Slurry oxidation device and method for jet air exhaust desulfurization tower

A technology of oxidation device and desulfurization tower, which is applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of exacerbating pump cavitation, decreasing desulfurization efficiency, increasing slurry temperature, etc. The effect of scale blockage and low oxidation air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with specific embodiments.

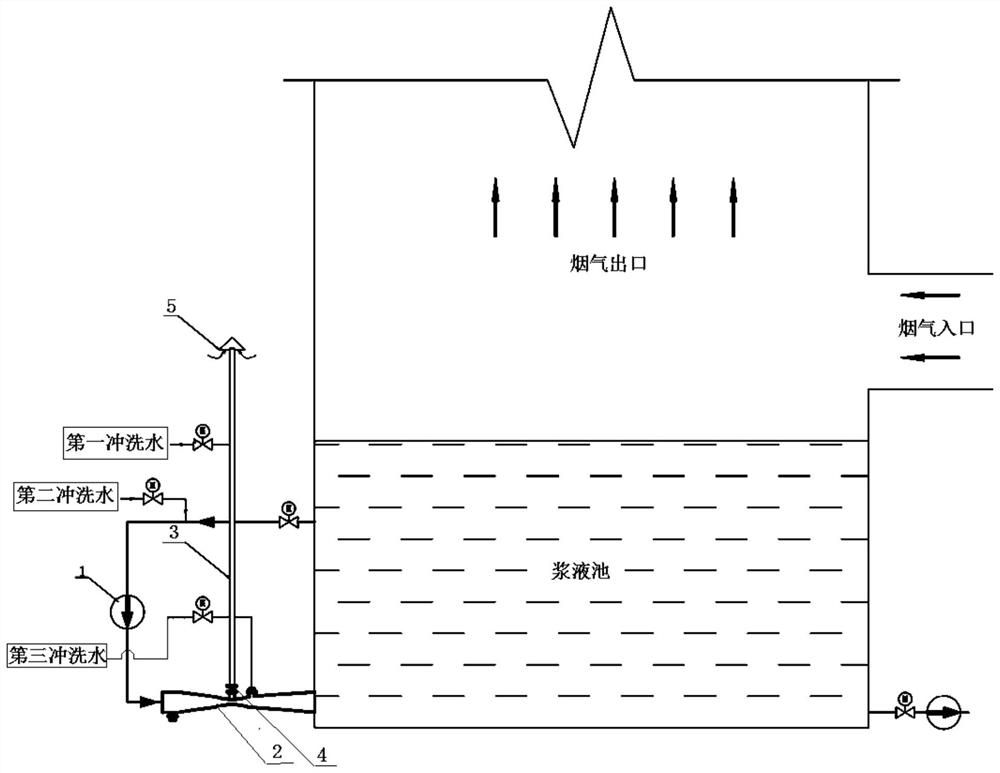

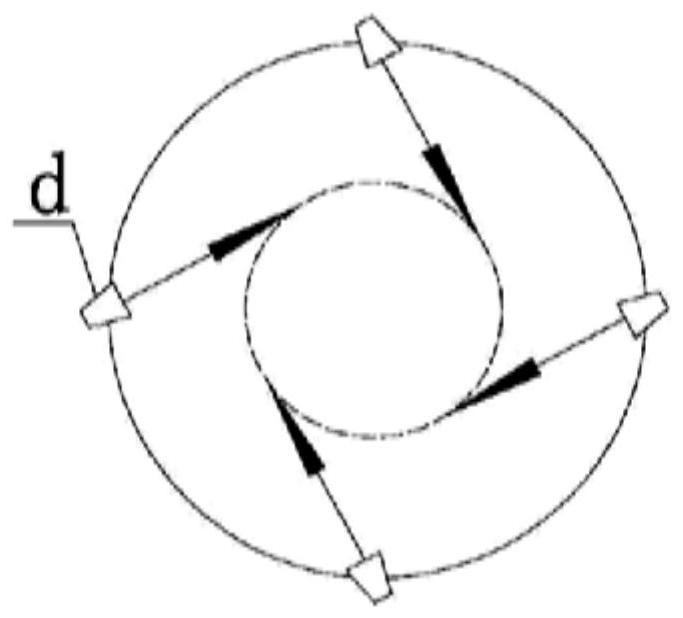

[0056] Such as Figure 1-3 shown. The invention discloses a jet pumping desulfurization tower slurry oxidation device, which comprises a desulfurization tower and a slurry pool at its lower part; a plurality of jet flow oxidation devices are arranged along the circumference of the slurry pool;

[0057] The jet oxidation device first extracts the slurry in the slurry pool, and oxidizes it with air in it, and the oxidized slurry is sprayed back to the bottom of the slurry pool, and a swirl field is generated under the action of the tangential jet; the role of the swirl field Stir and fully oxidize the slurry.

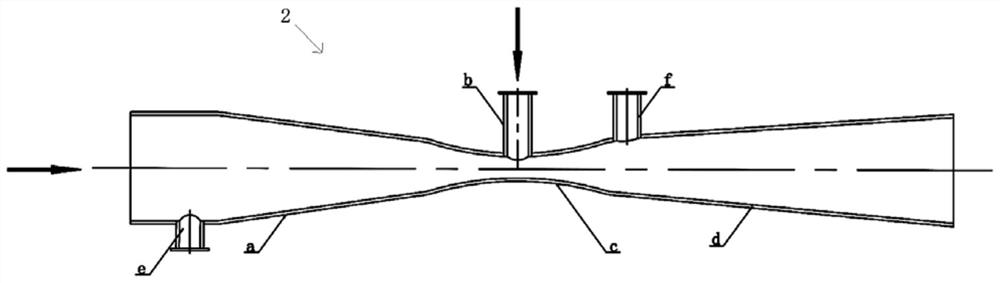

[0058] The jet oxidation device includes a Venturi jet oxidation nozzle 2, a jet pump 1 and an air pipe 3;

[0059] The Venturi jet oxidation nozzle 2 includes a Venturi nozzle a, a suction section b, a mixing section c, a diffusion section d, and a slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com