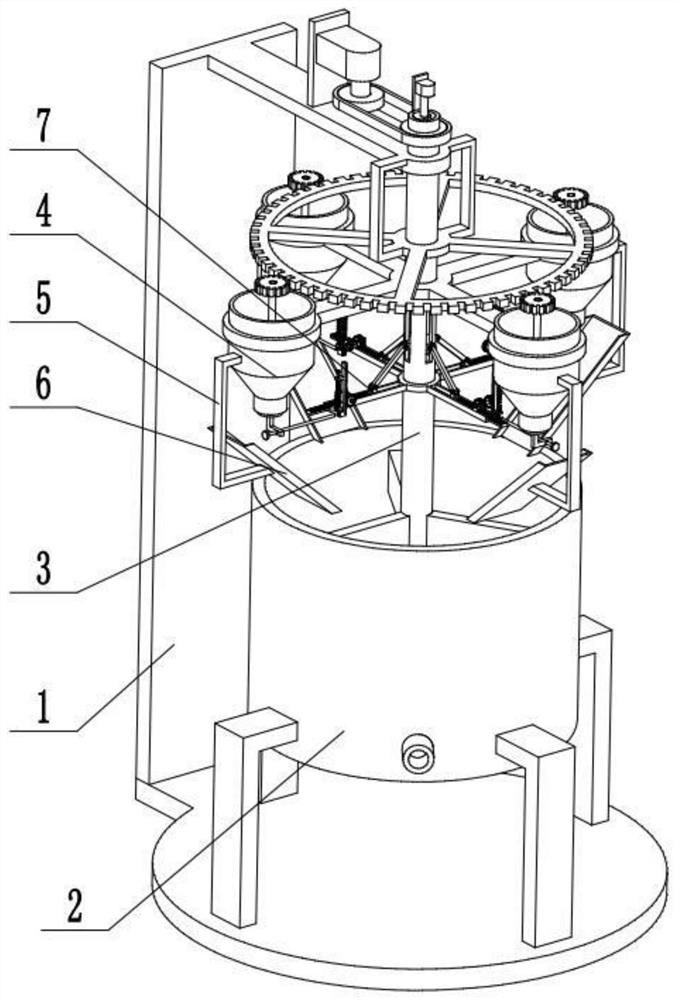

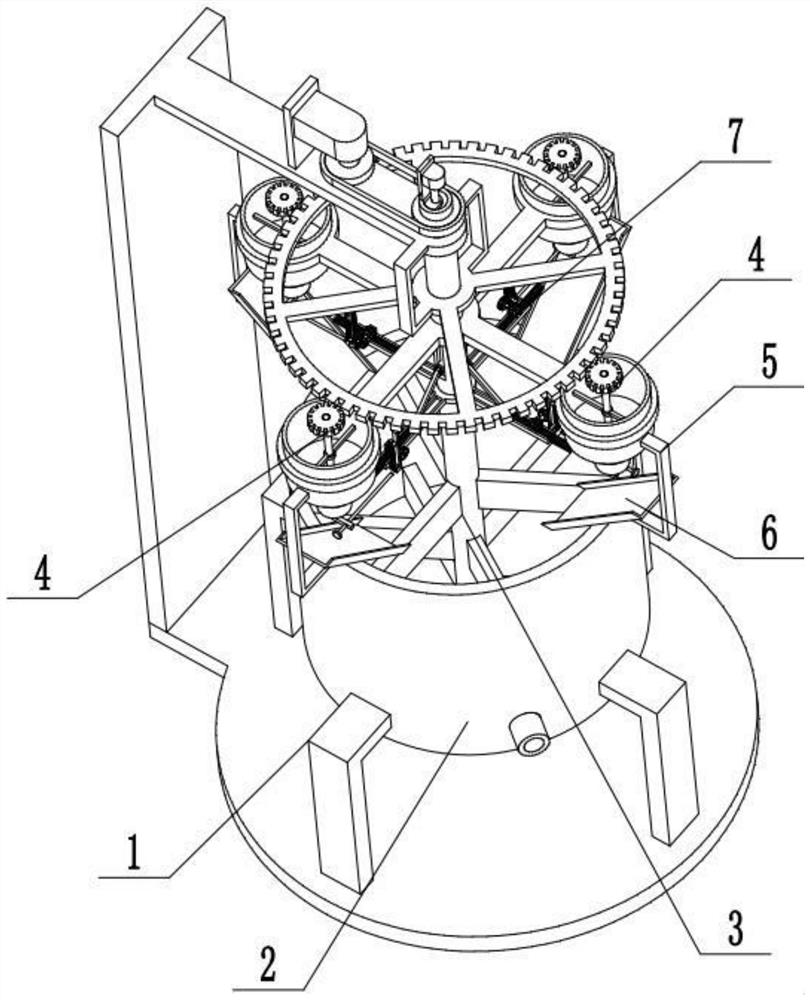

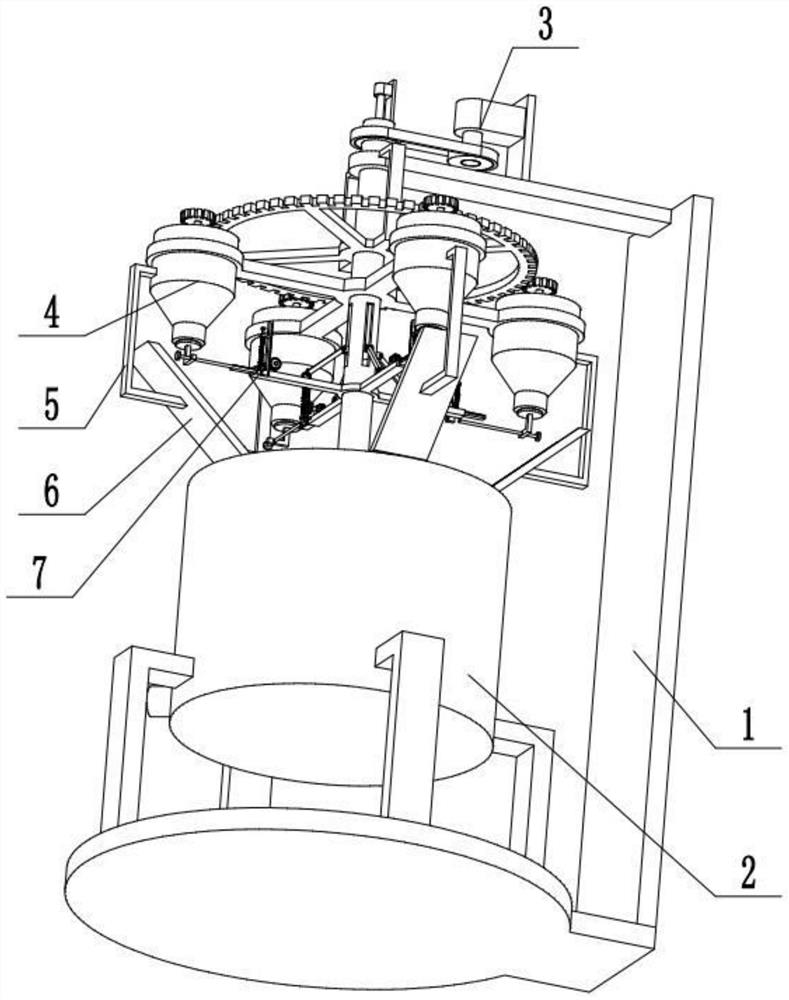

A kind of waterproof coating preparation system

ActiveCN110354718BAvoid cloggingEasy to stir and mixRotary stirring mixersTransportation and packagingProcess engineeringControl valves

The invention relates to a waterproof paint preparation system, which relates to the technical field of paint processing equipment, including a frame, a mixing drum, a stirring device, a feeding drum assembly, a connecting arm, a feeding swash plate and a feeding linkage control mechanism, and the beneficial technical effect is that the present invention can Control multiple ingredients to add at the same time, all kinds of ingredients can be uniformly dispersed and mixed together while filling, the finished product is of high quality, and the phenomenon of material clogging can be avoided at the same time. The mixing drum is fixedly connected to the frame, the lower end of the mixing drum is provided with a drain pipe with a control valve, the upper end of the stirring device is set on the frame, the lower end of the stirring device is located in the mixing drum, and the feeding drum assembly is set There are four, the four feeding tube assemblies are uniformly arranged on the stirring device, the four feeding tube assemblies are all located above the mixing drum, the four feeding tube assemblies are all connected to the frame transmission, and the four feeding tube assemblies are connected through the The arm is fixedly connected to a feeding ramp.

Owner:浙江圆程科技股份有限公司

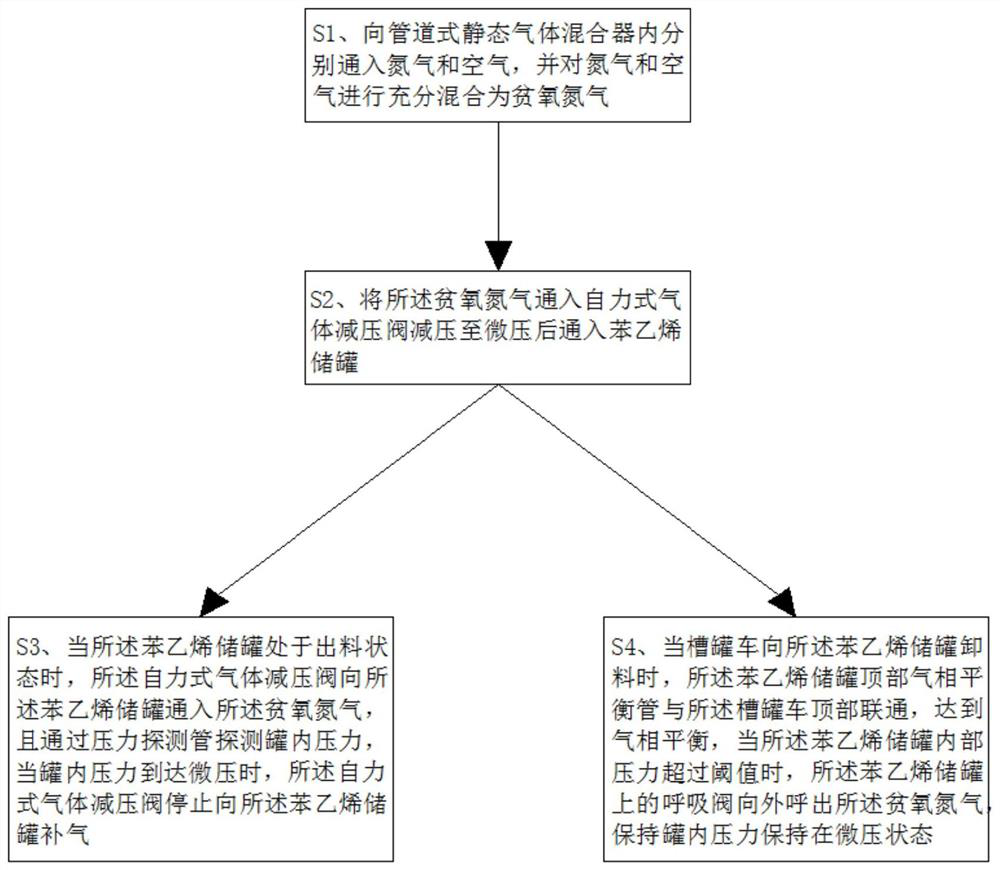

Oxygen-poor nitrogen sealing method matched with styrene storage tank

InactiveCN112193634ASolve the problem of easy polymerization,Solve problems that cause product spoilageLarge containersTank wagonsProcess engineeringEnvironmental engineering

The invention discloses an oxygen-poor nitrogen sealing method matched with a styrene storage tank. The oxygen-poor nitrogen sealing method comprises the following steps: respectively feeding nitrogenand air into a pipeline type static gas mixer and fully mixing the nitrogen with the air into oxygen-poor nitrogen; feeding the oxygen-poor nitrogen into a self-operated gas pressure reducing valve to be subjected to pressure reduction to micro pressure and then feeding the oxygen-poor nitrogen into the styrene storage tank; and when the styrene storage tank is in a discharging state, feeding theoxygen-poor nitrogen into the styrene storage tank through the self-operated gas pressure reducing valve, detecting the pressure in the tank through a pressure detection pipe, and when the pressure in the tank reaches the micro pressure, stopping supplementing gas to the styrene storage tank by the self-operated gas pressure reducing valve. According to the oxygen-poor nitrogen sealing method, the problem that styrene is prone to polymerization in a storage process, and then a product goes bad is effectively solved, a certain amount of oxygen is fed into a polymerization inhibitor, so that the activity of the polymerization inhibitor is guaranteed, the storage time of the styrene is effectively prolonged, meanwhile, escape of styrene gas is reduced, and the environmental safety of a workshop and the personal safety of workers are guaranteed.

Owner:长兴材料工业(广东)有限公司

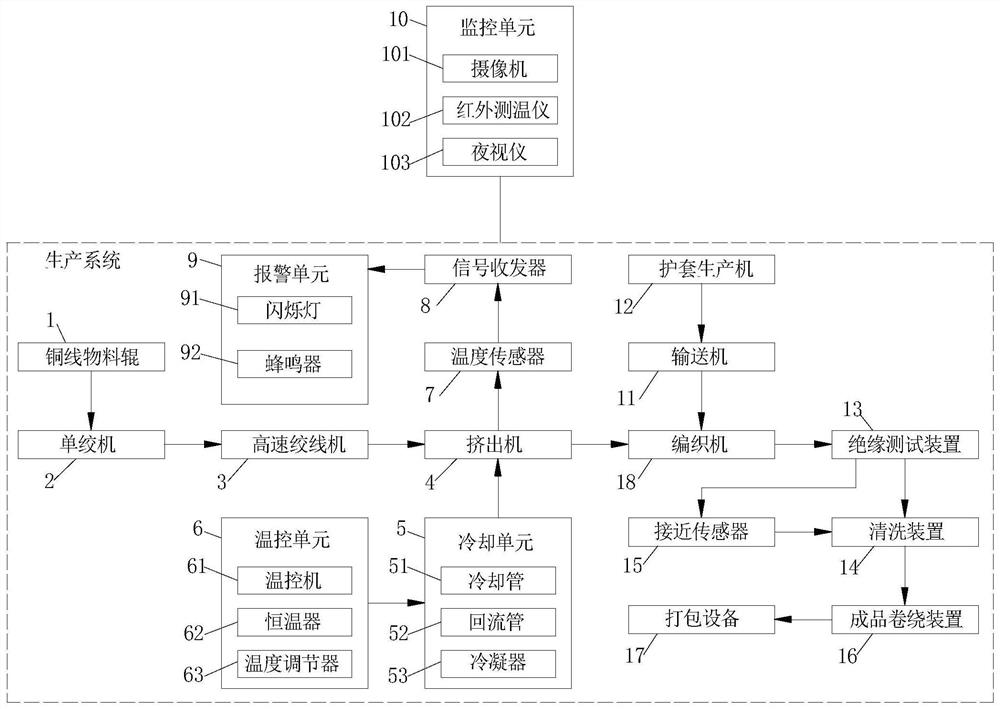

Skin effect heating cable system and process

InactiveCN113470891AHeat dissipation fastFreeze fastMeasurement devicesHeating element shapesTransceiverCopper wire

The invention relates to the technical field of skin effect heating cables, and discloses a skin effect heating cable system, which comprises a production system, wherein the production system comprises a copper wire material roller, a single stranding machine and a high-speed stranding machine, wherein the output end of the copper wire material roller is connected with the input end of the single stranding machine, the output end of the single stranding machine is connected with the input end of the high-speed stranding machine, the output end of the high-speed stranding machine is connected with the input end of an extruder, and the input end of the extruder is connected with the output end of a cooling unit. According to the invention, by arranging a temperature sensor, a signal transceiver and an alarm unit, the working temperature of an extruder can be monitored through the temperature sensor, then a signal can be transmitted to the signal transceiver and the alarm unit, and then when the temperature is high, a flashing lamp and a buzzer in the alarm unit work, and workers are reminded so as not to occur accidents in the processing process and so as to improve the quality of finished cables.

Owner:山东华宁电伴热科技有限公司

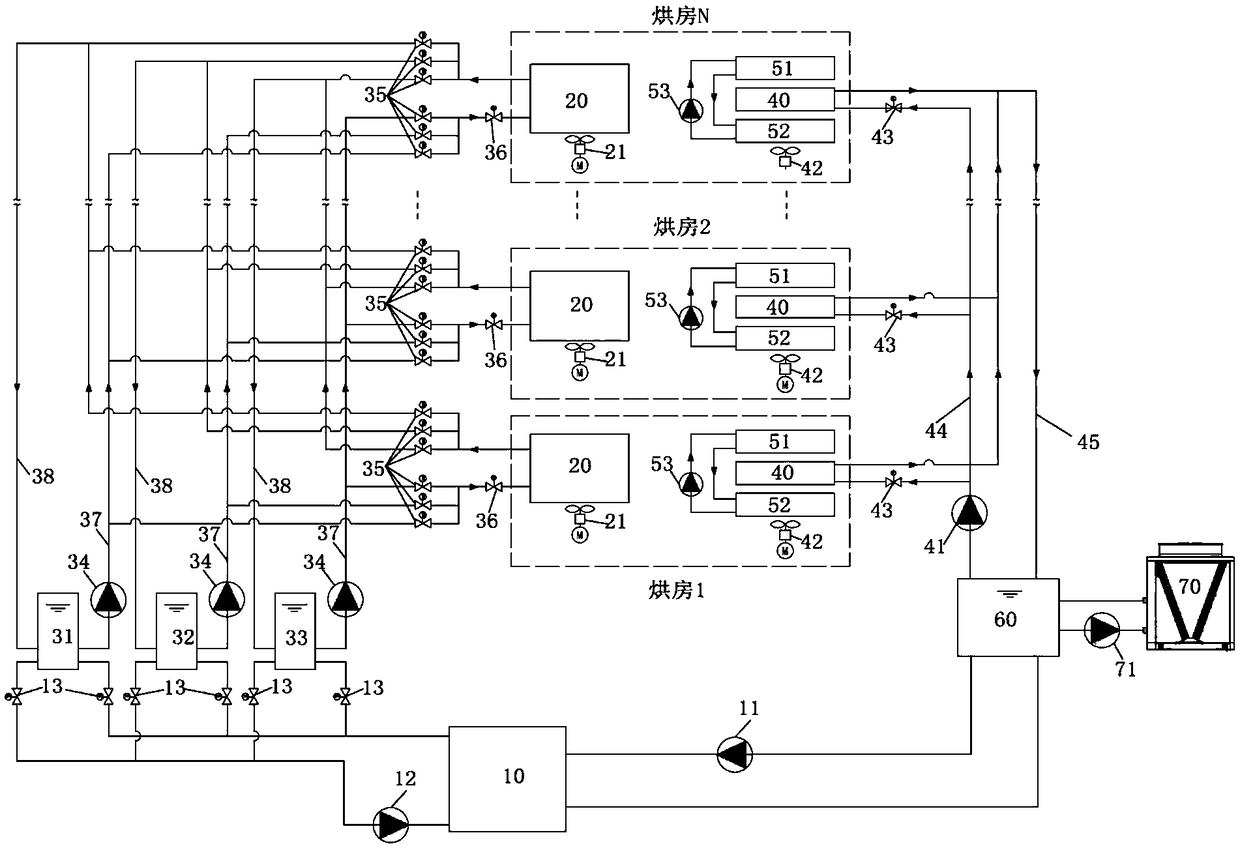

Closed dehumidification water-water heat pump drying system with multiple drying rooms

InactiveCN108759328AAchieve mutual exchangeImprove the quality of finished productsDrying machines with local agitationDrying machines with materials at restEvaporationChilled water

The invention relates to a closed dehumidification water-water heat pump drying system with multiple drying rooms. The closed dehumidification water-water heat pump drying system comprises a water-water heat pump, a hot water tank, an energy storage water tank and a plurality of drying rooms. A heating coil, a heating axial flow fan, a dehumidification coil and a dehumidification fan are arrangedin each drying room. Hot water generated by the water-water heat pump enters the hot water tank through a pipeline, the hot water in the hot water tank is pumped into each heating coil by a heating water pump through a heating water pipeline, and the hot water conducts heat exchange through the heating coil and then returns to the hot water tank through a first water return pipeline. The water inthe hot water tank enters the water-water heat pump through a water pump on a condensation side. Chilled water generated by the water-water heat pump enters the energy storage water tank through a pipeline. The cold water in the energy storage water tank is pumped into each dehumidification coil by a dehumidification water pump through a dehumidification pipeline, and the cold water conducts heatexchange through the dehumidification coil and then returns to the energy storage water tank through a second water return pipeline. The cold water in the energy storage water tank enters the water-water heat pump through a water pump on an evaporation side. The system saves energy, is environmentally friendly and has high drying quality.

Owner:江苏必领能源科技有限公司

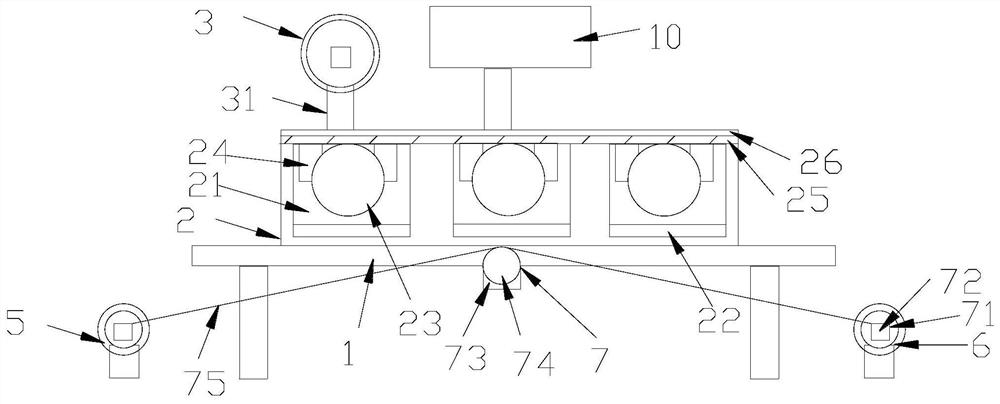

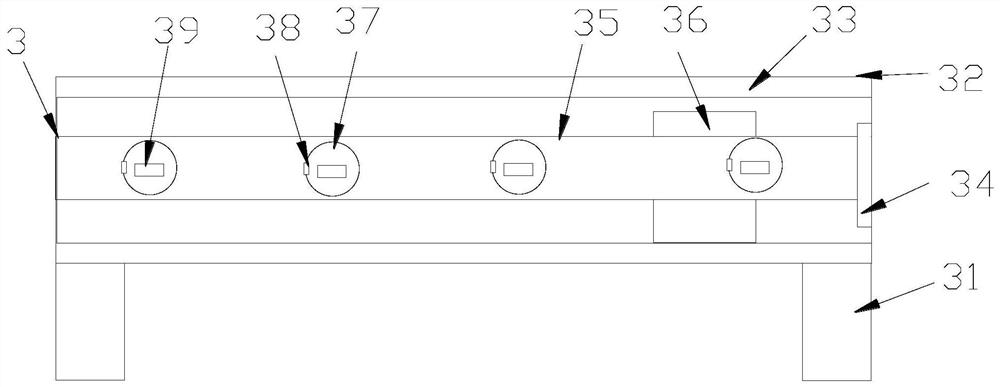

A cooling system of a setting machine

ActiveCN109137348BGuaranteed smoothImprove the quality of finished productsHeating/cooling textile fabricsFiberMachine

Owner:宣城凯欧纺织有限公司

A kind of packaging cardboard production additive and its preparation method

ActiveCN106948212BThe formula is novelLow costPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperCarbon fibersFireproofing

An additive for production of packing paperboards. The invention relates to the technical fields of packing materials. The additive is prepared from: sodium hydroxide, hydrogen peroxide, caustic soda, starch, silicon, borax, silica sand, petroleum sodium sulfonate, potassium permanganate, polyimide, carbon fibers, benzoyl peroxide, superfine magnesium hydroxide, zinc borate, potassium cyanide, sodium hypochlorite, calcium stearate and diphenyl silanediol. The additive has novel formula and processes and low raw material cost. A paperboard produced with the additive has outstanding entire performance and excellent quality, and has excellent high-temperature-resistant, waterproofing and fireproofing performances.

Owner:BENGBU ZHENHUA PACKING MACHINERY

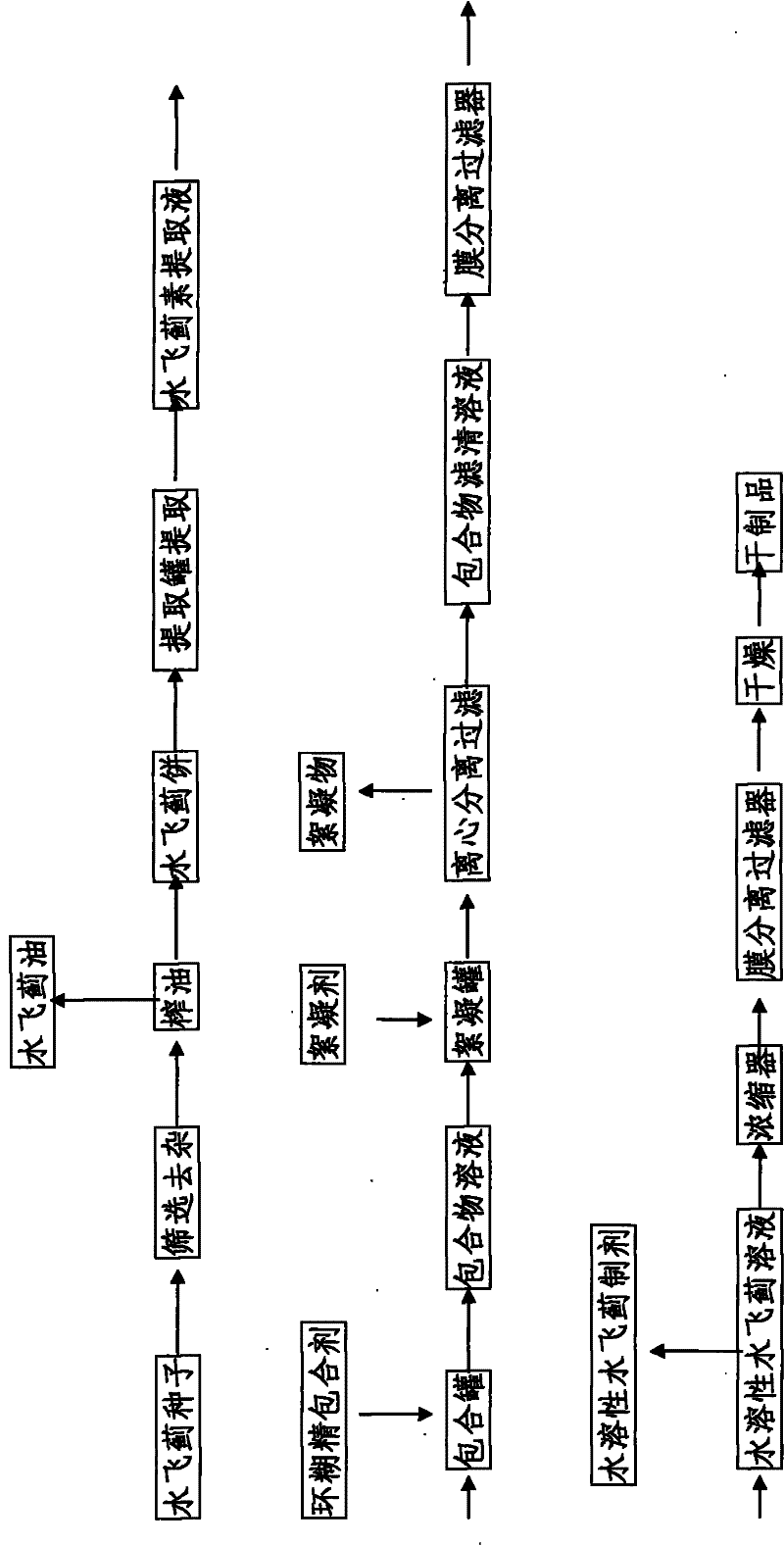

Linseed oil processing technology capable of improving product quality

InactiveCN112322380AImprove product qualityImprove qualityFatty-oils/fats refiningFatty-oils/fats productionOil processingProcess engineering

The invention discloses a linseed oil processing technology capable of improving product quality. The linseed oil processing technology comprises the following steps: conducting harvesting and screening, carrying out primary cold pressing, removing bitterness in oil, carrying out secondary filtering and pressing, conducting packaging and storing, and the like. According to the lineseed oil processing technology capable of improving the product quality, through the steps of harvesting and screening lineseeds, carrying out first-time cold pressing, removing bitter taste in oil, carrying out second-time filtering and pressing, conducting packaging and storing and the like, the prepared lineseed oil is pure in color, outstanding in fragrance and good in taste, and the quality of the lineseed oil is improved. Through primary cold pressing and secondary filtering pressing, the oil yield of the lineseed oil is high, the extraction efficiency of the lineseed oil is improved, meanwhile, a coldpressing method is adopted, it is effectively guaranteed that nutritional ingredients in the lineseed oil cannot be lost, and the quality of the lineseed oil is greatly improved; and the preparation method is excellent, and the processed product is good in quality.

Owner:梦之香(江苏)粮油工业有限公司

A method for high yield and self-seed retention of spinach

InactiveCN105009877BGood effectSprout time shortenedSeed and root treatmentPlant cultivationDiseaseInsect disease

The invention provides a method for high yield of spinach and reserving seeds for planting. The method includes the steps of cleaning seeds, immersing seeds, pre-treating growth hormone, accelerating germination, soil working and sowing, controlling insect diseases, managing field, selecting stock trees, bagging female plants, artificial pollination, removing bags and harvesting. The method greatly improves the disease-resistant and insect-resistant capability, lowers incidence of diseases, improves the quality of spinaches, and substantially increases high-yield capability. In this way, spinaches can be planted in summer. Excellent planting resources can be reserved, space can be saved, and a plurality of types of seeds can be reserved for planting in a same booth without interfering each other. The operation is simple and convenient.

Owner:SHANGHAI ACAD OF AGRI SCI +1

A kind of preparation method of water-soluble sesamin

The invention relates to a preparation method for water-soluble seamin. The preparation method comprises the following steps: selecting sesame seed meal as a raw material; performing secondary enzymatic hydrolysis, water washing, solvent extraction, active carbon treatment, cyclodextrin inclusion, membrane separation and freeze drying technology to obtain a water-soluble sesamin product of which the sesamin content is not lower than 65 percent by weight and the sesamin recovery rate is higher than 95 percent. The method is simple and convenient in steps; moreover, the conventional method using a toxic reagent, namely, diethyl ether or n-hexane is abandoned, so that the finished product quality of the sesamin product is ensured well, the water-soluble sesamin product is obtained directly, and subsequent production and utilization of the sesamin product are facilitated well.

Owner:内蒙古昶辉生物科技股份有限公司

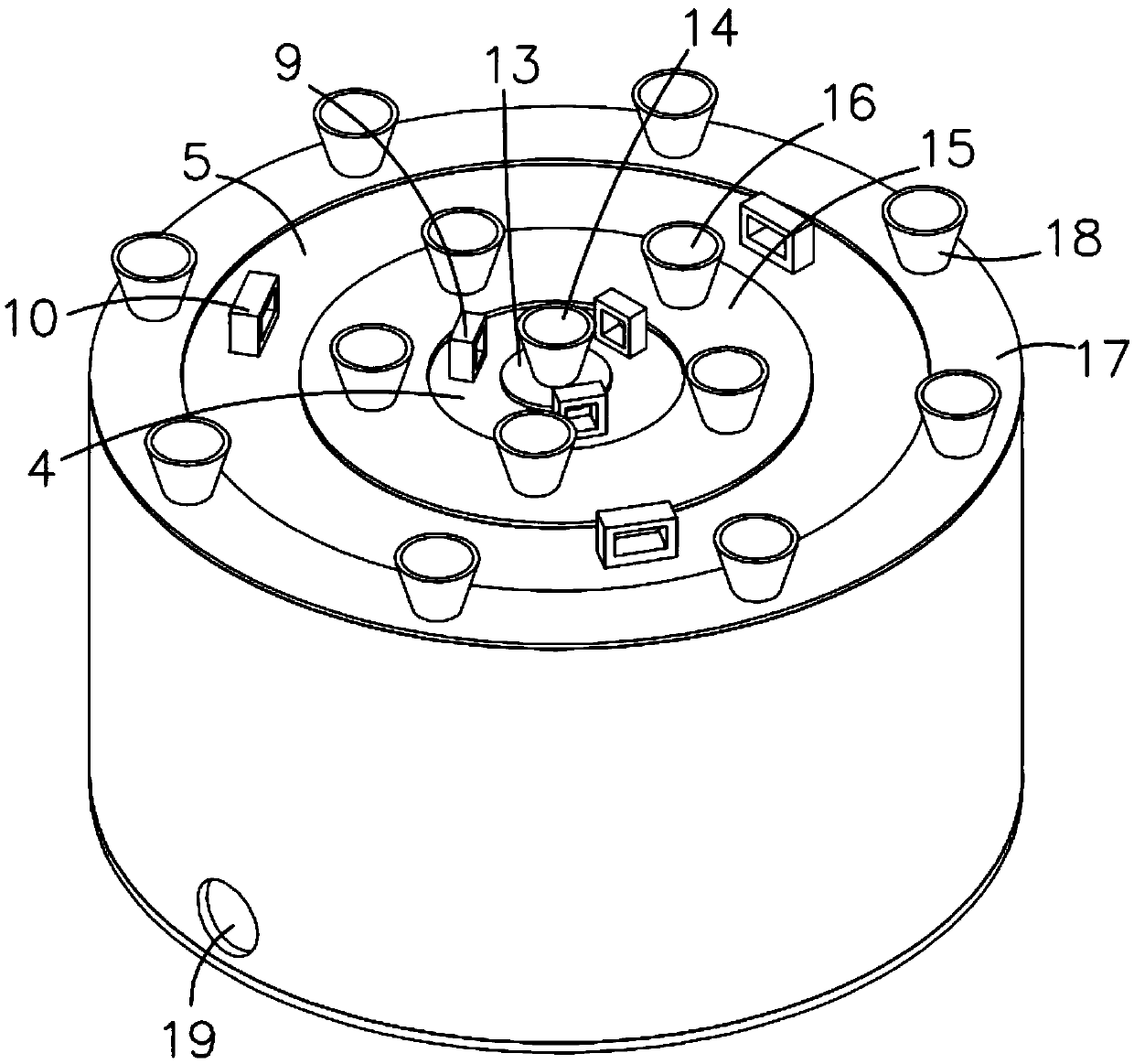

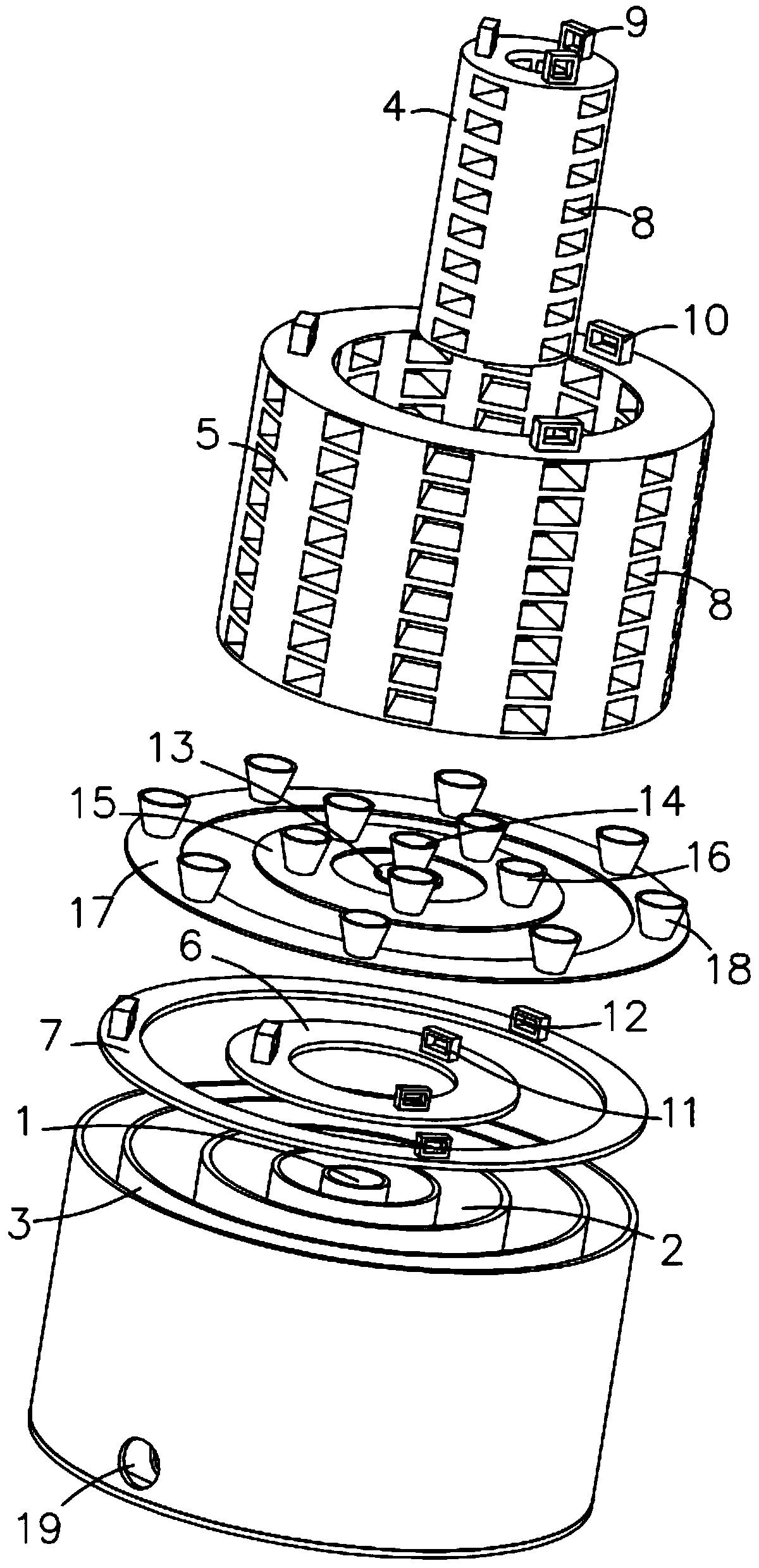

Livestock and poultry manure fermentation process

InactiveCN111943738AUniform temperature distributionIncrease productivityBio-organic fraction processingExcrement fertilisersBiotechnologyAgricultural science

The invention discloses a livestock and poultry manure fermentation process which comprises the following steps: step 1, conveying livestock and poultry manure into a stirrer, stirring, adding auxiliary materials and fermentation strains, uniformly stirring to form a mixture, controlling the moisture content of the mixture to be 45-55%, and heating to raise the temperature to 40-50 DEG C; step 2,conveying the mixture into a fermentation tower to be subjected to aerobic fermentation for 70-75 h, stirring the mixture while fermentation by a stirring device arranged in the fermentation tower, wherein a large amount of moisture in the mixture is rapidly evaporated during stirring fermentation, and when the moisture content of the mixture reaches 20-30%, the mixture can be bagged; the bagged mixture is conveyed to an bio-organic fertilizer bin by a conveyor for storage. The process has the advantages that the fermentation time is shortened, the production efficiency of the bio-organic fertilizer is improved, and meanwhile, the production cost of the bio-organic fertilizer is greatly reduced.

Owner:向月林

A control method for improving the quality of finished tobacco leaves based on leaf position characteristics

InactiveCN105580628BAvoid unnecessary consumptionImprove sensory qualityTobacco cultivationCultivating equipmentsEngineeringTobacco leaf

Owner:INST OF TOBACCO ANHUI ACADEMY OF AGRI SCI +1

Steering rod quenching process

InactiveCN111020122AHigh Rockwell hardnessInternal stress stabilityFurnace typesHeat treatment furnacesHeat conservationThermal treatment

The invention discloses a steering rod quenching process. The process comprises the steps that 1, a steering rod is subjected to hot forging and stretched, the temperature is preserved for at least 930 DEG C for 30min, and cascade cooling is carried out; 2, heating treatment is carried out, cascade heating is carried out, the temperature is increased to 925-935 DEG C, and preserved for 2-3h; 3, primary quenching is carried out, the temperature is reduced to 200-300 DEG C, the steering rod is taken out for heat preservation, corrected and stretched, and the steering rod is heated to 500-580 DEGC; 4 secondary quenching is carried out, the temperature is reduced to 100-150 DEG C, and the steering rod is heated to 200-250 DEG C; and 5, the steering rod is cooled in a quenching groove to normal temperature, and quenching of the steering rod is finished. The steering rod obtained by means of the quenching process is high in Rockwell hardness, stable in internal stress, good in deformation resistance and wear resistance and greatly improved in finished product quality.

Owner:十堰昌昊工贸有限公司

High-efficiency precise injection molding part producing and machining device and using method thereof

PendingCN114434704AReduce consumptionFast trimmingEdge grinding machinesGrinding drivesGear wheelElectric machinery

The invention discloses a high-efficiency precise injection molding part production and processing device and a use method thereof, relates to the technical field of injection molding processing, and aims to solve the problems that a manual trimming mode is easily influenced by the operation proficiency of workers, the manual trimming speed is limited, and a grinding sheet rotating quickly easily causes potential safety hazards to the workers. A driving motor is installed in the middle of the top of the fixing cover, the output end of the driving motor is connected with a driving bevel gear through a key groove, threaded holes are symmetrically formed in the four faces of the fixing cover, threaded rods are connected into the threaded holes through threads, connecting plates are arranged at one ends of the threaded rods, and connecting rods are arranged on the four faces of the inner wall of the fixing cover. A driven bevel gear is arranged at the other end of the connecting rod, a long gear is connected to the middle of the connecting rod through a key groove, a mounting plate is fixed to the lower end of the connecting plate, and a rotating rod is transversely arranged in the middle of the mounting plate.

Owner:南京海世达包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com