Bearing turning feeding mechanism

A turning and bearing technology, which is applied to turning equipment, automatic/semi-automatic lathes, tool holder accessories, etc., can solve the problems that hinder the production efficiency of enterprises and require the improvement of bearing product quality and precision, so as to improve the quality of finished products and improve efficiency , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

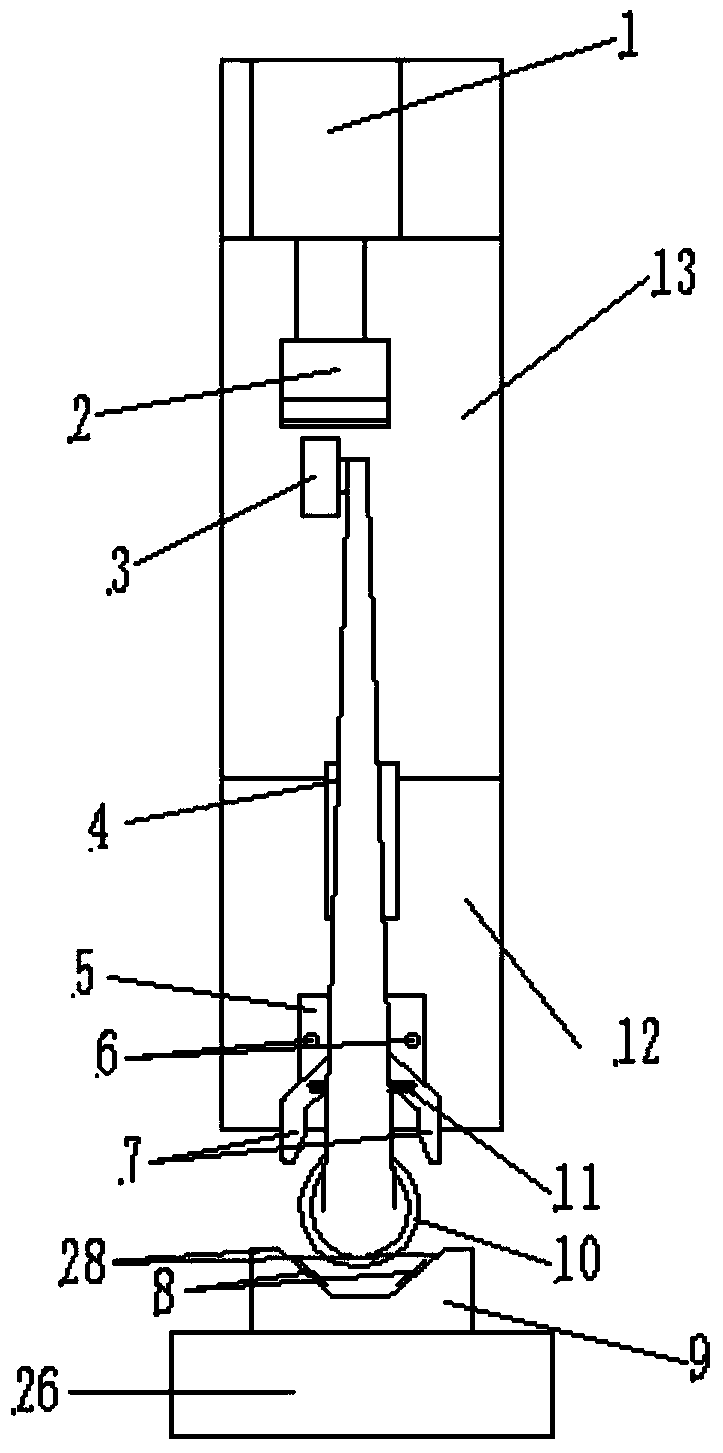

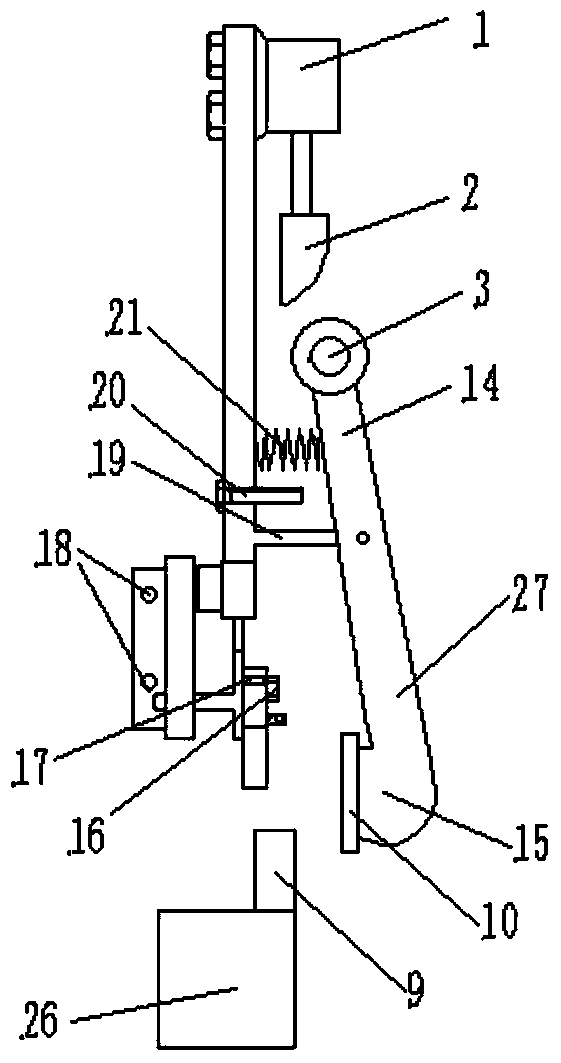

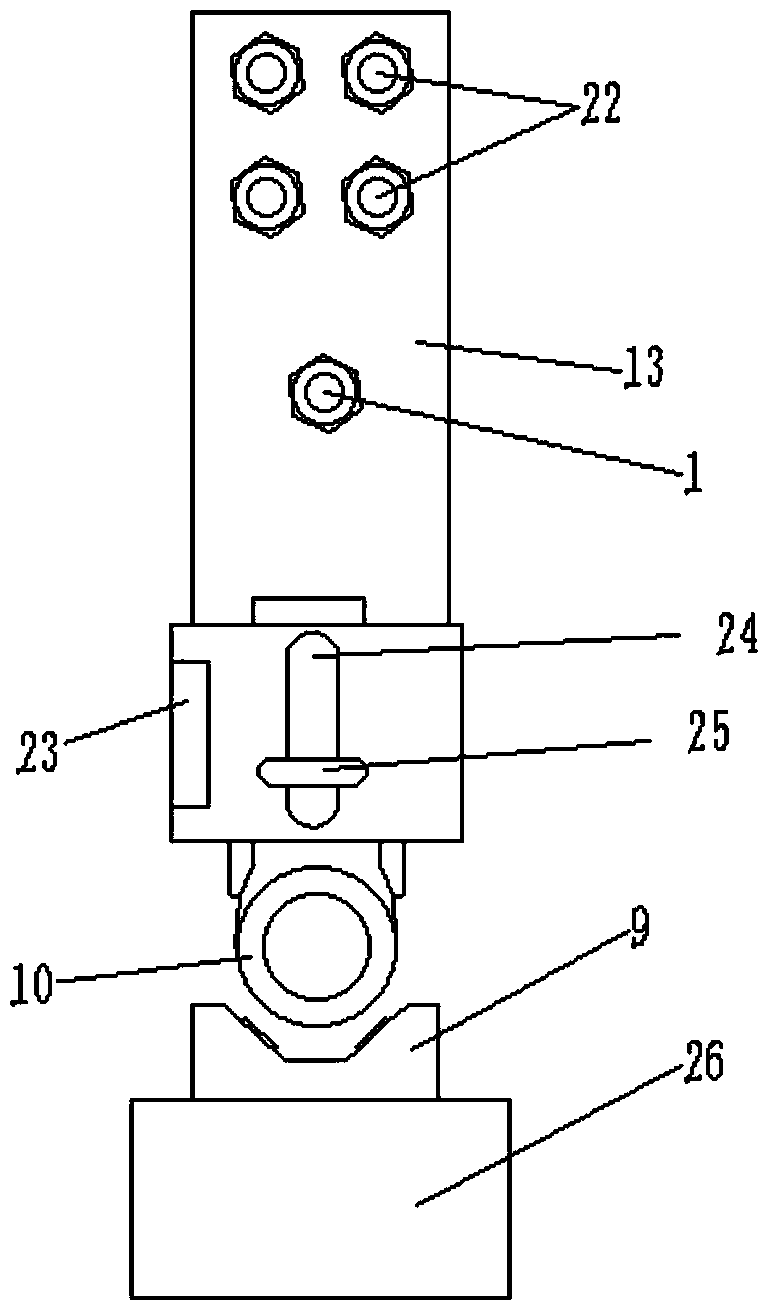

[0019] refer to figure 1 , figure 2 , image 3 , a bearing turning and feeding mechanism of the present invention, including a cylinder 1, a wedge block 2, a roller 3, a support plate 13, a fixing groove 9, a pressure ring 10, a clamping device 12, a pressure plate 27, a piston cylinder 4, a connecting support Frame 23, clamping mechanism 5, bed 26, described bed 26 is provided with fixed draw-in groove 9, fixed draw-in groove 9 is tightly connected with bed 26, and described connection support frame 23 is provided with piston cylinder 4 and Clamping mechanism 5, the fixed slot 9 is located below the clamping mechanism 5, the piston cylinder 4 is located above the clamping mechanism 5, the piston cylinder 4 is fixedly connected to the connecting support frame 23, and the support plate 13 is installed There are fixing bolts 22, and the support plate 13 is fastened to the cylinder 1 through the fixing bolts 22. The support plate 13 is provided with a connecting rod 19, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com