80Kg grade steel plate with ultrahigh toughness and extreme thickness and manufacturing method of the steel plate

An ultra-high toughness, kilogram-level technology, which is applied in the field of 80-kg ultra-high toughness, extremely thick steel plates and its manufacturing, can solve the problems of uneven strength and toughness of extra-thick quenched and tempered steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with embodiment.

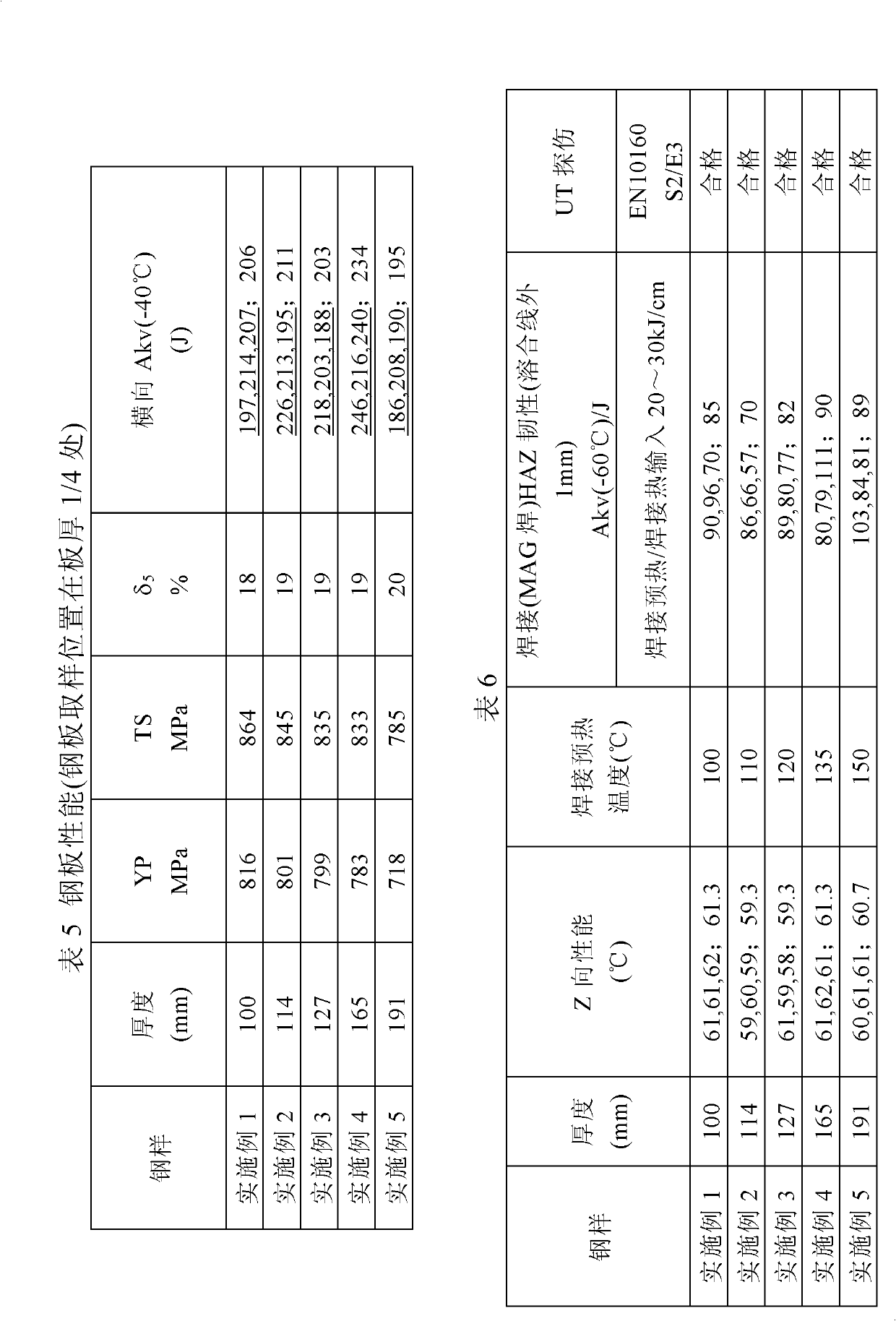

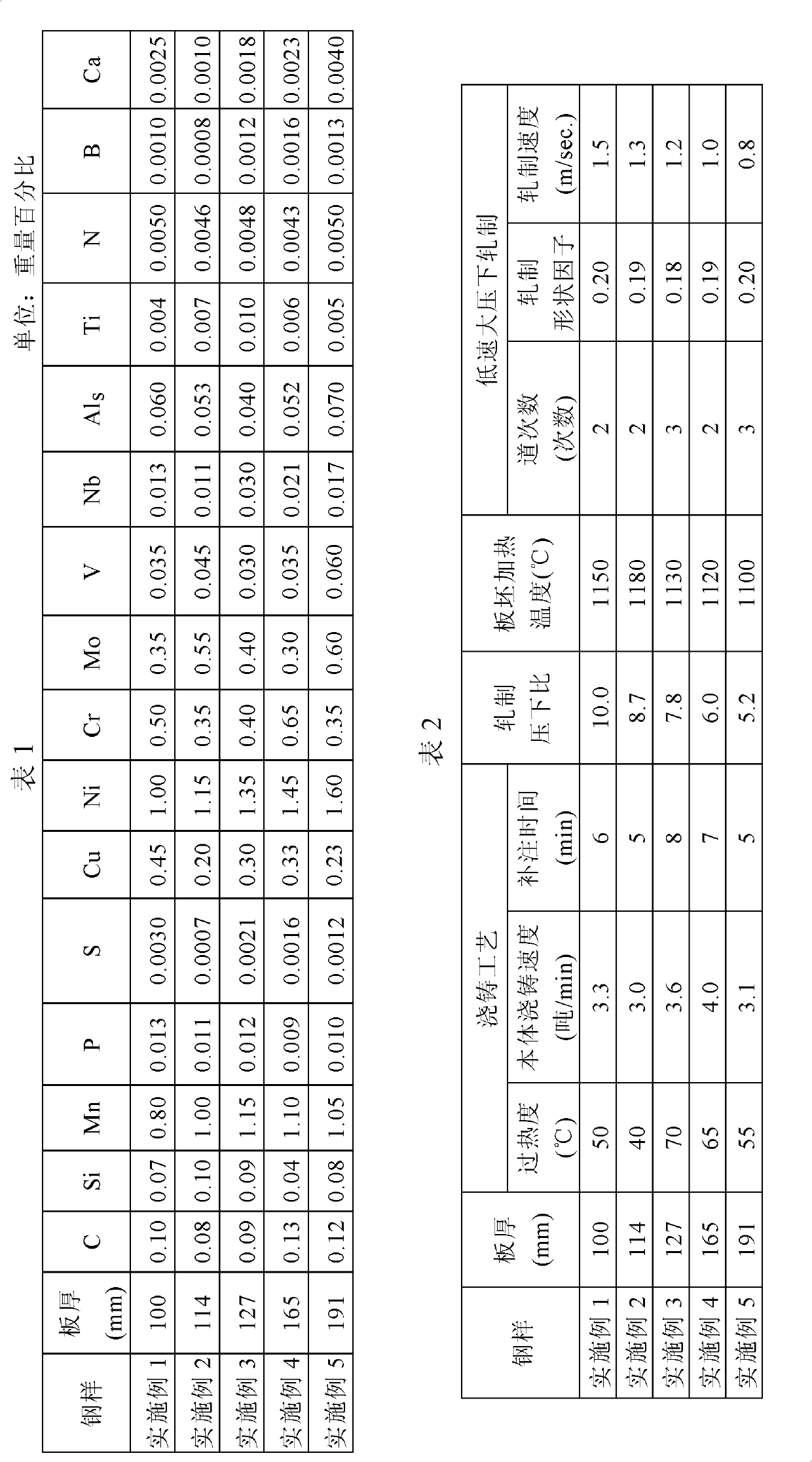

[0057] Table 1 shows the composition of the steel of the embodiment of the present invention, and Table 2, Table 3, and Table 4 show the manufacturing process of the steel of the embodiment of the present invention. Table 5 and Table 6 show the properties of the steels of the embodiments of the present invention.

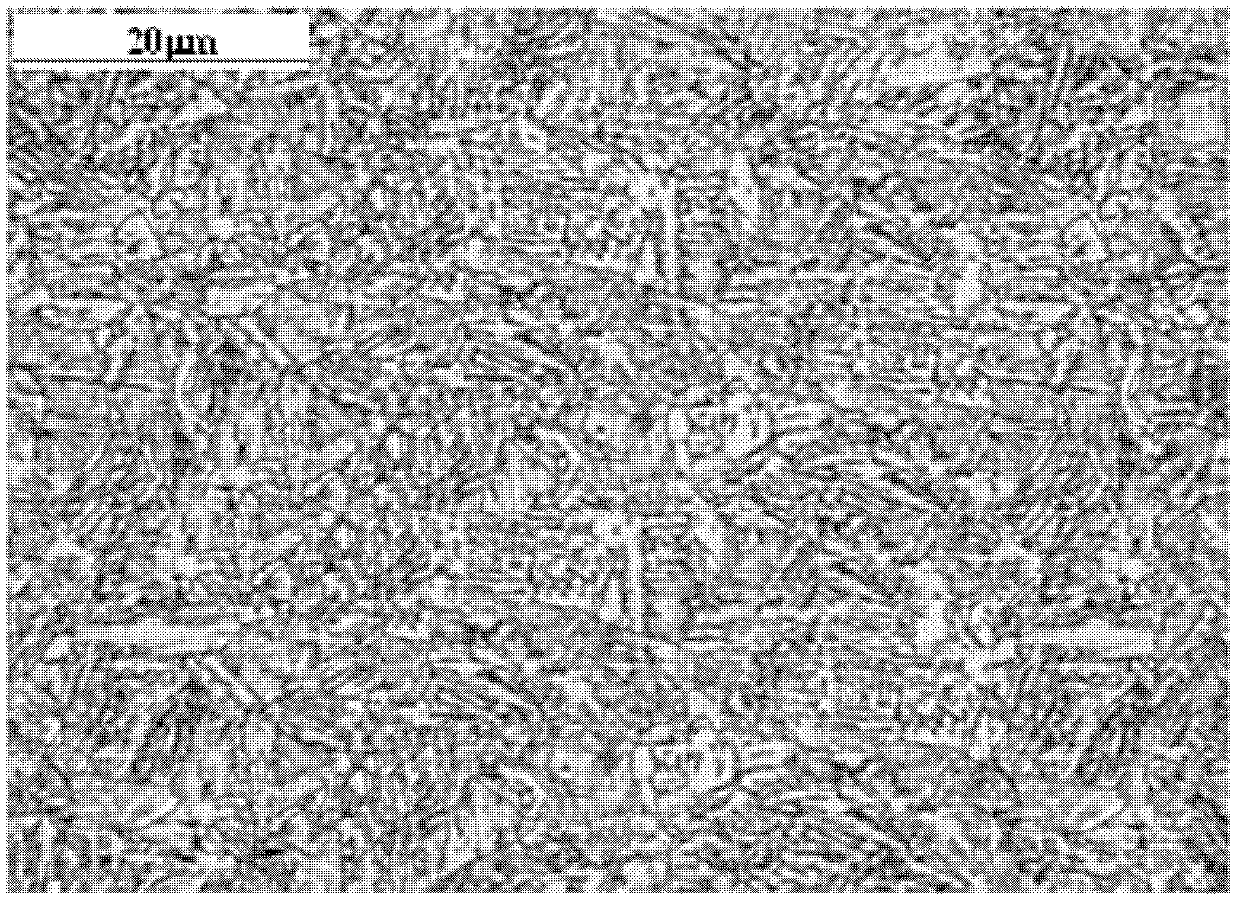

[0058] from figure 1 It can be seen from Table 5 and Table 6 that the microstructure of the steel plate of the present invention is fine tempered bainite + tempered martensite, and the average grain size is below 20 μm; excellent strength and toughness, strong plasticity matching and welding Excellent performance.

[0059] In summary, the present invention combines the combined design of steel plate alloy elements with the special quenching and tempering process (CR+QT) to obtain excellent strength, ultra-low temperature toughness and strength-toughness matching of extre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com