Rotary screen type big-flow fire extinguishing sprayer

A technology of fire extinguishing nozzle and large flow rate, which is applied in fire rescue and other directions, can solve the problems of untimely opening and small spraying radius, and achieve the effects of fast response speed, low layout density, and reduced project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

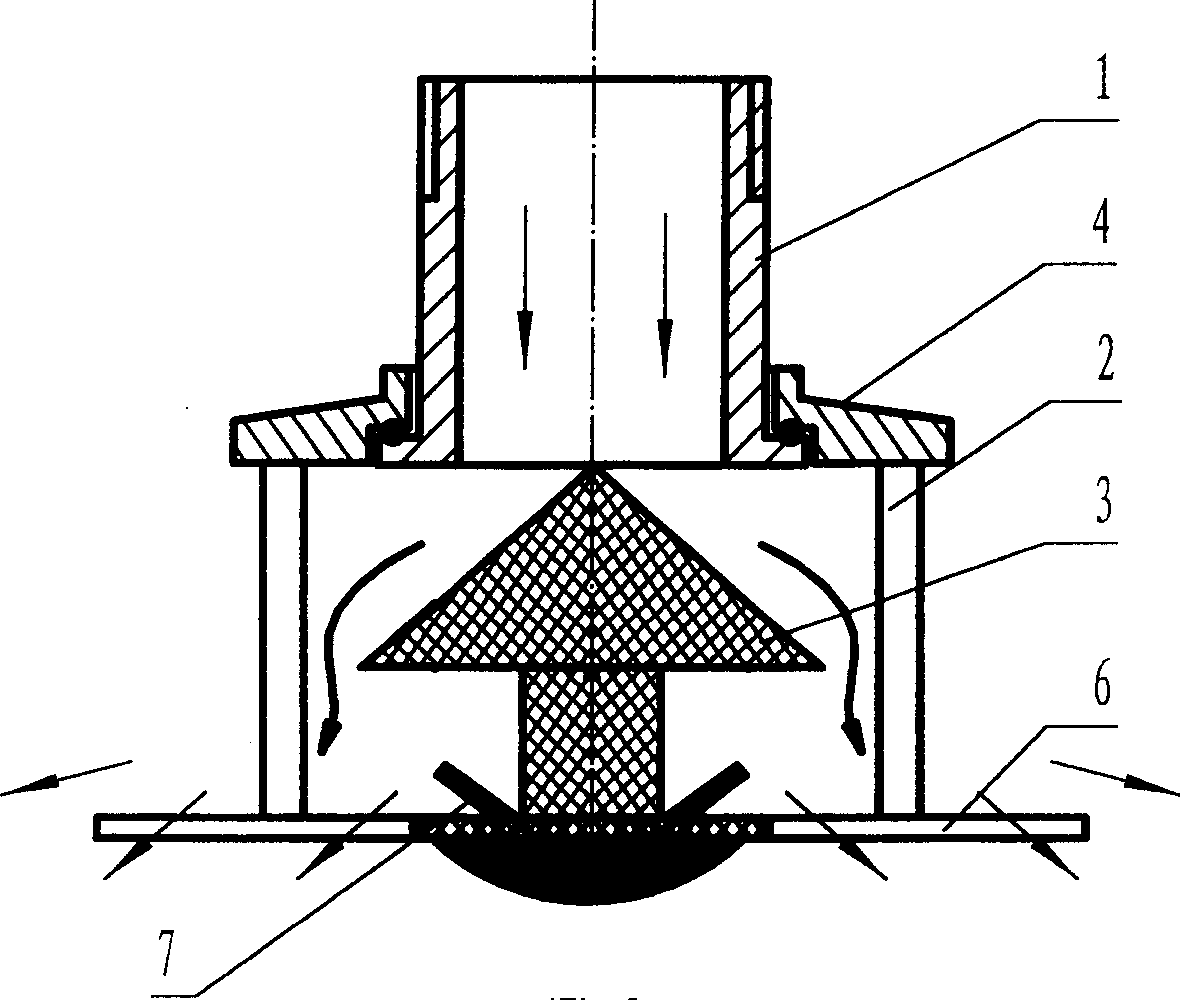

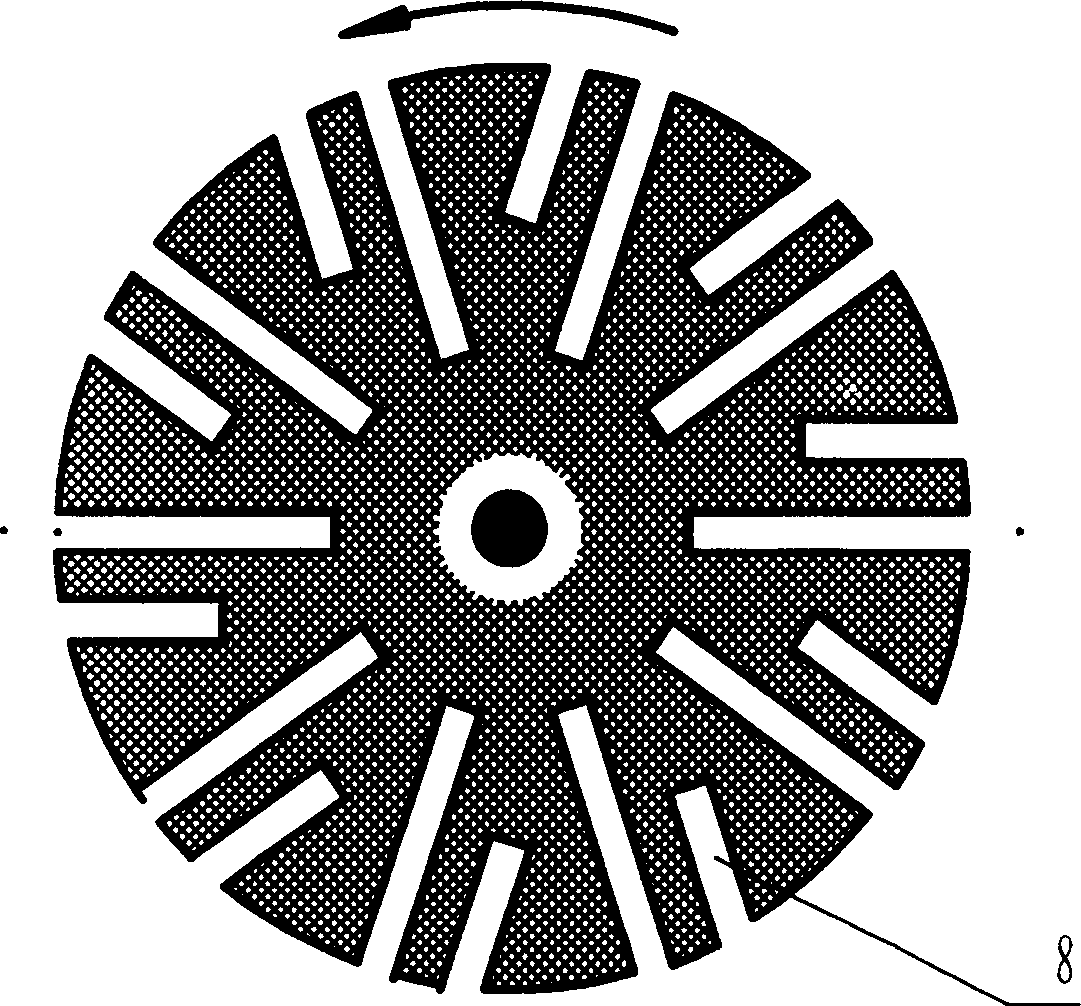

[0019] The pipe seat (1) of the rotary sieve type large-flow fire extinguishing nozzle is connected with the system fire extinguishing pipeline, and an electromagnetic valve (9) is arranged on its upper end, and the electromagnetic valve (9) is opened by the control of the flame detector (10). Such as figure 1 , figure 2 As shown, the shunt (3) at the lower end of the tube base (1) is connected and fixed by the bracket (2), and the tip of the conical shunt (3) is facing the center of the lower end of the tube base (1). ) is equipped with a circular water divider (6) below, which is evenly distributed with a plurality of bar-shaped sieves (8) radiating outwards with the axis, and two vortex blades ( 7), this water dividing wheel (6) forms a revolving pair by the bearing axle seat (4) and the pipe seat (1), and the inside is equipped with a bearing.

Embodiment 2

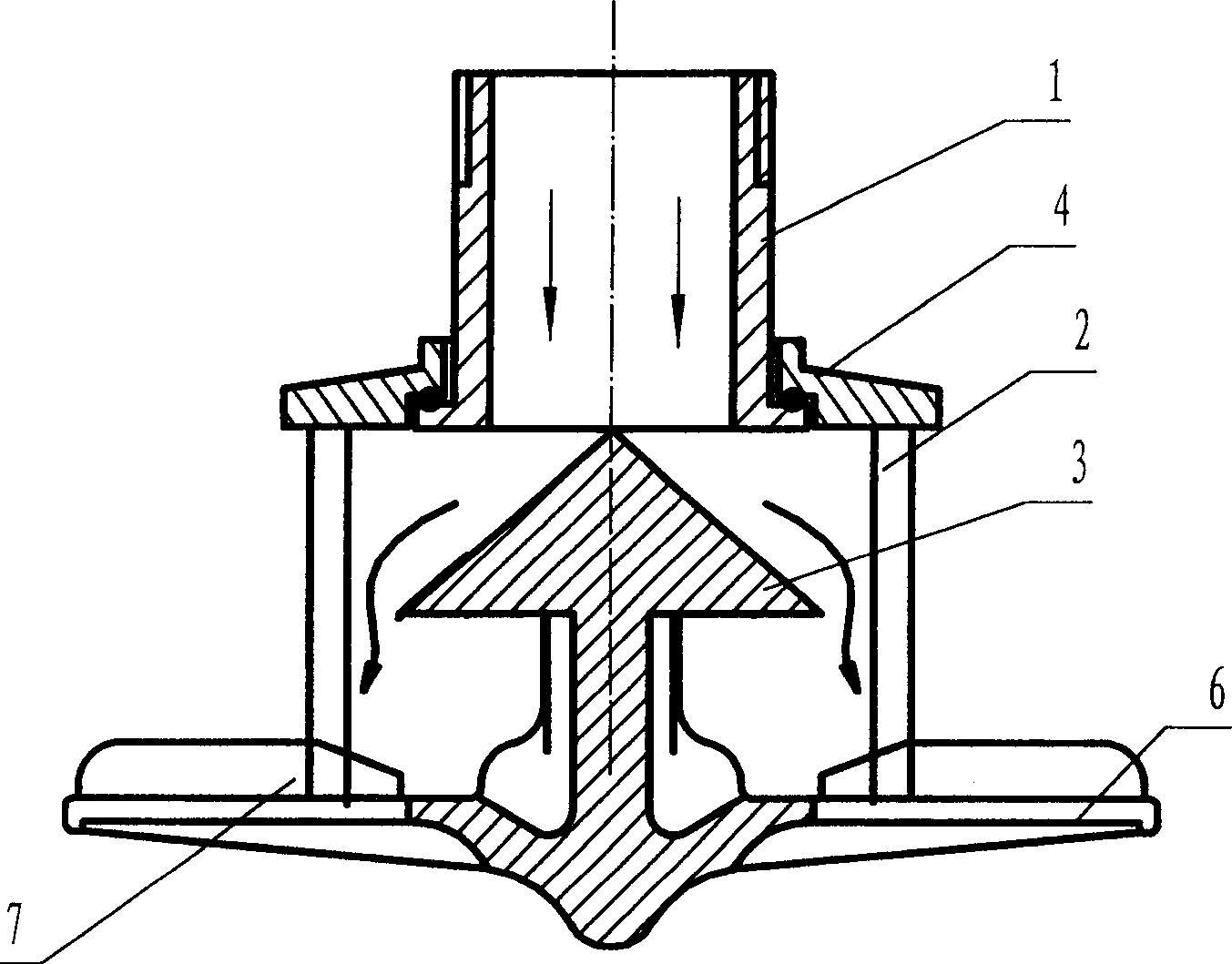

[0021] Such as image 3 , Figure 4 As shown, embodiment 2 is substantially the same as embodiment 1, except that the shape and structure of the two vortex blades are changed, which can change the spray radius during fire extinguishing.

[0022] When the large flow fire extinguishing nozzle is installed in the fire extinguishing system engineering, if Figure 5 As shown, the large space place of this project is 30 meters high, and the sprinklers (11), (12), (13), (14) are vertically installed on the top of the indoor ceiling, occupying a high position downwards, and form a group. A solenoid valve (9) is installed at the front end, and they are controlled by a flame detector (10) and can be opened simultaneously; 15) is connected, and the flame detector (10) is connected with the electric valve (9) of the bus control cabinet (16). (above-mentioned sprinkler head (11), (12), (13), (14) are all DN50).

[0023] Combine below Figure 5 Describe in detail the working process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com