Double-part support rotary micro-sprinkler

A micro-sprinkler and rotating body technology, applied in the field of double-supported rotating micro-sprinklers, can solve the problems of insufficient spraying diameter, uneven spraying, increased engineering costs, etc., to achieve reliable operation of the spraying process, reduce initial investment costs, and spray large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

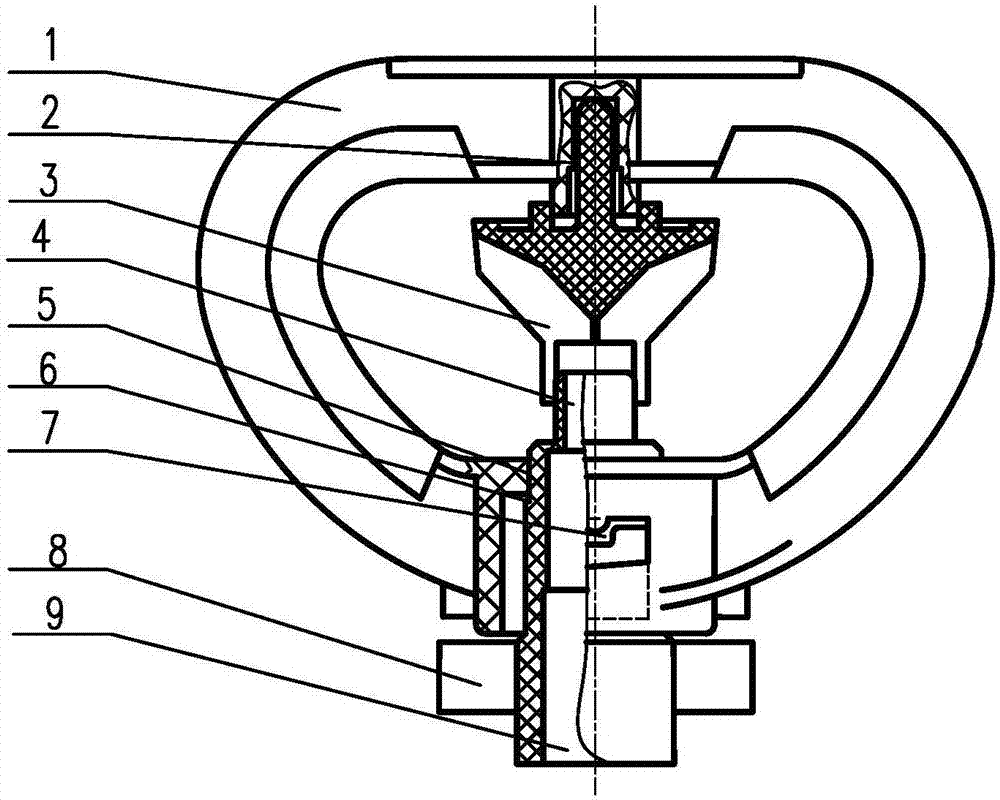

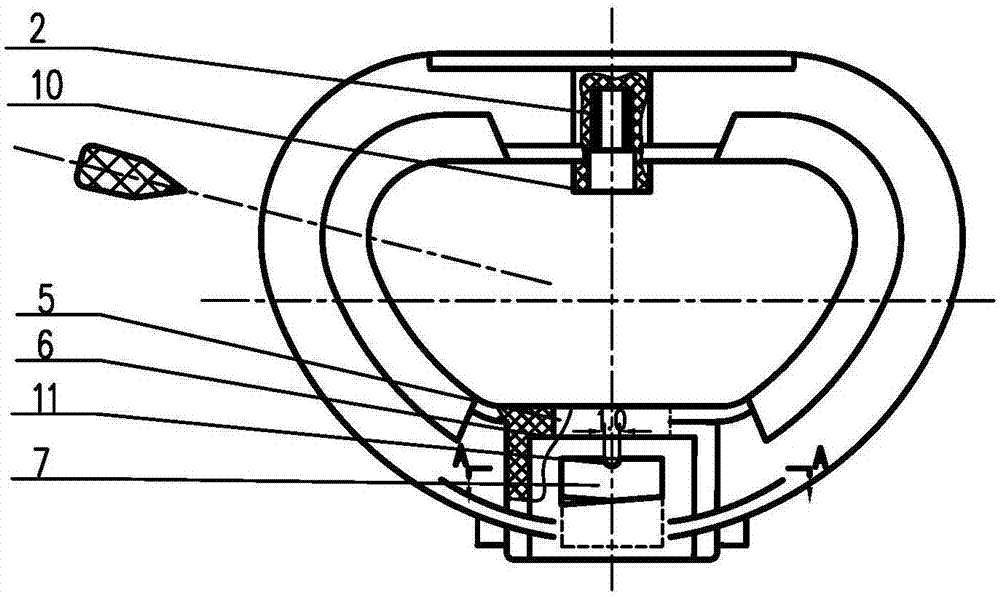

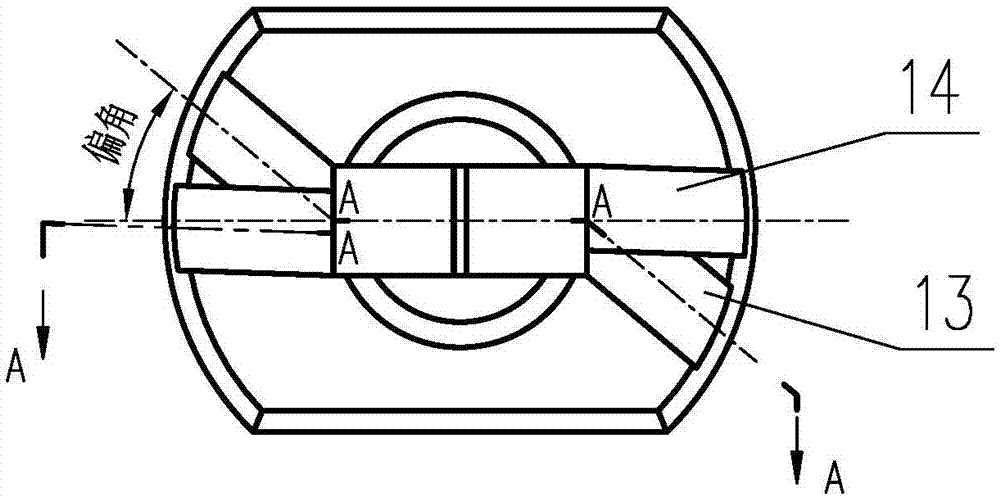

[0028] Such as Figure 1 to Figure 7 As shown, the present invention proposes a double-support rotating micro-spray head, which consists of three main parts: a double-support 1, a rotating body 3 and a nozzle 8, wherein the support is a double-branch butterfly composed of two G-shaped support arms. Shaped support (support shape can be other shapes, as circle, ellipse etc.), the outside of described support is provided with reinforcing rib, has guaranteed the intensity of support, is not easily deformed and is attractive in appearance when subjected to large water pressure. The positions of the reinforcing ribs are not limited, and for the sake of aesthetics, reinforcing ribs may be respectively provided on the inner side of the bracket, the outer side of the lower end, and the outer side of the upper end.

[0029] The upper end of the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com