Oxygen-poor nitrogen sealing method matched with styrene storage tank

A technology of nitrogen sealing and styrene, which is applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of increasing the land area of the site, increasing the production cost of the enterprise, and complex air components, so as to reduce the floor area of the workshop and extend the Long storage time and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

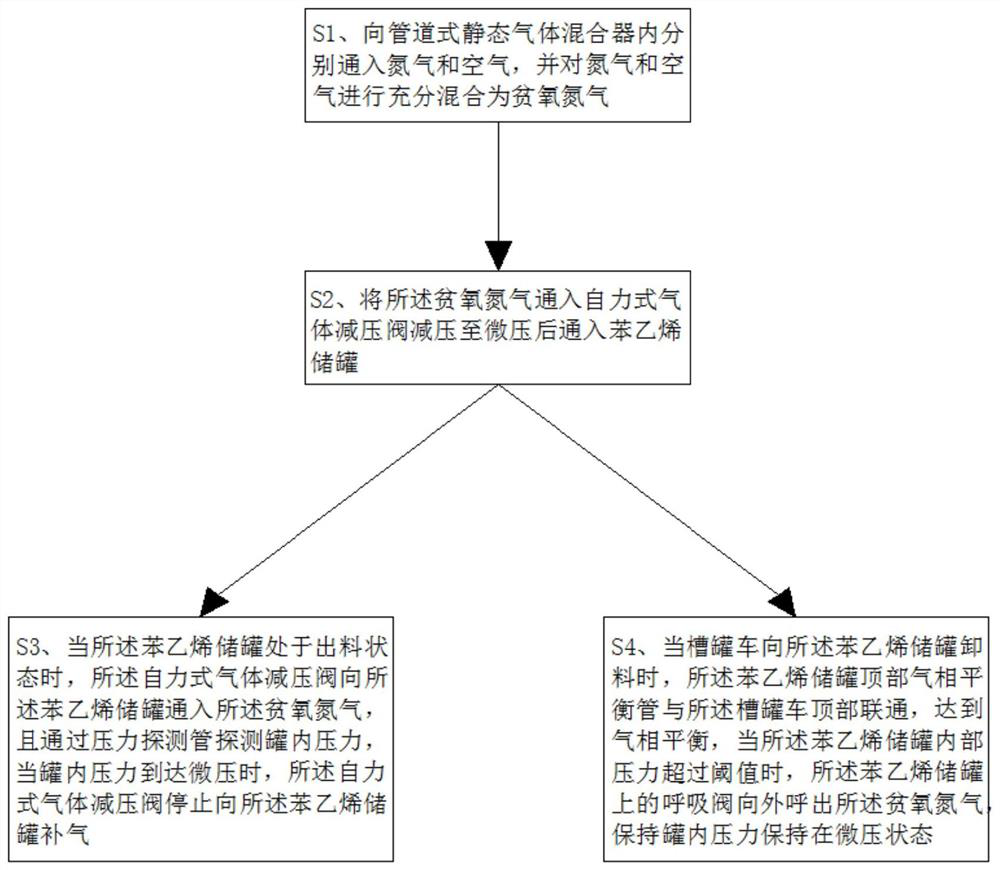

[0029] As a preferred embodiment of the present invention, the step S1 specifically includes:

[0030] The nitrogen containing 99.99% nitrogen and air are passed into the pipeline static gas mixer according to the flow ratio of 3:1, fully mixed into oxygen-deficient nitrogen, and detected by the oxygen concentration detector, and the oxygen content is controlled at 4-8 Among them, the air flow of the air pipeline is regulated by a manual valve, and the nitrogen flow of the nitrogen pipeline is regulated by a flow control valve and an oxygen concentration detector in a chain.

[0031] As a preferred embodiment of the present invention, the pressures of the nitrogen and the oxygen are both 0.1 MPa.

[0032] As a preferred embodiment of the present invention, the self-operated gas pressure reducing valve is arranged on the top of the styrene storage tank.

[0033] As a preferred embodiment of the present invention, the pressure value of the micro pressure is 0.0015 MPa.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com