A control method for improving the quality of finished tobacco leaves based on leaf position characteristics

A control method and a tobacco leaf technology, applied in the field of tobacco cultivation, can solve the problems of low proportion of high-quality tobacco in the middle, low quality of finished tobacco leaves, poor quality of tobacco leaves, etc. The effect of improving the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Main technical measures

[0020] The distance between transplanting rows is 1.2m×0.50m. Except for the various test treatments, measurements, records, investigations and other operations required by the test to be carried out according to the plan, other cultivation and modulation technical measures are implemented according to the local high-quality tobacco production technology plan. The test records the main growth period, investigates the agronomic traits of the tobacco leaves, etc. The tobacco leaves in each plot are listed for picking and roasting. Quality Evaluation.

[0021] 2. Results and Analysis

[0022] 2.1 Growth period and agronomic traits

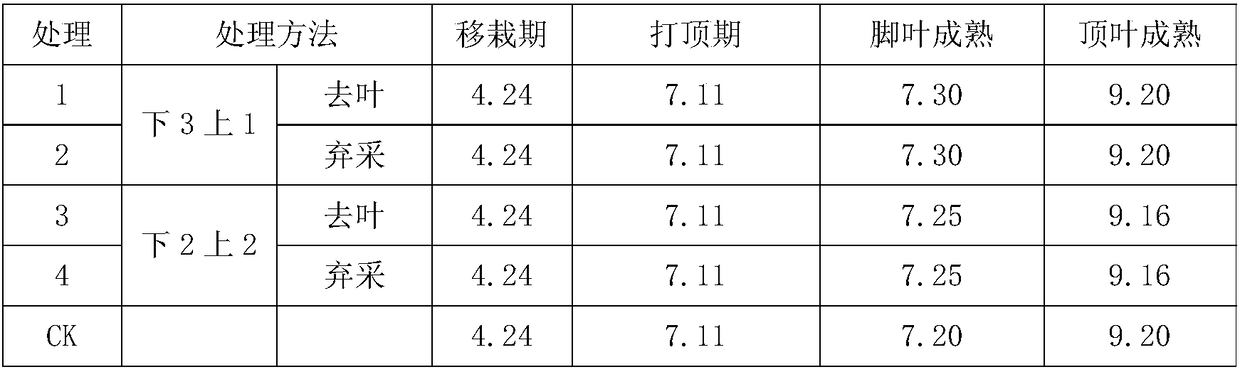

[0023] Fertility Questionnaire

[0024]

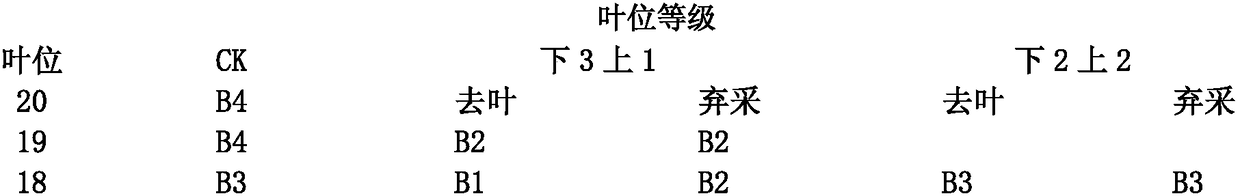

[0025] As the number of lower leaves removed increased, the maturity time of lower leaves was delayed. With the increase of the number of leaves removed from the upper leaves, the maturity time of the upper leaves was advanced. In general, the growth period of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com