Aluminum melting furnace capable of performing low-oxygen high-temperature combustion through flue gas reflowing

A high-temperature combustion and aluminum melting furnace technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of uneven mixing of gas and air, inability to effectively control the combustion state, incomplete combustion, etc., and achieve improved combustion and heat transfer process, save the initial investment cost, and reduce the effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

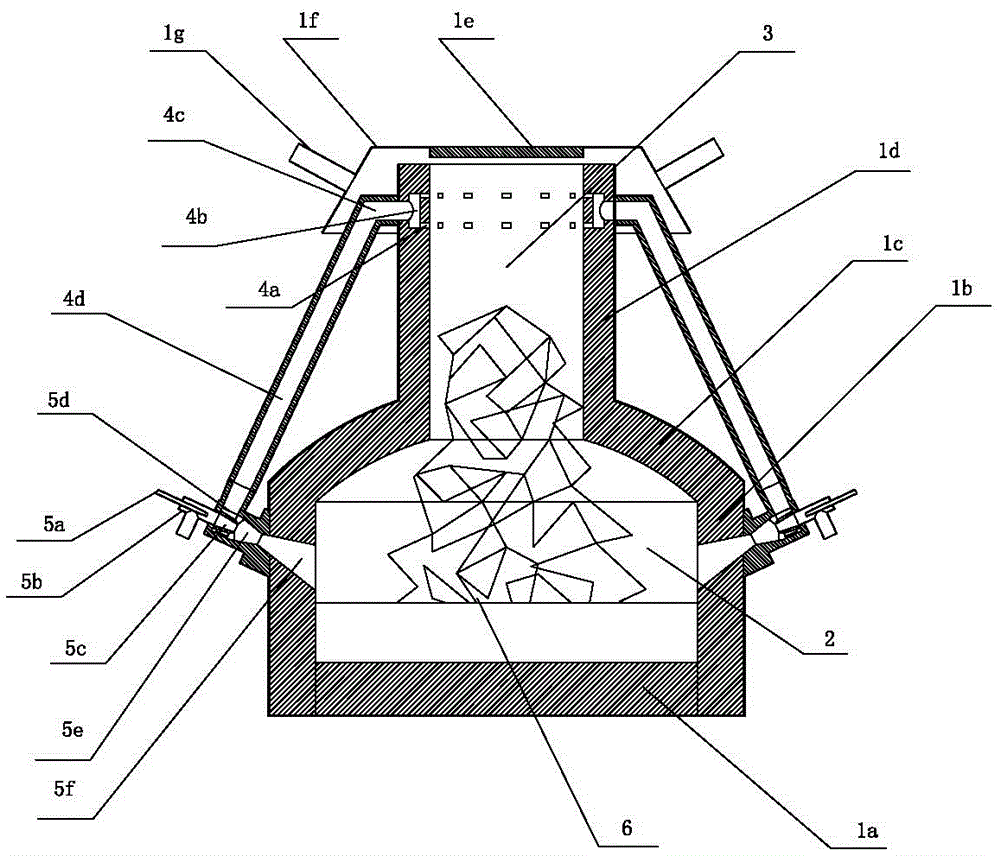

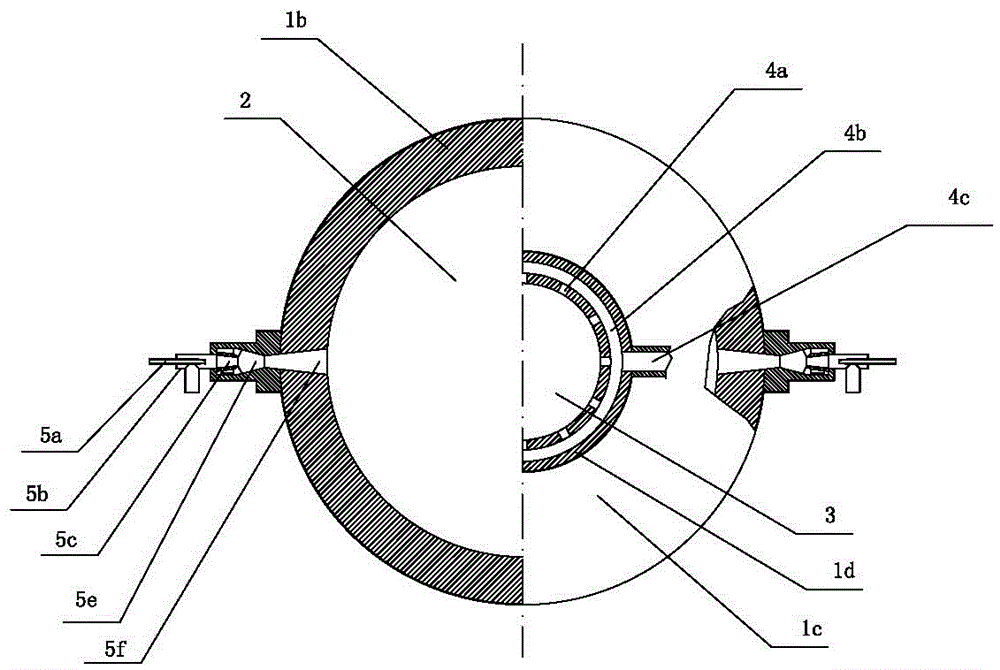

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] Such as figure 1 and figure 2 As shown, the structure of the present invention is that the periphery of the circular furnace bottom 1a is surrounded by an annular furnace wall 1b upwards, and the top of the annular furnace wall is covered with an upper arc-shaped top cover 1c, and the middle part of the upper arc-shaped top cover has a through hole. The through hole of the arc-shaped top cover is equipped with a middle feeding channel wall 1d upwards. The space surrounded by the middle feeding channel wall is the feeding and smoke outflow channel 3, and the space surrounded by the annular furnace wall is the combustion and smelting furnace 2, charging and smoke The gas outlet channel 3 communicates downwards with the through hole and the combustion and smelting furnace. The top of the feeding and flue gas outlet channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com