Detection restorative method of hydraulic valve jamming and chucking faults

A repair method and jamming technology, which are applied in the directions of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of normal working interference of the system, inability to overcome the clamping force, etc., and improve the service life. , The use effect is good, the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

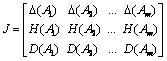

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Stuck Fault Detection and Self-Repair

[0041] refer to figure 2 , image 3 and Figure 4 , an intelligent hydraulic valve, including an electro-hydraulic proportional valve 30 , the electro-hydraulic proportional valve 30 includes a valve body 35 , a spool 34 , a valve cavity 33 for placing the spool, and a proportional electromagnet 24 . It also includes an ultrasonic generator 2, an ultrasonic transducer 3 and an intelligent controller 1 capable of detecting jamming faults of the electro-hydraulic proportional valve and controlling the operation of the ultrasonic generator. The intelligent controller 1 is electrically connected with the ultrasonic generator 2 and the electro-hydraulic proportional valve 30 respectively.

[0042] The output end of the ultrasonic generator 6 is electrically connected with the two electrodes of the ultrasonic transducer 7, and the ultrasonic transducer 7 is fixedly connected to the upper side of the electro-hydraulic prop...

Embodiment 2

[0049] Example 2: Clamping fault detection and self-repair

[0050] refer to figure 2 , image 3 and Figure 5 , an intelligent hydraulic valve, including an electro-hydraulic proportional valve 30 , the electro-hydraulic proportional valve 30 includes a valve body 35 , a spool 34 , a valve cavity 33 for placing the spool, and a proportional electromagnet 24 . It also includes an ultrasonic generator 2, an ultrasonic transducer 3 and an intelligent controller 1 capable of detecting jamming faults of the electro-hydraulic proportional valve and controlling the operation of the ultrasonic generator. The intelligent controller 1 is electrically connected with the ultrasonic generator 2 and the electro-hydraulic proportional valve 30 respectively.

[0051] The output end of the ultrasonic generator 6 is electrically connected with the two electrodes of the ultrasonic transducer 7, and the ultrasonic transducer 7 is fixedly connected to the upper side of the electro-hydraulic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com