Control system and control method for sheet glass quality stability

A technology of flat glass and control method, applied in glass manufacturing equipment, glass forming, glass forming and other directions, can solve the problem that a single pulling roller assembly cannot be adjusted independently, the shape and size of the "C" shape cannot be adjusted, and the large size cannot be adjusted. Substrate glass manufacturing development and other issues, to achieve the effect of increasing the opportunity of shape and size, convenient implementation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure and control method of the present invention will be further described in detail with reference to the accompanying drawings.

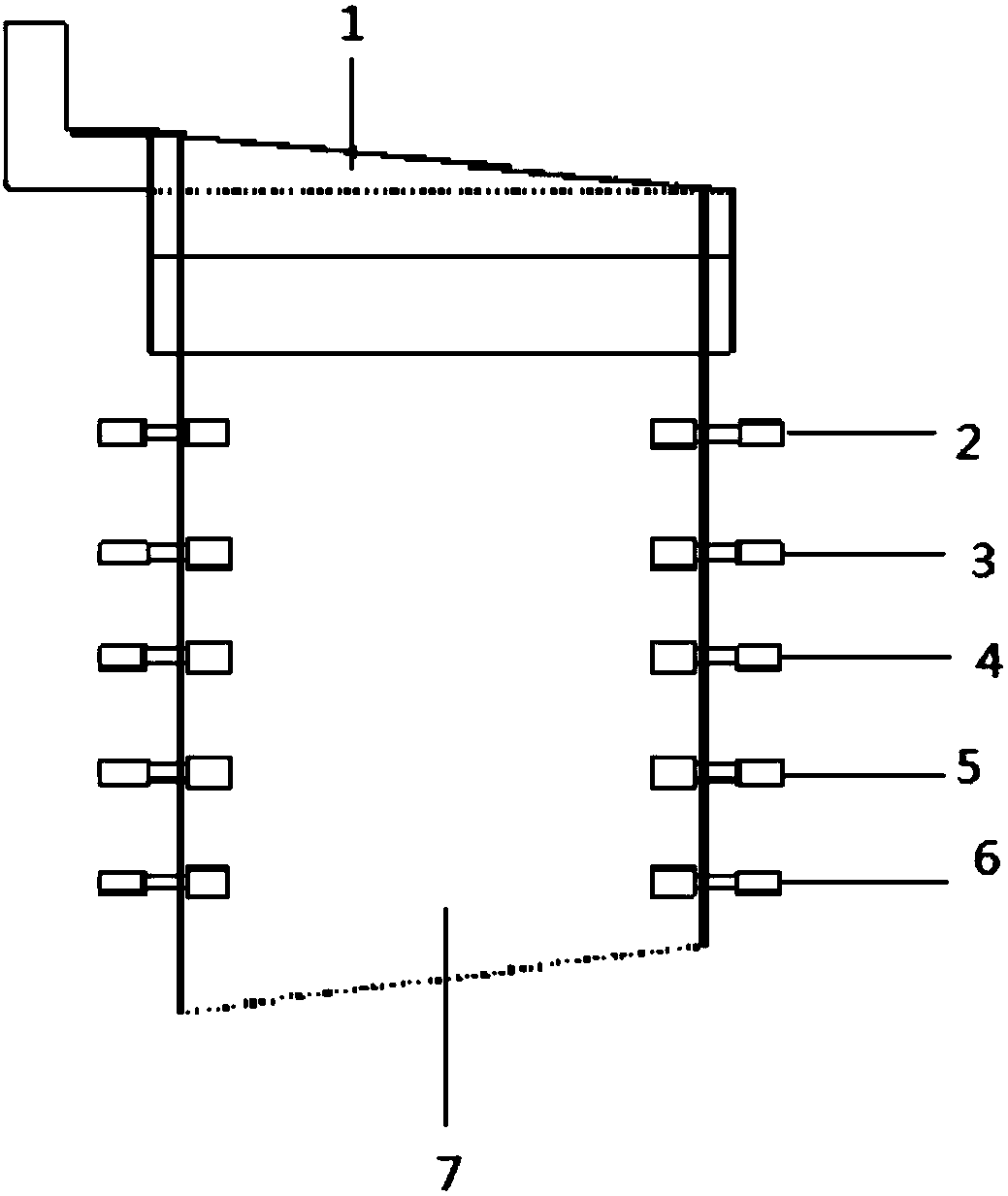

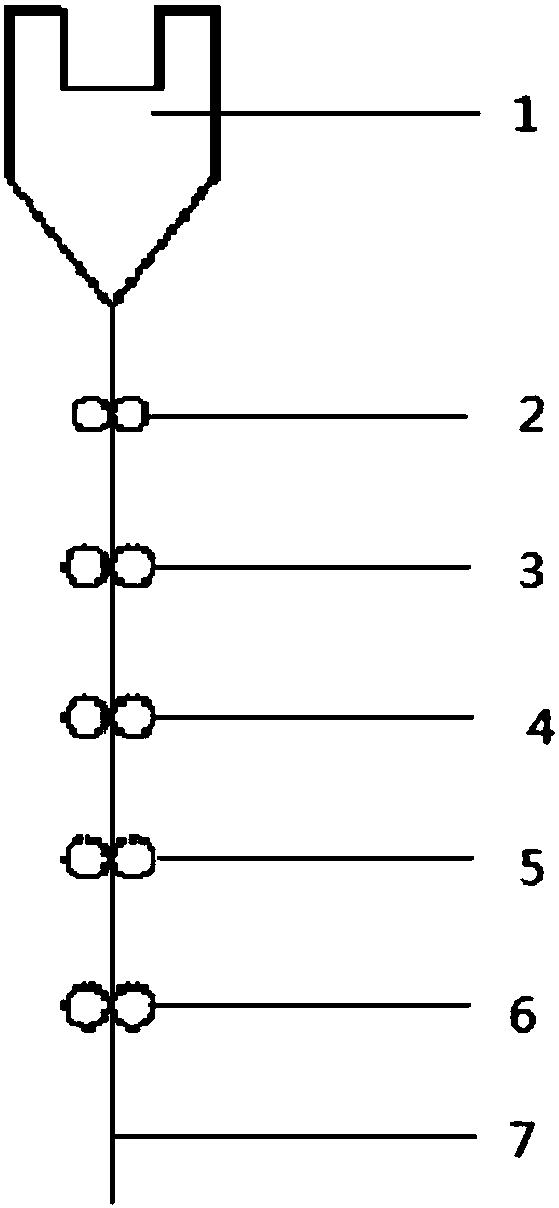

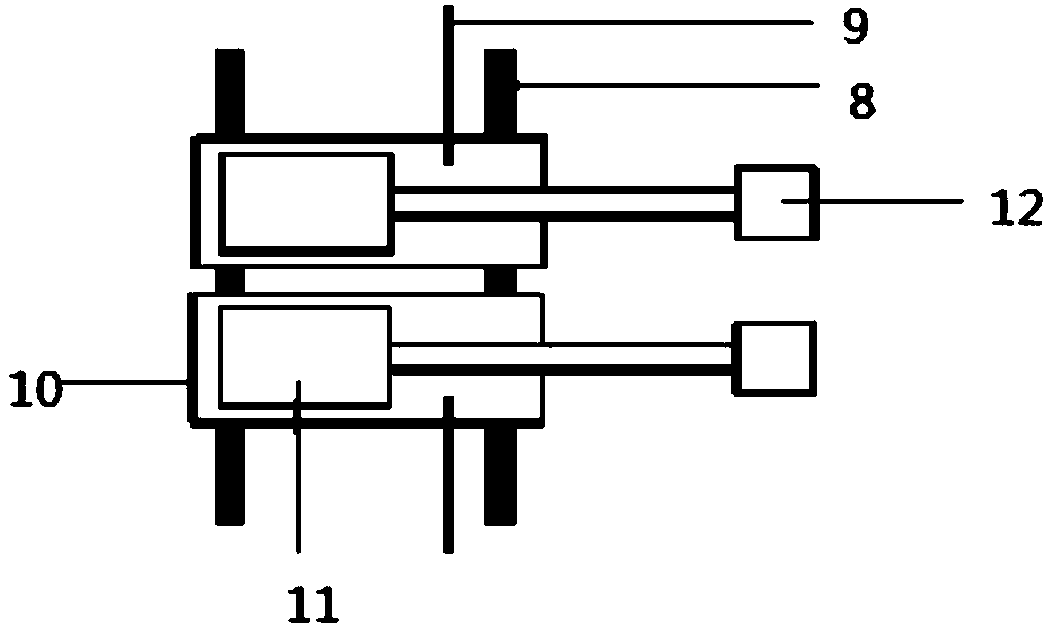

[0032] Refer to attached Figure 1-5 , to realize a control system for stabilizing the quality of flat glass of the present invention, including several groups of pulling roller assemblies that apply traction force to the glass ribbon 7 to form flat glass, the pulling roller assemblies are short roller assemblies; the several groups of pulling roller assemblies are two The two pairs form multiple pairs of traction roller assemblies, and the opposite two sets of traction roller assemblies are located on both sides of the glass ribbon 7 in the width direction, and are respectively in contact with a certain end of the glass ribbon 7 in the width direction. The roller assembly is used to provide downward force to the glass ribbon 7; multiple pairs of traction roller assemblies are arranged at intervals along the flow direction of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com