Air inlet mesh enclosure for extractor hood

A technology for range hoods and air inlet nets, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the problems of little influence on suction, poor separation of grease, and immature technology, so as to improve suction, The effect of improving the separation degree of oil and fat and improving the smoking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

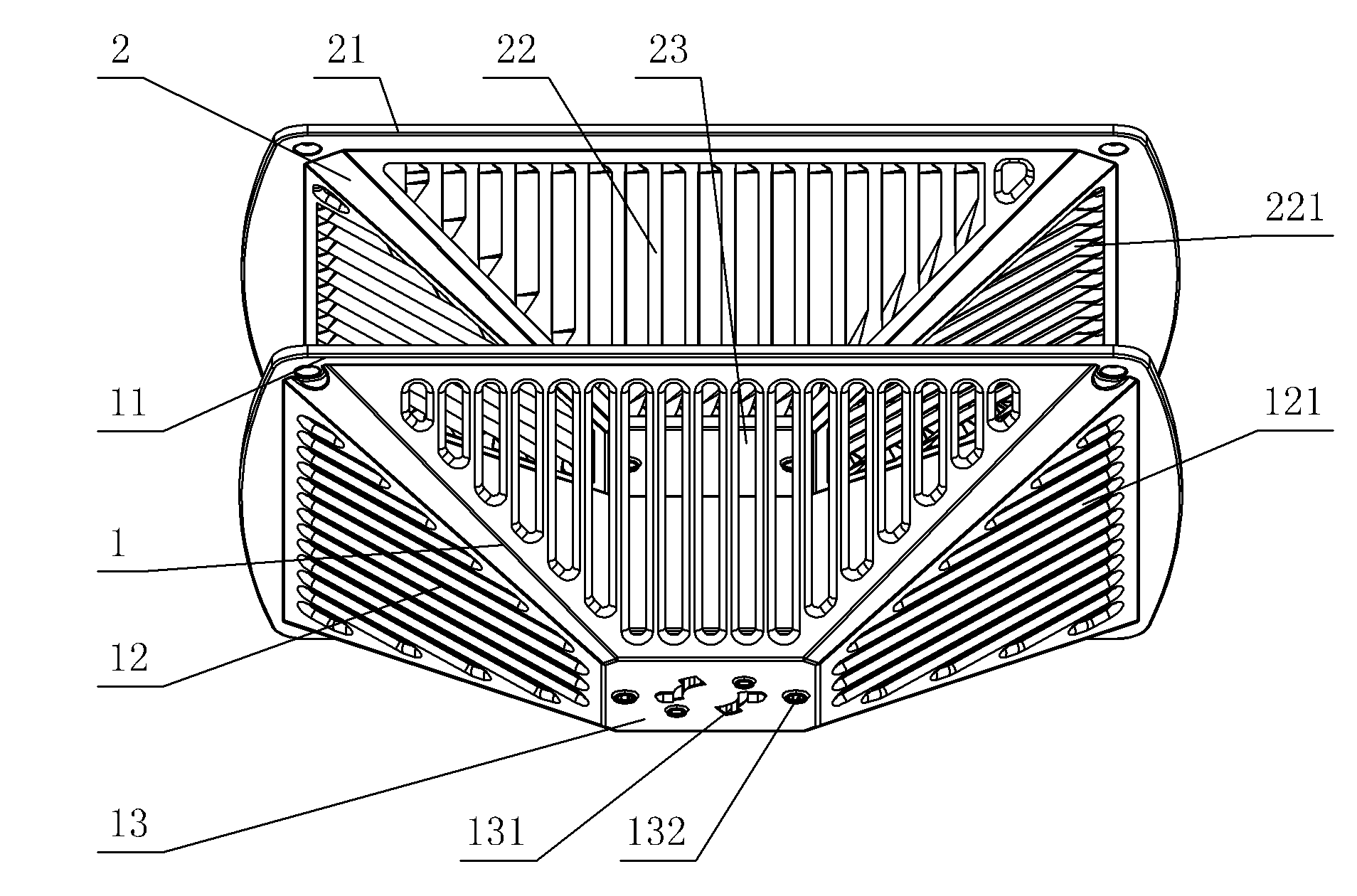

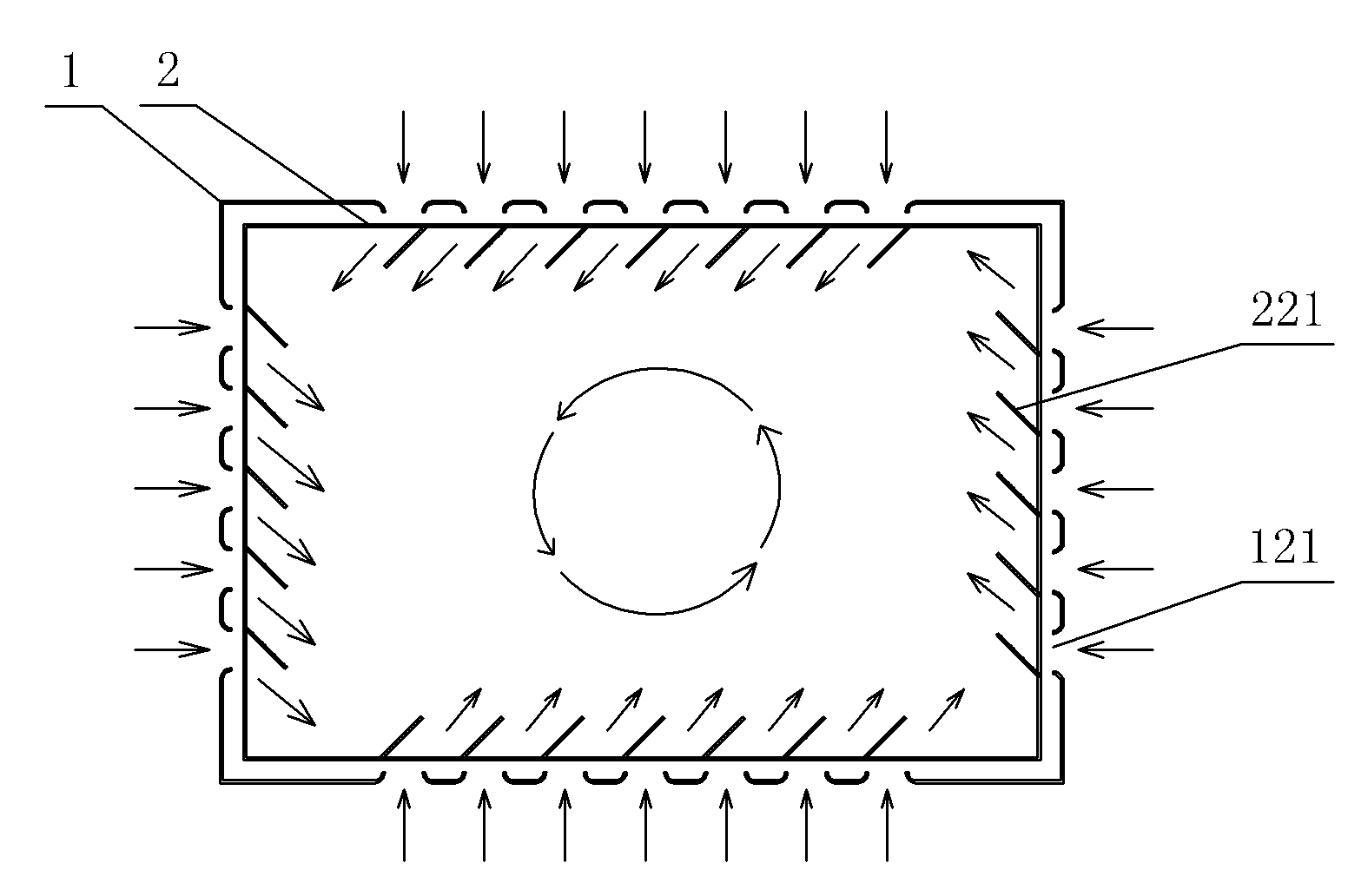

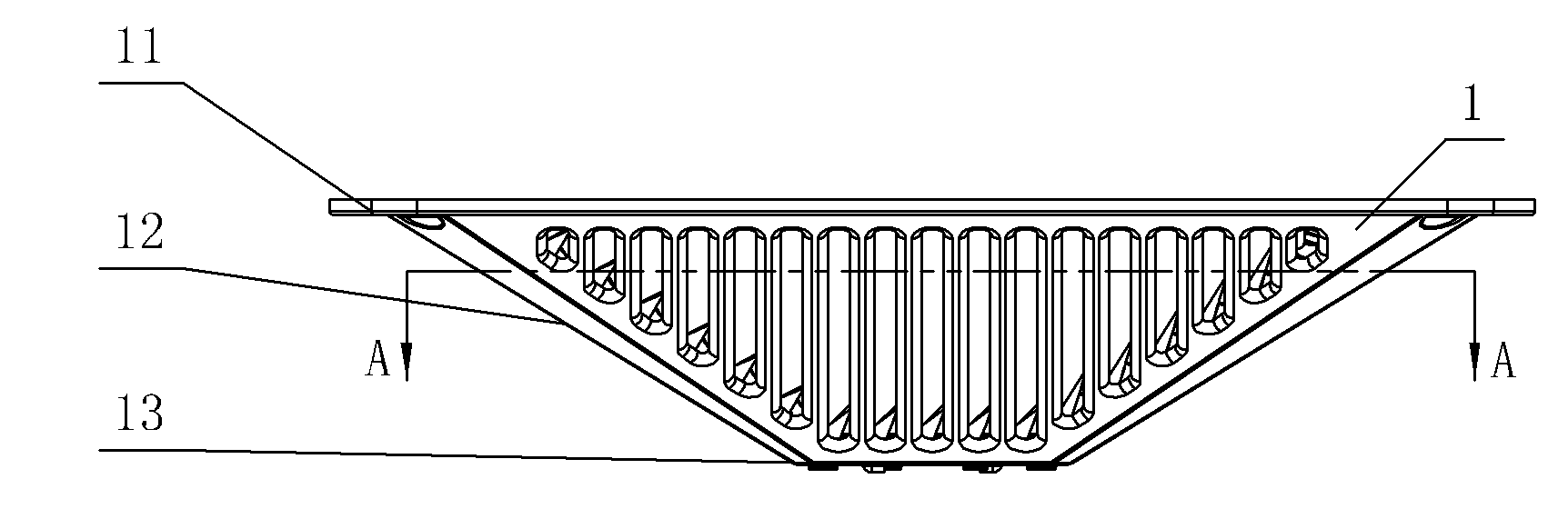

[0026] see Figure 1-Figure 6 , the air intake grille of the range hood includes an outer grille 1 and an inner grille 2 of a double-layer structure, the outer grille 1 is provided with an outer top surface 11, an outer wall surface 12, an outer bottom surface 13, and an inner grille 2 There are an inner top surface 21, an inner side wall surface 22, and an inner bottom surface 23, the inner and outer top surfaces are fixed connection surfaces, the inner and outer side wall surfaces are air inlet surfaces, and the inner and outer bottom surfaces are oil collecting surfaces. The outer wall surface 12 is distributed in parallel with the inner wall surface 22 of the inner screen cover 2, and the air inlets 121 with strip openings are evenly distributed on the outer wall surface 12, and the corresponding air inlets 121 are provided with louver blades 221 on the inner wall surface 22, and the louver blades 221 are connected with the air inlet. 121 are vertically oppositely arranged...

no. 2 example

[0031] see Figure 7-Figure 9 , the air intake grille of this range hood, its main difference from the first embodiment is that the outer grille 1 and the inner grille 2 are in the shape of a rounded table, and the inner and outer top surfaces are fixed connection surfaces or flange connections On the other hand, the air inlets 121 of the outer net cover 1 are arranged radially, and the lengths of each air inlet 121 and the louver blades 221 are the same. Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com