A cooling system of a setting machine

A technology of cooling system and setting machine, which is applied in the direction of heating/cooling fabric, textile and papermaking, fabric surface trimming, etc. It can solve the problems that the cooling system cannot achieve cooling efficiency and uneven cooling, and achieve compact structure, high degree of automation, Guarantee the effect of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

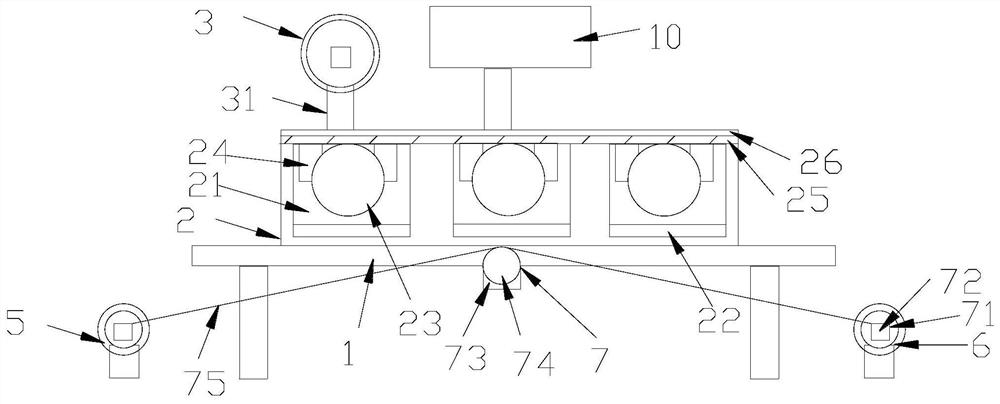

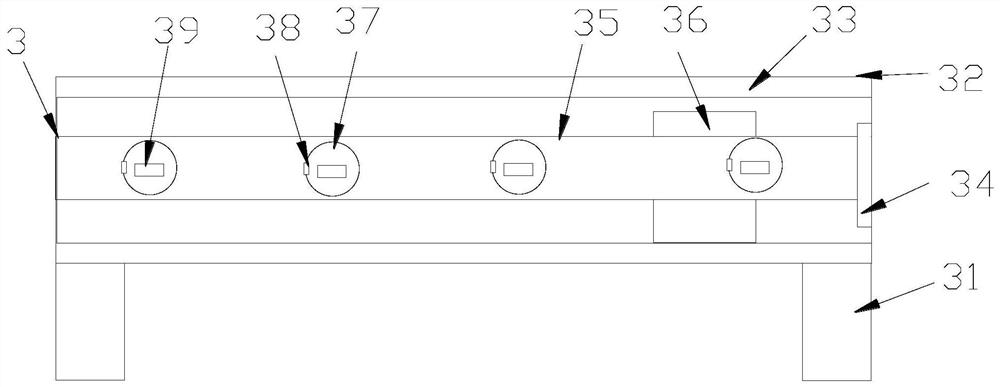

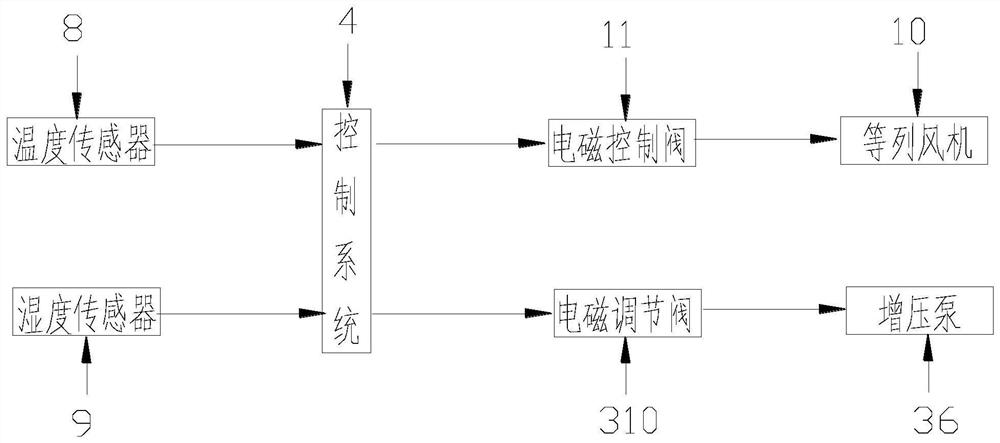

[0027] Example: such as Figure 1-3 As shown, the present invention provides a cooling system for a sizing machine, including a cooling platen 2, a water cooling mechanism 3 and a coaxial drive device 7;

[0028] The bracket 1 is installed under the cooling platen 2, the cooling platen 2 includes a circulating cooling pipe 23 and a heat conduction layer 25, the cooling platen 2 is provided with mounting grooves 21 at intervals, and a U-shaped transition port 22 is provided at the end of the adjacent mounting groove 21; Circulating cooling The pipe 23 is installed in the installation groove 21 in an S shape, and the circulating cooling pipe 23 is filled with cooling liquid; the upper end surface of the circulating cooling pipe 23 is equipped with a mold closing filling block 24, and the upper surface of the closing mold filling block 24 is flush with the upper surface of the cooling platen 2 Flat, the upper end of the adjacent mold closing filling block 24 is provided with a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com