Solar thermal collector freezing prevention system

A technology of solar collectors and antifreeze systems, applied in the field of collector antifreeze systems, can solve the problems of large initial investment in antifreeze systems, cracks in valves and pipes, residual moisture in the system, etc., to solve the problem of cracks in pipes and valves , Put an end to environmental pollution problems, and reduce the effect of initial investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

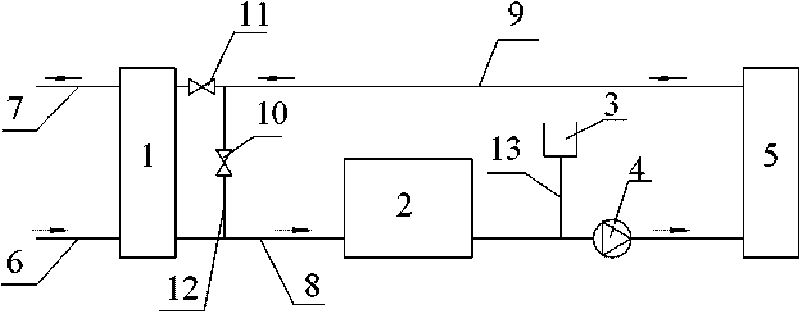

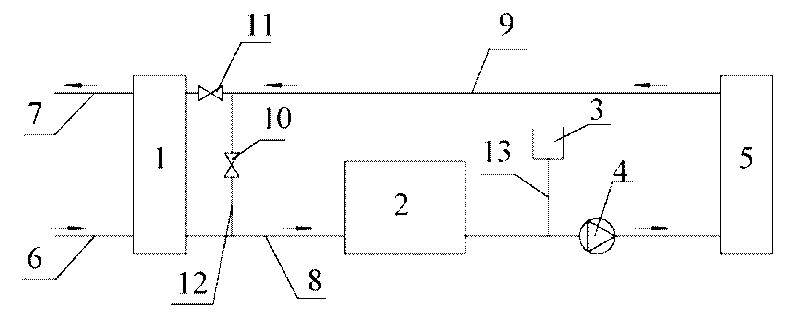

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of solar heat collector antifreeze system of this embodiment includes the first sewage heat exchanger 1, the solar heat collector 2, the first circulating water pump 4, the first heat user terminal 5, the high temperature sewage pipe 6, Low-temperature sewage pipe 7, circulating working fluid inlet pipe 8, circulating working medium return pipe 9, first valve 10, second valve 11 and first connecting pipe 12, the first sewage heat exchanger 1, solar heat collector 2 Arranged side by side with the first heat user terminal 5, the first sewage heat exchanger 1, the solar heat collector 2 and the first heat user terminal 5 are connected in turn through the circulating working fluid inlet pipe 8, and the first sewage heat exchanger 1 communicates with the first heat user terminal 5 through a circulating working medium return pipe 9, and the first circulating water pump 4 is installed on the ci...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the antifreeze system of this embodiment is also added with a first expansion tank 3 and a second communication pipe 13, the first expansion tank 3 communicates with the circulating working fluid inlet pipe 8 through the second communication pipe 13, and the second The two connecting pipes 13 are located on the circulating working fluid inlet pipe 8 between the solar heat collector 2 and the first circulating water pump 4 . Such setting plays the role of constant pressure supply. Other compositions and connections are the same as in the first embodiment.

[0009] The non-antifreeze operation mode of the antifreeze system in this embodiment: At this time, the circulating working medium in the antifreeze system of the solar collector is higher than its freezing point by more than 3°C. Since the system does not need antifreeze at this time, the first valve 10 is opened, and the second va...

specific Embodiment approach 3

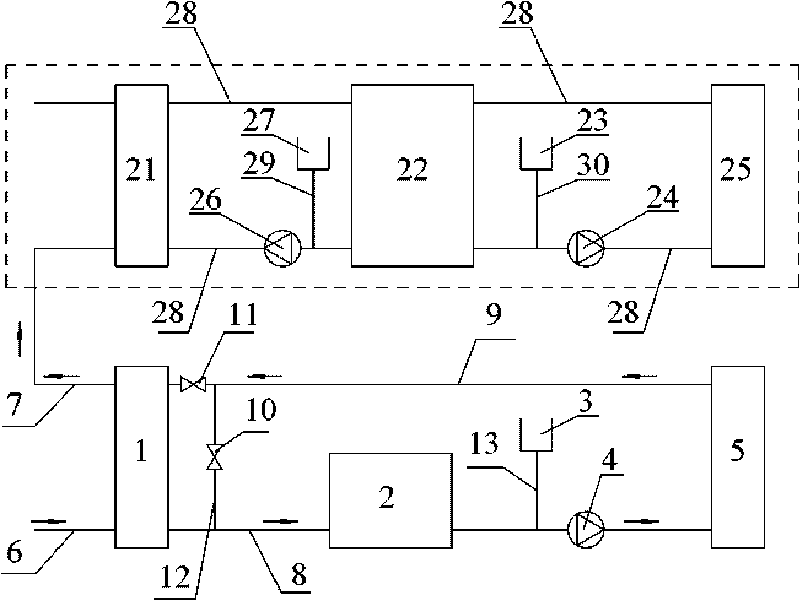

[0011] Specific implementation mode three: combination figure 2 Describe this embodiment, the antifreeze system and sewage source heat pump coupling system of this embodiment consists of a sewage source heat pump system, a first sewage heat exchanger 1, a solar heat collector 2, a first expansion tank 3, a first circulating water pump 4, a first A hot user terminal 5, high temperature sewage pipe 6, low temperature sewage pipe 7, circulating working fluid inlet pipe 8, circulating working medium return pipe 9, first valve 10, second valve 11, first communicating pipe 12 and second communicating pipe 13 composition; the first sewage heat exchanger 1, solar heat collector 2 and first heat user terminal 5 are arranged side by side, and the first sewage heat exchanger 1, solar heat collector 2 and first heat user terminal 5 The first sewage heat exchanger 1 and the first heat user terminal 5 are connected in series through the circulating working medium return pipe 9 in turn, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com