High-efficiency ice storage system method

An ice-storage and high-efficiency technology, applied in air-conditioning systems, heating methods, lighting and heating equipment, etc., can solve the problems of low cooling efficiency, increased energy consumption, and the ice does not melt for 10,000 years. Small volume, easy ice making and de-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

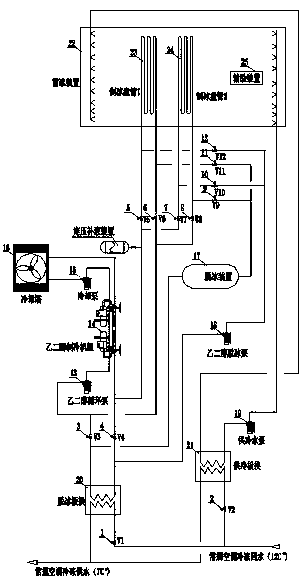

Embodiment 1

[0039] When the ice storage device of a high-efficiency ice storage system method is open:

[0040] S1. Conventional air conditioner refrigeration and ice-making unit joint cooling working condition: first, the conventional air-conditioner is operated, and the ice-making unit system is turned on, so that the ethylene glycol solution flows through the pipeline through the electric valve V44, and then through the pipeline through the ethylene glycol system. Ice unit 14, the cooled ethylene glycol solution flows through the pipeline through the ethylene glycol circulation pump 13, then through the pipeline through the electric valve V3 (3), then through the pipeline through the ethylene glycol deicing plate for 20, after heating The ethylene glycol solution flows through the pipeline through the electric valve V4 (4), and repeats in turn. During the entire refrigeration process, the ethylene glycol deicing plate is replaced by 20 as a cold transfer device to continuously supply co...

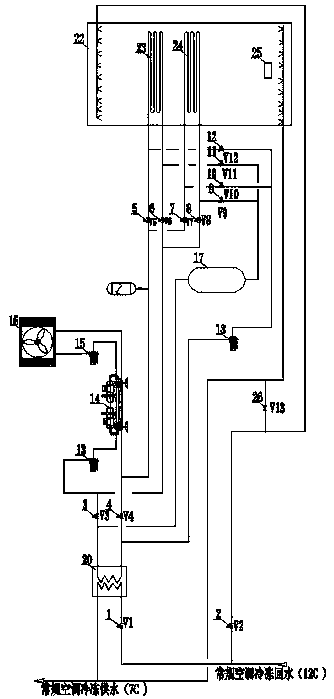

Embodiment 2

[0056] When the ice storage device of a high-efficiency ice storage system method is closed:

[0057] S1 Conventional air-conditioning refrigeration + ice-making unit joint cooling working condition: conventional air-conditioning operation - ice-making unit system on - ethylene glycol solution flows through the pipeline through the electric valve V4 (4) - then flows through the pipeline through the glycol ice-making unit (14) - The cooled ethylene glycol solution flows through the pipeline through the ethylene glycol circulation pump (13) - Through the pipeline through the electric valve V3 (3) - Through the pipeline through the ethylene glycol cooling plate exchange (20) - The heated ethylene glycol solution flows through the pipeline through the electric valve V4 (4)-repeated in turn, and the ethylene glycol cooling plate (20) serves as a cooling transfer device to continuously supply cooling to the end during the entire refrigeration process;

[0058] S2. Conventional air c...

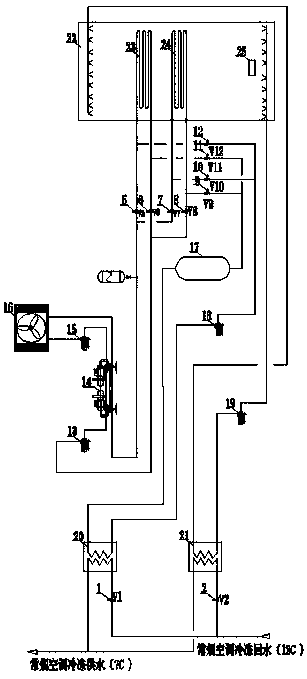

Embodiment 3

[0070] The ice storage device of a high-efficiency ice storage system method is open, and the ethylene glycol host is only used for ice storage and not for cooling:

[0071] S1. Conventional air conditioner refrigeration + ice storage unit ice storage working condition: Conventional air conditioner operation - ethylene glycol ice making system is on, ice making coil 1 (23) and ice making coil 2 (24) run alternately for ice making and deicing , when ice making coil 1 (23) makes ice and ice making coil 2 (24) deices, electric valves V5 (5), V6 (6) open, V11 (11), V12 (12) close, electric Valves V9(9) and V10(10) are open, V7(7) and V8(8) are closed; electric valve V5 is under ice-making coil 1 (23) deicing and ice-making coil 2 (24) ice-making conditions (5), V6(6) closed, V11(11), V12(12) opened, electric valves V9(9), V10(10) closed, V7(7), V8(8) opened;

[0072] a1. Ice-making coil 1 (23) ice-making process: ethylene glycol solution flows through the ethylene glycol ice maki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com